Investigation on Recovery of Copper from Smelting Slag by Asynchronous Flotation

-

摘要:

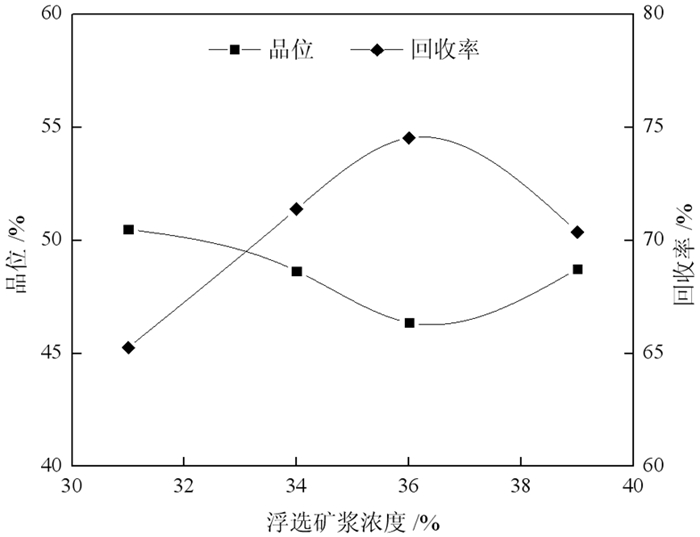

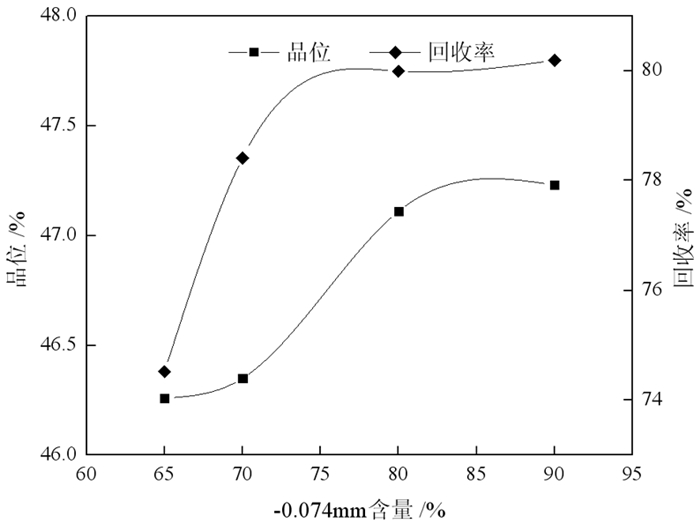

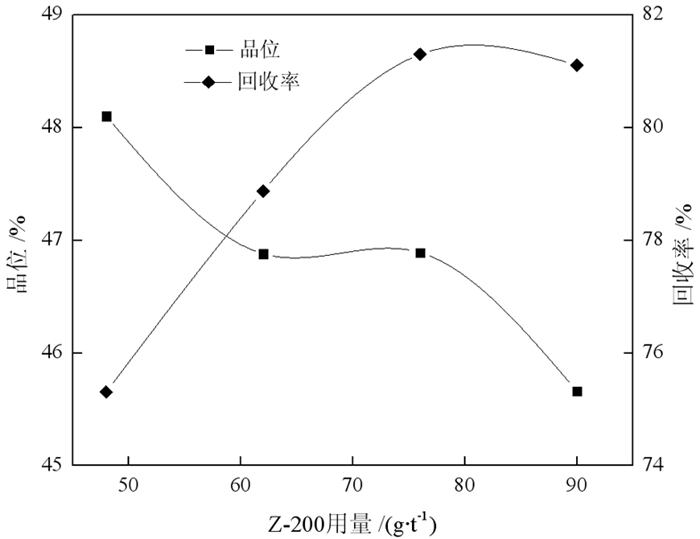

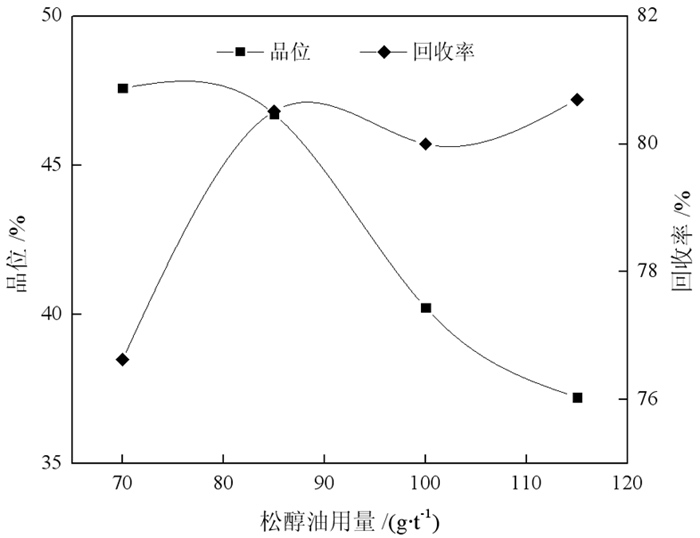

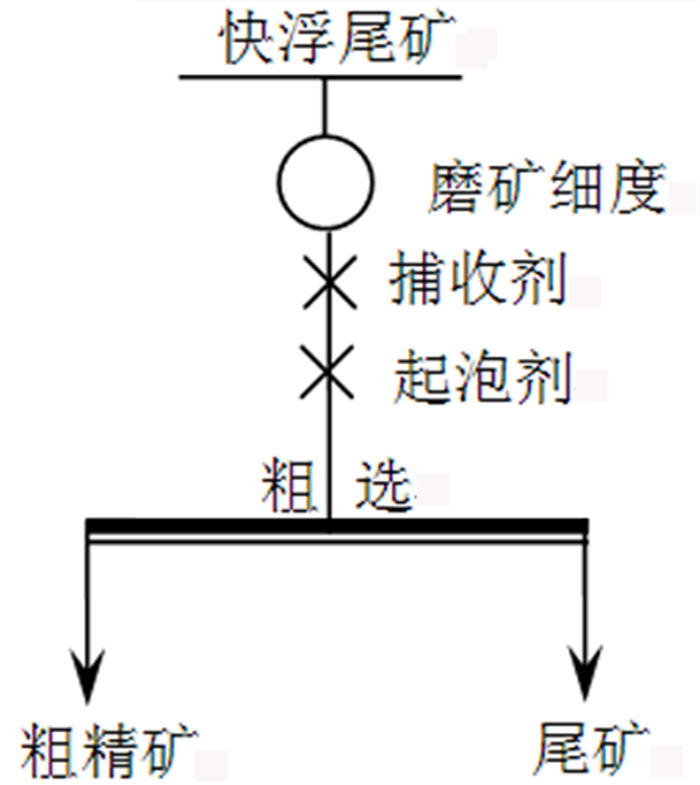

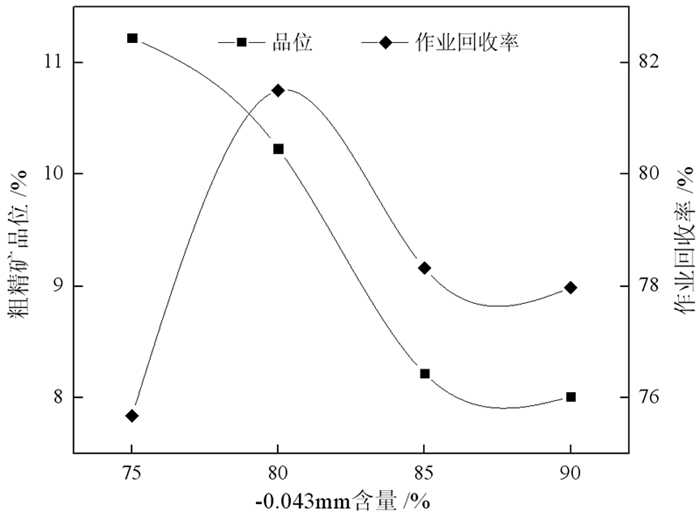

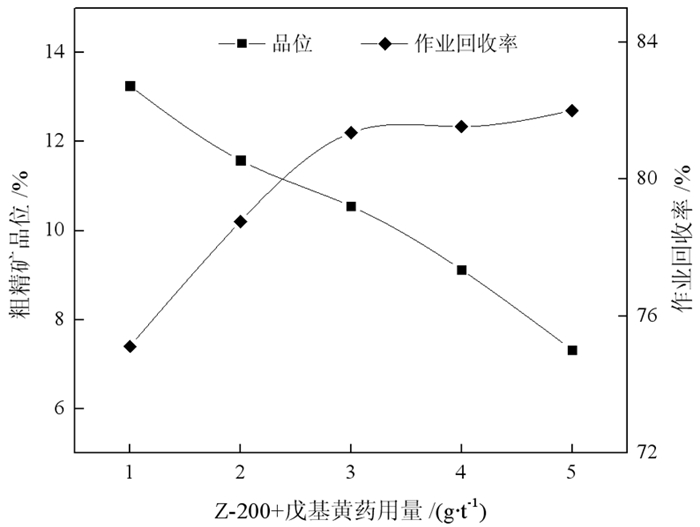

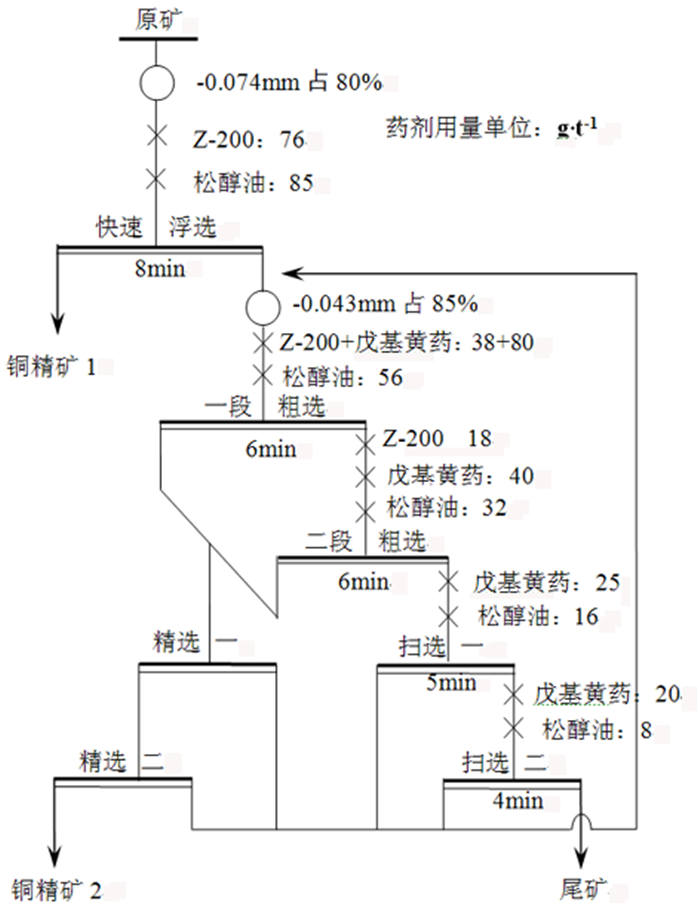

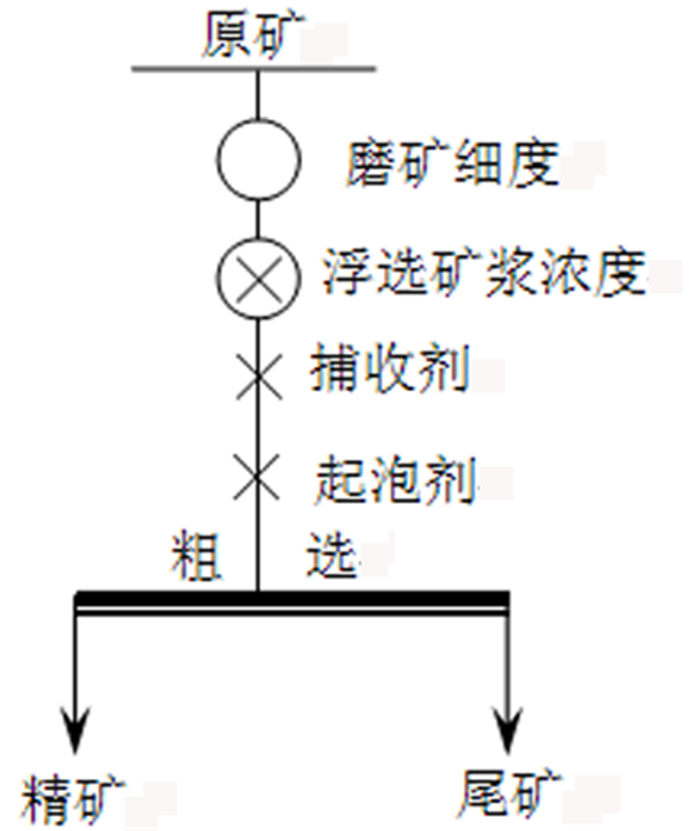

铜火法冶炼渣中铜品位为5.23%,具有良好的回收利用价值。原矿中铜矿物主要为冰铜和金属铜,脉石矿物主要为铁酸盐和铁橄榄石,还有大量的玻璃相。玻璃相的存在为选矿带来不利的影响。对该冶炼渣采用阶段磨矿—异步浮选工艺,在较粗的磨矿细度下优先回收可浮性较好的粗颗粒铜矿物,获得含铜45.36%、铜回收率81.65%的铜精矿,浮选尾矿再磨后回收细粒级的铜矿物,获得含铜13.65%、铜回收率13.74%的综合铜精矿,综合铜精矿含铜33.99%,含金3.42 g/t,含银79.17 g/t,铜回收率95.40%,金回收率85.94%,银回收率81.17%,该冶炼渣中的铜、金和银均得到较好的回收。

Abstract:The copper grade in copper smelting slag is 5.23%, which has good recycling value. Copper minerals in the raw slag are mainly matte and metallic copper. The gangue minerals are mainly ferrite and iron olivine. There are a large number of glass phases. The existence of glass phase has an adverse impact on beneficiation. Asynchronous flotation process is adopted for the smelting slag to preferentially recover coarse-grained copper minerals with good floatability under coarse grinding fineness. The copper concentrate with copper content of 45.36% and copper recovery of 81.65% was obtained. Fine grained copper minerals are recovered after regrinding of flotation tailings. The comprehensive copper concentrate with copper content of 13.65% and copper recovery of 13.74% was obtained. The concentrate contains 33.99% copper, 3.42 g/t gold and 79.17 g/t silver. The recovery rate gold and silver are 95.40%, 85.94% and 81.17% respectively. The copper, gold and silver in the smelting slag are all well recovered.

-

Key words:

- copper smelting slag /

- stage grinding /

- asynchronous flotation /

- matte

-

-

表 1 试样多元素分析结果

Table 1. Multi-elements analysis results of the sample

/% 元素 Cu Fe S SiO2 Au* Ag* 品位 5.23 39.04 2.64 22.90 0.56 12.38 注:“*”含量单位为g/t。 表 2 试样主要矿物组成

Table 2. Main mineral composition and relative content of the sample

/% 矿物名称 含量 矿物名称 含量 冰铜(铜锍) 6.65 铁橄榄石 28.78 金属铜 0.13 玻璃相 25.74 黄铜矿 0.04 石英 0.06 氧化铜 0.03 石膏等其他矿物 0.11 铁酸盐 38.43 绢云母 0.03 表 3 全流程闭路试验流程结果

Table 3. closed circuit test results of the whole process

/% 产品名称 产率 品位 回收率 铜 金* 银* 铜 金 银 铜精矿1 9.35 45.36 4.57 103.50 81.65 73.67 68.05 铜精矿2 5.23 13.65 1.36 35.66 13.75 12.26 13.12 合计精矿 14.58 33.99 3.42 79.17 95.40 85.93 81.17 尾矿 85.42 0.28 0.10 3.13 4.60 14.07 18.83 给矿 100.00 5.19 0.58 14.22 100.00 100.00 100.00 注:“*”含量单位为g/t。 -

[1] 赖祥生, 黄红军. 铜渣资源化利用技术现状[J]. 金属矿山, 2017(11): 205-208. doi: 10.3969/j.issn.1001-1250.2017.11.040

[2] 王春, 樊建云, 朱艳芬. 铜冶炼急冷渣、缓冷渣铜可选性试验研究[J]. 有色金属(选矿部分), 2016(1): 15-18. doi: 10.3969/j.issn.1671-9492.2016.01.004

[3] 余志翠. 选矿技术在铜渣综合利用中的应用[J]. 中国高新技术企业, 2016(28): 157-158. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGX201628078.htm

[4] 汪泰, 叶小璐. 从铜渣中综合回收铜、银的浮选试验研究[J]. 矿冶工程, 2017, 37(1): 22-27. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201701011.htm

[5] 李磊, 胡建杭, 魏永刚, 等. 铜渣中铜的回收工艺及新技术[J]. 材料导报, 2013, 27(6): 21-26. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201311003.htm

[6] 郭正启. 熔融改性强化铜渣铜铁分离技术的研究[D]. 长沙: 中南大学, 2014.

[7] 韩彬, 童雄, 张国浩, 等. 某铜炉渣的工艺矿物学研究[J]. 矿产保护与利用, 2015, 1(1): 63-68. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=bf0ae90c-aeda-43ba-8639-9356f27082fc

[8] 谢海云, 孙瑞, 吴继宗, 等. 铜炉渣的强化浮选试验研究[J]. 有色金属工程, 2020, 10(6): 58-64. doi: 10.3969/j.issn.2095-1744.2020.06.010

[9] 韩伟. 铜冶炼转炉渣选矿工艺研究与设计[J]. 铜业工程, 2013(1): 25-27. doi: 10.3969/j.issn.1009-3842.2013.01.007

[10] 张国. 铜冶炼渣浮选回收铜的试验研究[J]. 新疆有色金属, 2015(6): 80-81+83. https://www.cnki.com.cn/Article/CJFDTOTAL-XJYS201506035.htm

-

下载:

下载: