Simulation of Magnetic Field and Flow Field in an External Magnetic Drum Separator Using COMSOL Multiphysics

-

摘要:

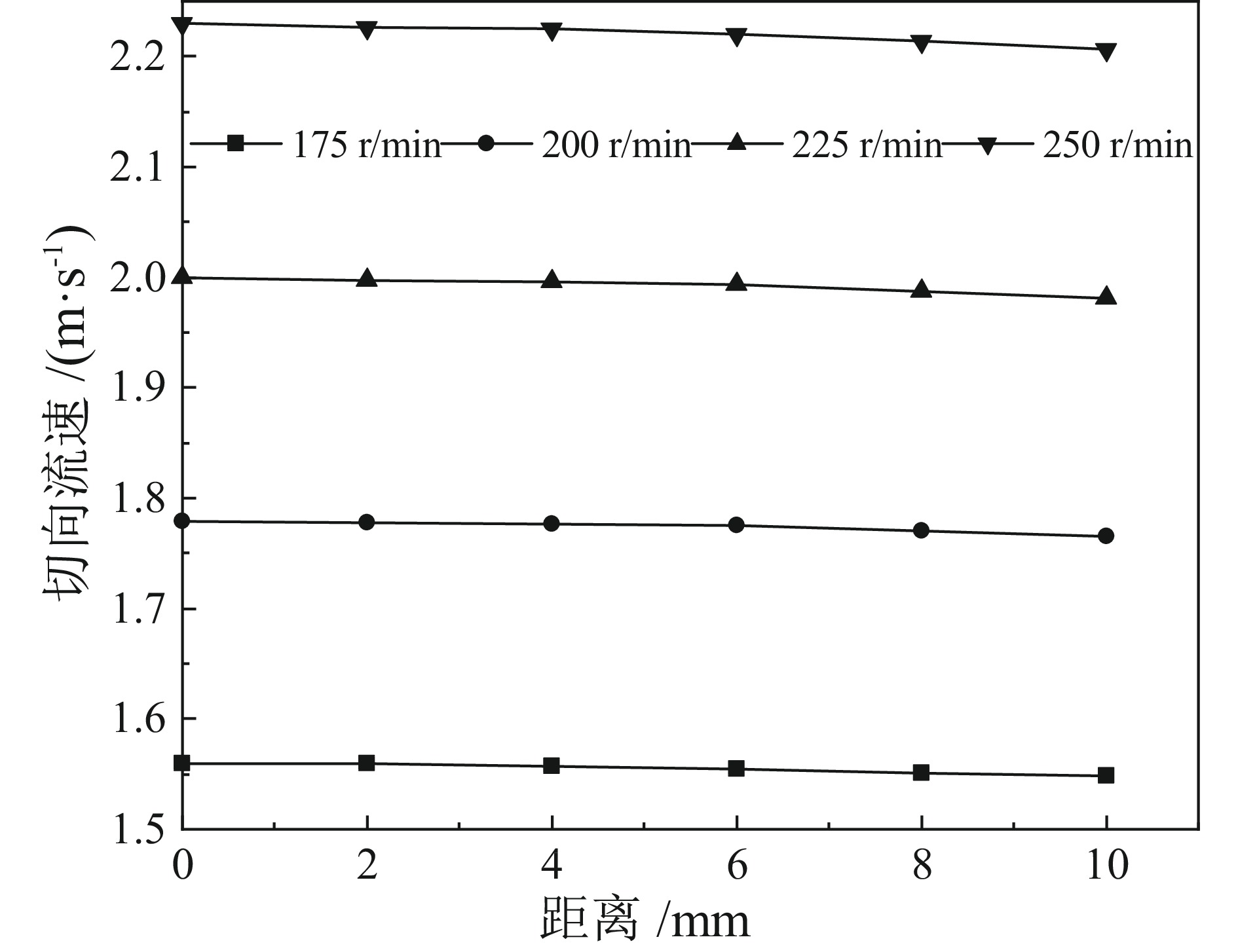

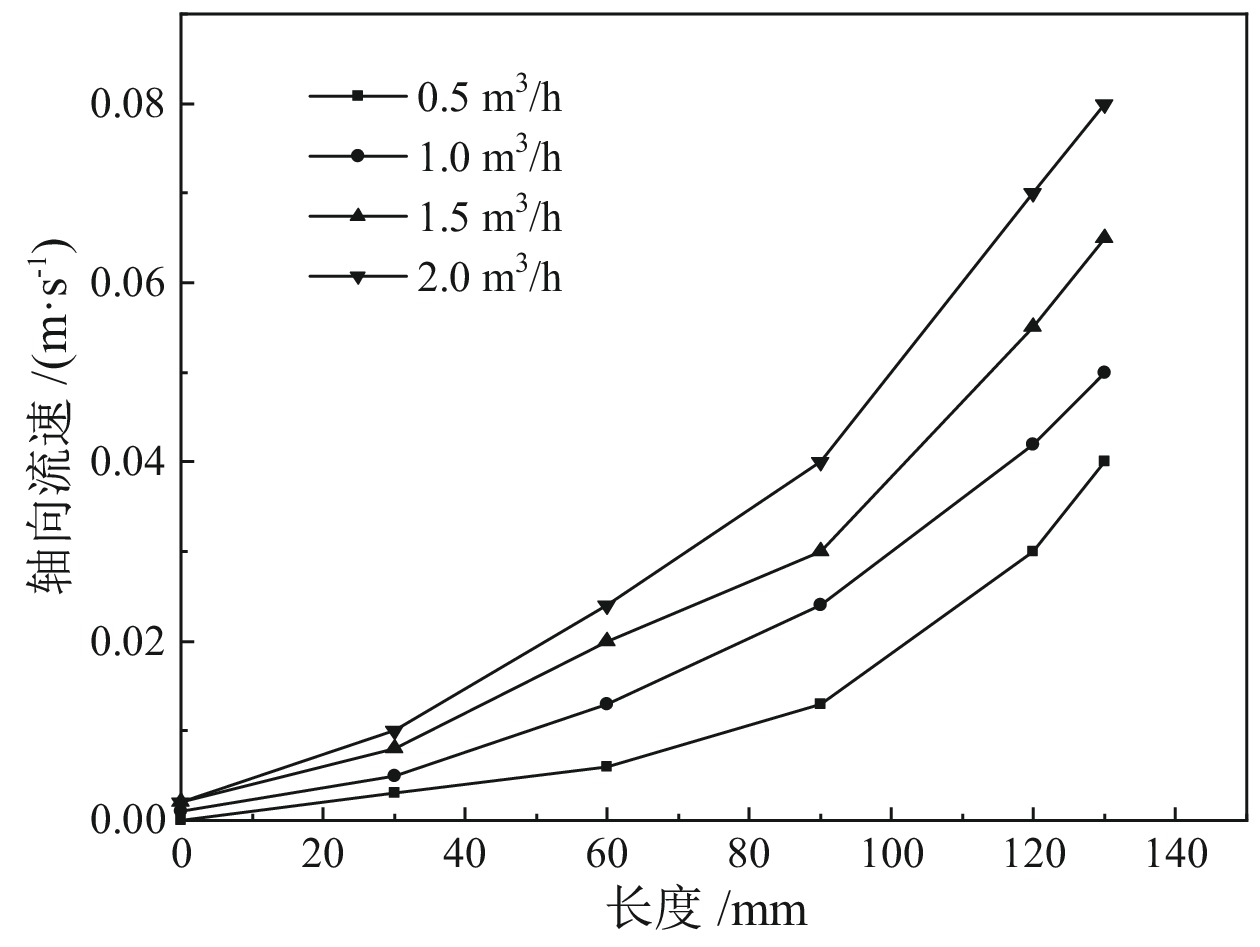

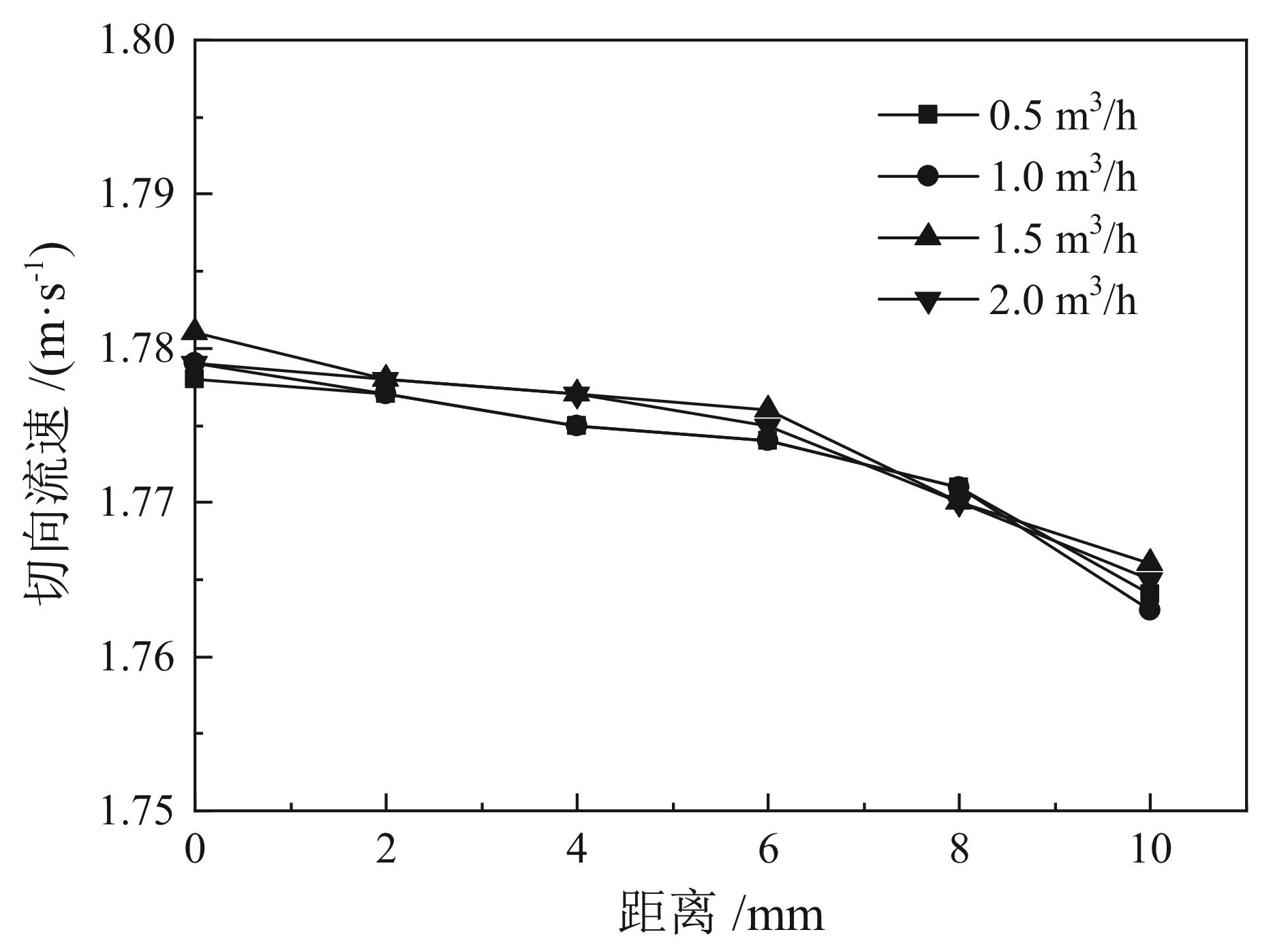

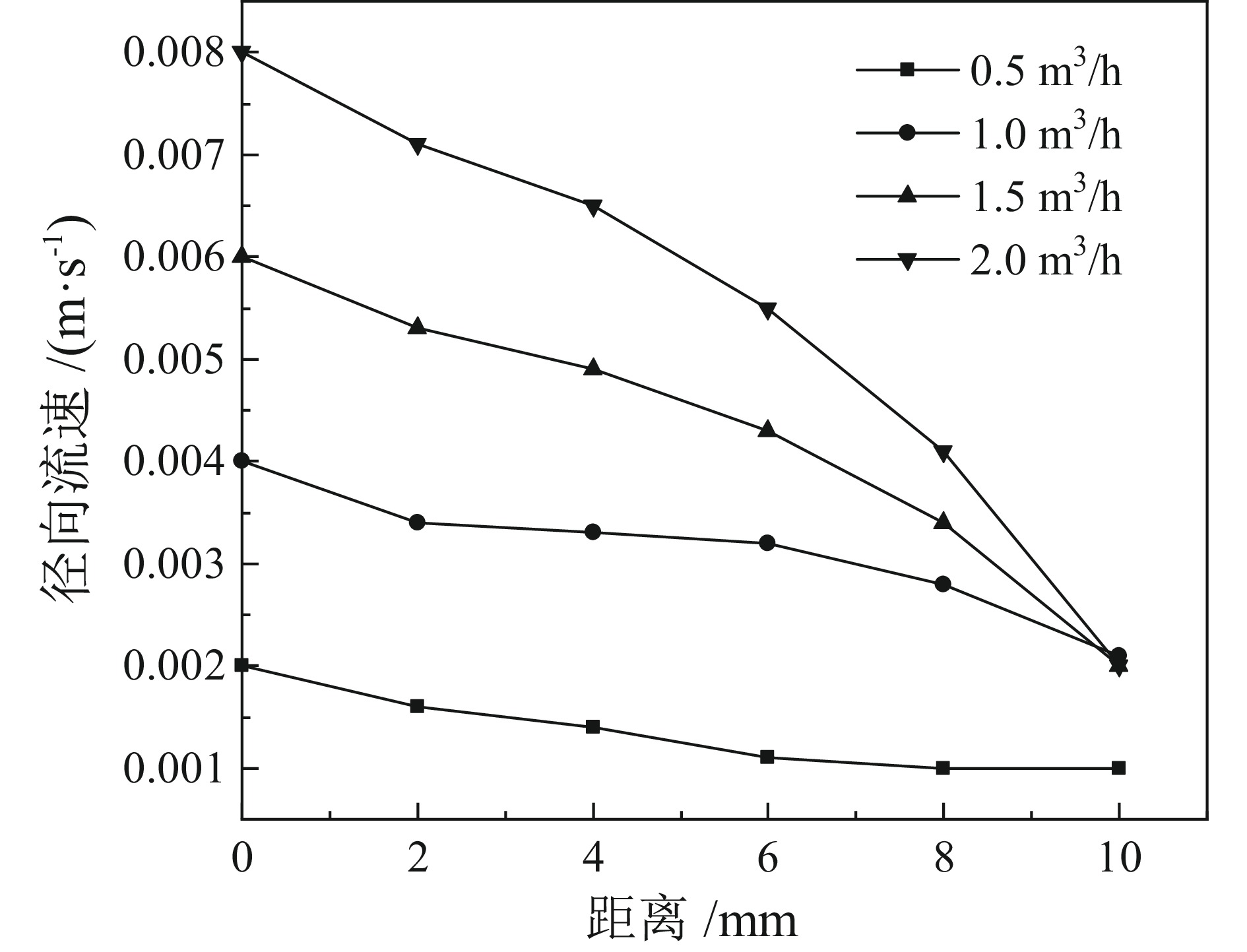

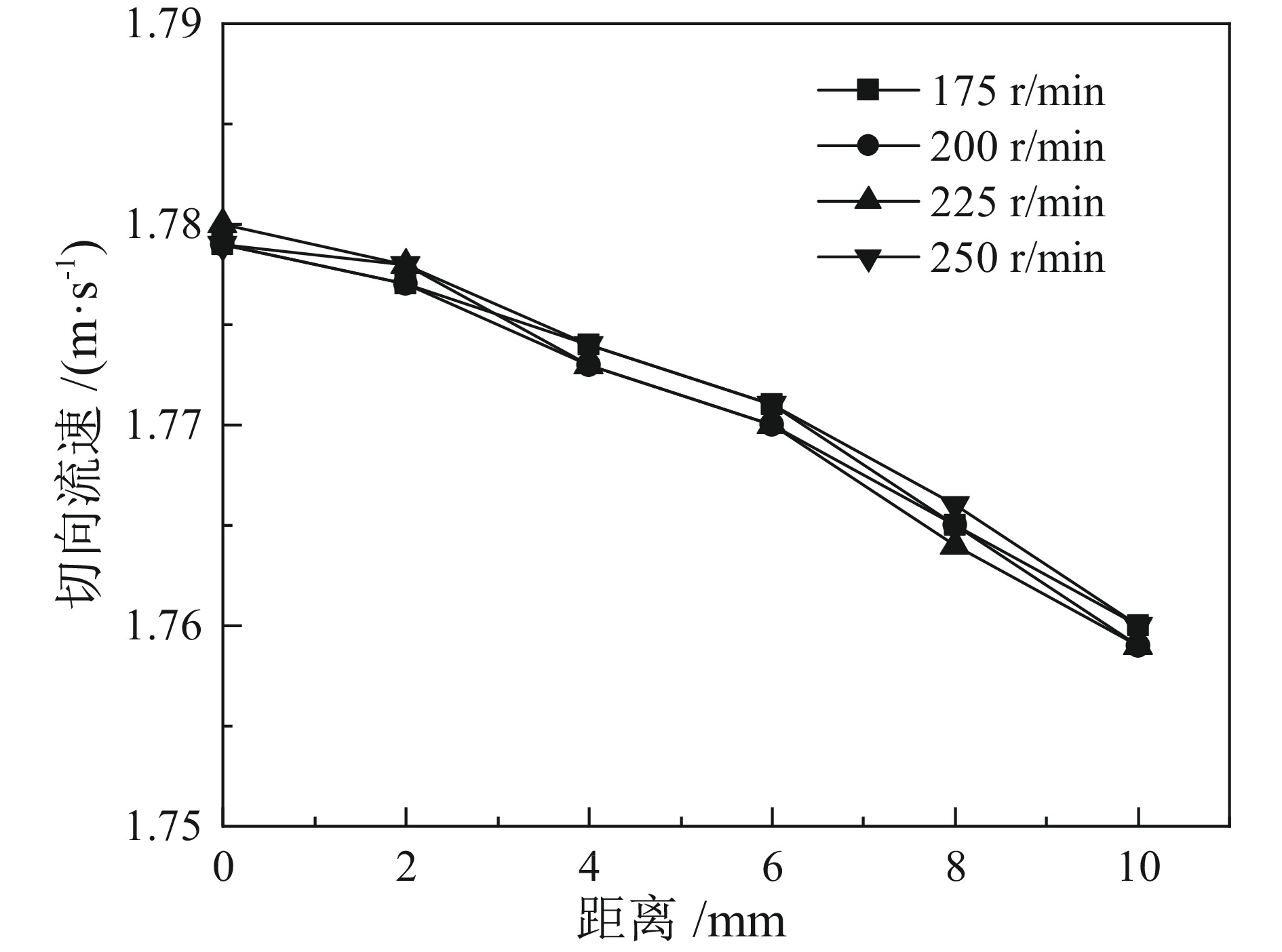

传统外磁筒式磁选机存在的离心捕收和颗粒分散之间的矛盾,导致低转速下细粒精矿流失严重,而提高转速,预选抛尾率和精矿品位均降低。为综合利用磁性矿物与脉石矿物密度和比磁化系数差异强化目的矿物的捕获,开发了一种新型外磁筒式磁选机,在筒面增加一个向心的冲洗水,以实现矿物颗粒捕收与分散的动态调控。采用COMSOL Multiphysics优化了磁系的磁感应强度、磁场梯度参数;探究了分选筒转速、进水量和筒体倾角对流场的影响,优化了流场特性。仿真结果表明:磁极的表面磁感应强度为1.8 T;磁系的磁力线集中于导磁介质处。同时,在导磁介质表面具有较大的磁场梯度(8×10−7 A/m2)且削减较少,利于磁性颗粒的捕收。本设备优势在于增加向心冲洗水,通过水速变化调节颗粒受力情况,可为永磁磁选机的优化设计提供理论依据。

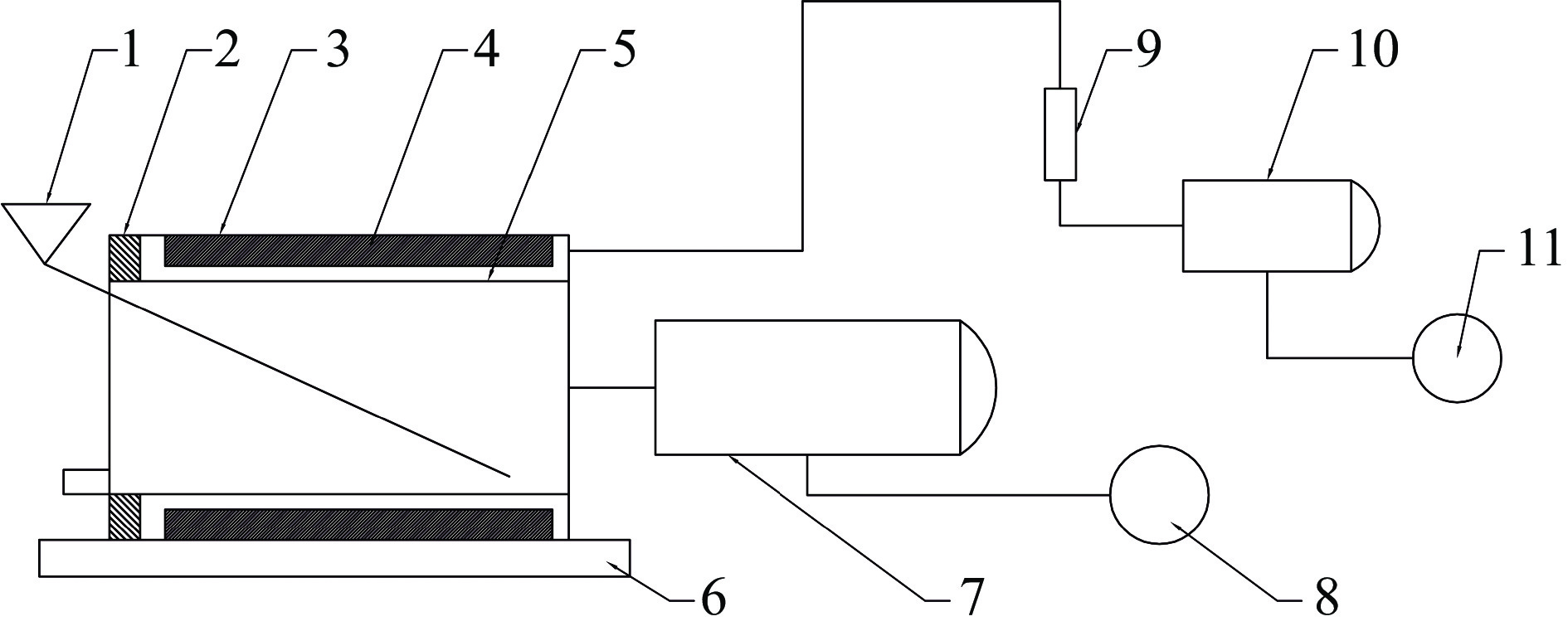

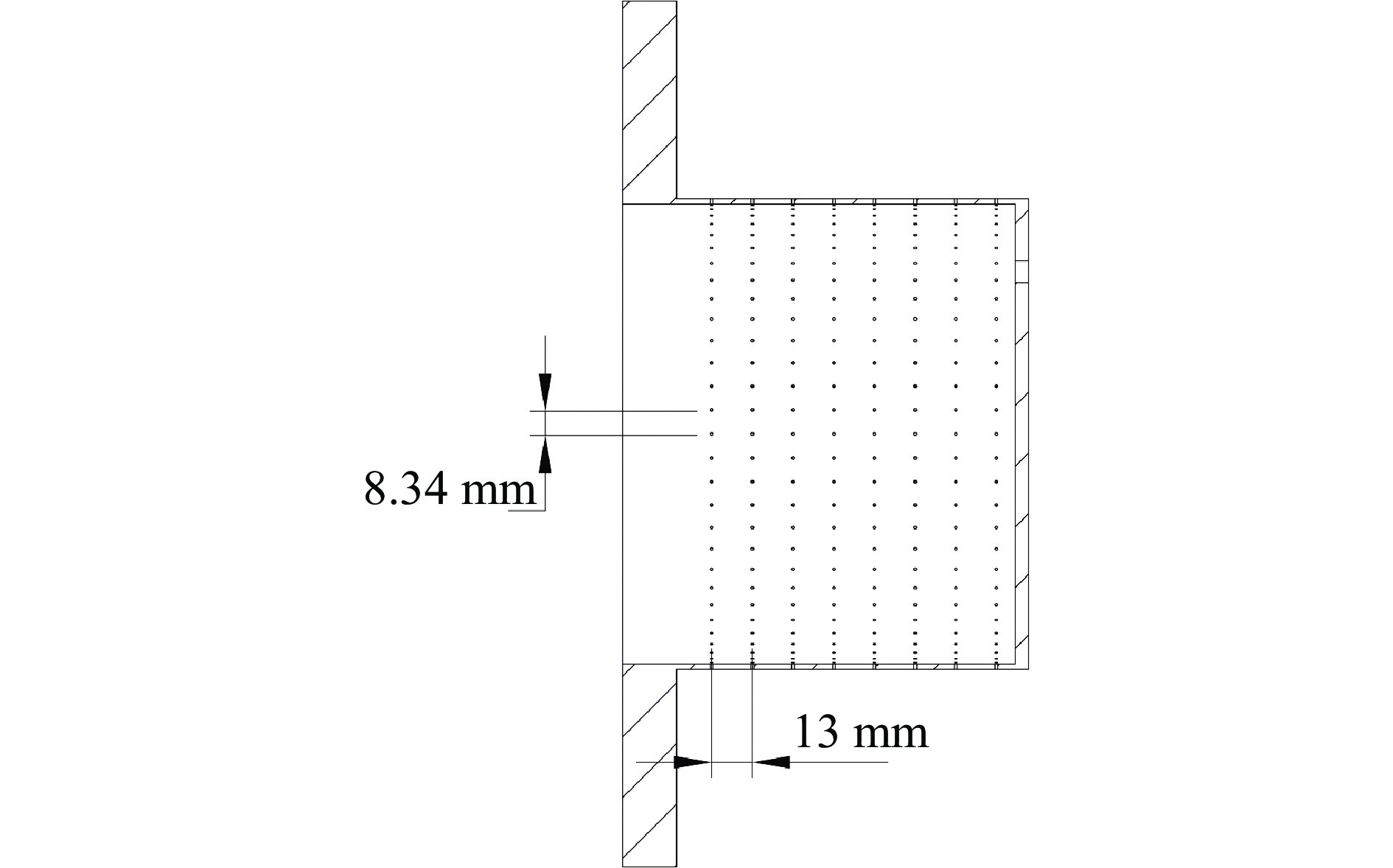

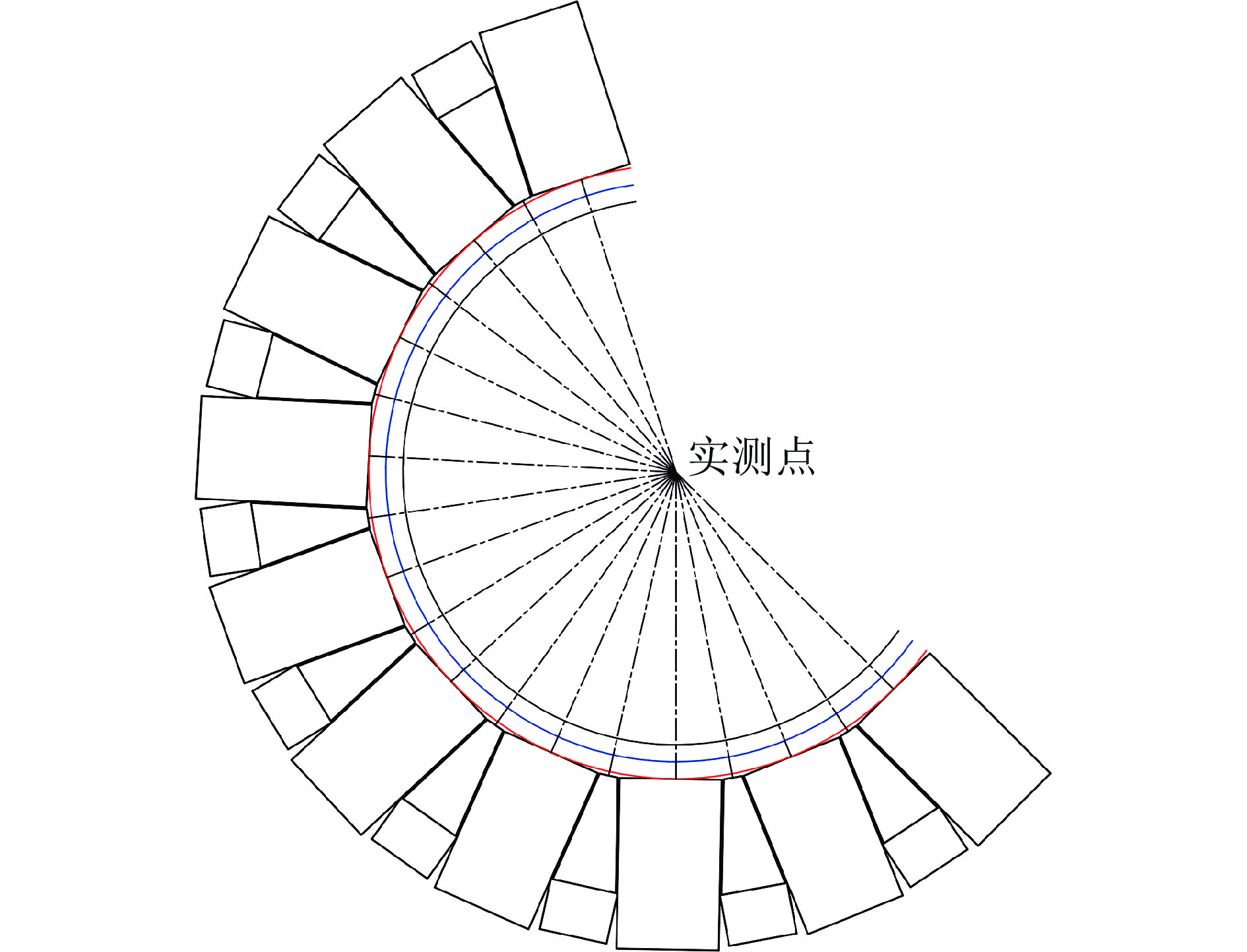

Abstract:The paradox between centrifugal capture and particle dispersion in traditional external magnetic cylinder magnetic separators led to significant losses of fine−grained concentrate at low rotational speeds, with elevated speeds diminishing both pre−selection tailing rates and concentrate grades. In response, a novel form of external magnetic cylinder magnetic separator was developed to exploit variations in density and specific magnetization coefficients between magnetic and chalcopyrite minerals, enhancing the capture of targeted minerals. Through the implementation of a centrifugal flushing water system on the cylinder's surface, a dynamic control mechanism for capturing and dispersing mineral particles has been successfully realized. COMSOL Multiphysics was used to optimize the magnetic induction intensity, magnetic field gradient parameters and the flow field characteristics of the magnetic system. The effects of sorting cylinder speed, water inlet dynamics, and cylinder inclination on the flow field were investigated. The simulation results indicated that the surface magnetic induction intensity of the magnetic pole was 1.8 T, and the magnetic field lines of the magnetic system were concentrated around the magnetic medium. Moreover, there was a substantial magnetic field gradient (8×10−7 A/m²) on the surface of the magnetic medium, with minimal reduction, which facilitated the capture of magnetic particles. An advantage of this device was the inclusion of centrifugal flushing water. Adjusting the particle forces through changes in water velocity could provide a theoretical basis for the optimization design of permanent magnet magnetic separators.

-

-

表 1 变频器频率与水流量对应关系

Table 1. Correspondence between inverter frequency and water flow

变频器频率 /Hz 0 5 10 15 20 25 水流量 /(m3·h−1) 0 0.4 0.8 1.2 1.6 2.0 表 2 N50钕铁硼材料主要性能参数

Table 2. Main performance parameters of N50 NdFeB material

最大磁能

积/(kJ·m−3)矫顽力

/(kA·m−1)内禀矫顽力

/(kA·m−1)剩磁/T 最高工作

温度/℃382~398 828~907 ≥876 1.41~1.45 ≤70 -

[1] BOCHKAREV G R, ROSTOVTSEV V I, VOBLY P D, et al. High−gradient magnetic separator for dressing of weak−magnetic ores[J]. Journal of Mining Science, 2004, 40(2): 199−204. doi: 10.1023/B:JOMI.0000047864.20604.ba

[2] CHEN L, ZENG J, GUAN C, et al. High gradient magnetic separation in centrifugal field[J]. Minerals Engineering, 2015, 78: 122−127. doi: 10.1016/j.mineng.2015.04.018

[3] ZHENG X, WANG Y, LU D. Study on capture radius and efficiency of fine weakly magnetic minerals in high gradient magnetic field[J]. Minerals Engineering, 2015, 74: 79−85. doi: 10.1016/j.mineng.2015.02.001

[4] ZHENG X, WANG Y, LU D. Study on buildup of fine weakly magnetic minerals on matrices in high gradient magnetic separation[J]. Fizykochemiczne Problemy Mineralurgii − Physicochemical Problems of Mineral Processing, 2017, 53: 94−109.

[5] LIU L, TAN Q, YUE T, et al. Pre−concentration of ultrafine crushed hematite ores[J]. Separation Science and Technology, 2014, 49(9): 1442−1448. doi: 10.1080/01496395.2013.879480

[6] 钱士湖, 陆虎, 李明军, 等. ZCLA选矿机湿式预选和睦山选厂磨前产品工业试验与生产实践[J]. 金属矿山, 2018(10): 76−79.

QIAN S H, LU H, LI M J, et al. Industrial test and practice of ZCLA separator for wet pre−concentration of pre−grinding products in hemushan plant[J]. Metal Mine, 2018(10): 76−79.

[7] 刘松. 铁矿石超细碎干式磁选抛尾技术研究[D]. 焦作: 河南理工大学, 2012.

LIU S. Research on dry preelection discarding tail technique of iron ore with superfine crushing[D]. Jiaozuo: Henan Polytechnic University, 2012.

[8] 刘安平, 衣德强, 张祖刚, 等. ZCLA型磁选机在重选2−0.5系统的应用[J]. 矿冶工程, 2020, 40(6): 59−61. doi: 10.3969/j.issn.0253-6099.2020.06.015

LIU A P, YI D Q, ZHANG Z G, et al. Application of ZCLA magnetic separator in meishan gravity concentration branch's 2−0.5 system[J]. Mining and Metallurgical Engineering, 2020, 40(6): 59−61. doi: 10.3969/j.issn.0253-6099.2020.06.015

[9] 张祖刚, 周润, 成磊. 外磁式磁选机用于梅山铁矿2~0.5mm混合铁矿磨前预选试验研究[J]. 有色金属(选矿部分), 2021(3): 131−134.

ZHANG Z G, ZHOU R, CHENG L. Experimental research on 2−0.5mm mixed iron ore pre−concentration before grinding with external magnet magnetic separator[J]. Nonferrous Metals (Mineral Processing Section), 2021(3): 131−134.

[10] 曾尚林, 张祖刚, 周润, 等. ZCLA选矿机应用于梅山铁矿预选工业试验研究[J]. 矿冶工程, 2020, 40(4): 57−59. doi: 10.3969/j.issn.0253-6099.2020.04.014

ZENG S L, ZHANG Z G, ZHOU R, et al. Application of ZCLA separator in commercial test of preconcentration of iron ore from meishan iron mine[J]. Mining and Metallurgical Engineering, 2020, 40(4): 57−59. doi: 10.3969/j.issn.0253-6099.2020.04.014

[11] 张祖刚. 外磁系与内磁系永磁筒式磁选机对比研究[J]. 矿冶工程, 2021, 41(6): 96−100. doi: 10.3969/j.issn.0253-6099.2021.06.024

ZHANG Z G. Comparative study on permanent magnetic drum separators with external or internal magnetic systems[J]. Mining and Metallurgical Engineering, 2021, 41(6): 96−100. doi: 10.3969/j.issn.0253-6099.2021.06.024

[12] 尚红亮, 史佩伟, 成磊, 等. 新型外磁式磁选设备的研制及应用[J]. 有色金属(选矿部分), 2017(4): 75−79.

SHANG H L, SHI P W, CHENG L, et al. Development and application of new type external magnet separation equipment[J]. Nonferrous Metals (Mineral Processing Section), 2017(4): 75−79.

[13] 柳衡琪, 曾维龙, 陈志强. 新型磁力预选设备−ZCLA磁选机[J]. 矿冶工程, 2016, 36(1): 49−51. doi: 10.3969/j.issn.0253-6099.2016.01.012

LIU H Q, ZENG W L, CHEN Z Q. Magnetic separator ZCLA: a new type of magnetic preconcentration equipment[J]. Mining and Metallurgical Engineering, 2016, 36(1): 49−51. doi: 10.3969/j.issn.0253-6099.2016.01.012

[14] 程志勇, 卢东方, 薛子兴, 等. 基于COMSOL Mutiphysics的履带式磁选机平面磁系磁场仿真与参数优化[J]. 中南大学学报(自然科学版), 2021, 52(4): 1049−1057.

CHENG Z Y, LU D F, XUE Z X, et al. COMSOL Mutiphysics−based magnetic field simulation and parameter optimization of planar magnetic system of crawler magnetic separator[J]. Journal of Central South University(Science and Technology), 2021, 52(4): 1049−1057.

[15] 于润桥, 付鑫, 夏桂锁, 等. 钕铁硼磁钢微磁检测方法及试验研究[J]. 南昌航空大学学报(自然科学版), 2014, 28(2): 92−96.

YU R Q, FU X, XA G S, et al. Micro magnetic testing method and experiment of ndfeb magnetic steel[J]. Journal of Nanchang Hangkong University (Natural science edition), 2014, 28(2): 92−96.

[16] 叶方平, 李宸宇, 曾剑武, 等. 基于Comsol的平板高梯度磁选机的仿真与实验研究[J]. 金属矿山, 2021(10): 155−161.

YE F P, LI H Y, ZENG J W, et al. Simulation and experimental research of flat plate high gradient magnetic separator based on comsol[J]. Metal Mine, 2021(10): 155−161.

[17] 成磊. 新型开放磁系永磁筒式强磁选机的研制与应用[J]. 矿产保护与利用, 2019, 39(2): 14−17.

CHENG L. Research of high gradient permanent magnetic drum separator with open magnetic circuit[J]. Conservation and Utilization of Mineral Resources, 2019, 39(2): 14−17.

[18] AHMED B, JAVED T. A study of full navier−stokes equations of peristaltic flow in a porous−saturated tube under the inducement of magnetic field: finite element analysis[J]. Chaos, Solitons & Fractals, 2019, 125: 79−87.

-

下载:

下载: