Experimental Study on Optimization of Grinding Medium Ratio in a Copper Mine Based on Grinding Kinetics

-

摘要:

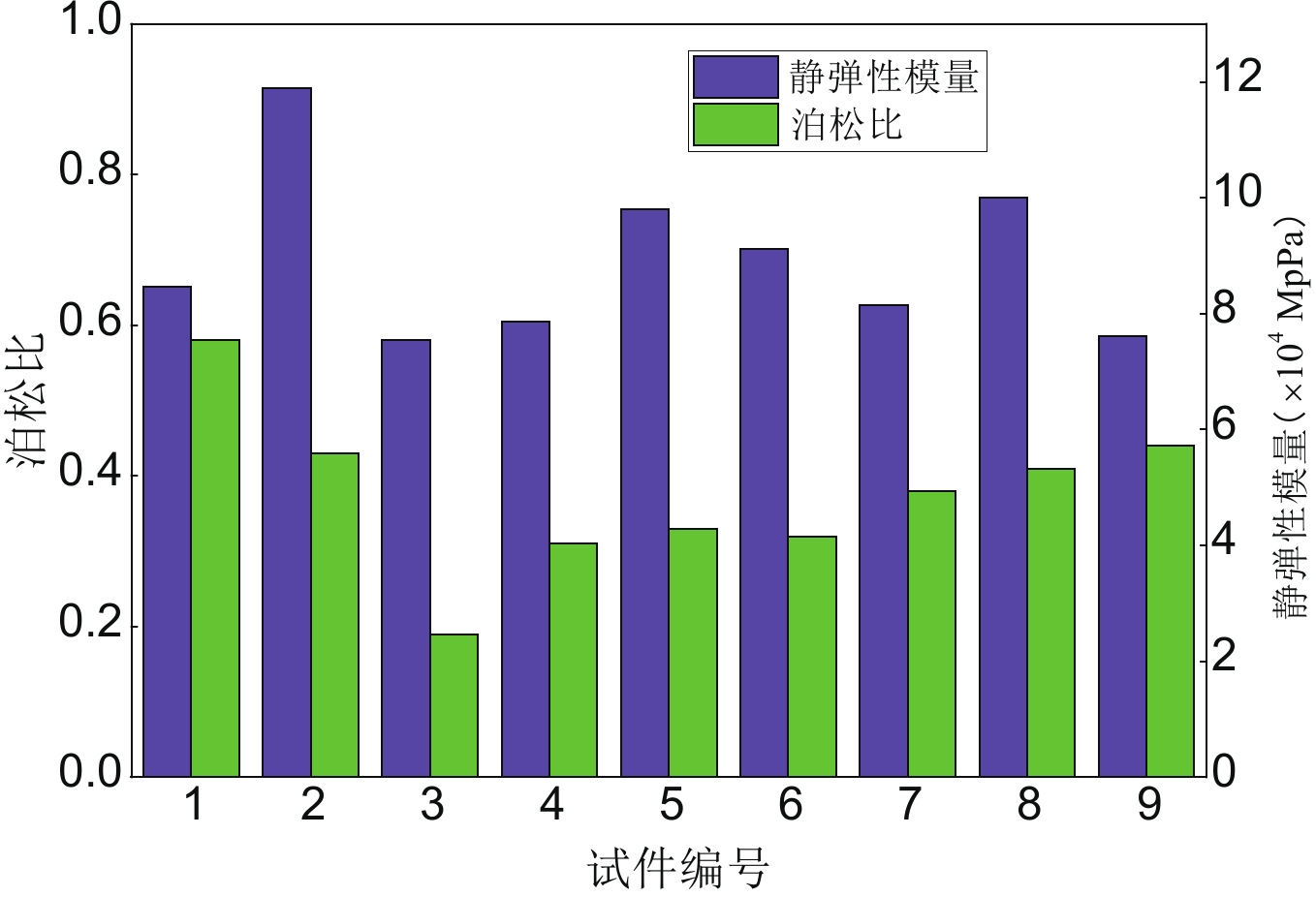

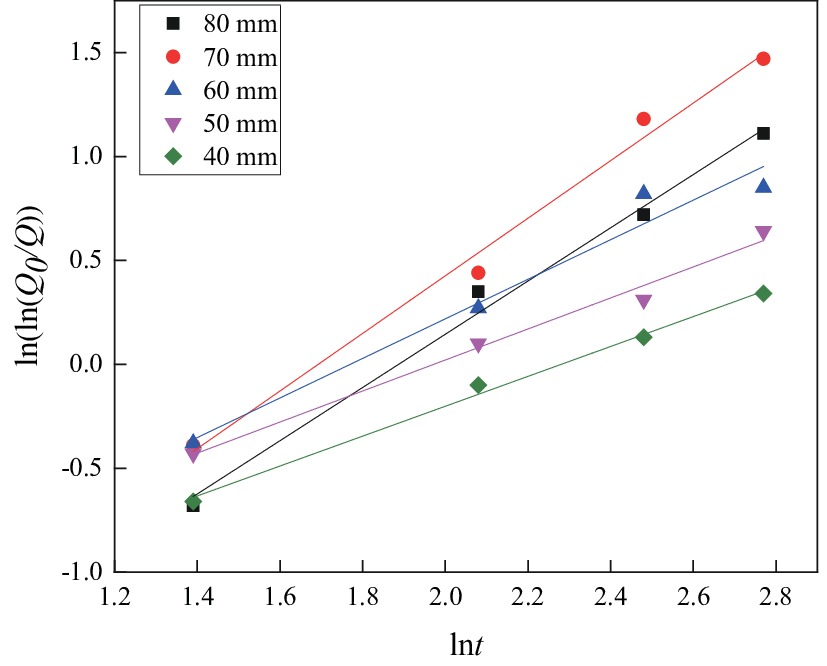

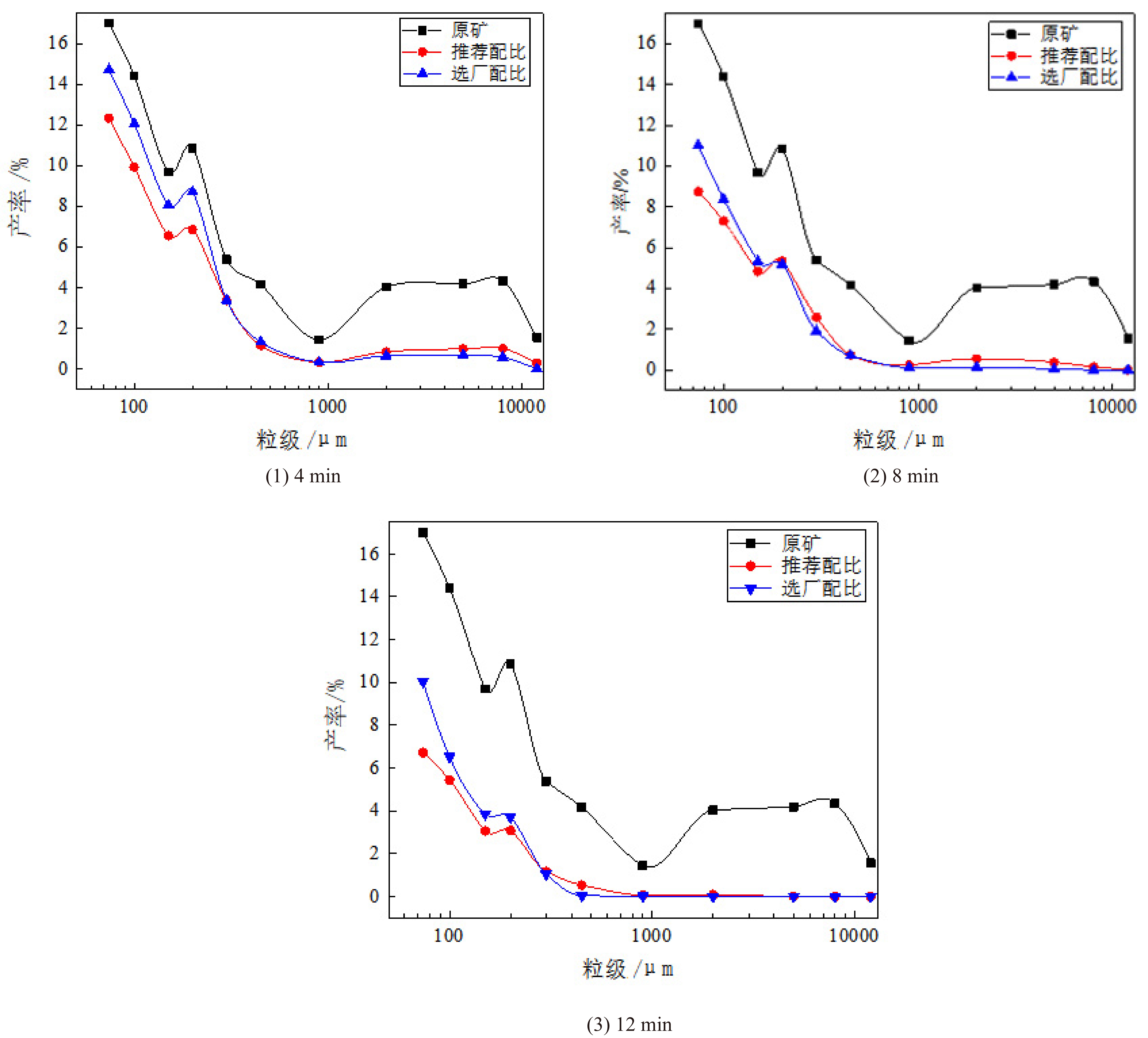

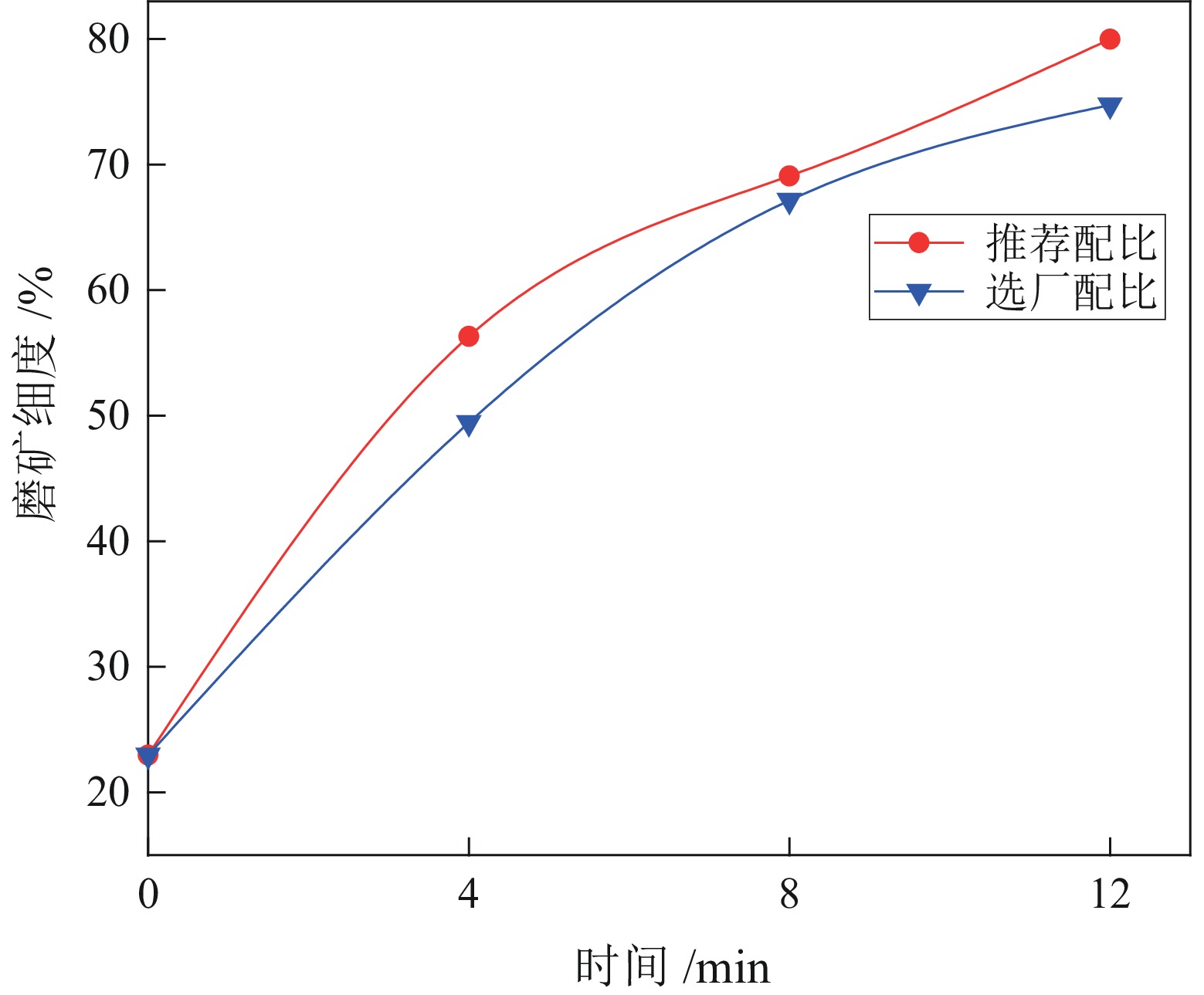

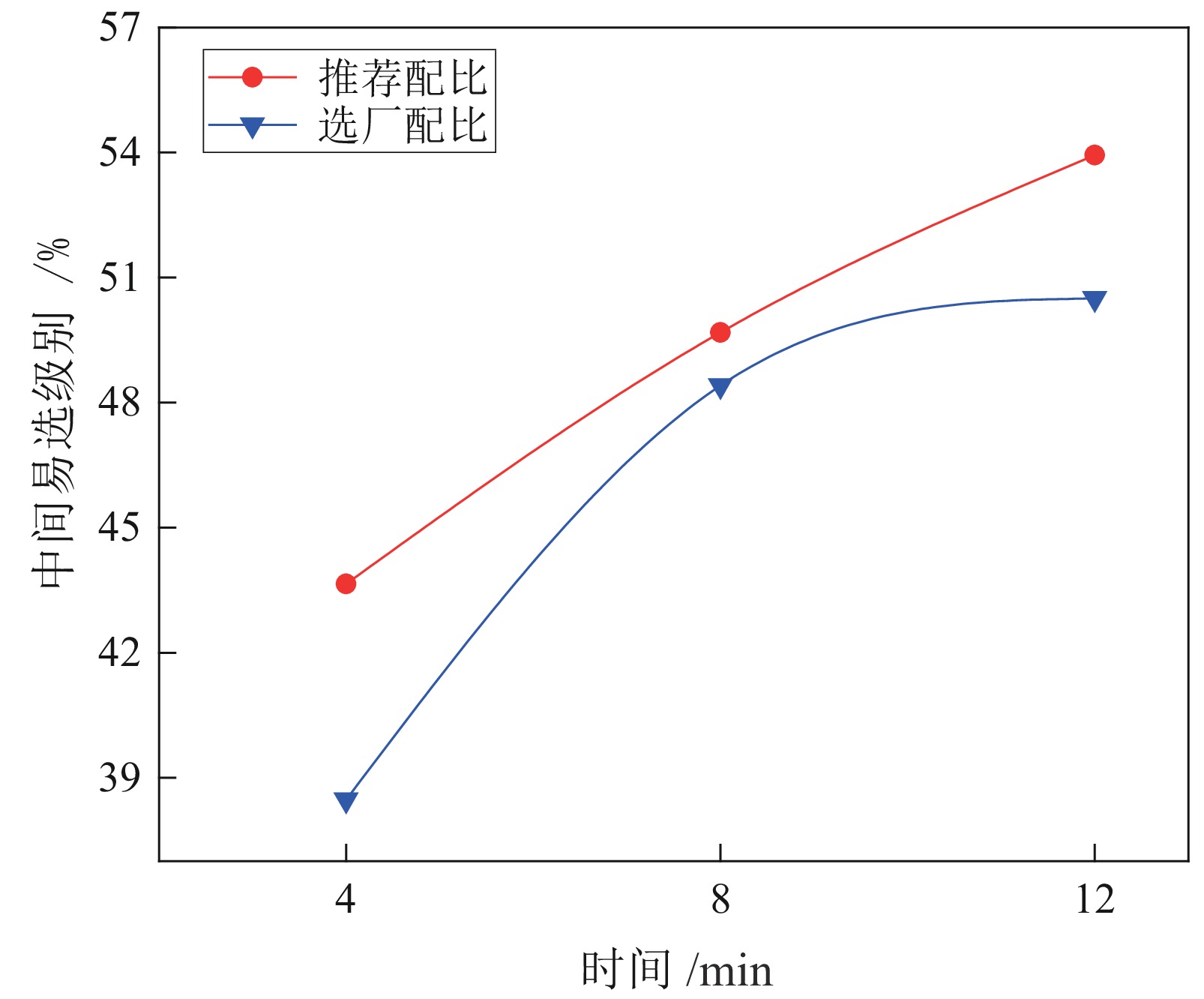

针对云南某铜矿磨矿介质配比m(Φ80)∶m(Φ60) =50∶50与球磨机给矿力学性质及粒度不匹配,导致磨矿细度及中间易选粒级产率偏低等问题,基于磨矿动力学原理可得到磨矿介质推荐配比m(Φ70)∶m(Φ60)∶m(Φ50)∶ m(Φ40) =15∶30∶10∶45。对比试验结果表明,推荐配比与现场配比相比,磨矿前期(4 min),+0.3 mm粒级物料产率提高1.01百分点,0.3~0.074 mm粒级产率降低7.88百分点;磨矿细度(−0.074 mm)在12 min时达到79.85%,且中间易选粒级与过粉碎粒级产率分别提高3.44、1.79百分点。最终推荐选厂选择基于磨矿动力学原理所得介质配比 m(Φ70)∶m(Φ60)∶m(Φ50)∶m(Φ40) =15∶30∶10∶45。

Abstract:In view of the problem of ore grinding fineness and intermediate easy-to-separate particle grades yield caused by the mismatch between the grinding medium ratio m(Φ80)∶m(Φ60)=50∶50 and the grinding feed mechanical properties and particle size distribution in a copper mine in Yunnan, the recommended grinding medium ratio m(Φ70)∶m(Φ60)∶m(Φ50)∶m(Φ40)=15∶30∶10∶45 can be obtained based on the grinding kinetics principle. Comparative test results showed that compared with the on-site ratio, in the early stage of grinding (4 min), the yield of material particles larger than 0.3 mm increased by 1.01 percentage points, while the yield of particles in the range of 0.3 to 0.074 mm decreased by 7.88 percentage points. The grinding fineness (less than 0.074 mm) reached 79.85 percentage at 12 min, and the yield of intermediate easy-to-separate particle grade and over-pulverized particle grade were increased by 3.44 and 1.79 percentage points, respectively. Finally, the recommended medium ratio of the grinding media was m(Φ70)∶m(Φ60)∶m(Φ50)∶m(Φ40)=15∶30∶10∶45 for the selection of the beneficiation plant based on the grinding kinetics principle.

-

Key words:

- grinding dynamics /

- grinding medium ratio /

- copper mine

-

-

表 1 球磨机总给矿正累积粒度分布

Table 1. Positive cumulative particle size distribution of ball mill total feed

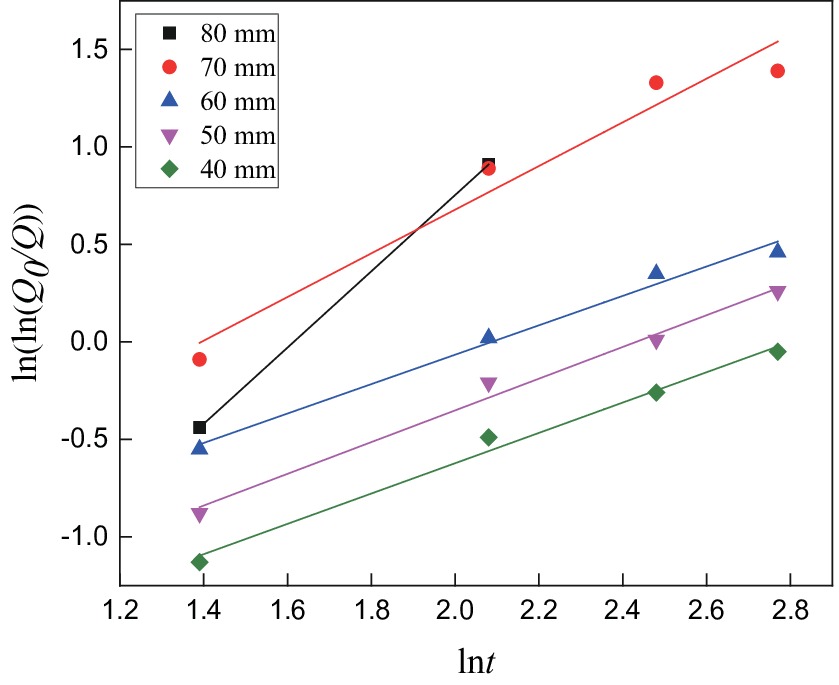

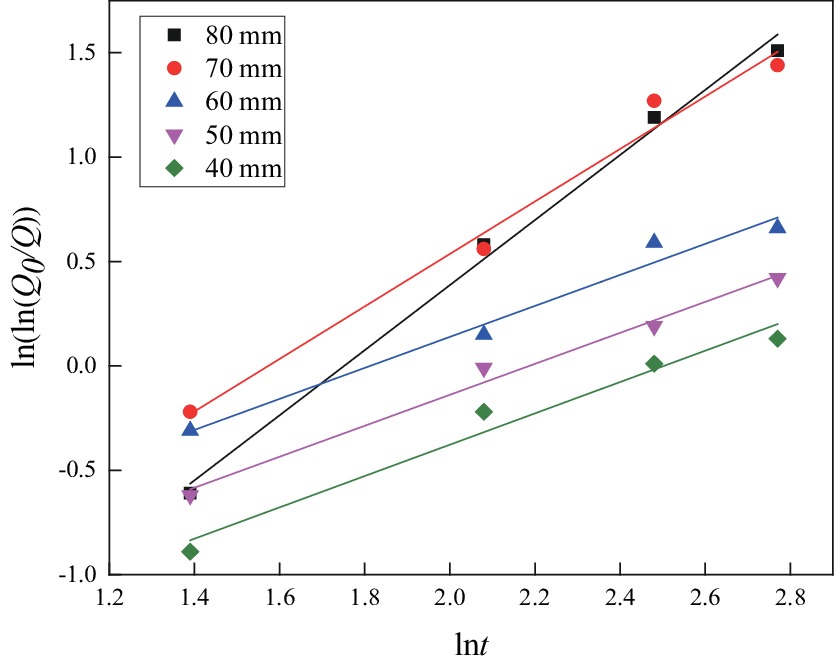

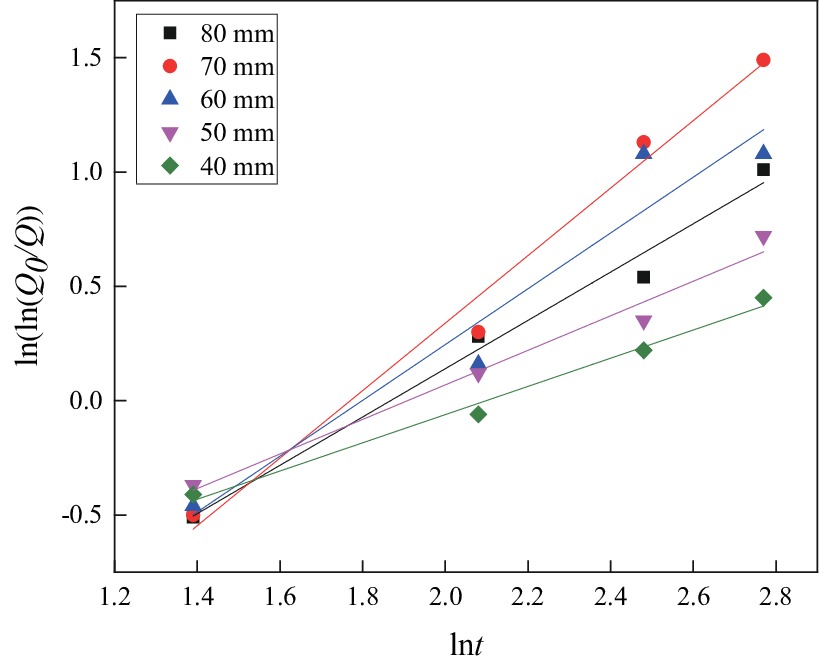

粒级/mm +15 +12 +2 +0.15 +0.074 皮带给矿/% 0.51 7.73 68.85 89.72 93.69 螺旋分级机返砂/% 0 0 0.42 34.64 72.88 表 2 磨矿动力学参数m值

Table 2. Grinding kinetic parameter m value

粒级/mm 80 70 60 50 40 +8 1.96 1.12 0.75 0.81 0.78 0.45~8 1.56 1.26 0.74 0.74 0.75 0.3~0.45 1.28 1.39 0.95 0.75 0.72 0.15~0.2 1.06 1.48 1.22 0.76 0.62 表 3 磨矿动力学参数lnk值

Table 3. Grinding kinetic parameter lnk value

粒级/mm 80 70 60 50 40 +8 −3.16 −1.56 −1.57 −1.98 −2.18 0.45~8 −2.73 −1.98 −1.35 −1.62 −1.88 0.3~0.45 −2.42 −2.35 −1.69 −1.47 −1.64 0.15~0.2 −1.97 −2.61 −2.20 −1.44 −1.29 表 4 各粒级最佳球径

Table 4. The best ball diameter of each particle size

粒级/mm +8 0.45~8 0.3~0.45 0.15~0.2 球径/mm 70 60 50 40 表 5 球磨机初装球配比方案

Table 5. Proportion scheme of ball mill initially loaded

级别/mm 配矿

产率/%扣除−0.15mm后

待磨产率γ待/%各组适宜

球径/mm推荐

球比/%+8 8.83 13.00 70 15 0.45~ 20.22 29.74 60 30 0.3~0.45 8.09 11.90 50 10 0.15~0.3 30.84 45.36 40 45 −0.15 32.02 − − − 合计 100.00 100.00 − 100.00 表 6 磨矿介质对比方案

Table 6. Comparison scheme of grinding media

配比名称 配比内容/% 平均球径/mm 推荐配比 m(Φ70)∶m(Φ60)∶m(Φ50)∶m(Φ40) =15∶30∶10∶45 51.5 选厂配比 m(Φ80)∶m(Φ60) =50∶50 70.0 -

[1] MU Y F, CHENG Y P, PENG Y J. The interaction of grinding media and collector in pyrite flotation at alkaline pH[J]. Minerals Engineering, 2020, 152: 106344. doi: 10.1016/j.mineng.2020.106344

[2] LARSSON S, PÅLSSON B I, PARIAB M, et al. A novel approach for modelling of physical interactions between slurry,grinding media and mill structure in wet stirred media mills[J]. Minerals Engineering, 2020, 148: 106180. doi: 10.1016/j.mineng.2019.106180

[3] DÍAZ E, L VOISIN, KRACHT W, et al. Using advanced mineral characterisation techniques to estimate grinding media consumption at laboratory scale[J]. Minerals Engineering, 2018, 121: 180−188. doi: 10.1016/j.mineng.2018.03.015

[4] 段希祥.碎矿与磨矿(第三版)[M].北京: 冶金工业出版社,2013.

DUAN X X. Ore crushing and grinding (3th Edition) [M]. Beijing: Metallurgical Industry Press, 2013.

[5] ZHOU W T, HAN Y X, SUN Y S, et al. Multi-scale impact crushing characteristics of polymetallic sulphide ores[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(9): 1929−1938. doi: 10.1016/S1003-6326(19)65100-9

[6] LIU S H, LI Q L, SONG J W. Study on the grinding kinetics of copper tailing powder[J]. Powder Technology, 2018, 330: 105−113. doi: 10.1016/j.powtec.2018.02.025

[7] IWASAKI T, YABUUCHI T, NAKAGAWA H, et al. Scale-up methodology for tumbling ball mill based on impact energy of grinding balls using discrete element analysis[J]. Advanced Powder Technology, 2010, 21(6): 623−629. doi: 10.1016/j.apt.2010.04.008

[8] CURRY J A, ISMAY M J L, JAMESON G J. Mine operating costs and the potential impacts of energy and grinding[J]. Minerals Engineering, 2014, 56: 70−80. doi: 10.1016/j.mineng.2013.10.020

[9] ZHANG X L, HAN Y X, GAO P, et al. Effects of particle size and ferric hydroxo complex produced by different grinding media on the flotation kinetics of pyrite[J]. Powder Technology, 2020, 360: 1028−1036. doi: 10.1016/j.powtec.2019.11.014

[10] NADOLSKI S, KLEIN B, KUMAR A, et al. An energy benchmarking model for mineral comminution[J]. Minerals Engineering, 2014, 65: 178−186. doi: 10.1016/j.mineng.2014.05.026

[11] MATIJASIC G, KURAJICA S. Grinding kinetics of amorphous powder obtained by solgel process[J]. Powder Technology, 2010, 197(3): 165−169. doi: 10.1016/j.powtec.2009.09.010

[12] OZKAN A, YEKELER M, CALKAYA M. Kinetics of wet grinding of zeolite in a steel ball mill in comparison to dry grinding[J]. International Journal of Mineral Processing, 2009, 90(1/2/3/4): 67−73. doi: 10.1016/j.minpro.2008.10.006

[13] RODRÍGUEZ B A, JUAN M, AGUADO M, et al. Transient stateanalysis by simulation in a closed grinding circuit[J]. Minerals Engineering, 2011, 24(5): 473−475. doi: 10.1016/j.mineng.2010.12.005

[14] BAZIN C, OBIANG P. Should the slurry density in a grinding mill be adjusted as a function of grinding media size[J]. Minerals Engineering, 2007, 20(8): 810−815. doi: 10.1016/j.mineng.2007.01.017

[15] FUERSTENAU D W, PHATAK P B, KAPUR P C, et al. Simulation ofthe grinding of coarse/fine(heterogeneous) systems in a ball mill[J]. International Journal of Mineral Processing, 2011, 99(1-4): 32−38. doi: 10.1016/j.minpro.2011.02.003

[16] 段希祥.碎矿与磨矿(第二版)[M].北京: 冶金工业出版社,2006:179-180.

DUAN X X. Ore crushing and grinding (2nd Edition) [M]. Beijing: Metallurgical Industry Press, 2006: 179-180.

[17] 段希祥. 磨矿动力学参数与磨矿时间的关系研究[J]. 昆明工学院学报, 1988, 13(5): 23−33.

DUAN X X. Relationship between grinding kinetic parameters and grinding time[J]. Journal of Kunming Institute of Technology, 1988, 13(5): 23−33.

[18] 李同清, 彭玉兴. 研磨介质形状对铁矿石磨矿动力学研究[J]. 有色金属(选矿部分), 2018(1): 84−89+99.

LI T Q, PENG Y X. Effect of grinding media shape on milling kinetics of iron ore particles[J]. Nonferrous Metals (Beneficiation), 2018(1): 84−89+99.

[19] 沈传刚.永平铜矿磨矿动力学模型的建立及应用研究[D].昆明:昆明理工大学,2017.

SHEN C G. Research on the establishment and application of grinding dynamics model of Yongping Copper Mine[D]. Kunming: Kunming University of Science and Technology, 2017.

[20] 侯英, 印万忠, 朱巨建, 等. 不同碎磨方式下紫金山金铜矿石的磨矿动力学行为[J]. 中南大学学报(自然科学版), 2017, 48(5): 1127−1133.

HOU Y, YIN W Z, ZHU J J, et al. Grinding dynamics behavior of gold-copper ore in Zijinshan under different grinding methods[J]. Journal of Central South University (Natural Science Edition), 2017, 48(5): 1127−1133.

[21] 侯英, 丁亚卓, 印万忠, 等. 磨矿动力学参数对磨矿速度的影响[J]. 东北大学学报(自然科学版), 2013, 34(5): 708−711.

HOU Y, DING Y Z, YIN W Z, et al. Influence of grinding kinetic parameters on grinding speed[J]. Journal of Northeastern University (Natural Science Edition), 2013, 34(5): 708−711.

[22] DAVIS E W. Fine crushing in ball mills[J]. Transactions AIME, 1919, 61: 250−296.

-

下载:

下载: