Floc Evolution and Characterization of Lead-zinc Tailing in Shearing Environment

-

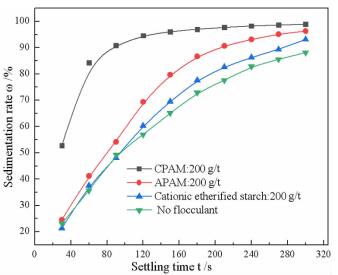

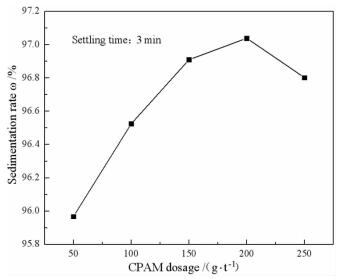

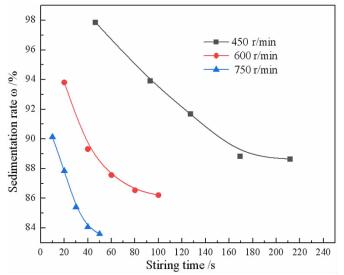

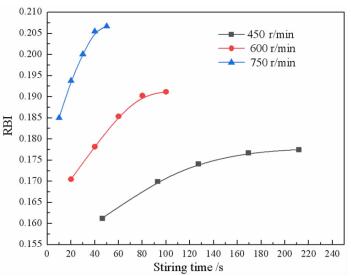

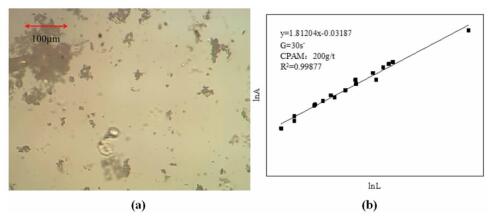

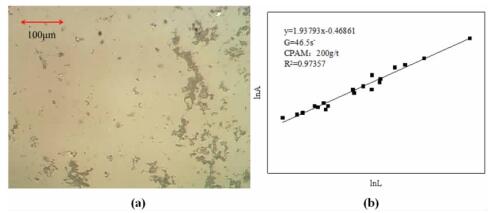

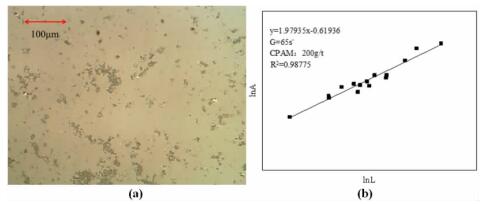

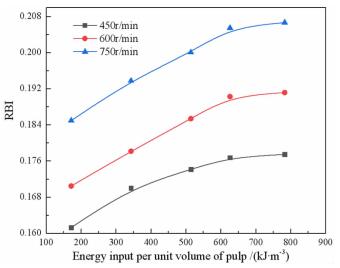

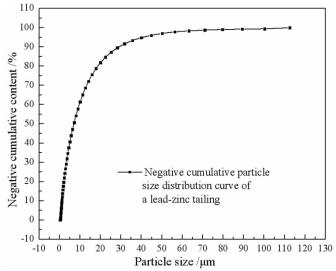

摘要: 某铅锌矿山对尾矿颗粒絮团强度有一定要求,为了研究如何表征并增大絮团强度,考察了絮凝剂的种类和用量、搅拌时间、搅拌速度以及单位矿浆输入能量等剪切环境因素对某铅锌尾矿剪切絮凝沉降的影响,进行了相应的絮凝沉降试验、颗粒录影显微技术(ParticleView V19)实时监测以及显微镜絮团图像分析,并讨论了絮凝机理,旨在揭示絮体形成过程与絮凝效果的关系。结果表明:对某铅锌尾矿的絮凝作用:阳离子聚丙烯酰胺>阴离子聚丙烯酰胺>阳离子醚化淀粉,阳离子聚丙烯酰胺(CPAM)最佳用量值为200 g/t,加入表面电荷相反的PAM,能使颗粒表面动电位降低而凝聚,当絮凝剂过量时,会使得整个体系变为带正电荷。由于正电荷间的互斥作用,絮凝体再次分散,发生再稳现象,从而使絮凝效果减弱。搅拌时间、搅拌速度、单位矿浆输入能量对某铅锌尾矿的剪切絮凝行为的影响很大;搅拌时间关系着絮团的成长破碎程度;搅拌强度的大小影响着絮团所受剪切强度,搅拌强度越大,絮团最终形成稳态的抗剪切强度越高,形貌越规则;单位矿浆输入能量存在一个极限值,超过极限值时,絮团形成与破碎达到了一个相对平衡的稳态,絮团能够在此搅拌体系下稳定存在。Abstract: A lead-zinc mine has certain requirements for the strength of the tailings particle floc. In order to study how to characterize and increase the floc strength, the shearing environmental factors such as the type and dosage of flocculant, stirring time, stirring speed, and input energy per pulp were investigated. The effect on the shear flocculation sedimentation of a lead-zinc tailing was tested by corresponding flocculation sedimentation test, particle video microscopy (ParticleView V19) real-time monitoring and microscopic floc image analysis. And the flocculation mechanism was discussed in order to reveal flocs relationship between formation process and flocculation effect. The results showed that the flocculation effect of flocculant on the lead-zinc tailings from strong to weak was as follows: cationic polyacrylamide> anionic polyacrylamide> cationic etherified starch. The optimal dosage of cationic polyacrylamide (CPAM) was 200 g/t. PAM could reduce the kinetic potential of the particle surface and agglomerate. When the flocculant dosage was excessive, the entire system became positively charged. Due to the mutual repulsion between the positive charges, the floes were dispersed again, and the re-stabilization phenomenon was occurred, which could weaken the flocculation effect. Stirring time, stirring speed, and unit pulp input energy had a great influence on the shear flocculation behavior of the lead-zinc tailing. The stirring time was related to the growth and fragmentation of the floc. The stirring intensity was related to the shear strength of the floc. The greater the stirring intensity, the higher the flocculation final stable shear strength and the more regular the morphology were. There was a limit value for the unit pulp input energy. When the limit value was exceeded, the floc formation and fragmentation reached a relatively balanced steady state, and the floc could exist stably under this stirring system.

-

Key words:

- shear environment /

- flocculation /

- floc characterization /

- floc strength

-

-

表 1 化学多元素测定

Table 1. Chemical multi-element determination

Element Pb Zn Cu Cd Hg Ge TFe SiO2 Al2O3 CaO MgO P As S C Ag* Content/% 0.82 0.40 0.0098 0.0011 0.0002 0.0007 7.53 27.23 4.64 21.28 1.58 0.031 0.10 7.46 5.38 6.88 Unit: g/t. 表 2 不同搅拌强度下絮凝参数

Table 2. Flocculation parameters with different stirring intensity

Rotating speedn /(r·min-1) Shear strength G/(s-) Fractal dimension Floc strength /pa 450 30 1.81204 0.027 600 46.5 1.93793 0.042 750 65 1.97935 0.058 表 3 絮团演化过程

Table 3. Process of floc evolution

Rotating speed/(r·min-1) Energy input per unit volume of pulp/(kJ·m-3) 450 600 750

(1) 171.31

(2) 342.62

(3) 531.93

(4) 626.04

(5) 782.55 -

[1] 吴文添加絮凝药剂的尾矿砂浆充填材料的单轴抗压强度试验研究[J].岩土力学, 2010, 31(11):3367-3372. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytlx201011002

[2] 邬顺科, 邓美姣, 孙伟.搅拌因素对高岭石疏水剪切絮凝浮选行为的影响及机理分析[C]//第三届全国选矿专业学术年会.2006.

http://d.wanfangdata.com.cn/conference/6216260 [3] 张金凤, 张庆河, 乔光.全水体紊动对黏性泥沙絮凝影响研究[J].水利学报, 2013, 44(1):67-72, 82. http://www.cnki.com.cn/Article/CJFDTotal-SLXB201301010.htm

[4] 张乃予, 周晶晶, 王捷.黏性泥沙絮团强度的试验研究综述[J].泥沙研究, 2015(5):75-80. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nsyj201505013

[5] 肖淑敏, 赵建海, 魏磊, 等.搅拌条件对氢氧化镁混凝性能及絮体特性的影响[J].化工进展, 2018, 37(2):761-766.. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201802045

[6] 宋少先, 李长, 崔洪山.细粒矿物絮团浮选的理论和应用[J].国外金属矿选矿, 2007(5):4-9, 40.. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gwjskxk200705001

[7] 张东晨, 侯志翔, 周倩倩, 等.煤炭生物絮凝絮体分形试验研究[J].煤炭学报, 2015, 40(5):1148-1152. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=mtxb201505026

[8] 王晓昌, 丹保宪仁.絮凝体形态学和密度的探讨——Ⅰ.从絮凝体分形构造谈起[J].环境科学学报, 2000, 20(3):257-262. http://www.cqvip.com/Main/Detail.aspx?id=4259216

[9] Anon. Sparkle effect of unique particle size distribution, KR101297023[P]. 2013-08-14.

[10] 牛福生, 李卓林, 张晋霞.微细粒赤铁矿絮凝体物理特性表征研究[J].矿产保护与利用, 2016(5):70-73, 78. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=a0039f02-d2b4-4c2f-9870-4bba398581dd

[11] 刘东京.废水制备聚硅硫酸盐絮凝剂及絮凝体分形仿真模拟[D].南昌: 南昌大学, 2012.

http://d.wanfangdata.com.cn/thesis/Y2141920 -

下载:

下载: