The Application of JKSimMet Software in the Multi-objective Collaborative Optimization of the Grinding and Classification System at a Gold Mine

-

摘要:

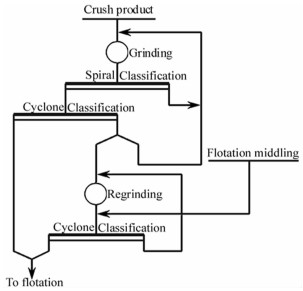

为了实现某金矿选厂的提产增效和节能降耗,采用JKSimMet模拟软件对该金矿的磨矿分级系统进行了多目标协同优化。采取的优化措施包括降低磨矿分级系统给矿粒度,调整球磨机和旋流器的关键工艺参数和增加粗磨旋流器底流给入再磨球磨机的比例。JKSimMet模拟结果显示,优化后磨矿分级系统的处理能力由35 t/h提升至44 t/h;粗磨比能耗从11.09 kWh/t降低至9.94 kWh/t,中矿再磨比能耗从9.93 kWh/t降低至7.23 kWh/t;粗磨产品细度P80从86 μm减小至80 μm。通过对整个磨矿分级系统各工艺参数的协同优化,增加了磨矿分级系统的处理能力,降低了磨矿比能耗,并且提高了磨矿产品的质量,达到了多目标优化的目的。

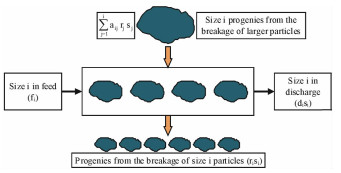

Abstract:The grinding and classification system at a gold mine was optimized using JKSimMet software in order to increase the throughput and reduce the energy consumption of the concentrator. The optimization measures taken include reducing the feed size of the grinding circuit, adjusting the key process parameters of the ball mill and cyclone, and increasing the proportion from the coarse grinding circuit to the regrinding mill. The simulation results showed that some indicators had been improved after optimization. The processing capacity of the grinding classification system was increased from 35 t/h to 44 t/h. The specific energy consumption of the coarse grinding circuit reduced from 11.09 kWh/t to 9.94 kWh/t. The specific energy consumption of the middling regrinding circuit reduced from 9.93 kWh/t to 7.23 kWh/t, and the P80 of the coarse grinding product reduced from 86 μm to 80 μm. The multi-objective optimization of the grinding products which included the improvement of processing capacity of the grinding classification system as well as the quality of the grinding products and the reduction of grinding specific energy consumption were achieved by the collaborative optimization of various process parameters of the entire grinding and the classification system.

-

-

表 1 JK SimMet软件球磨机模型输入参数

Table 1. Input parameters of the ball mill model in JKSimMet software

工作参数 粗磨磨机 中矿再磨磨机 筒体有效内径/m 2.54 1.94 筒体有效长度/m 3.60 3.00 给矿端耳轴直径/m 1.0 0.7 转速率/% 79.4 83.3 钢球填充率/% 40.6 31.9 钢球最大直径/mm 100 40 磨机内矿浆浓度/% 73.3 70.9 新鲜给矿速率/(t·h-1) 35 13.4 给矿含水率/% 4.0 4.0 给矿P80/μm 9 700 257 邦德球磨功指数/(kWh·t-1) 19.76 19.76 表 2 JK SimMet软件旋流器模型输入参数

Table 2. Input parameters of the cyclone model in JKSimMet software

工作参数 粗磨旋流器 中矿再磨旋流器 运行台数 1 4 内径Dc/mm 500 250 柱体高/mm 1 920 1 380 给料口径/mm 90 90 溢流管径/mm 105 115 溢流管插入深度/mm 300 300 底流口径/mm 70 34 锥角/(°) 20 15 给料压力/MPa 0.085 0.070 表 3 粗磨分级系统JKSimMet模拟结果

Table 3. JKSimMet simulation results of the coarse grinding and classification system

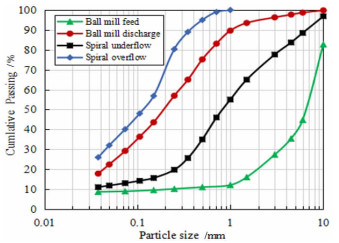

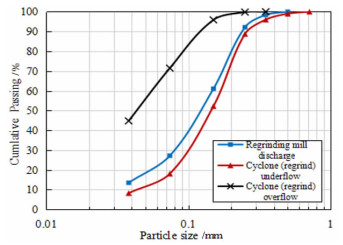

设备名称 工作参数 测量值 模拟值 粗磨球磨机 运行功率/kW 381 388 新鲜给矿量/(t·h-1) 35.0 35.0 给矿粒度F80/mm 10.0 10.0 排矿浓度/% 73.3 70.2 螺旋分级机 底流浓度/% 82.6 80.1 溢流浓度/% 47.0 47.5 底流P80/μm 3 596 1 721 溢流P80/μm 249 231 返砂比/% 63 52 粗磨旋流器 给料压力/MPa 0.085 0.088 给矿浓度/% 47.0 47.5 底流浓度/% 58.7 60.9 溢流浓度/% 30.3 30.8 给矿粒度P80/μm 249 231 底流粒度P80/μm 299 269 溢流粒度P80/μm 86 86 返砂比/% 231 247 表 4 中矿再磨分级系统JKSimMet模拟结果

Table 4. JKSimMet simulation results of the middlings regrinding- classification system

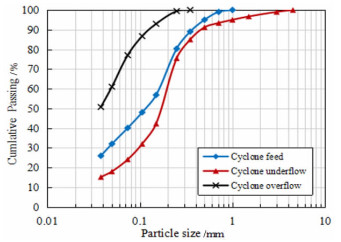

设备名称 运行参数 测量值 模拟值 再磨球磨机 运行功率/kW 165 139 处理量/(t·h-1) 13.4 14.0 排矿浓度/% 70.9 72.1 再磨旋流器 给料压力/MPa 0.070 0.055 给矿浓度/% 53.5 54.9 底流浓度/% 73.8 73.9 溢流浓度/% 29.1 30.4 给矿粒度P80/μm 203 208 底流粒度P80/μm 226 230 溢流粒度P80/μm 94 90 返砂比/% 388 309 表 5 磨矿分级系统整体优化调整参数

Table 5. Adjusted parameters of the grinding and classification system before and after optimization

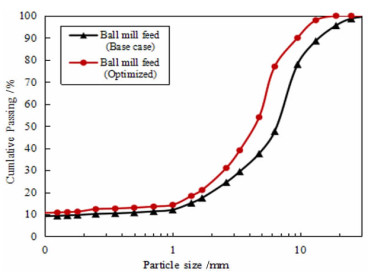

设备 参数 优化前 优化后 细碎圆锥破碎机 排矿口尺寸/mm 10 7 球磨机

(粗磨)新给矿量/(t·h-1) 35 43.75 给矿粒度F80/mm 10 7 球磨机

(中矿再磨)粗磨旋流器底流给入比例/% 8 13 球磨机钢球充填率/% 31 40 磨矿浓度/% 72.1 74.9 旋流器

(粗磨)沉砂口直径/mm 70 75 给料压力/MPa 0.087 0.108 给矿浓度/% 47.5 49.3 旋流器

(中矿再磨)沉砂口直径/mm 35 40 给料压力/MPa 0.055 0.124 给矿浓度/% 54.9 59.9 表 6 磨矿分级系统整体优化前后运行指标对比

Table 6. Comparison of the operating indices of the grinding and classification system before and after the optimization

设备名称 运行参数 优化前 优化后 球磨机

(粗磨)运行总功率/kW 388 391 新给矿量/(t·h-1) 35 44 磨矿比能耗/(kWh·t-1) 11.09 8.94 球磨机

(中矿再磨)运行总功率/kW 139 159 新给矿量/(t·h-1) 14 22 磨矿比能耗/(kWh·t-1) 9.93 7.23 旋流器

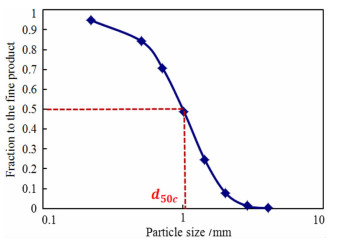

(粗磨)底流粒度P80/μm 269 274 溢流粒度P80/μm 86 80 返砂比/% 247 288 分级粒度d50/μm 111 104 旋流器

(中矿再磨)底流粒度P80/μm 230 226 溢流粒度P80/μm 90 91 返砂比/% 311 362 分级粒度d50/μm 78 75 -

[1] 曹进成, 冯安生, 吕振福, 等.矿产资源开发利用水平评估方法研究[J].矿产保护与利用, 2018(4):22-27. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=51b3e2c2-3039-425c-b717-a278a52dc3f4

[2] La Nauze, R.D., Temos, J. Technologies for sustainable operation[C]. CMMI congress.Cairns Queensland, AusIMM, 2002: 27-34.

[3] Curry, J.A., Ismay, et al. Mine operating costs and the potentialimpacts of energy and grinding[J]. Miner. Eng.2014(56):70-80. doi: 10.1016/j.mineng.2013.10.020

[4] 杨松荣, 蒋仲亚, 刘文拯.碎磨工艺及应用[M].北京:冶金工业出版社, 2013.

[5] 张锦瑞, 唐伟.选矿厂破碎磨矿节能降耗途径探讨[J].河北冶金, 1998, 5:104-107. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199800218196

[6] Morrison R.D., Richard son J.M. JKSimMet-a simulator for analysis, optimization and design of comminution circuits[C]. Mineral processing plant design, practice and control conference, SME, Vancouver, 2002, 442-460.

[7] 张萌, 于伟涛, 姬建钢, 等.JKSimMet粉磨流程模拟软件的建模原理及其应用[J].矿山机械, 2016, 44(9):51-57. http://d.old.wanfangdata.com.cn/Periodical/ksjx201609012

[8] 刘建远.国外几个矿物加工流程模拟软件述评[J].国外金属矿选矿, 2008, 45(1):4-12. http://d.old.wanfangdata.com.cn/Periodical/gwjskxk200801001

[9] Nageswararao, K. Further developments in the modelling and scale up of industrial hydrocyclones[D]. Australia: The University of Queensland, 1979.

[10] 戚厚永.大峪口磷选矿厂磨矿分级流程的评述[J].矿产保护与利用, 2003(4):29-31. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=9913d56e-618a-4701-ad03-7bb3ffab2d4b

-

下载:

下载: