Pilot Study on Direct Reduction of Low Grade Refractory Iron Ore by Rotary Hearth Furnace

-

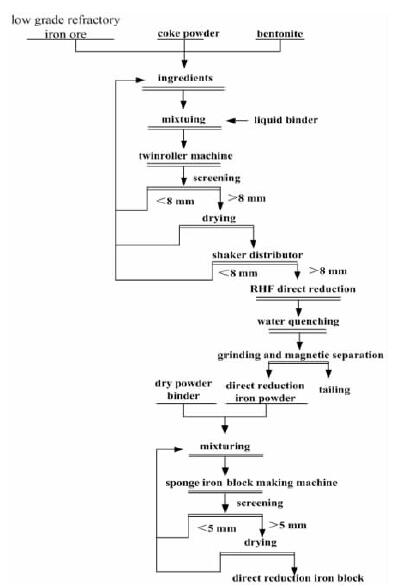

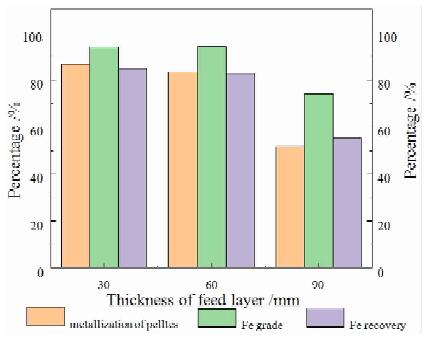

摘要: 采用转底炉直接还原焙烧-磁选方法,对低品位难选铁矿进行了转底炉中试试验研究。混合物料配比是m(原矿):m(焦粉):m(膨润土):m(液体粘结剂)=100:33:4:8,转底炉焙烧温度1 250℃~1 330℃,还原时间为42 min,含碳球团厚度3层(约60 mm),最终获得的球团平均金属化率83.44%,两段磨矿磁选所得还原铁粉产率39.52%,铁品位94.39%,铁回收率83.34%。对还原铁粉压块,压块密度为4.78 t/m3,可以作为优质的电炉炼钢原料。Abstract: The pilot scale test of the low grade refractory iron ore was carried out in a rotary hearth furnace by direct reduction roasting and magnetic separation. The metallized pellets with a average metallization rate of 83.44% could be obtained by the mixed material ratio of raw ores, coke powder, bentonite and liquid binder at the ratio of 100:33:4:8, rotary hearth furnace roasting temperature from 1 250 ℃ to 1 330 ℃, reduction time of 42 minutes, and the thickness of carbon-containing pellets of 3 layers (about 60 mm). After the two stages of grinding-magnetic separation, the reduction iron powder could be obtained with yield of 39.52%, TFe grade of 94.39% and iron recovery of 83.34%. The reduction iron powder could be compressed into blocks with the density of 4.78 t/m3, which could be used as a high-quality charge for electric steelmaking.

-

-

表 1 原矿化学多元素分析

/% Table 1. Multi-elements analysis results of raw ores

Element TFe FeO SiO2 Al2O3 CaO MgO K2O Na2O Pb Zn S P Content 44.76 2.01 19.64 2.22 2.56 1.45 0.78 0.23 0.33 0.34 0.68 0.09 表 2 原矿Fe的化学物相分析结果

/% Table 2. Multi-elements analysis results of Fe in raw ores

Category Fe in hematite(limonite) Fe in carbonate Fe in sulfide ores Fe in other ores total Content 40.50 2.35 0.51 1.61 45.02 Proportion 90.07 5.23 1.12 3.58 100.00 Explanation: ' Fe in other ores ' mainly refers to iron in silicate minerals. 表 3 转底炉中试试验主要设备

Table 3. Main equipments for pilot test of rotary hearth furnace

Serial number Equipment name Equipment model and parameters Application of the equipment Equipment sets 1 XLH mixer 22 kW, 380 V raw material mixture XLH mixer 2 twinroller machine maximum linear pressure 11t/cm preparation of pellets 1 3 mesh belt dryer three layers; 2.2 kW drying 1 4 RHF charging width: 2 m;3t/h reduction 1 5 ball grinding mill MQG1224 pellets grinding 2 6 magnetic separator DCIB600*600 magnetic separation 2 7 sponge iron briquetting machine 10~25 MPa reduced iron powder molding 1 表 4 模拟转底炉各区温度与时间参数

Table 4. Simulation parameters of temperature and time in different districts of rotary hearth furnace

Zone Angle/° Temperature/℃ Time/min Preheating zone 75 1 200-1 280 9 High temperature zone 205 1 280 24 Cooling zone 20 ≤1 050 2 Charging and discharging Zone 60 --- 7 Total 360 --- 42 表 5 转底炉还原各区工艺参数

Table 5. Process parameters in the different districtsof rotary hearth furnace

Process parameters Preheating zone Medium temperature area The first high temperature zone The second high temperature zone The colling zone Temperature /℃ 1 250~1 300 1 300~1 330 1 330±20 1 330±20 < 1 100 CO content /ppm > 10 000 > 30 000 > 40 000 > 40 000 Pressure/Pa negative pressure positive pressure positive pressure positive pressure positive pressure Total run time/ min/r 42 表 6 还原铁粉化学多元素分析

/% Table 6. Multi-elements analysis results of reduction iron powder

Element TFe MFe SiO2 Al2O3 MgO K2O Na2O Zn S P C Content 94.22 90.16 1.57 0.15 1.61 0.03 0.02 0.01 0.06 0.01 0.51 表 7 尾矿化学多元素分析

/% Table 7. Multi-elements analysis results of tailings

Element TFe MFe SiO2 Al2O3 CaO MgO K2O Na2O Zn S P C Content 12.46 2.24 45.32 5.38 5.16 2.33 0.81 0.15 0.01 1.66 0.03 16.92 -

-

下载:

下载: