Effect of Mechanical Force on Distribution of Particle Size and Pozzolanic Reactivity of Siderite Tailings

-

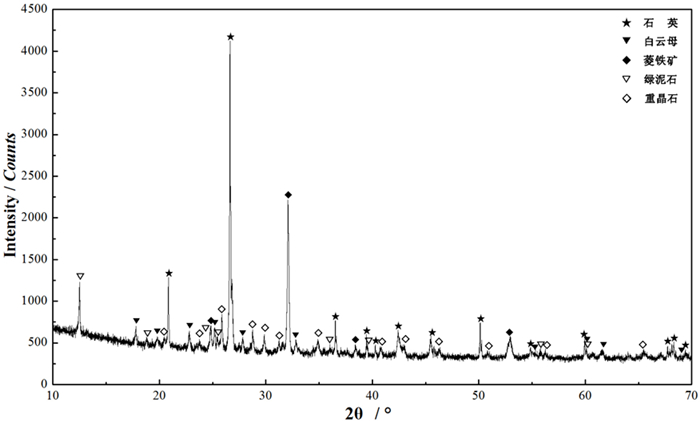

摘要: 基于机械力活化方法及理论,研究了机械力对菱铁尾矿的粒度分布及火山灰活性的影响。结果表明:试验所用菱铁尾矿的易磨性相对较好,机械力的作用使尾矿的粒度分布变化明显且活化后的尾矿具有一定的火山灰活性,但活化时间过长会因弱团聚现象的出现而导致活性降低,方差分析结果表明球磨转速和粉磨时长均对尾矿的比表面积和火山灰活性有显著影响,其中球磨转速的影响相对更大。Abstract: Based on mechanical force activation method and theory, the effects of mechanical force on distribution of particle size and pozzolanic reactivity of siderite tailings were studied. The results showed that the tailings were relatively easy to grind, the role of mechanical force was making the tailings particles distribution change significantly and leading to activation of tailings with a certain pozzolanic reactivity. However, the long time will result in the phenomenon that weak reunion was reduced. And the activity of variance analysis results showed that the ball grinding speed and grinding length had a significant impact on the specific surface of the tailings and pozzolanic reactivity, and among them, the influence of ball mill speed was better to the grinding time.

-

-

表 1 菱铁尾矿胶砂试块的原料配比

Table 1. The raw material proportion of the colloidal sand of siderite tailings

Raw material Cement/g Siderite tailings/g China ISO standard sand/g Tap water/mL Comparing block 450 0 1 350 225 Mortar block 300 150 1 350 225 表 2 菱铁尾矿的化学组成

Table 2. Chemical composition of siderite tailings

SiO2 Al2O3 CaO Fe2O3 SO3 K2O MgO V2O5 TiO2 Others Sum 71.06 8.04 5.65 5.21 3.06 1.85 1.73 1.22 0.97 1.21 100.00 表 3 不同活化条件的菱铁尾矿的D10、D50、D90

Table 3. D10、D50 and D90 of siderite tailings under different activation conditions

0 r/min 240 r/min 285 r/min 330 r/min 40 min 60 min 80 min 100 min 40 min 60 min 80 min 100 min 40 min 60 min 80 min 100 min D10/μm 11.278 3.535 3.184 2.037 2.433 2.419 2.052 1.568 1.992 1.797 1.595 1.313 1.373 D50/μm 200.183 29.685 24.935 13.376 15.924 19.443 15.081 9.776 14.857 12.957 11.326 8.785 9.188 D90/μm 501.264 228.046 177.759 82.120 105.351 141.135 106.666 46.003 94.269 74.910 59.653 33.803 41.053 表 4 不同活化条件下菱铁尾矿的抗压强度活性指数及方差分析结果

Table 4. Hc and results of variance analysis of siderite tailings under different conditions

40 60 80 100 240 0.50 0.55 0.74 0.60 285 0.60 0.65 0.92 0.71 330 0.74 0.81 0.89 0.81 Source SS df MS F P-value F crit R factor 0.0892 2 0.0446 26.3794 0.0011 5.1433 C factor 0.0905 3 0.0302 17.8591 0.0021 4.7571 Error 0.0101 6 0.0017 Total 0.1898 11 -

[1] 李萍, 王明珍.大西沟菱铁矿尾矿再回收试验研究[J].矿业快报, 2008(12):75-76. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kykb200812024

[2] 刘璇, 李如燕, 孙可伟, 等.尾矿资源综合利用的必要性及对策[J].再生资源与循环经济, 2015, 8(12):30-32. doi: 10.3969/j.issn.1674-0912.2015.12.009

[3] 孟跃辉, 倪文, 张玉燕, 等.我国尾矿综合利用发展现状及前景[J].中国矿山工程, 2010, 39(5):4-9. doi: 10.3969/j.issn.1672-609X.2010.05.003

[4] 刘璇, 崔孝炜.铁尾矿-粉煤灰基地质聚合物的制备及性能研究[J].商洛学院学报, 2016, 30(2):43-46. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=slsfzkxxxb201602010

[5] 黄勇刚.我国铁尾矿资源的利用现状及展望[J].资源与产业, 2013, 15(3):40-44. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zycy201303008

[6] 刘璇, 李如燕, 崔孝炜, 等.机械力活化对钼尾矿胶凝性能的影响研究[J].矿产保护与利用, 2018(4):108-111, 117. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=73d7ba5a-43f2-4921-be42-e5c44f2dc7f6

[7] ZHANG S, XUE S, LIU X, et al. Current situation and comprehensive utilization of iron ore tailing resources[J]. Journal of Mining Science, 2006, 42(4):403-408. doi: 10.1007/s10913-006-0069-9

[8] MULAK W, BALAZ P, CHOJNACKA M. Chemical and morphological changes of millerite by mechanical activation[J]. International Journal of Mineral Processing, 2002, 66(1):233-240. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=988e9668e61ed783422e87629f17070c

[9] 王恩, 倪文, 孙汉.工业固体废弃物制备地质聚合物技术的原理与发展[J].矿产综合利用, 2005(4):30-34. doi: 10.3969/j.issn.1000-6532.2005.04.008

[10] 王亚光, 韩凤兰, 赵世珍, 等.粉煤灰地质聚合物的制备及其抗压强度研究[J].新型建筑材料, 2017, 44(10):12-16. doi: 10.3969/j.issn.1001-702X.2017.10.004

[11] 吴辉, 倪文, 伏程红, 等.机械粉磨对铁尾矿制备高强结构材料的影响[J].矿物学报, 2010, 30(S1):72-73. http://www.cnki.com.cn/Article/CJFDTotal-KWXB2010S1042.htm

[12] 徐丽, 吴辉, 郭珍妮, 等.利用微磨球效应制备超高强铁尾矿混凝土[J].金属矿山, 2010(12):162-166. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsks201012039

[13] 郑永超, 倪文, 徐丽, 等.铁尾矿的机械力化学活化及制备高强结构材料[J].北京科技大学学报, 2010, 32(4):504-508. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bjkjdxxb201004018

[14] 蒙朝美, 侯文帅, 战晓菁.机械力活化高硅型铁尾矿粒度及活性分析研究[J].绿色科技, 2014(11):228-231. doi: 10.3969/j.issn.1674-9944.2014.11.102

[15] 王文宗, 董刚, 张文生.煤矸石火山灰活性的评价[J].中国建材科技, 2010(6):49-52. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgjckj201006015

[16] 朴春爱, 王栋民, 张力冉, 等.机械力活化对铁尾矿活化性能的影响研究[J].硅酸盐通报, 2016, 35(9):2973-2979. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gsytb201609050

-

下载:

下载: