Progress in Flotation Technology of Copper Oxide Ore

-

摘要:

随着易开采硫化铜矿资源的日益减少,氧化铜矿资源的回收利用成为了选矿的热点,本文总结了氧化铜矿的性质、选别难点、直接浮选技术和硫化浮选技术中浮选药剂与氧化铜矿的作用机理及其药剂研究进展,同时还评述了不同类型氧化铜矿浮选技术研究进展。

Abstract:With the decrease of easy−to−mine copper sulfide resources, the recovery and utilization of copper oxide resources have become a hot spot in mineral processing. This paper summarizes the properties of copper oxide ore, the difficulties in separation, the interaction mechanisms between flotation agents and copper oxide in both direct flotation technology and sulfuration flotation technology, and the advancements in reagent types. At the same time, the research progress in flotation technology for various types of copper oxide ore is also reviewed.

-

Key words:

- copper oxide ore /

- flotation reagents /

- flotation

-

-

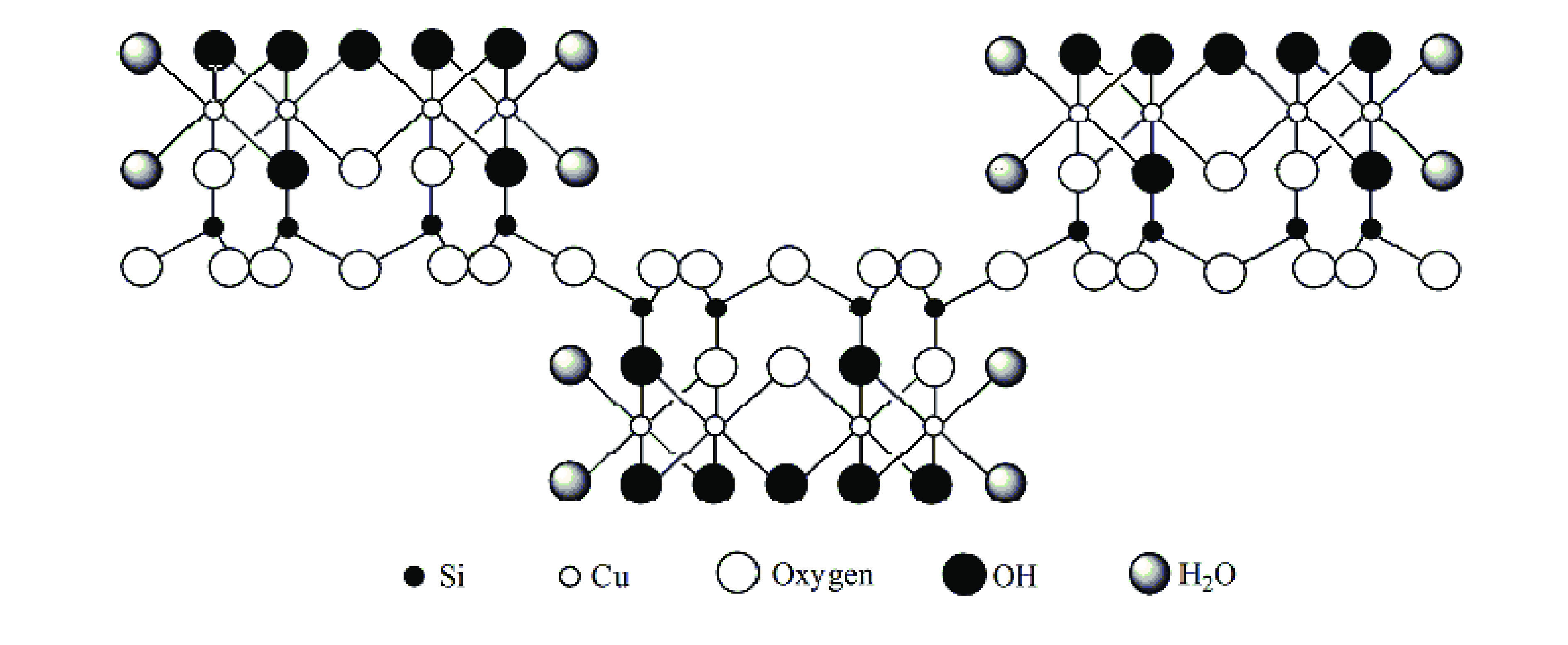

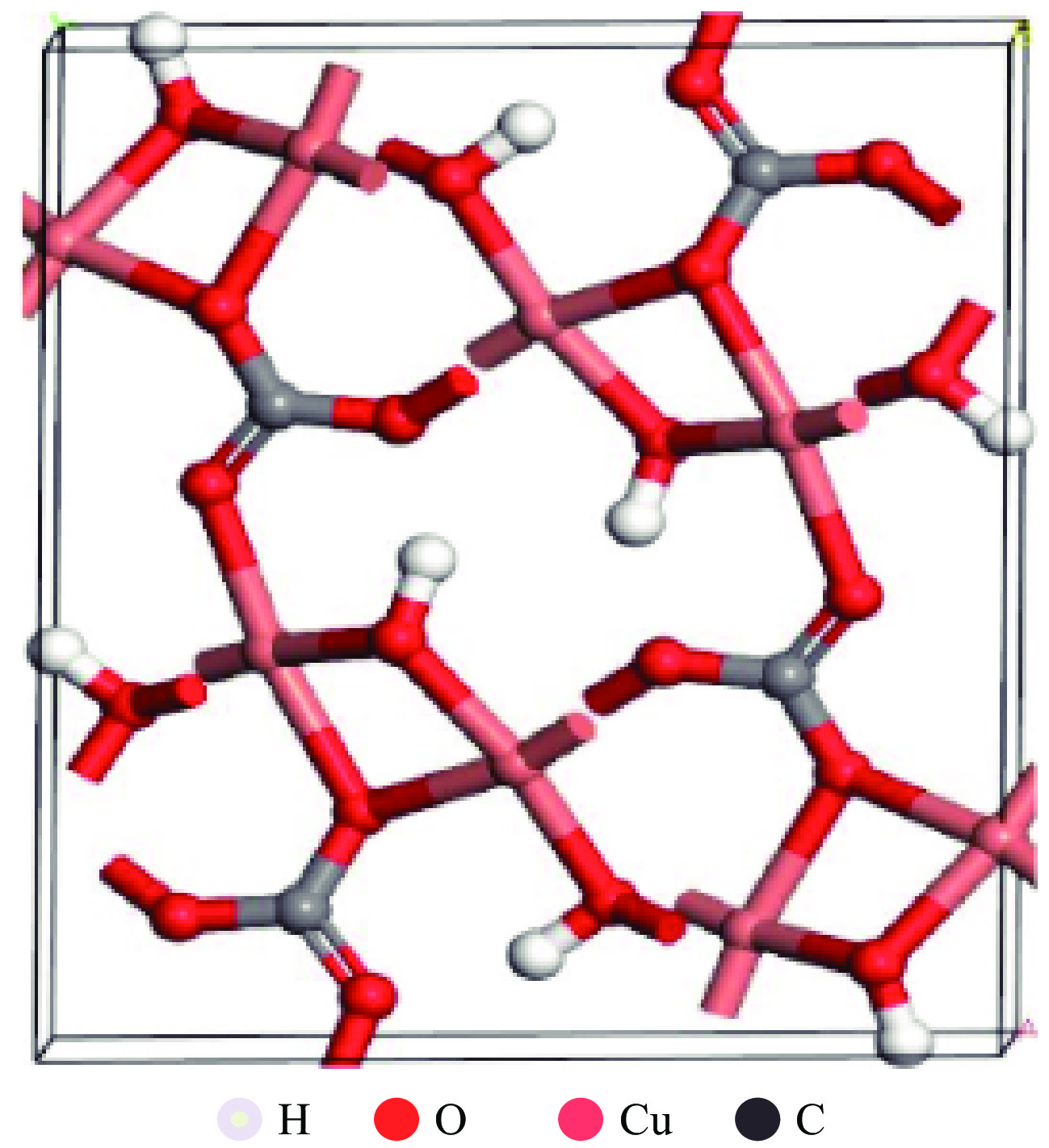

图 1 孔雀石的晶体结构[10]

Figure 1.

图 2 硅孔雀石的晶体结构示意图[12]

Figure 2.

-

[1] 李江丽. 蓝铜矿铵盐强化硫化浮选的机理初探[D]. 昆明: 昆明理工大学, 2021.

LI J L. Preliminary study on mechanism of azurite ammonium salt enhanced vulcanization flotation [D]. Kunming: Kunming University of Science and Technology, 2021.

[2] U. S. Geological Survey. Mineral commodity summaries 2022[R]. 2022.

[3] 韦华祖. 孔雀石硫化焙烧−浮选的研究[J]. 湖南有色金属, 1988(4): 31−34.

WEI H Z. Study on curing roasting−flotation of Malachite[J]. Hu’nan Nonferrous Metals, 1988(4): 31−34.

[4] 柳晓蒙, 王鹤强. 西藏某复杂难选氧化铜矿选矿试验研究[J]. 世界有色金属, 2018(4): 56+58.

LIU X M, WANG H Q. Experimental study on beneficiation of a complex refractory copper oxide in Xizang[J]. World Nonferrous Metals, 2018(4): 56+58.

[5] 鲍磊, 刘学勇. 氧化铜矿石浮选捕收剂的研究进展[J]. 矿业工程, 2011, 9(4): 36−37.

BAO L, LIU X Y. Research progress of flotation collector for copper oxide ore[J]. Mining Engineering, 2011, 9(4): 36−37.

[6] BILAL M, PARK I, HORNN V, et al. The challenges and prospects of recovering fine copper sulfides from tailings using different flotation techniques: a review[J]. Minerals, 2022, 12(5): 586. doi: 10.3390/min12050586

[7] LIN S W, ZHI Y G, HONG H T, et al. Copper recovery from copper slags through flotation enhanced by sodium carbonate synergistic mechanical activation[J]. Journal of Environmental Chemical Engineering, 2022, 10(3): 107671. doi: 10.1016/j.jece.2022.107671

[8] 蔺月萌, 韩百岁, 姜丽帅, 等. 氧化铜矿浮选方法及药剂的研究现状及展望[J/OL].矿产综合利用1-10[2023-11-07]. http://kns.cnki.net/kcms/detail/51.1251.td.20230707.1641.004.html.

LIN Y M, HAN B S, JIANG L S, et al. Research status and prospect of flotation methods and reagents of copper oxide[J/OL].矿产综合利用1-10[2023-11-07]. http://kns.cnki.net/kcms/detail/51.1251.td.20230707.1641.004.html.

[9] 孙乾予. 铜矿物的晶体化学基因特征及浮选机理研究[D]. 沈阳: 东北大学矿物加工工程, 2019.

SUN Q Y. Study on crystal chemical gene characteristics and flotation mechanism of copper ores[D]. Shenyang: Mineral Processing Engineering of Northeastern University, 2019.

[10] 孙鑫. 羟肟酸捕收剂的合成及其对孔雀石浮选性能研究[D]. 昆明: 昆明理工大学, 2022.

SUN X. Synthesis of hydroxamic acid collector and its performance for malachite flotation[D]. Kunming: Kunming University of Science and Technology, 2022.

[11] SHENGO L M, GAYDARDZHIEV S, KALENGA N M. Assessment of water quality effects on flotation of copper–cobalt oxide ore[J]. Minerals engineering, 2014, 65: 145−148. doi: 10.1016/j.mineng.2014.06.005

[12] 张琳. 胺(铵)盐强化硫化硅孔雀石的浮选机理研究[D]. 昆明: 昆明理工大学, 2018.

ZHANG L. Research on flotation mechanism of ammonium salt enhanced silicon malachite sulfide [D]. Kunming: Kunming University of Science and Technology, 2018.

[13] 王美丽, 丰奇成, 王涵. 氧化铜矿选冶研究现状及展望[J]. 矿产综合利用, 2021(4): 103−109+138.

WANG M L, FENG Q C, W H. Research status and prospect of copper oxide smelting[J]. Comprehensive Utilization of Mineral Resources, 2021(4): 103−109+138.

[14] 蒋太国, 方建军, 张铁民, 等. 氧化铜矿选矿技术研究进展[J]. 矿产保护与利用, 2014(2): 49−53.

JIANG T G, FANG J J, ZHANG T M, et al. Research progress on beneficiation technology of copper oxide[J]. Conservation and Utilization of Mineral Resources, 2014(2): 49−53.

[15] 陈建华, 朱阳戈. 硫化矿物表面水化层结构及其对药剂作用的影响[J]. 矿产保护与利用, 2018(3): 1−8.

CHEN J H, ZHU Y G. The surface hydration layer structure of sulfide minerals and its influence on the action of chemicals[J]. Conservation and Utilization of Mineral Resources, 2018(3): 1−8.

[16] 毕克俊, 魏志聪, 蒋太国, 等. 氧化铜矿石浮选活化剂的研究进展[J]. 矿产保护与利用, 2015(5): 74−78.

BI K J, WEI Z C, JIANG T G, et al. Research progress of flotation activators for copper oxide ores[J]. Conservation and Utilization of Mineral Resources, 2015(5): 74−78.

[17] LIU C, ZHU G, SONG S, et al. Interaction of gangue minerals with malachite and implications for the sulfidization flotation of malachite[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2018, 555: 679−684. doi: 10.1016/j.colsurfa.2018.07.045

[18] LIU C, SONG S, LI H, et al. Elimination of the adverse effect of calcite slimes on the sulfidization flotation of malachite in the presence of water glass[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2019, 563: 324−329. doi: 10.1016/j.colsurfa.2018.12.022

[19] 白旭. 赞比亚穆利亚希复杂混合铜矿选冶联合回收新工艺及浸出机理研究[D]. 昆明: 昆明理工大学, 2019.

BAI X. Study on new process and leaching mechanism of combined recovery of Mulyashi complex mixed copper mine in Zambia [D]. Kunming: Kunming University of Science and Technology, 2019.

[20] 申培伦, 刘瑞增, 赖浩, 等. 氧化铜矿浮选基础理论研究新进展[J]. 中国矿业大学学报, 2022, 51(3): 591−598.

SHEN P L, LIU R Z, LAI H, et al. New progress in basic theory research of copper oxide flotation [J]. Journal of China University of Mining and Technology, 202, 51(3): 591−598. (in Chinese)

[21] ZHI L L, FENG R, RAMIRO E G, et al. Partial replacement of sodium oleate using alcohols with different chain structures in malachite flotation[J]. Minerals Engineering, 2018, 127.

[22] XU H, ZHONG H, WANG S, et al. Synthesis of 2−ethyl−2−hexenal oxime and its flotation performance for copper ore[J]. Minerals Engineering, 2014, 66/67/68: 173−180. doi: 10.1016/j.mineng.2014.06.011

[23] HOPE G A, BUCKLEY A N, PARKER G K, et al. The interaction of n−octanohydroxamate with chrysocolla and oxide copper surfaces[J]. Minerals Engineering, 2012, 36/37/38: 2−11. doi: 10.1016/j.mineng.2012.01.013

[24] QIN J, LIU G, FAN H, et al. The hydrophobic mechanism of di(2−ethylhexyl) phosphoric acid to hemimorphite flotation[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2018, 545: 68−77.

[25] 武薇, 童雄. 氧化铜矿的浮选及研究进展[J]. 矿冶, 2011, 20(2): 5−9.

WU W, TONG X. Flotation and research progress of copper oxide[J]. Mining and Metallurgy, 2011, 20(2): 5−9.

[26] 夏节, 刘丹, 郭志强, 等. 硅孔雀石的结构与表面特性及浮选研究现状[J]. 硅酸盐通报, 2018, 37(2): 496−500,507.

XIA J, LIU D, GUO Z Q, et al. Structure, surface properties and flotation status of silico−malachite[J]. Bulletin of Silicate, 2018, 37(2): 496−500,507.

[27] 孙乾予, 印万忠, 曹少航, 等. 油酸钠直接浮选孔雀石的机理研究[J]. 东北大学学报(自然科学版), 2017, 38(5): 716−719+724.

SUN Q Y, YIN W Z, CAO S H, et al. Study on mechanism of direct flotation of malachite by sodium oleate[J]. Journal of Northeastern University (Natural Science Edition), 2017, 38(5): 716−719+724.

[28] 卫召, 孙伟, 韩海生, 等. 铅离子−苯甲羟肟酸配合物捕收剂(Pb−BHA)的单晶结构分析[J]. 中国有色金属学报, 2023: 1−18.

WEI Z, SUN W, HAN H S, et al. Analysis of single crystal Structure of Lead ion−benzohydroxamic acid complex collector (Pb−BHA) [J]. Chinese Journal of Nonferrous Metals, 2023: 1−18.

[29] 贾音. 选矿用捕收剂中苯甲羟肟酸含量测定[J]. 轻金属, 2019(11): 22−24.

JIA Y. Determination of benzohydroxamic acid content in collector for beneficiation[J]. Light Metals, 2019(11): 22−24.

[30] 刘明宝, 鱼博, 强旭旭, 等. 水杨羟肟酸在钛铁矿表面的吸附特性研究[J]. 表面技术, 2018, 47(4): 236−242.

LIU MI B, YU B, QIANG X X, et al. Study on adsorption properties of salicylhydroxamic acid on the surface of ilmenite[J]. Surface Technology, 2018, 47(4): 236−242.

[31] 黄伟秦, 顾帼华, 王艳红, 等. 含水杨羟肟酸捕收剂废水对铅锑锌硫化矿浮选行为的影响[J]. 矿冶工程, 2021, 41(6): 16−20.

HUANG W Q, GU G H, WANG Y H, et al. Effect of wastewater containing salicylhydroxamic acid collector on flotation behavior of lead−antimony−zinc sulfide ore[J]. Mining and Metallurgy Engineering, 201, 41(6): 16−20. (in Chinese)

[32] WAN Z Y, QIAN Y S, DONG L I, et al. Mechanism and application on sulphidizing flotation of copper oxide with combined collectors[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(1).

[33] LI Z, RAO F, SONG S, et al. Effects of common ions on adsorption and flotation of malachite with salicylaldoxime[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2019, 577: 421−428. doi: 10.1016/j.colsurfa.2019.06.004

[34] 荣洋, 卢宇熙, 王帅, 等. N−酰基苯胲的合成及其对孔雀石浮选性能[J]. 矿产保护与利用, 2019, 39(4): 109−114.

RONG Y, LU Y X, WANG S, et al. Synthesis of N−acylbenzene hydroxylamine and its performance for malachite flotation[J]. Conservation and Utilization of Mineral Resources, 2019, 39(4): 109−114.

[35] 孙鑫, 黄凌云, 胡博, 等. 新型羟肟酸捕收剂的合成及其对孔雀石的捕收机理研究[J]. 矿产保护与利用, 2022, 42(1): 52−60.

SUN X, HUANG L Y, HU B, et al. Synthesis of a new hydroxamic acid collector and its mechanism for malachite collection[J]. Conservation and Utilization of Mineral Resources, 202, 42(1): 52−60.

[36] 余新阳, 钟宏, 刘广义. 阳离子反浮选脱硅捕收剂研究现状[J]. 轻金属, 2008(6): 6−10.

YU X Y, ZHONG H, LIU G Y. Research status of cationic reverse flotation desilication collector[J]. Light Metals, 2008(6): 6−10.

[37] 周永锋, 罗溪梅, 宋水祥, 等. 四种阳离子捕收剂对赤铁矿和石英浮选行为的影响[J]. 矿产保护与利用, 2020, 40(2): 56−61.

ZHOU Y F, LUO X M, SONG S X, et al. Effects of four cationic collectors on flotation behavior of hematite and quartz[J]. Conservation and Utilization of Mineral Resources, 2020, 40(2): 56−61.

[38] 佟柯霖, 刘文宝, 刘文刚, 等. 季铵化对阳离子捕收剂N, N−十二烷基二乙醇胺性能的影响研究[J]. 金属矿山, 2021(12): 28−33.

TONG K L, LIU W B, LIU W G, et al. Effects of quaternization on properties of cationic collector N, N−dodecyl diethanolamine[J]. Metal Mines, 2021(12): 28−33.

[39] 李光音. 硅酸盐矿物浮选过程中胺类捕收剂捕收性能的量子化学分析研究[D]. 郑州: 郑州大学, 2018.

LI G Y. Quantum Chemical analysis of the collecting performance of amine collectors in silicate mineral flotation[D]. Zhengzhou: Zhengzhou University, 2018.

[40] 郭志强. 桥联改性活化浮选硅孔雀石研究[D]. 昆明: 昆明理工大学, 2019.

GUO Z Q. Research on floatation of silicon malachite by modified activation by bridge[D]. Kunming: Kunming University of Science and Technology, 2019.

[41] CHEN L, XIAO J, RUAN K, et al. Homogeneous solutions of equimolar mixed cationic−anionic surfactants[J]. Langmuir, 2002, 18(20): 7250−7252. doi: 10.1021/la025878d

[42] 徐龙华, 田佳, 巫侯琴, 等. 组合捕收剂在矿物表面的协同效应及其浮选应用综述[J]. 矿产保护与利用, 2017(2): 107−112.

XU L H, TIAN J, WU H Q, et al. Review on synergistic effects of combined collectors on mineral surfaces and their flotation applications[J]. Conservation and Utilization of Mineral Resources, 2017(2): 107−112.

[43] 杨虎. 硫化钠强化回收次生斑铜矿的浮选试验及作用机理研究[D]. 昆明: 昆明理工大学, 2022.

YANG H. Study on flotation test and mechanism of sodium sulfide Enhanced recovery of secondary bornite[D]. Kunming: Kunming University of Science and Technology, 2022.

[44] TIJSSELING L T, DEHAINE Q, ROLLINSON G K, et al. Flotation of mixed oxide sulphide copper−cobalt minerals using xanthate, dithiophosphate, thiocarbamate and blended collectors[J]. Minerals Engineering, 2019, 138: 246−256. doi: 10.1016/j.mineng.2019.04.022

[45] LI F, ZHONG H, XU H, et al. Flotation behavior and adsorption mechanism of α−hydroxyoctyl phosphinic acid to malachite[J]. Minerals Engineering, 2015, 71: 188−193. doi: 10.1016/j.mineng.2014.11.013

[46] 陈代雄, 严宇扬, 肖骏, 等. 苯甲羟肟酸和丁基黄药协同浮选氧化铜矿石试验[J]. 现代矿业, 2015(8): 70−73.

CHEN D X, YAN Y Y, XIAO J, et al. Experimental study on synergistic flotation of copper oxide ores by benzohydroxamic acid and butyl xanthoxanthate[J]. Modern Mining, 2015(8): 70−73.

[47] 马英强, 李诗澜, 宋振国, 等. 异戊基黄药与水杨羟肟酸对硅孔雀石硫化浮选行为的影响[J]. 金属矿山, 2023(4): 117−123.

MA Y Q, LI S L, SONG Z G et al. Effect of isoamyl xanthoxanthate and salicylhydroxamic acid on vulcanization flotation behavior of silicachalite[J]. Metal Mine, 2023(4): 117−123.

[48] K. L, D. A, J. M, et al. Flotation of mixed copper oxide and sulphide minerals with xanthate and hydroxamate collectors[J]. Minerals Engineering, 2008, 22(4).

[49] 韩广. 赤铜矿预氧化−强化硫化黄药浮选试验与理论研究[D]. 昆明: 昆明理工大学, 2022.

HAN G. Test and theoretical study on pre−oxidation and enhanced vulcanization xanthate flotation of copper ore[D]. Kunming: Kunming University of Science and Technology, 2022.

[50] CO K C, KA M, O CONNOR C T, et al. The recovery of oxide copper minerals from a complex copper ore by sulphidisation[J]. Minerals Engineering, 2017, 102: 15−17. doi: 10.1016/j.mineng.2016.11.011

[51] 任大伟. 细粒氧化蓝辉铜矿选择性聚团浮选研究[D]. 西安: 西安建筑科技大学, 2022.

REN D W. Study on selective agglomeration flotation of Fine oxidized bluechene[D]. Xi 'an: Xi 'an University of Architecture and Technology, 2022.

[52] KONGOLO K, KIPOKA M, MINANGA K, et al. Improving the efficiency of oxide copper−cobalt ores flotation by combination of sulphidisers[J]. Minerals Engineering, 2003, 16(10): 1023−1026. doi: 10.1016/S0892-6875(03)00263-2

[53] PARK K, PARK S, CHOI J, et al. Influence of excess sulfide ions on the malachite−bubble interaction in the presence of thiol−collector[J]. Separation and Purification Technology, 2016, 168: 1−7. doi: 10.1016/j.seppur.2016.04.053

[54] 李佳磊. 孔雀石浮选中的硫化及其铵盐强化机制探究[D]. 昆明: 昆明理工大学, 2019.

LI J L. Vulcanization in Malachite flotation and its strengthening mechanism of ammonium salt[D]. Kunming: Kunming University of Science and Technology, 2019.

[55] JUN W H, JUN X, WEN Q Q, et al. Copper recovery from yulong complex copper oxide ore by flotation and magnetic separation[J]. JOM, 2017, 69(9).

[56] 李佳, 马英强, 周璞燏, 等. 孔雀石分段硫化浮选行为及动力学基因特性研究[J]. 金属矿山, 2020(6): 114−121.

LI J, MA Y Q, ZHOU P J, et al. Study on the behavior and dynamic gene characteristics of malachite flotation by stage curing[J]. Metal Mine, 2020(6): 114−121.

[57] 冯宇博, 梁欢, 张汉泉, 等. 云南某混合型低品位铜尾矿浮选工艺试验研究[J]. 有色金属(选矿部分), 2022(6): 56−64.

FENG Y B, LIANG H, ZHANG H Q, et al. Experimental study on flotation process of a mixed low−grade copper tailings in Yunnan[J]. Nonferrous Metals (Mineral Processing Section), 2022(6): 56−64.

[58] 别雪祥. 江西某混合铜矿选矿试验研究[D]. 武汉: 武汉理工大学, 2018.

DON X X. Experimental research on beneficiation of a mixed copper mine in Jiangxi [D]. Wuhan: Wuhan University of Technology, 2018.

[59] 毛莹博. 铵—胺盐强化硫化孔雀石浮选理论与试验研究[D]. 昆明: 昆明理工大学, 2016.

MAO Y B. Theoretical and experimental research on flotation of sulphurized malachite enhanced by ammonium−amine salt[D]. Kunming: Kunming University of Science and Technology, 2016.

[60] 胡本福. 微细粒孔雀石硫化—浮选的强化研究[D]. 长沙: 中南大学, 2011.

HU B F. Research on strengthening vulcanization−flotation of Fine malachite[D]. Changsha: Central South University, 2011.

[61] SHEN P, LIU D, ZHANG X, et al. Effect of (NH4)2SO4 on eliminating the depression of excess sulfide ions in the sulfidization flotation of malachite[J]. Minerals Engineering, 2019, 137: 43−52. doi: 10.1016/j.mineng.2019.03.015

[62] 李飞, 黄国贤, 余江鸿. 青海某氧化铜矿选矿工艺试验研究[J]. 世界有色金属, 2022(5): 34−36.

LI F, HUANG G X, YU J H. Experimental study on beneficiation process of a copper oxide in Qinghai[J]. World Nonferrous Metals, 2022(5): 34−36.

[63] 刘国晨. 旋流器脱泥提升某氧化铜矿浮选指标的工业试验研究[J]. 矿冶工程, 2019, 43(3): 89−92.

LIU G C. Industrial test study on improving flotation index of copper oxide by cyclone desliming[J]. Mining and Metallurgy Engineering, 2019, 43(3): 89−92.

[64] 许汉丰. 新疆沟口泉铁矿选择性絮凝脱泥分选试验研究[D]. 沈阳: 东北大学, 2015.

XU H F. Experimental Study on selective flocculation and desliming separation of Goukouquan Iron Ore in Xinjiang [D]. Shenyang: Northeastern University, 2015.

[65] 汤雁斌. B−130在铜绿山矿难选氧化铜矿选矿中的应用[J]. 四川有色金属, 2005(2): 1−3.

TANG Y B. Application of B−130 in beneficiation of refractory copper oxide in Tonglushan Mine[J]. Sichuan Nonferrous Metals, 2005(2): 1−3.

[66] 孔胜武. 某高含泥氧化铜矿石的可选性探讨[J]. 有色金属(选矿部分), 2002(4): 1−3.

KONG S W. Study on the beneficiability of a copper oxide ore with high mud content[J]. Nonferrous Metals (Mineral Processing Section), 2002(4): 1−3.

[67] 费九光, 王庆久. 内蒙古难选氧化铜矿浮选工艺的研究[J]. 有色矿冶, 2000(1): 16−19.

FEI J G, WANG Q J. Study on flotation process of refractory oxidized copper ore in Inner Mongolia[J]. Nonferrous Metals and Metallurgy, 2000(1): 16−19.

[68] 徐晓衣, 俞献林, 杨招君, 等. 新疆某低品位难选氧化铜矿选矿试验研究[J]. 矿冶工程, 2019, 39(6): 39−42.

[69] 王毓华, 钟宏, 冯其明. 组合捕收剂浮选低氧化率混合铜矿石试验研究[J]. 矿冶工程, 2001(3): 53−55.

WANG Y H, ZHONG H, FENG Q M. Experimental study on flotation of mixed copper ore with low oxidation rate by combined collector[J]. Mining and Metallurgy Engineering, 2001(3): 53−55.

[70] 金万超. 高铁细粒氧化铜高效回收选矿工艺研究与开发[D]. 昆明: 昆明理工大学, 2014.

JIN W C. Research and development of high efficiency recovery and beneficiation process of high iron fine copper oxide [D]. Kunming: Kunming University of Science and Technology, 2014.

[71] YAO G H, GUANG Y L, JUN L, et al. Thiadiazole−thione surfactants: Preparation, flotation performance and adsorption mechanism to malachite[J]. Journal of Industrial and Engineering Chemistry, 2018, 67.

[72] 路亮, 张行荣, 朱阳戈, 等. 一种新型氧化铜矿捕收剂及其浮选性能研究[J]. 有色金属(选矿部分), 2019(5): 119−124.

LU L, ZHANG X R, ZHU Y G, et al. A new type of copper oxide collector and its flotation performance[J]. Nonferrous Metals (Mineral Processing Section), 2019(5): 119−124.

[73] 童友焜. 云南永平水泄瓦场氧化铜矿选矿试验研究[J]. 福建地质, 2016, 35(1): 78−83.

TONG Y K. Experimental study on beneficiation of copper oxide in Yongping Shuigou Tile Field, Yunnan Province[J]. Fujian Geology, 2016, 35(1): 78−83.

[74] CAO Z F, ZHONG H, LIU G Y, et al. Techniques of copper recovery from Mexican copper oxide ore[J]. Mining Science and Technology (China), 2008, 19(1).

[75] 王杰. 方解石晶体结构及表面吸附浮选药剂的第一性原理研究[D]. 贵阳: 贵州大学, 2016.

WANG J. Study on the first principles of calcite crystal structure and surface adsorption flotation agents [D]. Guiyang: Guizhou University, 2016.

[76] 黄彦龙, 柏少军, 文书明, 等. 云南某难选氧硫混合铜矿石的选矿试验研究[J]. 矿产综合利用, 2012(3): 18−22.

HUANG Y L, BAI S J, SHU M, et al. Experimental study on beneficiation of a refractory oxy−sulfur mixed copper ore in Yunnan[J]. Comprehensive Utilization of Mineral Resources, 2012(3): 18−22.

[77] 吕梦阳, 文书明, 刘建, 等. 云南楚雄难处理氧化铜矿酸浸试验研究[J]. 矿产综合利用, 2012(2): 21−23,39. doi: 10.3969/j.issn.1000-6532.2012.02.006

LV M Y, WEN S M, LIU J, et al. Experimental study on acid leaching of refractory oxidized copper ore in Chuxiong, Yunnan[J]. Comprehensive Utilization of Minerals, 2012(2): 21−23,39. doi: 10.3969/j.issn.1000-6532.2012.02.006

[78] 西安建筑科技大学. 一种低品位混合氧化铜矿石的选矿方法: CN202110929483.3[P]. 2021−11−12.

Xi 'an University of architecture and technology. beneficiation method of low grade mixed copper oxide ore : CN202110929483.3[P]. 2021−11−12

[79] 王刚, 于云龙. 国外某难选沉积岩型氧硫混合铜矿选矿工艺研究[J]. 矿冶, 2023, 32(2): 49−57.

WANG G, YU Y L. Study on beneficiation process of a refractory sedimentary rock type oxy−sulfur mixed copper mine abroad[J]. Mining and Metallurgy, 2023, 32(2): 49−57.

[80] 刘殿文, 方建军, 文书明, 等. 难处理高钙镁氧化铜矿高效选冶新技术[C]//2009年全国复杂难处理矿石选矿技术学术会议, 太原, 2009.

LIU D W, FANG J J, WEN S M, et al. New technology for efficient separation and smelting of refractory high calcium magnesia copper ore[C]//2009 National Conference on Mineral Processing Technology of Complex Refractory Ores, Taiyuan, 2009.

-

下载:

下载: