Research on Heat Treatment Process of Foam Glass-ceramics From Iron Tailings

-

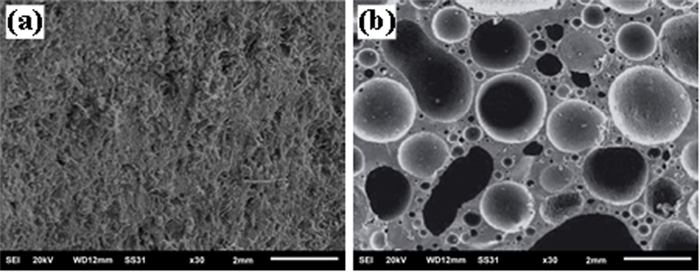

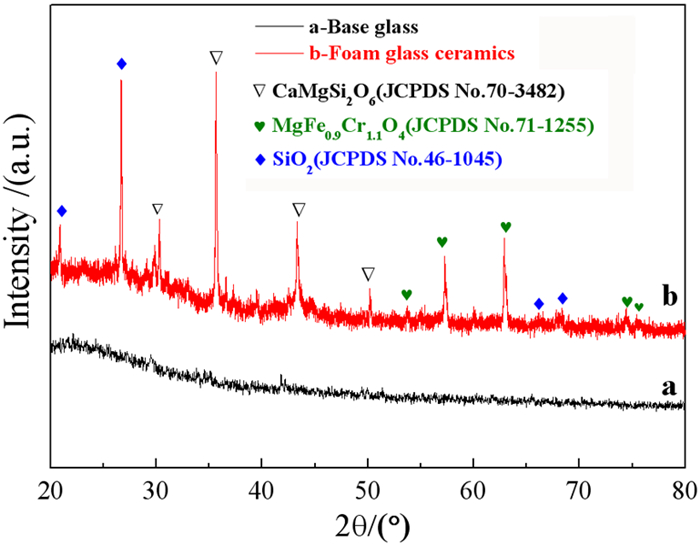

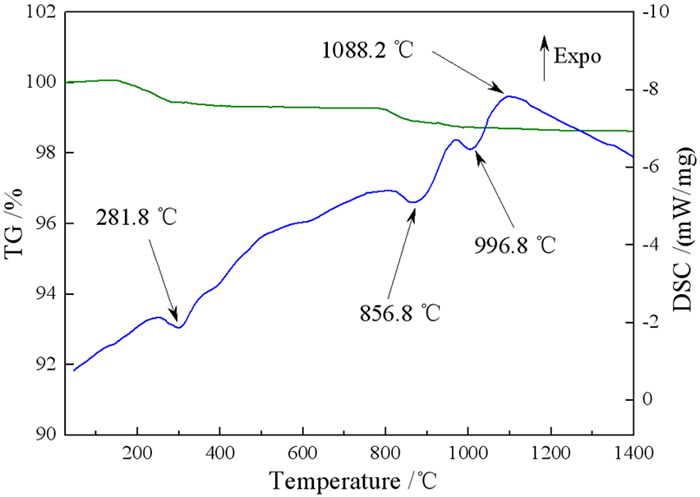

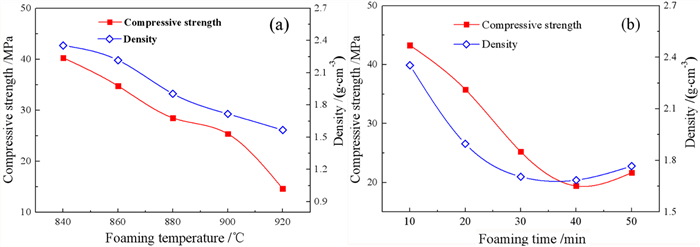

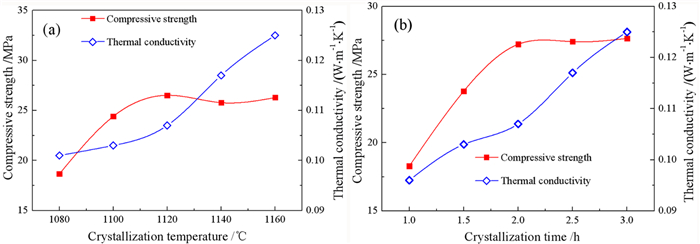

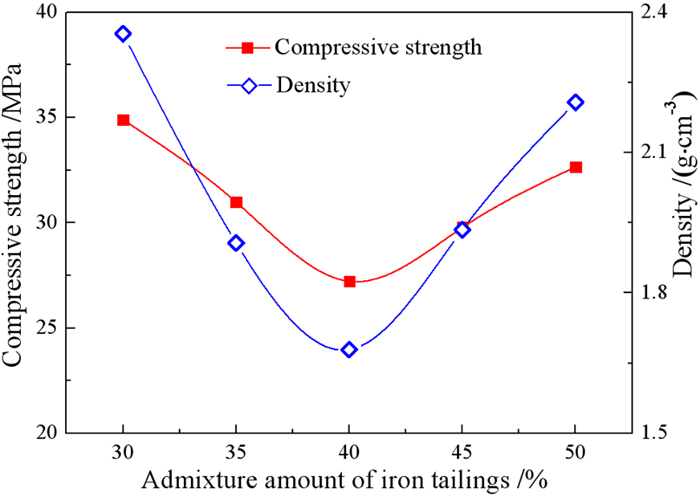

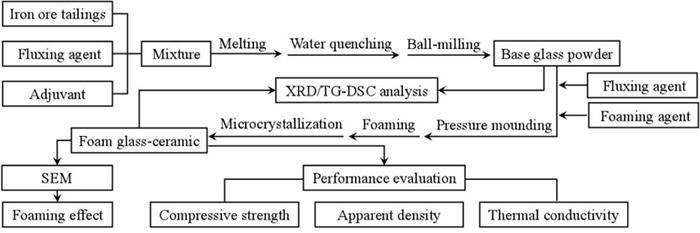

摘要: 以商洛某尾矿库现存铁尾矿为主要原料,以废玻璃为增硅剂,CaCO3为发泡剂,TiO2和CaF2作为复合晶核剂,采用粉末法二次烧结法制备微晶泡沫玻璃,研究了发泡工艺和微晶化工艺对其抗压强度、密度以及热导率的影响。结果表明:在1 350℃、保温2 h条件下获得了最佳熔制效果的基础玻璃;铁尾矿掺入质量分数为40%,在900℃时发泡30 min、1 120℃微晶化处理2 h后,制得了孔径尺寸为1.6~2.0 mm、表观密度为1.679 g·cm-3、抗压强度27.22 MPa、热导率为0.107 W·(m·K)-1的微晶泡沫玻璃。Abstract: The foam glass-ceramics were prepared by sintering method using the iron tailings from a tailings pond in Shangluo area as the main raw material, waste glass as silicatization agent, calcium carbonate as foaming agent, titanium dioxide and calcium fluoride as composite crystal nucleating agents. The effects of key parameters in foaming and microcrystallization process on its compressive strength, density and thermal conductivity were discussed. Results showed that when the content of iron tailings is 40%, foamed for 30 min at 900 ℃ and then crystallized at 1150 ℃ for 2 h, the high-strength foam glass ceramics was prepared with average pore diameter of 1.6~2.0 mm, the apparent density of 1.679 g·cm-3, the compressive strength of 27.22 MPa and the thermal conductivity of 0.107 W/(m·k).

-

Key words:

- iron tailings /

- foam glass-ceramics /

- compressive strength /

- thermal conductivity

-

-

表 1 铁尾矿的化学成分

/% Table 1. Chemical composition of iron tailings

Composition SiO2 Al2O3 CaO MgO Fe2O3 FeO TiO2 K2O Na2O Others Content 66.00 7.06 1.86 0.25 3.18 4.15 0.67 2.59 0.86 13.38 表 2 废玻璃粉的化学成分

/% Table 2. Chemical composition of iron tailings

Composition SiO2 Al2O3 CaO MgO Fe2O3 Na2O TiO2 K2O Ba2O Others Content 72.87 3.14 5.81 1.07 1.24 9.35 0.064 1.58 0.39 4.47 表 3 不同熔制温度下得到熔制效果

Table 3. The characteristics of the base glass at different melting temperatures

Melting temperature Melting time Evaluation of melting results 1 200 ℃ 2 h Refractory and more impurities particles on the surface 1 250 ℃ 2 h A degree of fluidity, but still more particles 1 300 ℃ 2 h High viscosity, less particulate matter 1 350 ℃ 2 h Small viscosity, good fluidity, no surface particles and no bubbles 1 400 ℃ 2 h Good fluidity and large bubbles in fluid and surface layer 表 4 不同熔制时间下得到的基础玻璃效果

Table 4. The characteristics of the base glass at different melting time

Melting time Melting temperature Evaluation of melting results 1 h 1 350 ℃ Viscous with little fluidity 1.5 h 1 350 ℃ Low viscosity and poor uniformity 2 h 1 350 ℃ Small viscosity, good fluidity, uniform fluid, no bubbles 2.5 h 1 350 ℃ Good fluidity with bubbles of different sizes in the fluid -

[1] 张景书.商洛市尾矿资源综合利用现状及其对策[J].商洛学院学报, 2013, 27(4):3-7. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=slsfzkxxxb201304001

[2] 刘淑鹏, 张小伟.我国金属矿山尾矿综合利用现状及对策[J].中国资源综合利用, 2020, 38(3):75-78. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgzyzhly202003023

[3] 王海军, 薛亚洲.我国矿产资源节约与综合利用现状分析[J].矿产保护与利用, 2017(2):1-5. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=2c473a5c-bd79-411b-917b-6292a7223516

[4] 吕绍伟, 姜屏, 钱彪, 等.铁尾矿砂力学特性及再生利用研究进展[J].硅酸盐通报, 2020, 39(2):466-470. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gsytb202002020

[5] 张泽平, 李珠, 董彦莉, 等.建筑保温节能墙体的发展现状与展望[J].工程力学, 2007, 24(z2):121-128. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gclx2007z2011

[6] MUGONI C, MONTORSI M, SILIGARDI C, et al. Design of glass foams with low environmental impact[J]. Ceramics International, 2014, 41(3):3400-3408. http://cn.bing.com/academic/profile?id=8bc34005a5d4b78ed0882eaa5d274f00&encoded=0&v=paper_preview&mkt=zh-cn

[7] XUAN W, NA X, ZHI D Y, et al. Preparation and characterization of novel foamed porous glass-ceramics[J]. Transition Metal Chemistry, 2015, 103(2):90-100. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=454ab79afb673df564a4aa205f4856b1

[8] 于乔, 姜妍彦, 王承遇.泡沫玻璃与固体废弃物的循环利用[J].材料导报, 2009, 23(1):93-96. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cldb200901022

[9] 范明德, 屈培真.吸声微晶泡沫玻璃制品及应用[J].噪声与震动控制, 1993(3):26-29. http://www.cnki.com.cn/Article/CJFDTotal-ZSZK199303010.htm

[10] 徐博, 曹建尉, 梁开明.ZnO和CaO含量对CaO-Al2O3-SiO2系泡沫微晶玻璃析晶与发泡的影响[J].无机材料学报, 2012, 27(2):191-194. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wjclxb201202014

[11] 舒明勇, 尹海英.利用选钛尾矿制备微晶泡沫玻璃及其性能研究[J].钢铁钒钛, 2017, 38(4):74-81. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gtft201704015

[12] ZHANG Q, HE F, SHU H, et al. Preparation of high strength glass ceramic foams from waste cathode ray tube and germanium tailings[J]. Construction and Building Materials, 2016, 111:105-110. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=4ab64355c18ea308dac6792cfff2d111

[13] 戚昊, 何峰, 张雨笛, 等.利用CRT屏玻璃制备板状泡沫玻璃[J].环境工程学报, 2013, 7(6):2327-2332. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjwrzljsysb201306055

[14] LIU T Y, LIN C W, LIU J L, et al. Phase evolution, pore morphology and microstructure of glass ceramic foams derived from tailings wastes[J]. Ceramics International, 2018, 44(12):14393-14400. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=5762b673af2249ba8cfa7b82a866ceea

[15] YIN H, MA M, BAI J, et al. Fabrication of foam glass from iron tailings[J]. Materials Letters, 2016, 185:511-513. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=a9b7cf1fbff4cef1fc878b92a99c8296

[16] 张雪峰, 陈志强, 贾晓林.以山西铜尾矿为主要原料制备泡沫玻璃的研究[J].中国陶瓷, 2016, 52(1):64-70. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgtc201601014

[17] XI C P, ZHENG F, XU J H, et al. Preparation of glass -ceramic foams using extracted titanium tailing and glass waste as raw materials[J]. Construction and Building Materials, 2018, 190:896-909. http://cn.bing.com/academic/profile?id=7f1b0d2c300035017df64859eadec677&encoded=0&v=paper_preview&mkt=zh-cn

[18] LIU T Y, LIN C W, LIU P, et al. Preparation and characterization of partially vitrified ceramic material[J]. Journal of Non-Crystalline Solids, 2019, 505:92-101. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=c7b37209842e25163b3bd72b05602385

[19] 肖兴成, 江伟辉, 王永兰, 等.钛渣微晶玻璃微晶化工艺的研究[J].玻璃与搪瓷, 1998, 27(2):7-11. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=blytc199902002

[20] WU L, ZHAO Y H, CHEN R F, et al. Influence of the heat treatment on the structure and property of the foam glass[J]. Applied Mechanics and Materials, 2014, 488-489:90-93. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.4028/www.scientific.net/AMM.488-489.90

[21] EFTEKHARI YEKTA B, HAMNABARD Z. Sintering and crystallization behavior of machinable fluorphlogopite-gehlenite glass-ceramic[J]. International Journal of Applied Ceramic Technology, 2009, 6(1):72-79. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=59e4d5f44cedbab2f5af7cd9fe5907ce

[22] 马明鑫.铁尾矿泡沫玻璃制备及添加量研究[D].西安: 陕西科技大学, 2017.

http://cdmd.cnki.com.cn/Article/CDMD-10708-1017070909.htm -

下载:

下载: