Experimental Study on Fine Slime Dressing of Wolframite and Scheelite with Floatation-Magnetic Separation-Gravity Concentration Combined Process

-

摘要:

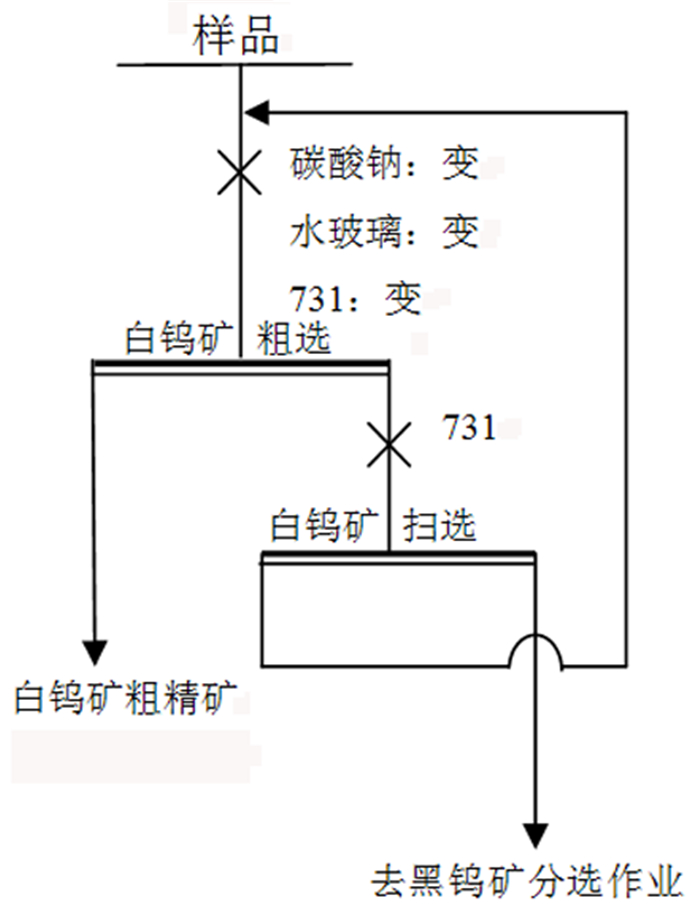

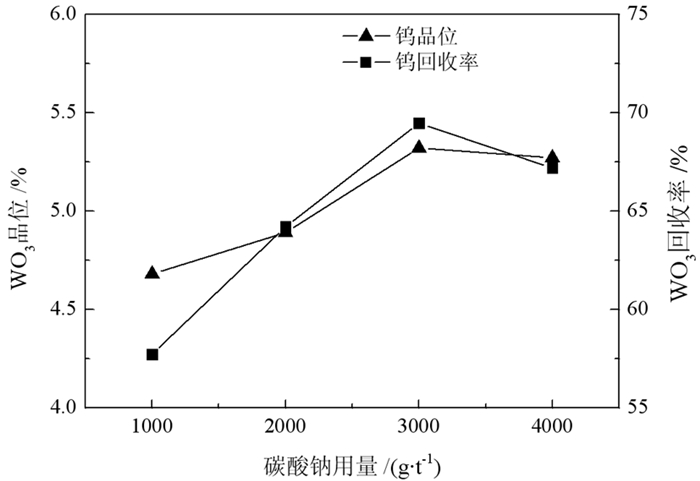

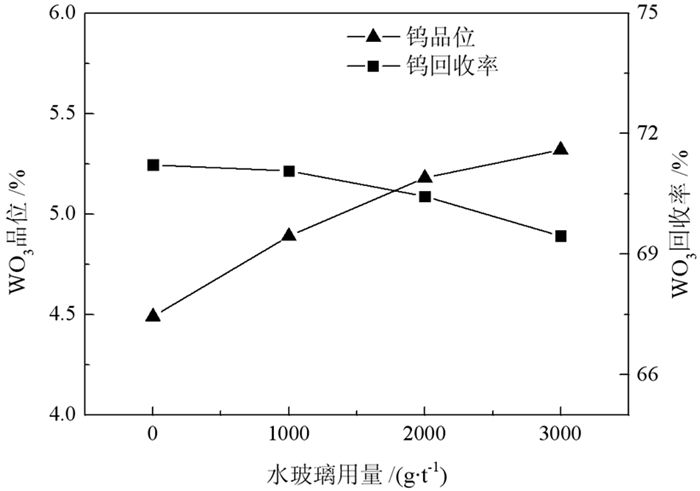

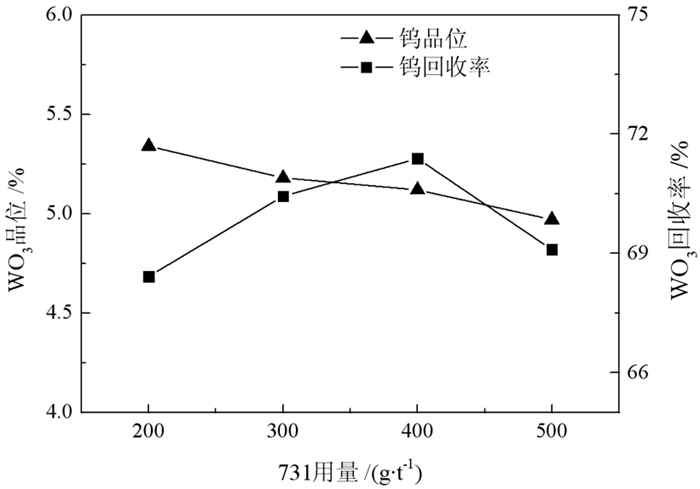

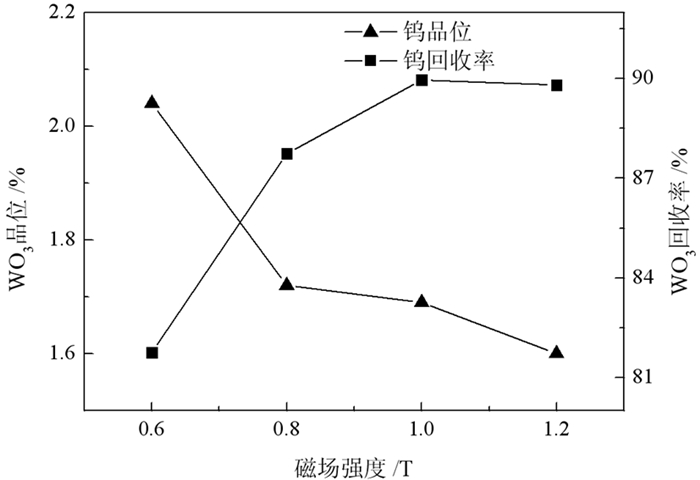

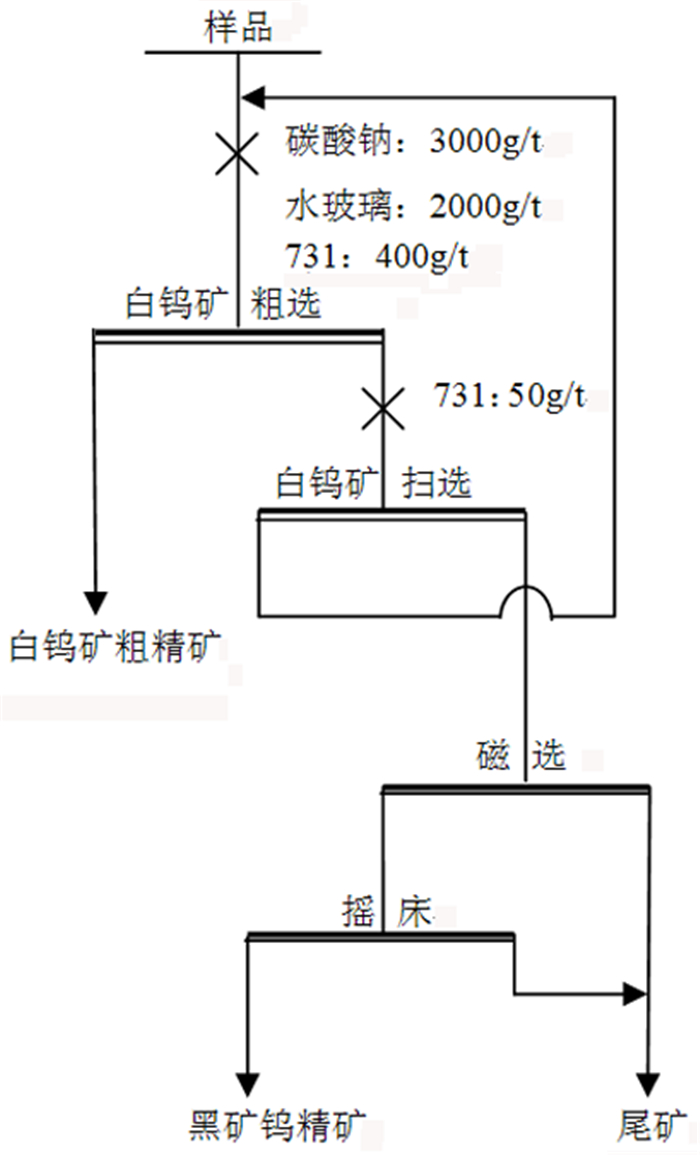

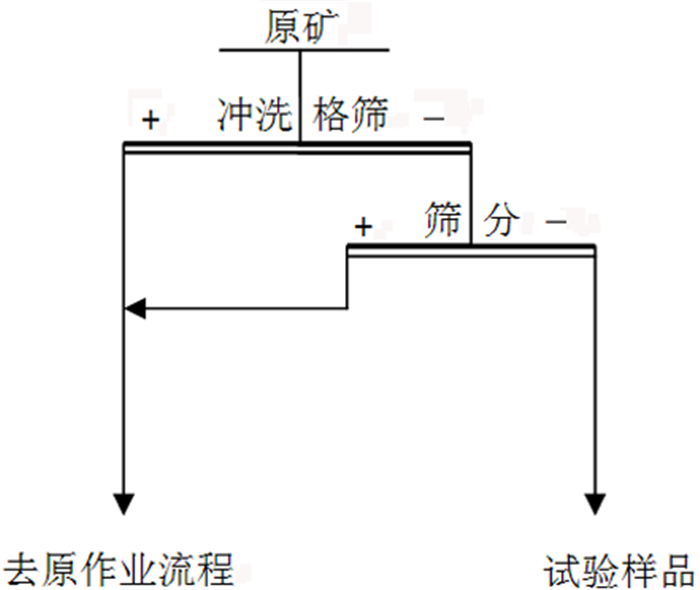

为解决某选矿厂钨矿细泥对浮选工艺的影响,针对原矿洗矿后的微细粒风化细泥研发出白钨矿浮选—黒钨矿磁选粗选—摇床精选工艺,即利用高速剪切搅拌桶+旋流微泡浮选柱的设备组合浮选回收白钨矿,浮选尾矿经高梯度磁选机预选、摇床精选工艺产出黑钨矿精矿,产出的白钨矿粗精矿进入选矿厂原加温精选作业。试验结果表明:当样品WO3品位0.96%时,可获得WO3品位5.04%、WO3回收率71.80%的白钨粗矿精矿和WO3品位52.41%、WO3回收率20.86%的合格黑钨精矿,WO3综合回收率92.66%。

Abstract:In order to solve the impact of the tungsten slime on the flotation operation, after the ore is washed, the new asynchronous separation process of"scheelite flotation-wolframite magnetic rough separation-table cleaning"was developed for tungsten slime, that is, flotation and recovery of scheelite using a combination of high-speed shear mixing barrel+ cyclonic micro-bubble flotation column, the flotation tailings are pre-selected by high gradient magnetic separator and the table cleaning produces wolframite concentrate, the produced rough scheelite concentrate is feeds further in the original heating and cleaning process. The test results showe that when the feed ore grade is 0.96% WO3, the grade of scheelite concentrate is 5.04% and the recovery is 71.80%; the grade of wolframite concentrate is 52.41% and the recovery is 20.86%, and the comprehensive recovery is 92.66%.

-

-

表 1 样品化学多元素分析结果

Table 1. Analysis results of multi-element of feed ore

/% 元素 WO3 Pb Zn Fe S As 含量 0.96 0.015 0.076 5.09 0.54 0.034 元素 SiO2 CaO MgO Al2O3 Mn Cu 含量 64.80 13.71 2.78 7.55 0.14 0.027 表 2 样品钨物相分析结果

Table 2. Analysis results of tungsten phase in feed ore

/% 钨物相 白钨矿 黑钨矿 钨华 总钨 WO3含量 0.64 0.28 0.037 0.957 分布率 66.88 29.26 3.86 100.00 表 3 样品筛析结果

Table 3. Results of sieve tests for feed ore

粒级/mm 产率/% WO3/% WO3分布率/% 个别 累计 +0.125 9.43 0.54 5.33 5.33 -0.125+0.074 16.98 0.67 11.90 17.23 -0.074+0.045 33.96 0.93 33.02 50.25 -0.045+0.037 18.87 1.18 23.28 73.53 -0.037 20.76 1.22 26.47 100.00 合计 100.00 0.96 100.00 / 表 4 摇床精选结果

Table 4. Results of Shaker cleaning selection

产品名称 产率/% WO3品位/% 作业回收率/% 摇床精矿 2.96 52.54 92.50 摇床尾矿 97.04 0.130 7.50 样品 100.00 1.68 100.00 表 5 闭路试验结果

Table 5. Results of closed-circuit tests

产品名称 产率/% WO3品位/% WO3回收率/% 白钨精矿 13.67 5.04 71.80 黑钨精矿 0.38 52.41 20.86 尾矿 85.95 0.082 7.34 样品 100.00 0.96 100.00 -

[1] 周晓彤, 邓丽红, 关通, 等. 从某低品位多金属矿中回收黑白钨矿的选矿试验研究[J]. 中国矿业, 2011, 20(7): 86-89. doi: 10.3969/j.issn.1004-4051.2011.07.022

[2] 刘露玲, 钟能. 锯齿波跳汰机在江西某钨矿的应用[J]. 矿业研究与开发, 2019, 39(1): 96-99. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK201901022.htm

[3] 吴江林, 范毅. 大吉山钽铌钨矿细泥选矿工艺对比试验[J]. 现代矿业, 2016, 32(4): 100-102+105. doi: 10.3969/j.issn.1674-6082.2016.04.031

[4] 高玉德, 徐晓萍, 邹霓, 等. 复杂难选黑白钨矿粗细分流同步选别新工艺[J]. 中国钨业, 2015, 30(1): 41-43+60. doi: 10.3969/j.issn.1009-0622.2015.01.008

[5] 刘培坤, 许慧林, 张悦刊, 等. 双旋流钨矿脱泥试验研究[J]. 矿山机械, 2019, 47(3): 41-45. doi: 10.3969/j.issn.1001-3954.2019.03.010

[6] 孙景敏, 黄业豪, 王誉树. 从小秦岭某浮金尾矿中回收白钨矿的试验研究[J]. 矿业研究与开发, 2018, 38(6): 74-78. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK201806016.htm

[7] 陈慧杰, 张莉. 重-磁联合工艺回收某白钨矿试验[J]. 矿产综合利用, 2016(3): 10-12+18. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201603003.htm

[8] 郭阶庆. 行洛坑钨矿钨细泥选别工艺改造[J]. 金属矿山, 2011(6): 97-100. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201106032.htm

[9] 邓丽红, 周晓彤, 罗传胜, 等. 江西某钨矿钨细泥选矿新工艺应用研究[J]. 矿产综合利用, 2010(1): 8-11. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201001001.htm

-

下载:

下载: