Research on Optimizing Particle Size Composition of Grinding Products of Dongguashan Copper Mine to Improve Flotation Index

-

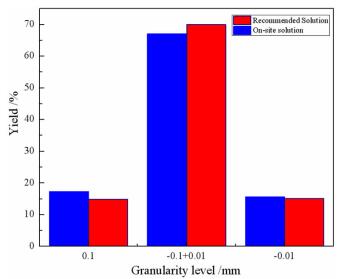

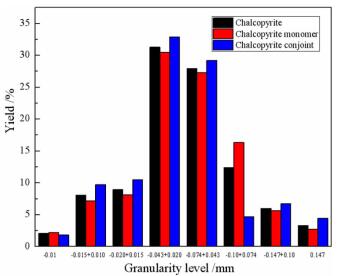

摘要: 针对冬瓜山入浮颗粒粒度较粗且粒度组成分布不合理问题,基于磨矿产品的粒度分布及矿石力学性质对磨矿介质配比进行调整以优化入浮颗粒的粒度组成,结果表明:冬瓜山一段磨矿介质尺寸方案为m(φ60):m(φ40):m(φ30):m(φ25)=40:10:30:20,采用推荐方案可提高磨矿产品中-0.1+0.01 mm颗粒产率2.28%。推荐方案与现场方案磨矿产品经一粗两精两扫的浮选闭路对比试验,推荐方案铜精矿回收率90.11%,较现场方案提高1.34%,精矿品位提高了0.94%。对浮选尾矿筛分并检测分析可知推荐方案磨矿产品在-0.1+0.01 mm颗粒中铜的回收效果优于现场方案,利用推荐的介质配比方案优化磨矿产品粒度组成,有效提高了冬瓜山选铜浮选指标。Abstract: In order to solve the problem of coarse and unreasonable particle size composition distribution in Dongguashan, the particle size composition of floating particles was optimized by adjusting the proportion of grinding medium based on the particle size distribution of grinding products and the dynamics properties of ores. The results showed that the size scheme of one stage of grinding media in Dongguashan is m (φ60):m (φ40):m (φ30):m (φ25) = 40:10:30:20. The yield of -0.1+0.01mm particles in grinding mineral products could be increased by 2.28% used the recommended scheme. Compared with the recommended scheme and the field scheme experienced flotation closed circuit test with one rough and two fine sweeps, the recovery rate of copper concentrate used recommended scheme was 90.11%, which was 1.34% higher than that of the field scheme. And the concentrate grade used recommended scheme was 0.94% higher than that of the field scheme. According to the screening and detection analysis of the flotation tailings, the recovery of copper in -0.1+0.01mm particles of grinding minerals in the recommended scheme was better than that in the field scheme. The recommended medium ratio scheme was used to optimize the particle size composition of grinding minerals, which effectively improved the flotation index of copper in Dongguashan.

-

Key words:

- grinding /

- particle size composition /

- flotation

-

-

表 1 矿石多元素分析结果

Table 1. Multi-element analysis results of run-of-mine ore

Element Cu Fe S SiO2 Al2O3 CaO MgO K2O Na2O Content 0.795 21.62 9.89 30.89 3.98 15.90 4.53 0.92 0.24 表 2 矿物相分析结果

Table 2. Analysis results of mineral phase

Mineral facies Chal copyrite Pyrite Magnetite Serpentine Talc Uartz Calcium iron garnet Diopside Calcite Muscovite Biotite Plaster Feldspar Pyrrhotite Other minerals Total Content 2.11 4.59 3.40 5.83 2.16 6.58 22.59 12.00 6.73 4.55 3.06 3.83 4.44 3.04 15.09 100.00 表 3 矿石主要力学性质

Table 3. Mechanical characteristics of rock

Mechanical properties Test weight /(g·m-3) Compressive strength /(kg·cm-2) Platts hardness coefficient(f) Elastic Modulus /(kg·cm-2) Poisson’s ratio(μ) Value 3.45 907.90 9.08 7.55×104 0.29 表 4 一段球磨初装球比计算表

Table 4. The ball milling ball loading ratio in the first stage

Level /mm Mineral yield /% Yield after deduction -0.10 mm /% Suitable ball diameter for each group /mm Recommended ball ratio /% +0.45 30.93 42.55 60 40 0.45~0.30 8.03 11.05 40 10 0.30~0.15 20.76 28.56 30 30 0.15~0.10 12.98 17.86 25 20 -0.10 27.31 —— —— —— Total 100.00 100.00 —— 100.00 表 5 浮选产品指标

Table 5. Flotation product index

Test plan Products Yield /% Grade /% Recovery rate/% On-site solution Concentrate 4.99 17.40 88.77 Tailing 95.01 0.116 11.23 Raw ore 100.00 0.98 100.00 Recommended Solution Concentrate 4.88 18.34 90.11 Tailing 95.12 0.103 9.89 Raw ore 100.00 0.99 100.00 表 6 尾矿铜分布

Table 6. Copper distribution in tailings

Test plan Products Yield /% Grade /% Copper distribution /% Relative raw copper loss rate/% On-site solution Tailings +0.10 mm 17.05 0.219 31.64 3.55 -0.01+0.10 mm 67.50 0.083 47.48 5.33 -0.01 mm 15.45 0.16 20.95 2.35 Total 100.00 0.118 100.00 11.23 Recommended Solution Tailings +0.10 mm 14.92 0.166 24.28 2.40 -0.01+0.10 mm 69.75 0.080 54.71 5.41 -0.01 mm 15.33 0.14 21.04 2.08 Total 100.00 0.102 100.00 9.89 -

[1] 周平.新常态下中国铜资源供需前景分析与预测[D].北京: 中国地质大学(北京), 2015.

[2] 苏敏, 窦培谦, 张瑞洋, 等.谦比希铜矿中铜矿物的解离特性及其可浮性研究[J].金属矿山, 2019(4):105-110. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsks201904022

[3] 王素, 齐向红, 田江涛, 等.河北省某铜尾矿综合回收试验研究[J].矿产综合利用, 2019(3):113-117. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kczhly201903025

[4] HOSSEINI, FORSSBERG. Studies on selective flotation of smithsonite from silicate minerals using mercaptans and one stage desliming[J]. Mineral Processing and Extractive Metallurgy, 2011, 120(2):79-84. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1179/1743285510Y.0000000001

[5] 蒋婷婷, 熊巍.江西地区铜矿工艺矿物学特征及选矿影响因素研究[J].中国金属通报, 2019(10):70-72. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgjstb201910044

[6] 薛季玮, 姚金, 唐远, 等.粒度对蓝辉铜矿与黄铁矿浮选分离特性的影响[J].金属矿山, 2018(8):73-78. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsks201808015

[7] 汪太平, 肖庆飞, 李博.冬瓜山铜矿一段磨矿产品粒度组成优化研究[J].矿产保护与利用, 2014(4):22-26 doi: 10.13779/j.issn.1001-0076.2014.04.006

[8] 康怀斌.大山选厂浮选回收率与磨矿产品粒度均匀性的多元线性回归模型及应用研究[D].昆明: 昆明理工大学, 2015.

[9] 杨金林, 莫凡, 周文涛, 等.选择性磨矿研究概述[J].矿产综合利用, 2017(5):1-6 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kczhly201705001

[10] 王翠花, 支永勋, 李学忠.选择性磨矿在萤石矿选矿工艺中的应用[J].化工矿物与加工, 2013, 42(6):37-39. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgkwyjg201306013

[11] 邓禾淼, 康怀斌, 肖庆飞.改善冬瓜山铜矿磨矿效果提高铜回收率的研究[J].有色金属(选矿部分), 2017(1):65-68. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ysjs-xk201701015

[12] 王改荣, 杨洪英, 佟琳琳, 等.赞比亚卢安夏氧化铜矿工艺矿物学研究[J].东北大学学报(自然科学版), 2019, 40(3):350-355. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dbdxxb201903009

[13] 肖庆飞, 康怀斌, 张红华, 等.优化球荷特性提高磨矿产品粒度均匀性的研究[J].矿产保护与利用, 2015(5):25-28. doi: 10.13779/j.cnki.issn1001-0076.2015.05.005

[14] 段希祥, 肖庆飞.碎矿与磨矿[M].北京:冶金工业出版社, 2012:1-5.

-

下载:

下载: