Experimental Study on Flotation of A Copper Mine in Shanxi Province with A Novel Environmental Collector CYL-5

-

摘要:

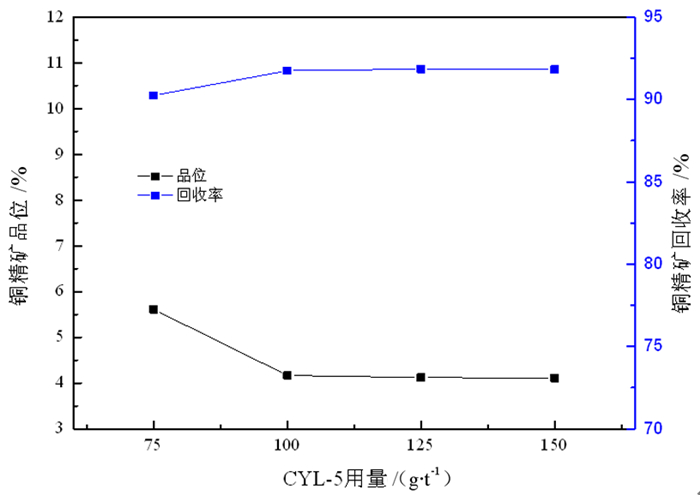

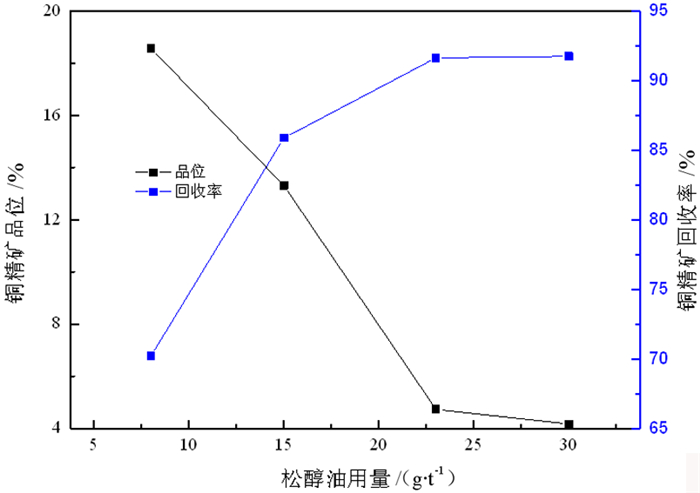

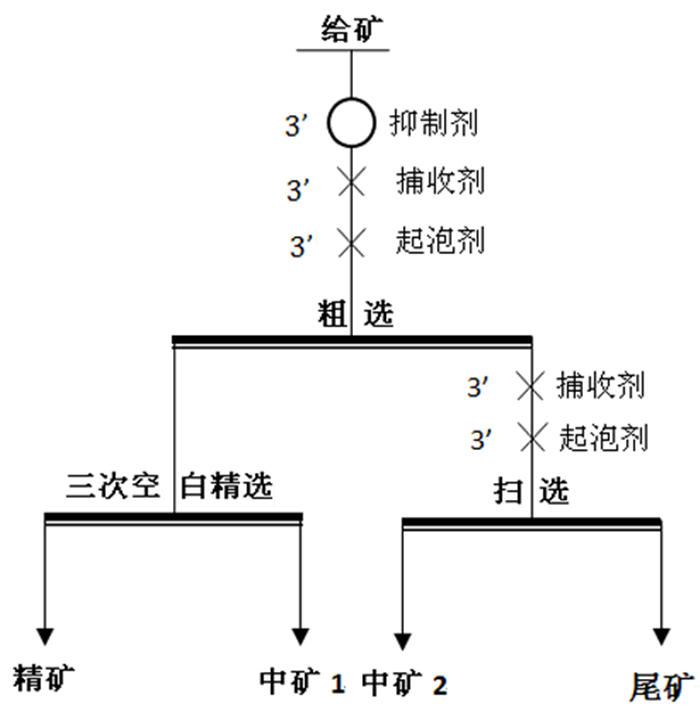

山西某铜矿山长期采用丁基黄药作为铜矿捕收剂, 生产现场丁基黄药刺激性气味强烈、选矿废水中黄原酸根离子超标。为解决黄药使用的环保问题, 针对该铜矿, 采用新型环保型捕收剂CYL-5进行浮选试验研究, 经一次粗选三次精选一次扫选的闭路浮选流程, 取得铜精矿Cu品位为25.13%、回收率为93.30%的浮选指标。与丁基黄药浮选指标相比, 铜精矿Cu品位提高2.06百分点, 铜回收率提高0.50百分点, 可达到优于丁基黄药浮选的目的。

Abstract:Butyl xanthate has been used as copper collector in a copper mine in Shanxi province for a long time. Butyl xanthate has a strong pungent smell on the production site and the xanthate ion in benefication wastewater exceeds the standard. In order to solve the environmental problems of xanthate, Novel environmental collector CYL-5 was used to carry out for flotation experiment in the copper mine. Through the closed-circuit flotation process of one roughing, three cleanings and one scavengings, the copper concentrate with Cu grade of 25.13% and recovery of 93.30% was obtained. Compared with the flotation index of butyl xanthate, the grade of copper concentrate was increased by 2.06 percentage points and the copper recovery was increased by 0.50 percentage points using the collector CYL-5, which was better than butyl xanthate.

-

Key words:

- copper mine /

- collector /

- flotation /

- CYL-5 /

- environmental

-

-

表 1 矿石化学多元素分析结果

/% Table 1. Chemical multielement analysis results of the ore

Cu Pb K2O CaO Na2O MgO 0.41 0.018 11.21 0.45 1.56 2.45 Al2O3 Zn Mo Fe S SiO2 18.24 0.02 0.001 6.58 0.63 60.31 表 2 矿石中铜的化学物相分析结果

/% Table 2. Chemical phase analysis results of copper in the ore

铜相 含量 分布率 原生硫化铜 0.389 94.89 次生硫化铜 0.005 1.22 自由氧化铜 0.007 1.70 结合氧化铜 0.009 2.19 合计 0.41 100.00 -

[1] 刘小舟. 我国重要有色金属资源-铜矿的现状及展望[J]. 西北地质, 2007, 40(1): 83-88. https://www.cnki.com.cn/Article/CJFDTOTAL-XBDI200701008.htm

LIU X Z. Present situation and prospect of copper mine, an important nonferrous metal resource in my country[J]. Northwestern Geology, 2007, 40(1): 83-88. https://www.cnki.com.cn/Article/CJFDTOTAL-XBDI200701008.htm

[2] 王美丽, 丰奇成, 王涵. 氧化铜矿选冶研究现状及展望[J]. 矿产综合利用, 2021(4): 103-109+138. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL202104016.htm

WANG M L, FENG Q C, WANG H. Research status and prospect of beneficiation and metallurgy of oxidized copper ore[J]. Mineral Resources, 2021(4): 103-109+138. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL202104016.htm

[3] 袁铭泽, 周兴龙, 王兰华, 等. 四川某硫化铜矿浮选新药剂试验研究[J]. 矿冶工程, 2017, 37(1): 46-48+51. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201701013.htm

YUAN M Z, ZHOU X L, WANG L H, et al. Performance of new flotation reagents in beneficiation of copper sulfide ore from Sichuan[J]. Mining and Metallurgical Engineering, 2017, 37(1): 46-48+51. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201701013.htm

[4] 杨玮, 覃文庆, 张建文. 云南某硫化铜矿浮选试验研究[J]. 金属矿山, 2009(9): 94-97. doi: 10.3321/j.issn:1001-1250.2009.09.023

YANG W, QIN W Q, ZHANG J W. Research on the flotation tests of a Yunan sulfide copper ore[J]. Metal Mine, 2009(9): 94-97. doi: 10.3321/j.issn:1001-1250.2009.09.023

[5] G·汉戈勒, 崔洪山, 肖力子. 用巯基捕收剂及其混合物从Okiep矿石中浮选硫化铜矿[J]. 国外金属矿选矿, 2005, 42(9): 22-25+8. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200509004.htm

G·H, CUI H S, XIAO L Z. Flotation of copper sulfide from Okiep with sulfhydryl collector and its mixture[J]. Metallic Ore Dressing Abroad, 2005, 42(9): 22-25+8. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200509004.htm

[6] A·T马康扎, 孙吉鹏, 童雄, 等. 用混合捕收剂浮选含金黄铁矿矿石[J]. 国外金属矿选矿, 2008, 45(11): 8-13. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200811002.htm

A·T, SUN J P, TONG X, et al. Flotation of gold bearing pyrite ore with mixed collector[J]. Metallic Ore Dressing Abroad, 2008, 45(11): 8-13. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200811002.htm

[7] 钟宏, 张湘予, 马鑫, 等. 酰氨基黄药的制备及其对黄铜矿、黄铁矿的浮选性能研究[J]. 矿产保护与利用, 2021, 41(2): 13-22. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=c224e886-f769-43f4-a907-df9fc072e779

ZHONG H, ZHANG X Y, MA X, et al. Preparation of amido xanthate and its flotation performance for chalcopyrite and pyrite[J]. Conservation and Utilization of Mineral Resources, 2021, 41(2): 13-22. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=c224e886-f769-43f4-a907-df9fc072e779

[8] 徐承焱, 孙体昌, 鄢功军, 等. 磨矿因素对黄药在硫化矿浮选过程中分布的影响[J]. 中国矿业, 2019, 28(1): 150-155. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA201901028.htm

XU C Y, SUN T C, YAN G J, et al. Effects of grinding factors on distribution of xanthate in flotation process of sulfide ore[J]. China Mining Magazine, 2019, 28(1): 150-155. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA201901028.htm

[9] 卢绿荣, 陈建华, 李玉琼. 硫化矿浮选捕收剂分子结构与性能的电子态密度研究[J]. 中国有色金属学报, 2018, 28(7): 1482-1490. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201807022.htm

LU L R, CHEN J H, LI Y Q. Electronic density of states study on molecular structure and properties of sulfide ore flotation collector[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(7): 1482-1490. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201807022.htm

[10] 李成秀, 文书明. 多金属硫化矿浮选研究的新进展[J]. 国外金属矿选矿, 2004, 41(1): 8-12+7. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200401001.htm

LI C X, WEN S M. New progress in flotation of polymetallic sulfide ores[J]. Metallic Ore Dressing Abroad, 2004, 41(1): 8-12+7. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200401001.htm

-

下载:

下载: