Study on Beneficiation Process of Sulfur-oxygen Mixed Copper-cobalt Ore in Katanga Mining Area of Congo(DRC)

-

摘要:

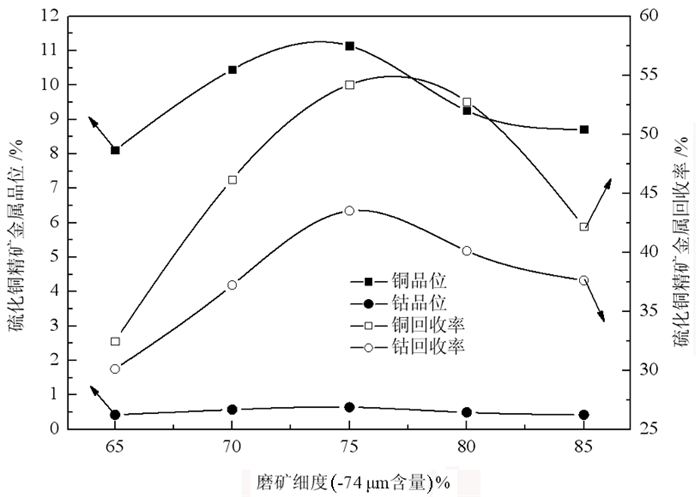

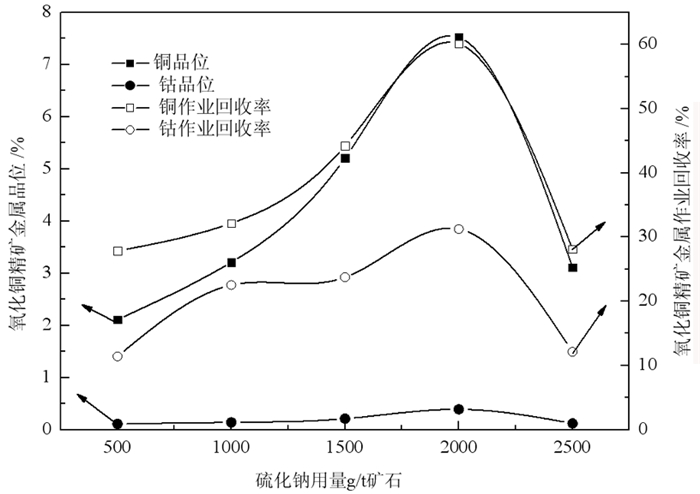

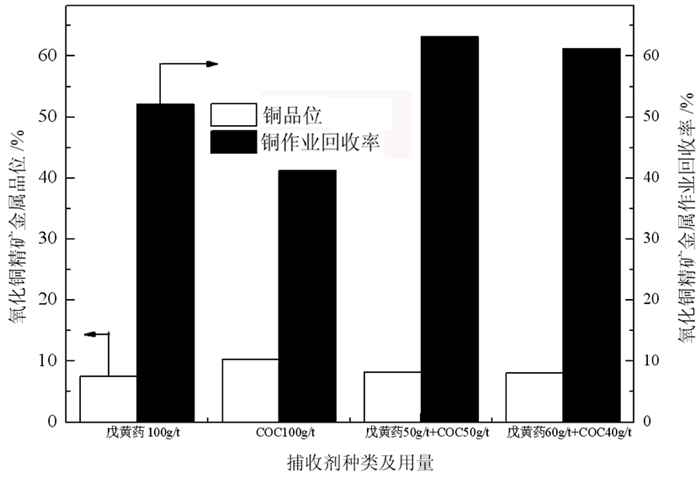

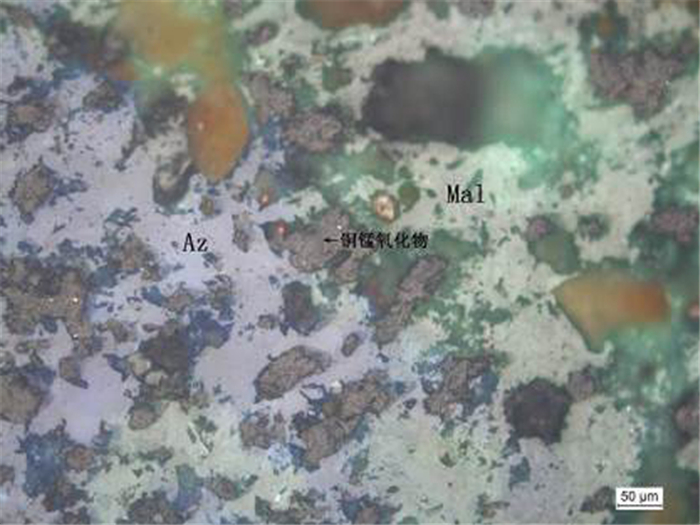

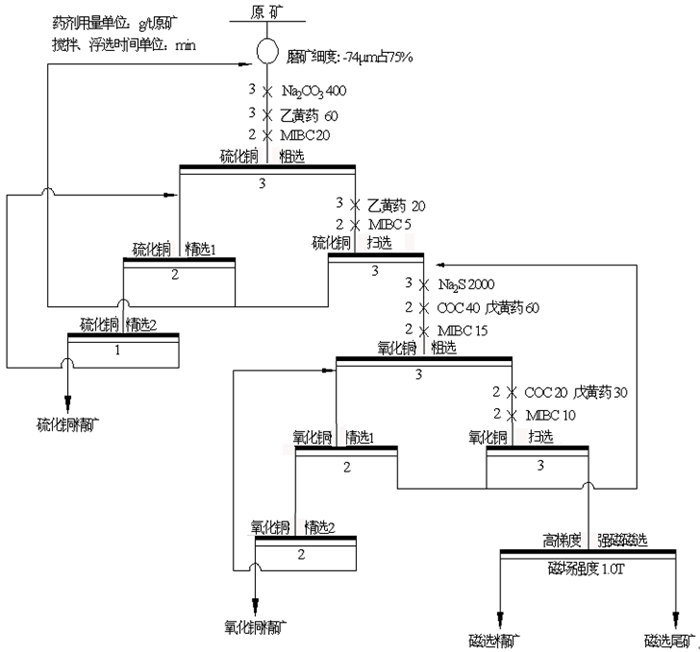

刚果(金)加丹加矿区硫氧混合型铜钴矿石含Cu2.21%和Co0.16%,铜钴元素均达到了工业回收标准,为确定合理高效的选矿工艺,进行了矿石性质分析及选矿试验研究。结果表明:该硫氧混合型铜钴矿石中的目的矿物种类复杂,目的元素铜除硫化铜和氧化铜形态赋存外,还有部分铜以铜锰铝硅氧化结合物中的铜形态赋存。钴主要以含钴黄铁矿及水钴矿形式赋存,脉石矿物主要以易泥化的碳酸盐类脉石为主。结合矿石性质分析和探索条件试验的结果确定了硫化矿物浮选—氧化矿物硫化钠硫化、组合捕收剂协同捕收浮选氧化铜矿物—氧化矿尾矿高梯度强磁选的选矿工艺,该工艺根据不同类型的目的矿物可浮性和磁性的差异性,分段产出硫化铜精矿、氧化铜精矿和磁选精矿三个产品,三个产品总铜回收率达到了91.54%,总钴回收率达到了56.48%,实现了对该硫氧混合型铜钴矿石主要元素的综合回收。

Abstract:The sulfur-oxygen mixed copper cobalt ore in Katanga mining area of Congo(DRC) contains 2.21% Cu and0.16% Co, which elements have reached the industrial recovery standard.In order to determine a reasonable and efficient beneficiation process, the ore property analysis and beneficiation test research are carried out.The results show that the types of the target minerals in the sulfur-oxygen mixed type copper cobalt ore are complex.Besides copper sulfide and copper oxide, some copper occurs in the form of copper in the copper manganese aluminum silicon oxide complex.Cobalt mainly occurs in the form of cobalt bearing pyrite and hydrocobaltite.At the same time, the gangue minerals are mainly carbonate gangues which are easy to mud.Combined with the results of ore property analysis and exploration condition tests, the beneficiation process of sulphide flotation-sulfide sulfide of oxide minerals by sodium sulfide-flotation of oxide minerals with combined collector collaborative collectors and high gradient strong magnetic separation of oxide flotation tailings was determined.According to the floatability and magnetic difference of different types of target minerals, The copper sulfide concentrate, copper oxide concentrate and magnetic separation concentrate were produced in different stages.The recovery rate of total copper and cobalt of the three products reached 91.54% and 56.48%, respectively, which realized the comprehensive recovery of the main target elements of the sulfur-oxygen mixed copper cobalt ore.

-

Key words:

- copper oxide /

- copper sulfide /

- cobalt /

- flotation /

- sulfide /

- magnetic separation

-

-

表 1 原矿化学多元素分析结果

Table 1. Multi-elements analysis results of of raw ores

/% 成分 Cu Co Fe S SiO2 Al2O3 Ni 含量 2.21 0.16 4.81 2.04 48.50 6.12 0.002 成分 MgO CaO Na2O K2O Ag* Au* As 含量 12.21 7.52 0.31 2.22 1.5 0.10 0.01 *Au、Ag单位为g/t。 表 2 原矿的矿物组成

Table 2. Mineral composition of raw ores

/% 矿物 含量 矿物 含量 黄铁矿 2.90 水钴矿 0.16 黄铜矿、斑铜矿 1.50 石英 24.50 辉铜矿、蓝辉铜矿 0.70 绿泥石 6.30 铜蓝 0.20 白云石、方解石 21.40 孔雀石 1.39 白云母、绢云母 18.20 赤铁矿、褐铁矿 1.80 黏土矿物 3.40 硅孔雀石 0.25 菱镁矿 17.30 合计 100.00 表 3 矿石中铜物相分析结果

Table 3. Analysis results of Cu phase

/% 相态 含量 分布率 主要存在的矿物 原生硫化铜 1.1 49.77 黄铜矿 次生硫化铜 0.21 9.50 斑铜矿、辉铜矿、蓝辉铜矿等 自由氧化铜 0.64 28.96 孔雀石 结合氧化铜 0.26 11.77 硅孔雀石、氧化铁锰中致密结合的铜 总铜 2.21 100.00 表 4 矿石中钴物相分析结果

Table 4. Analysis results of Co phase

/% 相态 含量 分布率 主要存在的矿物 硫化钴 0.10 62.50 含钴黄铁矿 氧化钴 0.02 12.50 水钴矿,赤铁矿、褐铁矿中的钴 硅酸盐中钴 0.04 25.00 类质同象赋存于云母等硅酸盐矿物中钴 总钴 0.16 100 表 5 推荐选矿指标

Table 5. Recommended beneficiation index

/% 产品名称 产率 品位 回收率 Cu Co Cu Co 硫化铜精矿 4.66 24.12 1.19 50.13 35.00 氧化铜精矿 1.89 34.23 0.99 28.92 11.84 磁选精矿 7.27 3.85 0.21 12.49 9.64 尾矿 86.18 0.22 0.08 8.46 43.52 原矿 100.00 2.24 0.16 100.00 100.00 -

[1] AGORHOM E A, LEM J P, SKINNER W, et al. Challenges and opportunities in the recovery/rejection of trace elements in copper flotation-a review[J]. Minerals Engineering, 2015, 78: 45-57. doi: 10.1016/j.mineng.2015.04.008

[2] 廖乾, 冯其明, 欧乐明, 等. 某复合型铜钴矿合理选矿工艺及硫化作用机理研究[J]. 矿冶工程, 2010, 30(5): 44-48. doi: 10.3969/j.issn.0253-6099.2010.05.011

[3] 印万忠, 吴凯. 难选氧化铜矿选冶技术现状与展望[J]. 有色金属工程, 2013, 3(6): 66-70. doi: 10.3969/j.issn.2095-1744.2013.06.016

[4] BRUCKARD W J, SPARROW G J, WOODCOCK J T. A review of the effects of the grinding environment on the flotation of copper sulphides[J]. International Journal of Mineral Processing, 2011, 100(1): 1-13.

[5] MICHEL LUTANDULA SHENGOA, MESCHAC-BILL KIMEB, MATANDA PASCAL MAMBWEC. A review of the beneficiation of coppercobalt-bearing minerals in the Democratic Republic of Congo[J]. Journal of Sustainable Mining, 2019, 18(4): 226-246 doi: 10.1016/j.jsm.2019.08.001

[6] LIU GUANGYI, ZHONG HONG, XIA LIUYIN et al. Improving copper flotation recovery from a refractory copper porphyry ore by using ethoxycarbonyl thiourea as a collector[J]. Minerals Engineering, 2011, 24(8): 817-824. doi: 10.1016/j.mineng.2011.01.009

[7] 刘方华. 国外某沉积岩型难选硫氧混合铜矿石浮选试验[J]. 金属矿山, 2019, 48(11): 73-78. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201911013.htm

[8] 张世民, 叶国华, 张爽, 等. 云南某低品位硫氧混合型铜矿浮选试验研究[J]. 矿产综合利用, 2016, 17(3): 40-43. doi: 10.3969/j.issn.1000-6532.2016.03.010

[9] LEE K, ARCHIBALD D, MCLEAN J, et al. Flotation of mixed copper oxide and sulphide minerals with xanthate and hydroxamate collectors[J]. Minerals Engineering, 2009, 22(4): 395-401. doi: 10.1016/j.mineng.2008.11.005

[10] KONGOLO K, KIPOKA M, MINANGA K, et al. Improving the efficiency of oxide copper-cobalt ores flotation by combination of sulphidisers[J]. Minerals Engineering, 2003, 16(10): 1023-1026. doi: 10.1016/S0892-6875(03)00263-2

[11] ZHAN-FANG C, HONG Z, GUANG-YI L, et al. Techniques of copper recovery from Mexican copper oxide ore[J]. Mining science & amp; Technology, 2009, 27(1): 45-48.

[12] SOPHIE DECReE, POURRET O, BAELE J M. Rare earth element fractionation in heterogenite(CoOOH): Implication for cobalt oxidized ore in the Katanga Copperbelt(Democratic Republic of Congo)[J]. Journal of Geochemical Exploration, 2015, 159: 290-301. doi: 10.1016/j.gexplo.2015.10.005

[13] 惠博, 朱志敏. 四川拉拉地区天生坝铁矿中铜矿化的发现及地质意义[J]. 科学技术与工程, 2017(1): 137-141. doi: 10.3969/j.issn.1671-1815.2017.01.024

[14] HERRERA-URBINA R, SOTILLO F J, FUERSTENAU D W. Effect of sodium sulfide additions on the pulp potential and amyl xanthate flotation of cerussite and galena[J]. International Journal of Mineral Processing, 1999, 55(3): 157-170. doi: 10.1016/S0301-7516(98)00029-5

[15] NATARAJAN K A, IWASAKI I. Electrochemical aspects of grinding media-mineral interactions in magnetite ore grinding[J]. International Journal of Mineral Processing, 1984, 13(1): 53-71. doi: 10.1016/0301-7516(84)90011-5

[16] CASTRO S, SOTO H, GOLDFARB J. et al. Sulphidizing reactions in the flotation of oxidized copper minerals, Ⅱ. Role of the adsorption and oxidation of sodium sulphide in the flotation of chrysocolla and malachite[J]. International Journal of Mineral Processing, 1974, 1(2): 151-161. doi: 10.1016/0301-7516(74)90011-8

[17] CHANDER S. A brief review of pulp potentials in sulfide flotation[J]. International Journal of Mineral Processing, 2003, 72(1): 141-150.

[18] BAI X, WEN S, FENG Q, et al. Utilization of high-gradient magneticseparation-secondary grinding-leaching to improve the copper recovery from refractory copper oxide ores[J]. Minerals Engineering, 2019, 136: 77-80. doi: 10.1016/j.mineng.2019.03.009

[19] 易运来. 云南某难选氧化铜矿浮—磁联合选矿试验[J]. 现代矿业, 2018, 34(9): 24-27+34. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB201809005.htm

[20] HAN JUNWEI, XIAO JUN, QIN WENQIN, et al. Copper Recovery from Yulong Complex Copper Oxide Ore by Flotation and Magnetic Separation[J]. JOM, 2017(5): 6-11.

-

下载:

下载: