Solidification of Municipal Solid Waste Incineration Fly Ash with Metallurgically Based Cementitious Materials

-

摘要:

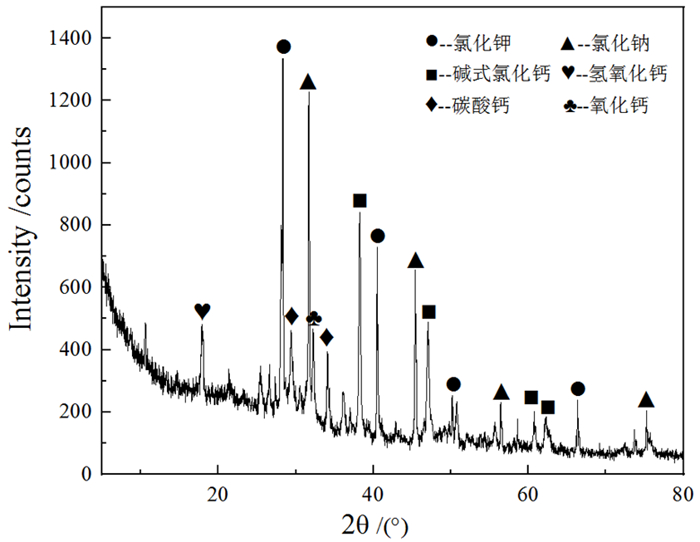

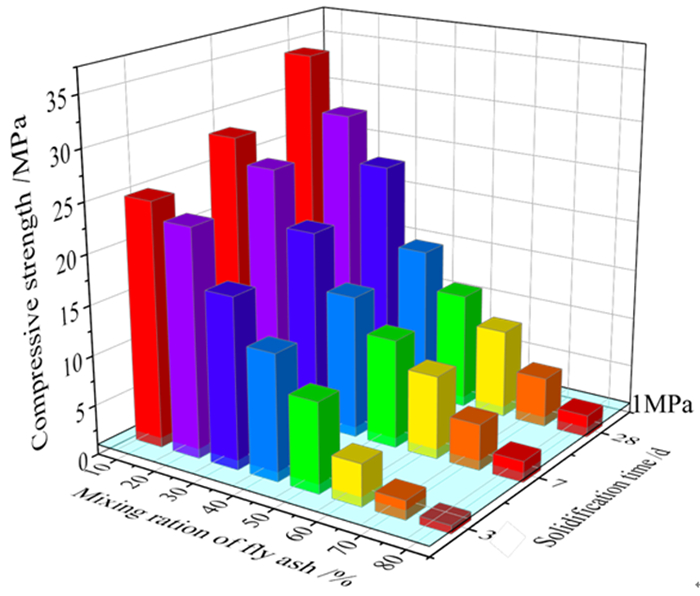

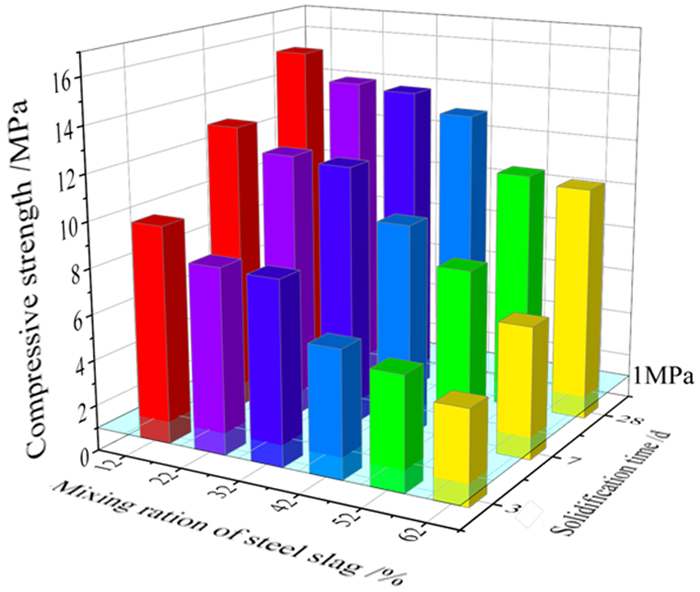

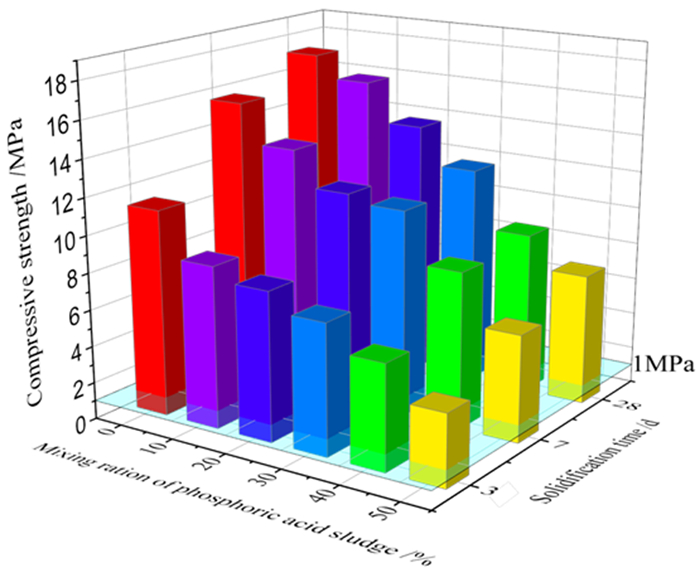

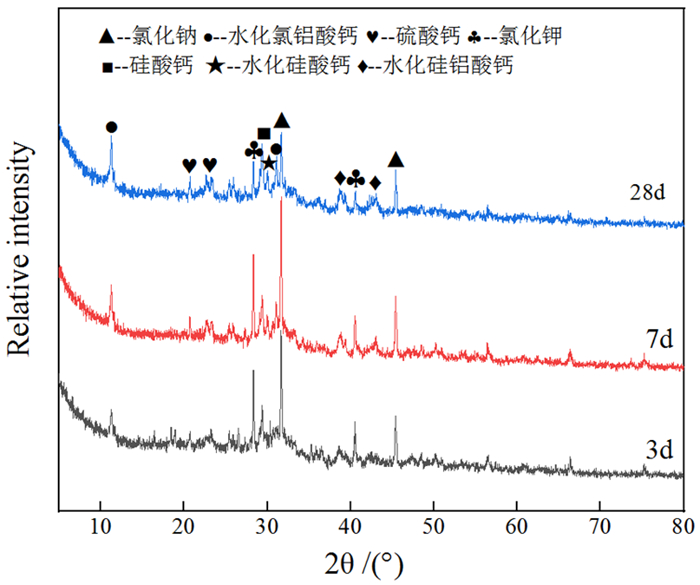

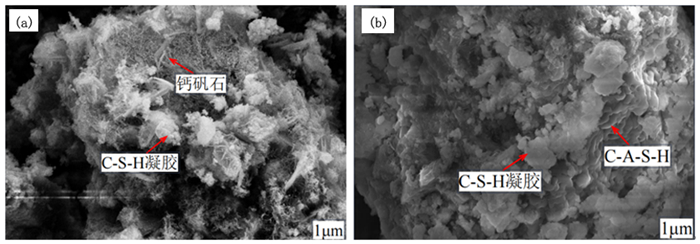

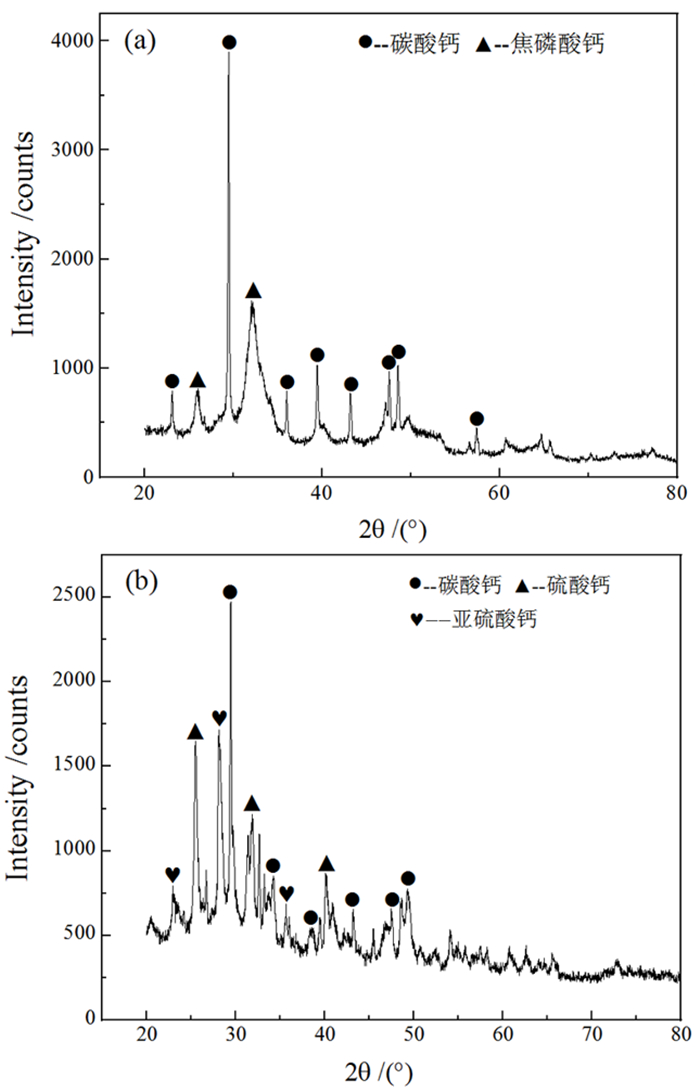

以矿渣、钢渣、脱硫灰和磷酸淤渣为原材料,优化4种原料的配合比,制备出冶金渣基胶凝材料,考察其对垃圾焚烧飞灰中重金属的固化性能。结果表明:当m(矿渣):m(钢渣):m(脱硫灰):m(磷酸淤渣)=36%:32%:12%:20%时,冶金渣基胶凝材料净浆试块的抗压强度达35.2 MPa。随着垃圾焚烧飞灰掺入量从10%增加到80%,固化体的强度不断下降;但是,当垃圾焚烧飞灰掺量高达到80%时,固化体抗压强度仍达2.2 MPa,Pb、Zn、Cr、Hg和As的固化率仍超过99%,垃圾焚烧飞灰固化体的抗压强度和重金属浸出浓度均满足《生活垃圾卫生填埋场污染控制标准(GB 16889—2008)》的要求。

Abstract:The metallurgically based cementitious materials were prepared by optimizing the mass ratio of blast furnace slag, steel slag, desulfurization ash and phosphoric acid sludge. The immobilization performances of heavy metals in Municipal Solid Waste Incineration (MSWI) fly ash were evaluated by using metallurgically based cementitious materials as binding agent. The results showed that the compressive strength of cement paste for metallurgically based cementitious materials reached 35.2 MPa with the mass ratio of blast furnace slag, steel slag, desulfurization ash and phosphoric acid sludge of 36%: 32%: 12%: 20%. When the mixing ratio of MSWI fly ash increased from 10% to 80%, the compressive strength of solidified matrix decreased gradually. However, while the mixing ratio of MSWI fly ash was as high as 80%, the compressive strength of solidified matrix still reached 2.2 MPa, and the immobilization rates of Pb, Zn, Cr, Hg and As were higher than 99%. The leaching concentration of heavy metals and the compressive strength of solidified matrix well met the requirements of 《Standard for Pollution Control on the Landfill Site of Municipal Solid Waste (GB 16889-2008)》.

-

-

表 1 4种原材料的主要化学成分

Table 1. Main chemical compositions of four raw materials

/% 原材料 Fe2O3 Al2O3 SiO2 CaO MgO K2O Na2O P2O5 磷酸淤渣 0.48 1.14 4.73 44.52 1.56 0.32 0.33 21.76 钢渣 26.32 4.30 14.17 38.93 8.22 0.01 0.07 1.29 脱硫灰 5.65 0.83 2.12 32.23 0.83 3.20 0.80 0.36 矿渣 1.07 15.73 35.03 36.61 8.59 0.01 0.30 0.13 表 2 4种原料和垃圾焚烧飞灰中重金属含量

Table 2. Heavy metal contents in four raw materials and MSWI fly ash

/(mg·kg-1) 材料 Pb Zn Cr As Hg 磷酸淤渣 4.22 50.95 ND 32.12 0.01 钢渣 1.26 39.75 422.30 8.14 0.17 脱硫灰 2 412.81 192.20 ND 22.57 2.35 矿渣 0.06 16.67 ND ND ND 垃圾焚烧飞灰 1 502.00 2 526.00 42.40 28.70 6.46 注:ND为未检测出。 表 3 正交试验方案配比及固化体的抗压强度

Table 3. Orthogonal experimentof ratios of four raw materials and compressive strength of solidified matrix

编号 胶凝材料配比/% 抗压强度/MPa 钢渣 脱硫灰 磷酸淤渣 矿渣 3 d 7 d 28 d A1 28 8 20 44 5.40 15.3 23.3 A2 28 10 26 36 4.19 15.2 24.5 A3 28 12 32 28 3.26 10.8 19.2 A4 28 14 38 20 2.03 6.6 14.8 A5 32 8 26 34 5.25 16.6 21.2 A6 32 10 20 38 4.26 15.7 26.0 A7 32 12 38 18 2.26 9.5 17.3 A8 32 14 32 22 2.70 11.4 19.2 A9 36 8 32 24 3.28 12.0 16.6 A10 36 10 38 16 1.8 8.4 13.5 A11 36 12 20 32 2.13 16.9 22.6 A12 36 14 26 24 0.96 12.0 20.4 A13 40 8 38 14 1.31 6.9 13.8 A14 40 10 32 18 1.60 8.9 16.7 A15 40 12 26 22 1.11 11.6 22.2 A16 40 14 20 26 0.85 13.7 23.1 表 4 最优配比下冶金渣基胶凝材料净浆试块的抗压强度

Table 4. Compressive strength of metallurgically based cement paste with optimized ratio of four raw materials

胶凝材料配比/% 抗压强度/MPa 磷酸淤渣 钢渣 脱硫灰 矿渣 3 d 7 d 28 d 20 32 12 36 26.9 28.3 35.2 表 5 垃圾焚烧飞灰掺入量对重金属浸出浓度和固化率的影响

Table 5. Effect of MSWI fly ash contents on leaching concentration and immobilization rate of five heavy metals

垃圾焚烧飞灰掺入量/% 重金属浸出浓度/(μg·L-1) 重金属固化率/% Zn Cr As Pb Hg Zn Cr As Pb Hg 10 9.6 1.4 1.4 2.3 4.60 99.77 99.98 99.86 99.99 99.01 20 34.6 1.3 6.7 1.3 7.07 99.97 99.98 99.58 100.00 99.13 30 7.1 1.5 2.9 2.0 3.10 99.92 99.98 99.50 99.99 99.14 40 30.1 1.4 3.9 4.2 5.70 99.82 99.98 99.62 99.99 98.80 50 95.7 1.2 3.3 4.7 8.70 99.88 99.95 99.61 99.99 98.53 60 78.5 2.3 3.8 9.4 8.33 99.99 99.94 99.59 99.98 98.82 70 8.3 2.6 4.3 25.6 5.08 99.99 99.94 99.27 99.96 99.38 80 5.1 2.2 8.5 148.0 2.60 99.99 99.84 99.44 99.77 99.72 标准值* 100 000 4 500 300 250 50 *注:《生活垃圾卫生填埋场污染控制标准》(GB 16889-2008)对垃圾焚烧飞灰经固化稳定化后进入卫生填埋场的入场要求。 表 6 胶凝材料中钢渣配比对5种重金属固化率影响

Table 6. Effect of steel slag content in cementitious materials on the immobilization rate of five heavy metals

/% 钢渣配比/% Zn Cr As Pb Hg 12 99.99 99.82 99.54 99.84 98.76 22 99.99 99.81 99.68 99.90 99.12 32 99.99 99.93 99.63 99.91 99.60 42 99.99 99.92 99.59 99.92 98.35 52 99.99 99.90 99.55 99.83 99.46 62 99.99 99.90 99.38 99.87 99.26 表 7 胶凝材料中磷酸淤渣配比对重金属固化率影响

Table 7. Effect of phosphoric acid sludge contentin cementitious materials on the immobilization rate of five heavy metals

/% 磷酸淤渣配比/% Zn Cr As Pb Hg 10 99.99 99.93 99.24 99.98 99.63 20 99.99 99.97 99.40 99.87 99.60 30 99.99 99.93 99.63 99.91 99.65 40 100.00 99.65 99.63 99.89 99.68 50 99.99 99.80 99.60 99.94 96.16 60 99.99 99.77 99.45 99.92 93.97 -

[1] 中华人民共和国生态环境部. 2020年全国大、中城市固体废物污染环境防治年报[R]. 北京: 中华人民共和国生态环境部, 2020.

[2] LUNA G Y, FERNáNADEZ P C, VALE J. Stabilization/solidification of a municipal solid waste incineration residue using fly ash-based geopolymers [J]. Journal of Hazardous Materials, 2011, 185(1): 373-381. doi: 10.1016/j.jhazmat.2010.08.127

[3] 宋立杰. 生活垃圾焚烧炉渣特性及其在废水处理中的应用研究[D]. 上海: 同济大学, 2006.

[4] 张磊, 张亚楠, 荣辉, 等. 垃圾焚烧灰高温重构矿渣水泥复合体系安全应用研究[J]. 混凝土与水泥制品, 2018(4): 12-17. doi: 10.3969/j.issn.1000-4637.2018.04.003

[5] 毛罕钦, 姜成国, 葛兴隆, 等. 城市生活垃圾处理现状及方式浅析[J]. 科技展望, 2016(30): 275-276. doi: 10.3969/j.issn.1672-8289.2016.30.239

[6] MANGIALARDIT. Disposal of MSWI fly ash through a combined washing-immobilisation process[J]. Journal of Hazardous Materials, 2003, 98(1): 225-240. http://www.ncbi.nlm.nih.gov/pubmed/12628790

[7] 邓光亮. 水泥窑协同处置生活垃圾中氯碱硫分布及制品重金属安全性研究[D]. 广州: 华南理工大学, 2015.

[8] 肖衡林, 徐谦. 垃圾焚烧灰性质分析及控制方法[J]. 环境工程, 2012, 30(S2): 313-316. https://www.cnki.com.cn/Article/CJFDTOTAL-HJGC2012S2087.htm

[9] 刘文莉, 孙伟, 熊辉, 等. 针铁矿对垃圾焚烧飞灰中重金属离子的固化作用及机理分析[J]. 矿产保护与利用, 2018(6): 87-93. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=123a8300-646f-485c-9613-912321b02603

[10] 薛志强, 秦建武. 城市垃圾焚烧飞灰的混合水泥固化/稳定化技术研究[J]. 中国资源综合利用, 2018, 36(5): 118-122. doi: 10.3969/j.issn.1008-9500.2018.05.036

[11] 杨恒, 倪文, 马旭明, 等. 胶结充填采矿协同资源化利用垃圾焚烧飞灰固化机理研究[J]. 金属矿山, 2018(3): 196-200. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201803037.htm

[12] 王一杰, 李克庆, 倪文, 等. 矿渣基胶凝材料固化垃圾焚烧飞灰中重金属的研究[J]. 金属矿山, 2019(7): 194-198. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201907032.htm

[13] 蒋建国, 张妍, 许鑫, 等. 可溶性磷酸盐处理焚烧飞灰的稳定化技术[J]. 环境科学, 2005, 26(4): 191-194. doi: 10.3321/j.issn:0250-3301.2005.04.038

[14] 王军, 蒋建国, 隋继超, 等. 垃圾焚烧飞灰H3PO4稳定化技术及机理研究[J]. 环境科学, 2006, 27(8): 1692-1696. doi: 10.3321/j.issn:0250-3301.2006.08.040

[15] 杨磊, 王静波, 邱景平, 等. 基于正交试验的全尾砂胶结充填材料配比优化[J]. 矿产保护与利用, 2017(3): 21-25. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=67399567-2a93-41fb-b22f-908401979d3b

[16] 张大捷, 刘文士, 田晓峰, 等. 矿渣胶结材固化处理垃圾焚烧飞灰[J]. 环境工程, 2008, 26(4): 14-16, 2. doi: 10.3969/j.issn.1672-9242.2008.04.004

[17] 唐强, 陈辉, 尹立新, 等. 生活垃圾焚烧飞灰固化体力学及重金属浸出特性[J]. 环境工程, 2017, 35(4): 111-114, 159. https://www.cnki.com.cn/Article/CJFDTOTAL-HJGC201704023.htm

[18] 崔孝炜, 狄燕清, 冷欣燕, 等. 冶金渣胶凝材料协同固化铅的试验研究[J]. 矿产保护与利用, 2018(6): 103-106. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=c36054f4-04e8-4957-90ea-142cf5d166a8

-

下载:

下载: