Comparative Experimental Study on the Grinding Effect of a Lead-zinc Mine Through Vertical Mill and Ball Mill

-

摘要:

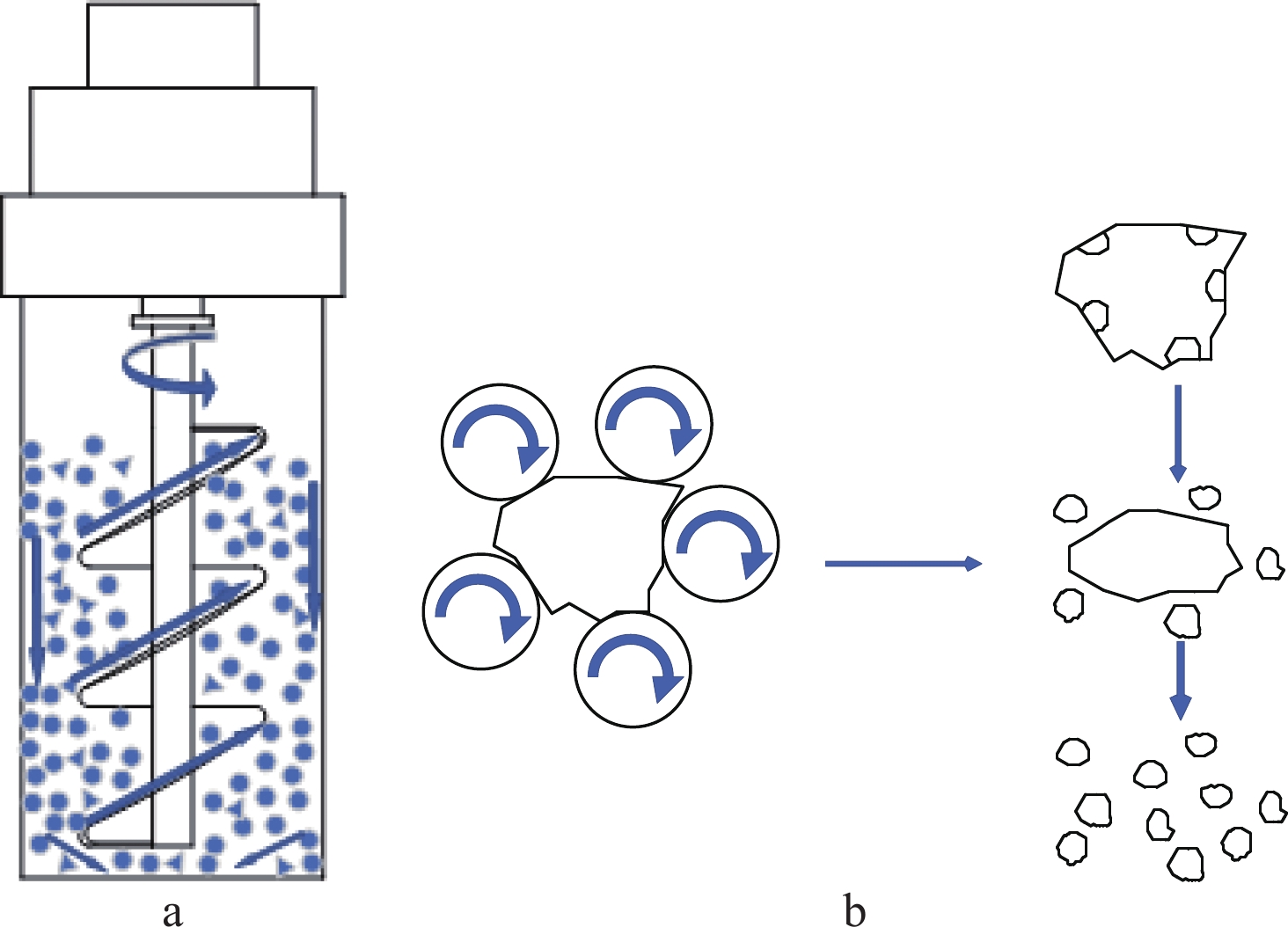

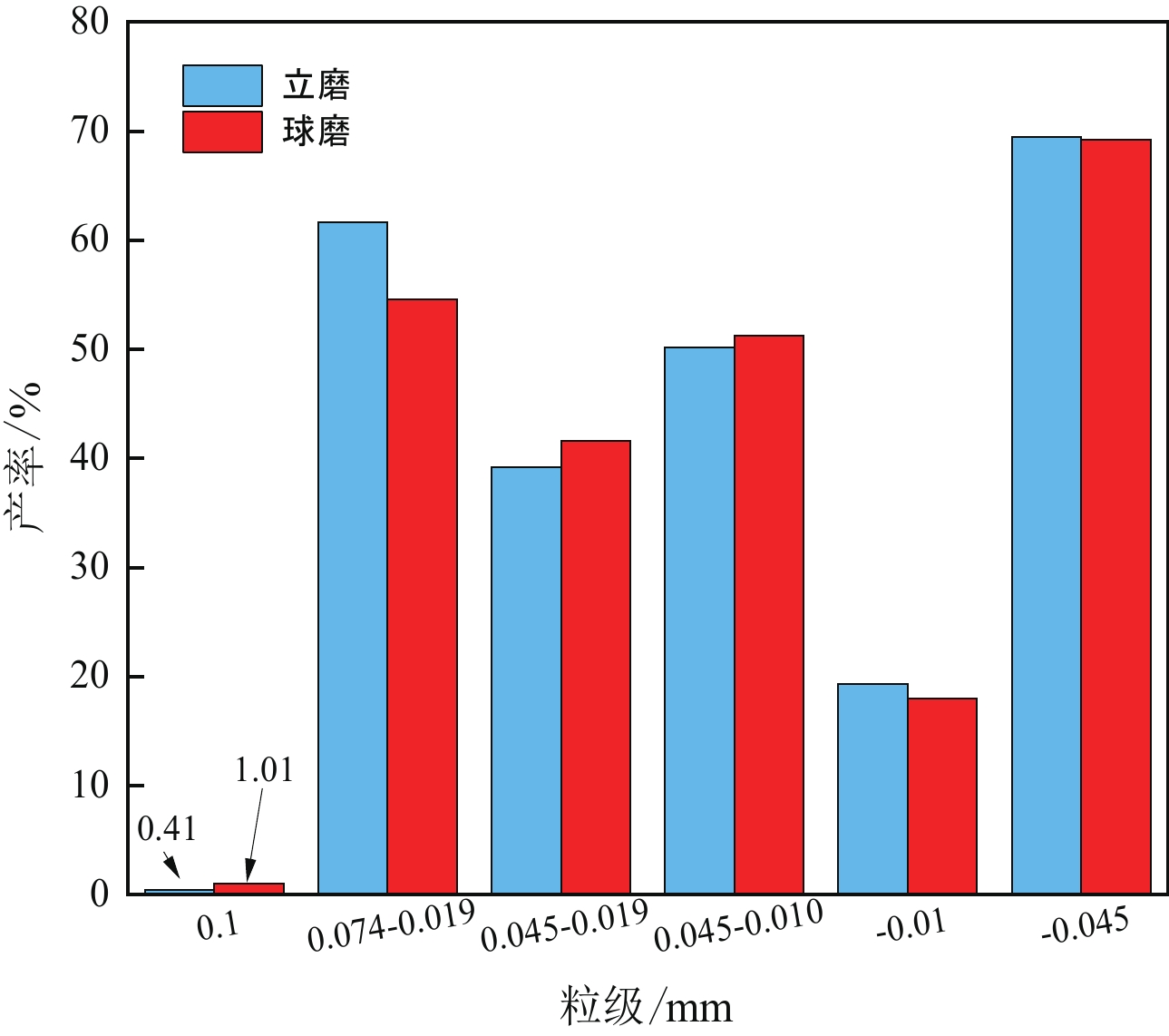

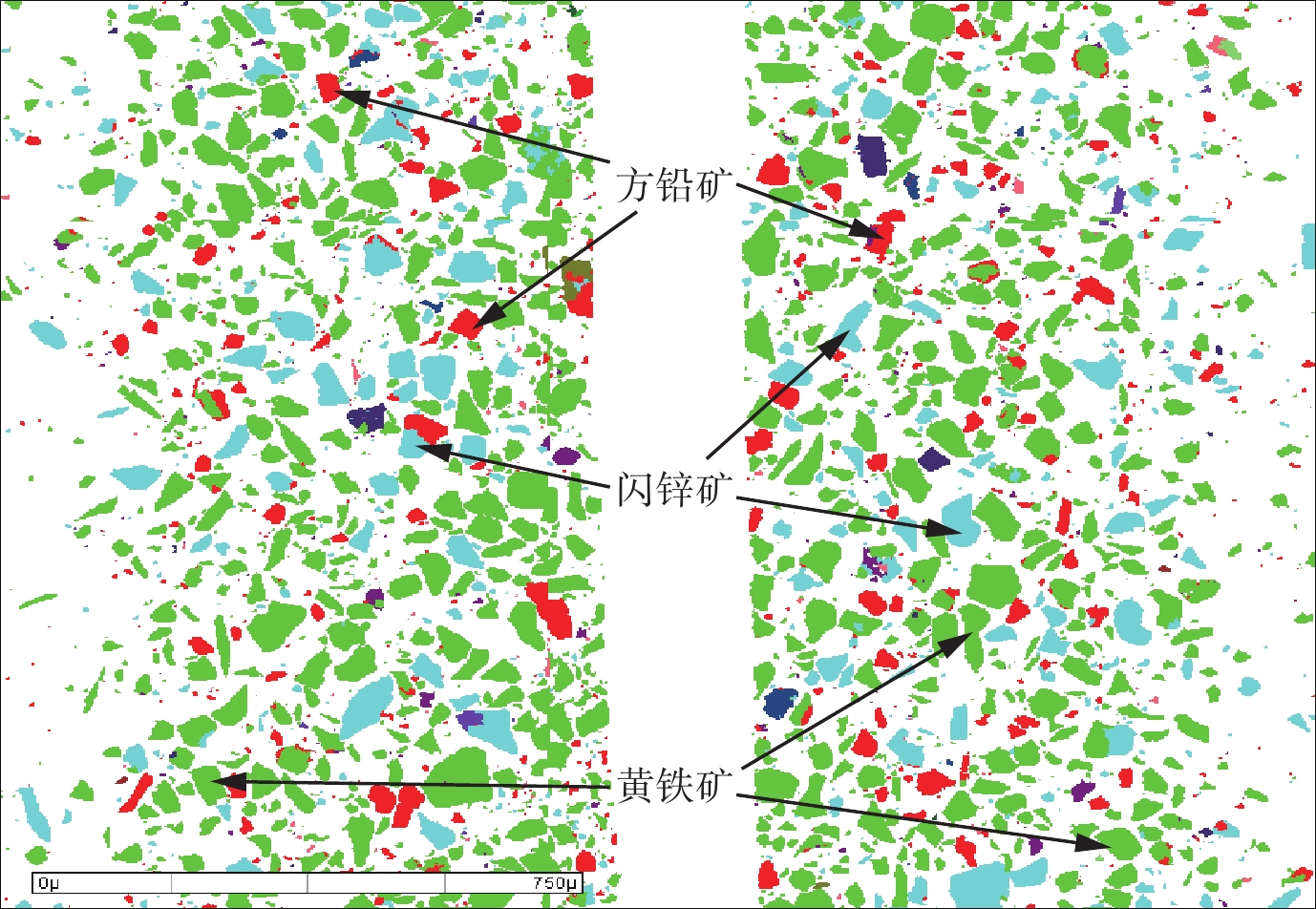

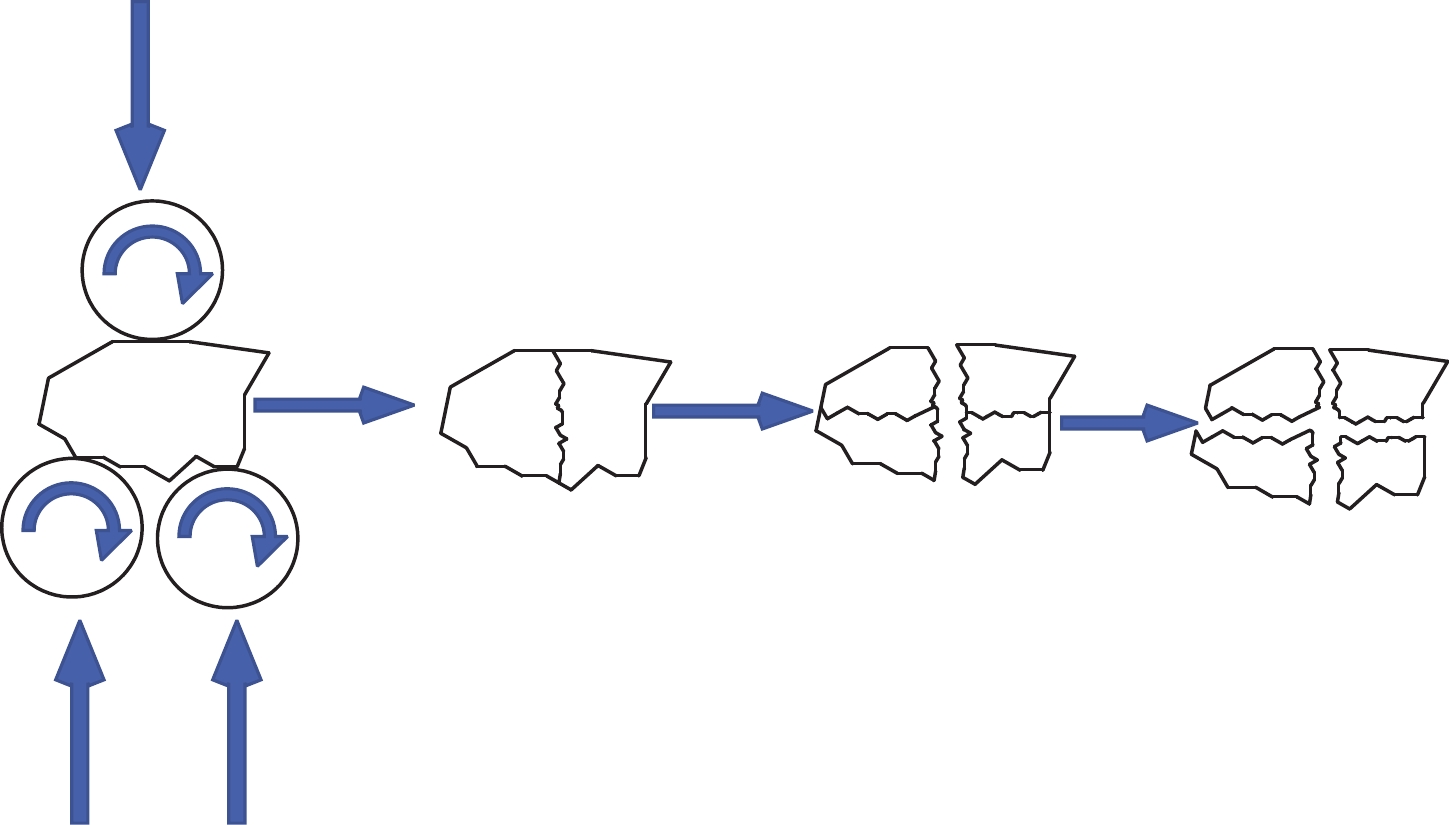

立磨机和球磨机都是大型工业磨粉设备,被广泛应用于选矿、冶金、化工和煤炭等行业。本文针对某铅锌矿对比两种磨机的磨矿效果,采用立磨机与球磨机进行磨矿试验,并对试验产品进行筛分分析、单体解离度分析及浮选试验。试验结果表明:立磨机磨矿试验产品中粗粒级含量较球磨机试验产品下降了0.6百分点,方铅矿和闪锌矿单体解离度分别提高2.28和1.60百分点;立磨—浮选试验产品中铅精矿中铅品位及累计回收率较球磨机分别提高0.65和0.61,锌精矿中锌品位及累计回收率较之分别提高0.34和1.03百分点,硫精矿中铅和锌含量分别下降0.02、0.06百分点。综上所述针对该铅锌矿立磨机磨矿效果均优于球磨机。

Abstract:Both vertical mills and ball mills are large grinding equipment in industry, which are widely used in mineral processing, metallurgy, chemical engineering, coal, and other fields. The vertical mill and ball mill were used for grinding tests to compare the grinding effect on certain lead-zinc ore, meanwhile sieve analysis, monomer dissociation analysis and froth flotation tests on above products were also conducted. The results of sieve analysis and monomer dissociation analysis showed that the content of coarse fraction in the product after vertical mill grinding decreased by 0.6 percentage compared with the test results of ball mill. In addition, the liberation degree of galena and sphalerite increased by 2.28 and 1.60 percentage respectively. The froth flotation tests demonstrated that compared with the ball mill-flotation test results, the grade and cumulative recovery of lead in the lead concentrate increased by 0.65 and 0.61 respectively, and the grade and cumulative recovery of zinc in the zinc concentrate increased by 0.6 and 0.6 respectively. The lead and zinc content in the sulfur concentrate decreased by 0.02 and 0.06 percentage. In summary, the grinding effect of the vertical mill for this lead-zinc ore is better than that of the ball mill.

-

Key words:

- vertical mill /

- ball mill /

- grinding /

- single liberation degree /

- lead-zinc ore /

- flotation

-

-

表 1 −0.074+0.045 mm粒级中其他粒级占比

Table 1. Other size classes proportion in −0.074+0.019 mm size class

/% 粒级/mm 立磨方案 球磨方案 −0.074+0.045 30.92 20.26 −0.045+0.028 26.98 51.02 −0.028+0.019 26.98 13.68 −0.019 15.12 15.04 总计 100.00 100.00 表 2 立磨和球磨试验产品3/4解离~完全解离累计解离度

Table 2. Dissociation characteristics of vertical mill and ball mill test products

/% 矿物名称 立磨机试验方案 球磨机试验方案 方铅矿 90.74 88.46 闪锌矿 92.33 90.73 黄铁矿 96.46 94.09 表 3 立磨及球磨磨矿产品浮选对比试验指标

Table 3. Comparative flotation test indexes of vertical and ball mill products

试验方案 产品名称 产率/% 品位/% 回收率/% Pb Zn Pb Zn 个别 累计 个别 累计 个别 累计 个别 累计 个别 累计 立磨试验 铅精矿 12.62 12.62 62.56 62.56 3.51 3.51 74.73 74.73 4.15 4.15 中矿1 3.78 16.40 34.69 56.14 11.21 5.28 12.40 87.13 3.97 8.12 中矿2 3.40 19.80 14.59 49.01 11.49 6.35 4.69 91.82 3.66 11.78 中矿3 1.08 20.88 10.45 47.01 13.12 6.7 1.07 92.89 1.33 13.11 中矿4 0.87 21.75 5.02 45.32 15.83 7.07 0.42 93.31 1.30 14.41 锌精矿 14.8 36.55 1.38 27.53 54.35 26.21 1.93 95.24 75.44 89.85 中矿5 3.92 40.47 2.36 25.1 9.90 24.63 0.87 96.11 3.64 93.49 中矿6 3.45 43.92 0.98 23.20 6.79 23.23 0.32 96.43 2.20 95.69 硫精矿 56.08 100.00 0.67 10.57 0.82 10.66 3.57 100.00 4.31 100.00 给矿 100.00 —— 10.57 —— 10.66 —— 100.00 —— 100.00 —— 球磨试验 铅精矿 12.9 12.90 61.91 61.91 3.77 3.77 74.13 74.13 4.48 4.48 中矿1 3.71 16.61 34.24 55.74 11.83 5.57 11.77 85.90 4.03 8.51 中矿2 3.63 20.24 14.22 48.3 11.7 6.67 4.78 90.68 3.90 12.41 中矿3 1.20 21.44 9.88 46.14 13.81 7.07 1.10 91.78 1.53 13.94 中矿4 1.01 22.45 6.02 44.33 15.22 7.44 0.57 92.35 1.42 15.36 锌精矿 14.98 37.43 1.65 27.25 54.01 26.07 2.29 94.64 74.41 89.77 中矿5 4.22 41.65 3.36 24.83 9.83 24.43 1.32 95.96 3.82 93.59 中矿6 3.41 45.06 1.65 23.08 6.26 23.05 0.52 96.48 1.96 95.55 硫精矿 54.94 100.00 0.69 10.78 0.88 10.87 3.52 100.00 4.45 100.00 给矿 100.00 —— 10.78 —— 10.87 —— 100.00 —— 100.00 —— -

[1] 程武忠. 铅锌硫化矿选矿工艺及机理浅析[J]. 世界有色金属, 2019(21): 52−53. doi: 10.3969/j.issn.1002-5065.2019.21.032

CHENG W Z. A brief analysis of the beneficiation process and mechanism of lead-zinc sulfide ore[J]. World Nonferrous Metals, 2019(21): 52−53. doi: 10.3969/j.issn.1002-5065.2019.21.032

[2] 王潇, 文书明, 韩广, 等. 硫化铅锌矿石浮选分离技术研究进展[J]. 矿产保护与利用, 2021, 41(5): 168−178. doi: 10.13779/j.cnki.Issn1001-0076.2021.05.023

WANG X, WEN S M, HAN G, et al. Research progress of flotation separation technology for lead-zinc sulfide ores[J]. Mineral Conservation and Utilization, 2021, 41(5): 168−178. doi: 10.13779/j.cnki.Issn1001-0076.2021.05.023

[3] 周源, 陈江安. 铅锌选矿技术[M]. 北京: 化学工业出版社, 2012: 20−21.

ZHOU Y, CHEN J A. Lead-zinc beneficiation technology [M]. Beijing: Chemical Industry Press, 2012: 20−21.

[4] JIA Y, HUANG XP, HUANG K, et al. Synthesis, flotation performance and adsorption mechanism of 3-( ethylamino)-N-phenyl-3 -thioxopropanamide onto galena/sphalerite surfaces[J]. Journal of Industrial and Engineering Chemistry, 2019, 77(C): 416−425.

[5] 唐攀科, 王春艳, 梅友松, 等. 中国铅锌矿产资源成矿特征与资源潜力评价[J]. 地学前缘, 2018, 25(3): 31−49. doi: 10.13745/j.esf.2018.03.003

TANG P K, WANG C Y, MEI Y S, et al. Evaluation of metallogenic characteristics and resource potential of lead-zinc mineral resources in China[J]. Geological Foreground, 2018, 25(3): 31−49. doi: 10.13745/j.esf.2018.03.003

[6] 唐攀科, 王春艳. 中国铅锌矿资源潜力评价及其成矿远景预测[J]. 矿床地质, 2014, 33(S1): 819-820. DOI:10.16111/j.0258-7106. 2014. s1.412.

TANG P K, WANG C Y. Evaluation of the resource potential of lead-zinc ore in China and its prospective prediction of mineralization[J]. Mineral Deposit Geology, 2014, 33(S1): 819-820. DOI: 10.16111/j. 0258-7106. 2014. s1.412.

[7] NWOYE CI. Model for predicting the initial solution ph at pre - assumedfinal ph and concentration of dissolved lead during leaching of galena inbutanoic acid solution[J]. Journal of Enginering Science and Technolo-gy, 2010, 5(2): 176.

[8] ZHANG, G. W. , ZHAO, et al. Research and application of vertical screw stirred mill. XXV. In: International Mineral Processing Congress, Brisbane, Australia, 1437–1443.

[9] X. XIAO, G. W. ZHANG, Y. G. LI, et al. Intensifying separation of reverse flotation tailings from concentrator of baogang group by fine grinding with the stirred mill Min. Metall. Eng. , 2011, 31 (2) , 32-34.

[10] 段希祥. 提高磨矿过程矿物单体解离度及改善磨矿产品质量研究[J]. 有色金属(选矿部分), 1998(3): 33−38+43.

DUAN X X. Research on improving the dissociation degree of mineral monomer in grinding process and improving the quality of grinding products[J]. Non-ferrous Metals (Mineral Processing), 1998(3): 33−38+43.

[11] XIE H, LIU Y, RAO B, et al. Selective passiv ation b ehav ior of g alenasurface by sulfuric acid and a novel flotation separation method forcopper - lead sulfide ore without collector and inhibitor[J]. Separationand Purification Technology, 2021, 267(1/2): 118621.

[12] 杨稳权, 方世祥, 庞建涛, 等. 胶磷矿不同磨矿细度单体解离度测定及其浮选应用[J]. 武汉工程大学学报, 2014, 36(4): 31−34. doi: 10.3969/j.issn.1674-2869.2014.04.007

YANG Y Q, FANG S X, PANG J T, et al. Determination of monomer dissociation degree of colloidal phosphate ore with different grinding fineness and its flotation application[J]. Journal of Wuhan Engineering University, 2014, 36(4): 31−34. doi: 10.3969/j.issn.1674-2869.2014.04.007

[13] 张跃军, 陈东, 余悦. 立磨机与球磨机对钾石盐矿的磨矿性能对比研究[J]. 矿产保护与利用, 2013(6): 33−36. doi: 10.13779/j.cnki.Issn1001-0076.2013.06.008

ZHANG Y J, CHEN D, YU Y. A comparative study on the grinding performance of vertical mill and ball mill for potash salt ore[J]. Mineral Conservation and Utilization, 2013(6): 33−36. doi: 10.13779/j.cnki.Issn1001-0076.2013.06.008

[14] 董天龙, 薛春华. 塔磨机在铜精矿细磨中的应用[J]. 云南冶金, 2017, 46(1): 19−22. doi: 10.3969/j.issn.1006-0308.2017.01.004

DONG T L, XUE C H. Application of tower mill in fine grinding of copper concentrate[J]. Yunnan Metallurgy, 2017, 46(1): 19−22. doi: 10.3969/j.issn.1006-0308.2017.01.004

[15] 陈来保, 谢蔼祥, 阚延松. TM系列塔磨机在某铜矿细磨再选工艺中的应用[J]. 现代矿业, 2017, 33(3): 191−192.

CHEN L B, XIE A X, KAN Y S. Application of TM series tower mill in a copper ore fine grinding and re-election process[J]. Modern Mining, 2017, 33(3): 191−192.

[16] 段希祥. 碎矿与磨矿[M]. 北京: 冶金工业出版社, 2012: 210-213.

DUAN X X. Ore crushing and grinding [M]. Beijing: Metallurgical Industry Press, 2012: 210−213.

[17] 李腾飞, 林蜀勇, 张博, 等. 不同转速率下球磨机内钢球的碰撞研究[J]. 中南大学学报(自然科学版), 2019, 50(2): 251−256.

LI T F, LIN S Y, ZHANG B, et al. Study on the collision of steel balls in ball mills at different rotation rates[J]. Journal of Central South University (Natural Science Edition), 2019, 50(2): 251−256.

[18] XIAO X, ZHANG G W, FENG Q M, et al. The liberation effect of magnetite fine ground by vertical stirred mill and ball mill, Minerals Engineering, 2012, 34: 63−69.

[19] 陈彦如, 王腾宇, 纪鸿, 等. 超细搅拌磨的研发现状及发展趋势[J]. 中国非金属矿工业导刊, 2013(3): 46−48+20. doi: 10.3969/j.issn.1007-9386.2013.03.015

CHEN Y R, WANG T Y, JI H, et al. Current status and development trend of ultrafine stirred mill[J]. China Nonmetallic Mining Industry Journal, 2013(3): 46−48+20. doi: 10.3969/j.issn.1007-9386.2013.03.015

[20] 张国旺, 黄圣生, 李自强, 等. 超细搅拌磨机的研究现状和发展[J]. 有色矿冶, 2006(S1): 123−125+127.

ZHANG G W, HUANG S S, LI Z Q, et al. Research status and development of ultrafine stirred mill[J]. Nonferrous Mining and Metallurgy, 2006(S1): 123−125+127.

[21] GAO M W, E. FORSSBERG, Prediction of product size distributions for a stirred ball mill powder technol. , 1995, 84: 101-106.

[22] R. HOGG, Breakage mechanisms and mill performance in ultrafine grinding Powder Technology, 1999, 105: 135−140.

[23] 曾桂忠, 段希祥. 立式球磨机在铝土矿选择性磨矿的试验研究[J]. 矿山机械, 2009, 37(17): 58−60.

ZENG G Z, DUAN X X. Experimental study of vertical ball mill in selective grinding of bauxite ore[J]. Mining Machinery, 2009, 37(17): 58−60.

-

下载:

下载: