Research on Technology Optimization of Fine Grinding and Magnetic Separation for a Fine-grained Iron Ore in Qinhuangdao

-

摘要:

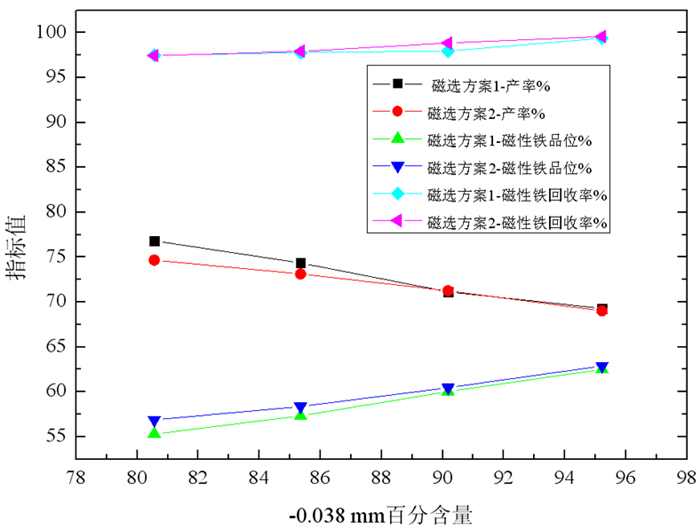

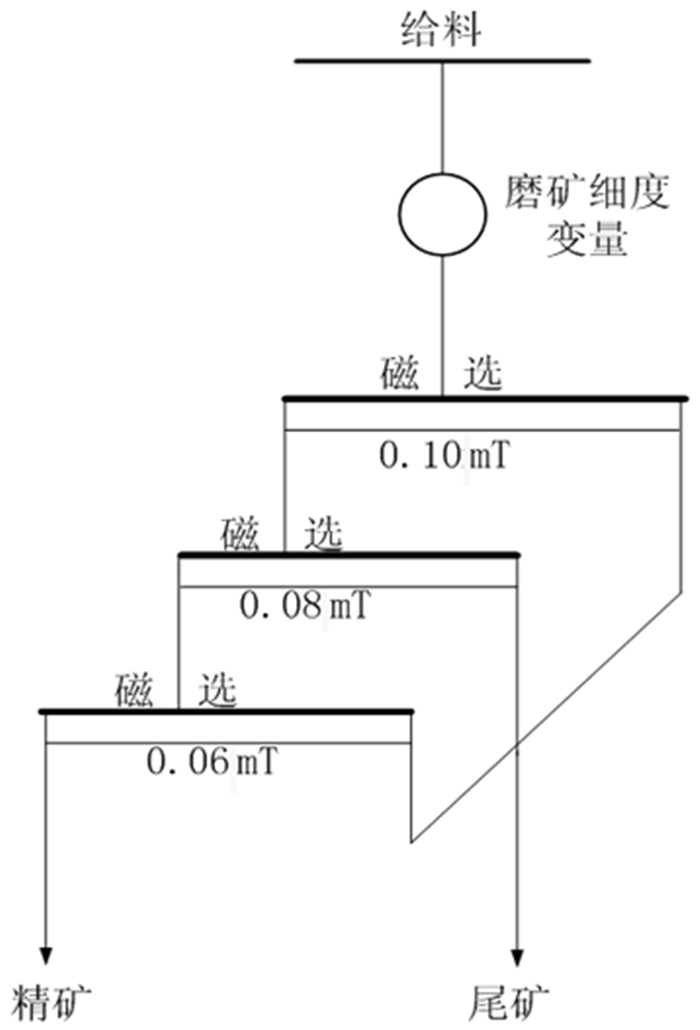

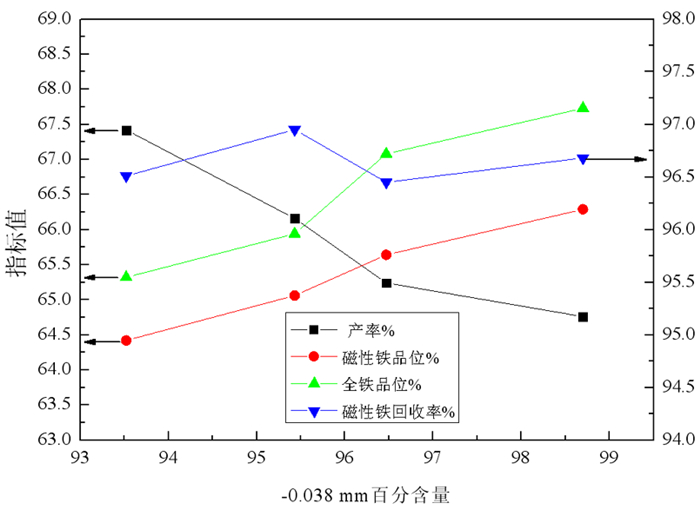

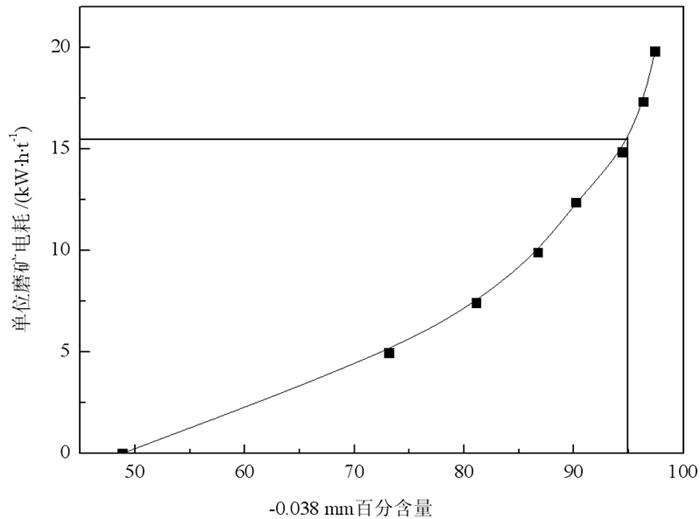

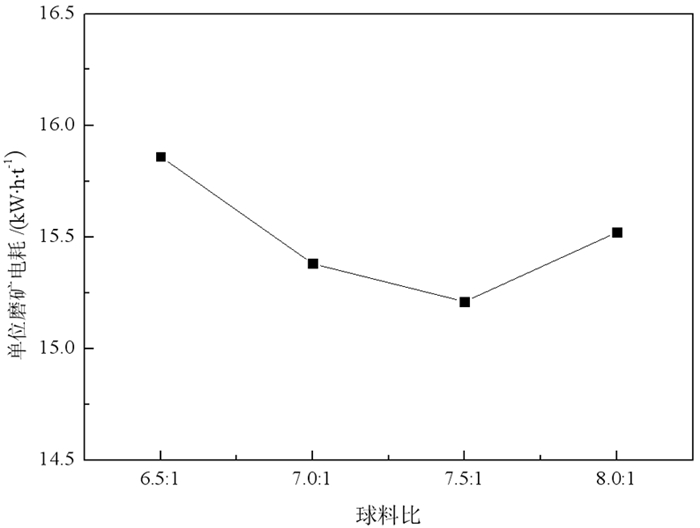

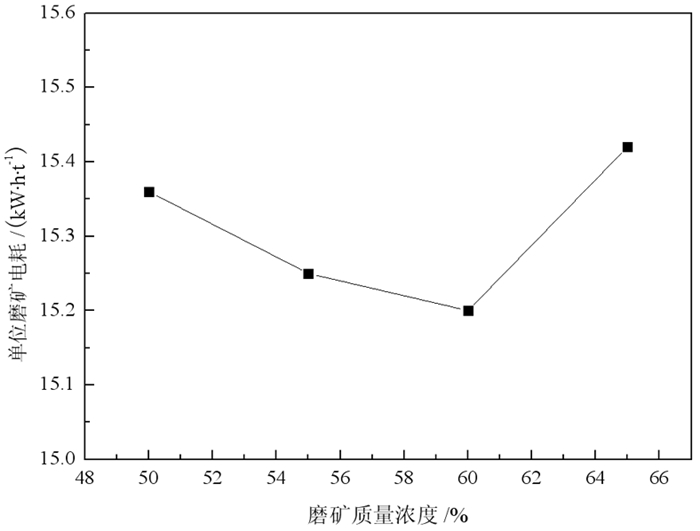

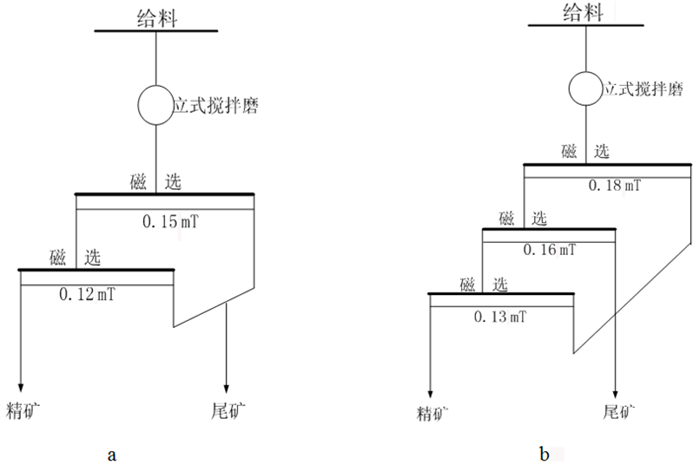

采用立式搅拌磨机作为微细粒级矿物的再磨设备,以秦皇岛地区微细粒级铁矿为试验样品,进行了磨矿及磁选条件试验研究,结果表明,磨矿产品粒度达到-0.038mm占95.43%,经一次粗选和两次精选可以获得产率66.12%、磁性铁品位为64.06%、回收率为97.16%,全铁品位为65.94%的优质铁精粉。磨机磨矿电耗测试表明,当磨矿产品粒度达-0.038mm约占95.00%时,磨矿电耗为15.20kW·h/t。该试验表明,秦皇岛地区的铁矿可以通过细磨解离获得好的选矿指标,立式搅拌磨机是一种高效的细磨设备。

Abstract:A vertical stirring mill is used as the regrinding equipment for fine-grained minerals.The fine-grained iron ore in the Qinhuangdao area is used as the test sample to conduct a test study on grinding and magnetic separation conditions.The results show that the particle size of the ground product reaches -0.038 mm It accounts for 95.43%.Highquality iron powder with a yield of 66.12%, a magnetic iron grade of 64.06%, a recovery rate of 97.16%, and a total iron grade of 65.94% can be obtained after one rough selection and two selections.The grinding power consumption test of the mill shows that when the particle size of the grinding product reaches -0.038 mm, which accounts for about 95.00%, the grinding power consumption is 15.20 kW·h/t.The test shows that the iron ore in the Qinhuangdao area can obtain good beneficiation indexes through fine grinding and dissociation.The vertical mixing mill is an efficient fine grinding equipment.

-

Key words:

- fine-grained iron ore /

- fine grinding /

- vertical stirring mill /

- magnetic separation

-

-

表 1 给料中不同铁物相含量

Table 1. Phase analysis results of feed ore

/% 铁相 磁铁矿中铁 碳酸铁中铁 赤褐铁矿中铁 硫化铁中铁 硅酸铁中铁 假象赤铁矿中铁 总铁 含量 43.58 0.32 0.39 0.07 0.33 1.17 45.86 分布率 95.03 0.70 0.85 0.15 0.72 2.55 100.00 表 2 给料中主要化学成分的含量

Table 2. Results of chemical analysis of feed ore

/% 成分 mFe TFe SiO2 P S 含量 43.58 45.86 30.43 0.021 0.086 表 3 给料粒度分析结果

Table 3. The particle size analysis results of feed ore

粒级范围/mm 产率/% mFe/% SiO2/% +0.15 7.17 24.89 46.77 -0.15+0.075 15.09 29.99 44.37 -0.075+0.045 18.19 37.88 40.09 -0.045+0.038 10.73 41.22 35.68 -0.038 48.82 53.18 17.46 合计 100.00 43.58 30.43 表 4 试验中所用的主要设备

Table 4. Main equipments and instruments used in the tests

名称 规格型号 生产厂家 备注 立式螺旋搅拌磨机 JM-180/0.75kW 长沙矿冶研究院 带扭矩测试仪测定电耗 立式螺旋搅拌磨机 JM-260/5.5kW 长沙矿冶研究院 辊筒式电磁磁选机 DCФ400x300-0.18T 长沙矿冶研究院 真空过滤机 XTLZ-Φ260/Φ200 武汉探矿 数显鼓风干燥箱 GZX-9240MBE 上海一恒 标准筛 Φ200×50 中国航空工业第540厂 -

[1] 江林波, 李珍, 江林林, 等. 秦皇岛北吴庄磁铁矿的特征及地质意义[J]. 东华理工大学学报(自然科学版), 2013, 36(S1): 110-113. https://www.cnki.com.cn/Article/CJFDTOTAL-HDDZ2013S1024.htm

[2] 敖顺福, 陈丽昆, 徐峰, 等. 搅拌磨技术及其选矿应用现状[J]. 矿山机械, 2021, 49(1): 8-13. doi: 10.3969/j.issn.1001-3954.2021.01.002

[3] 黄胤淇. 磨矿条件对立式搅拌磨磨矿产品粒度特性的影响及应用[D]. 昆明: 昆明理工大学, 2019.

[4] 王振刚, 刘明. 某微细粒铁矿石选矿磨矿工艺对比试验[J]. 新疆钢铁, 2017(1): 54-57. doi: 10.3969/j.issn.1672-4224.2017.01.020

[5] 陈朝. 白云鄂博铁矿磨矿细度与可选性关系实验研究[D]. 包头: 内蒙古科技大学, 2019.

[6] 赵湘. 立式搅拌磨机在超纯铁精矿选矿中的磨矿选型及工业应用[J]. 矿冶工程, 2017, 37(1): 49-51. doi: 10.3969/j.issn.0253-6099.2017.01.014

-

下载:

下载: