A Comparative Study on the Impact Crushing Characteristics of the Material Layer Between the Leroy Tetrahedron and the Traditional Grinding Medium

-

摘要:

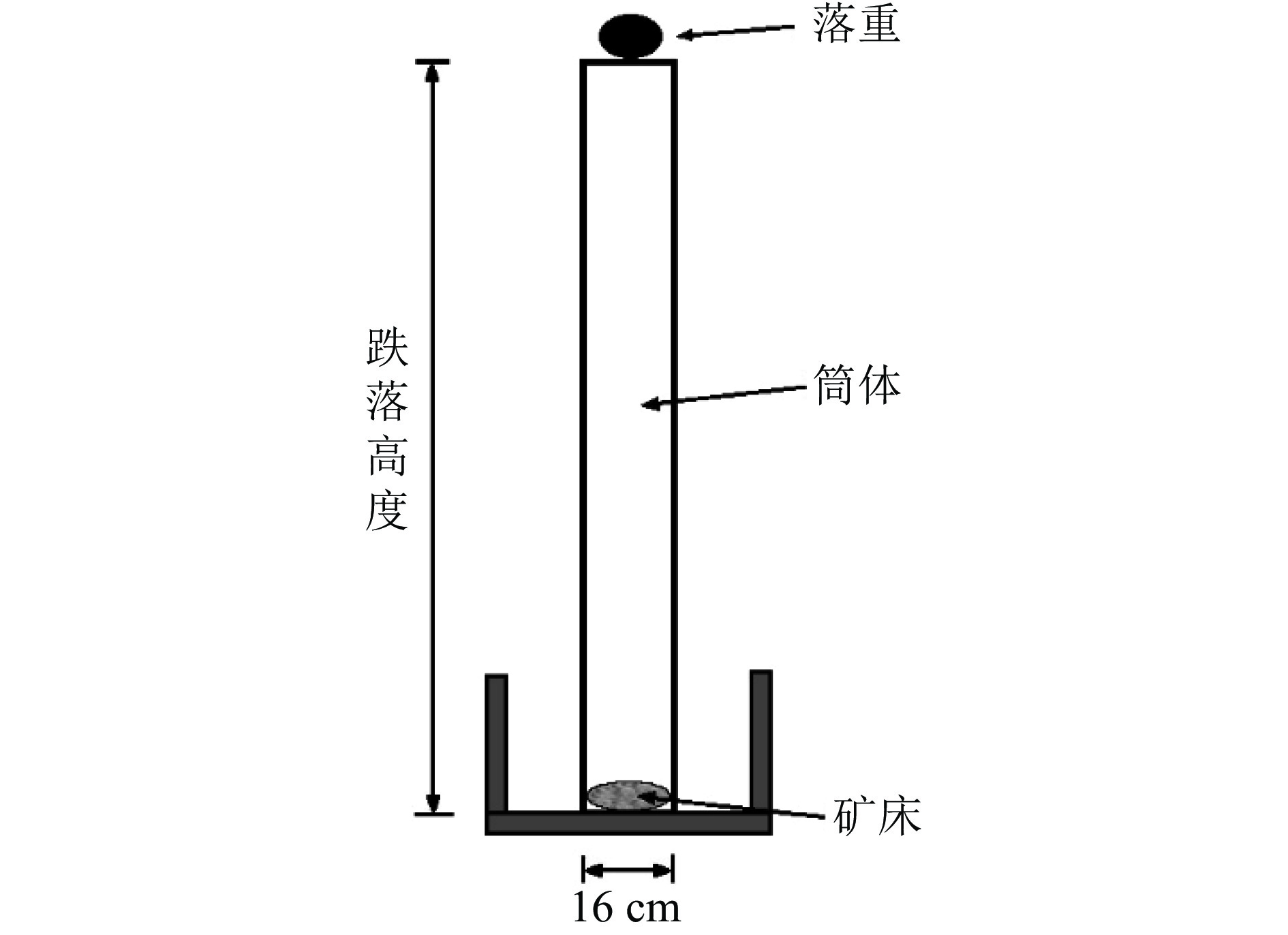

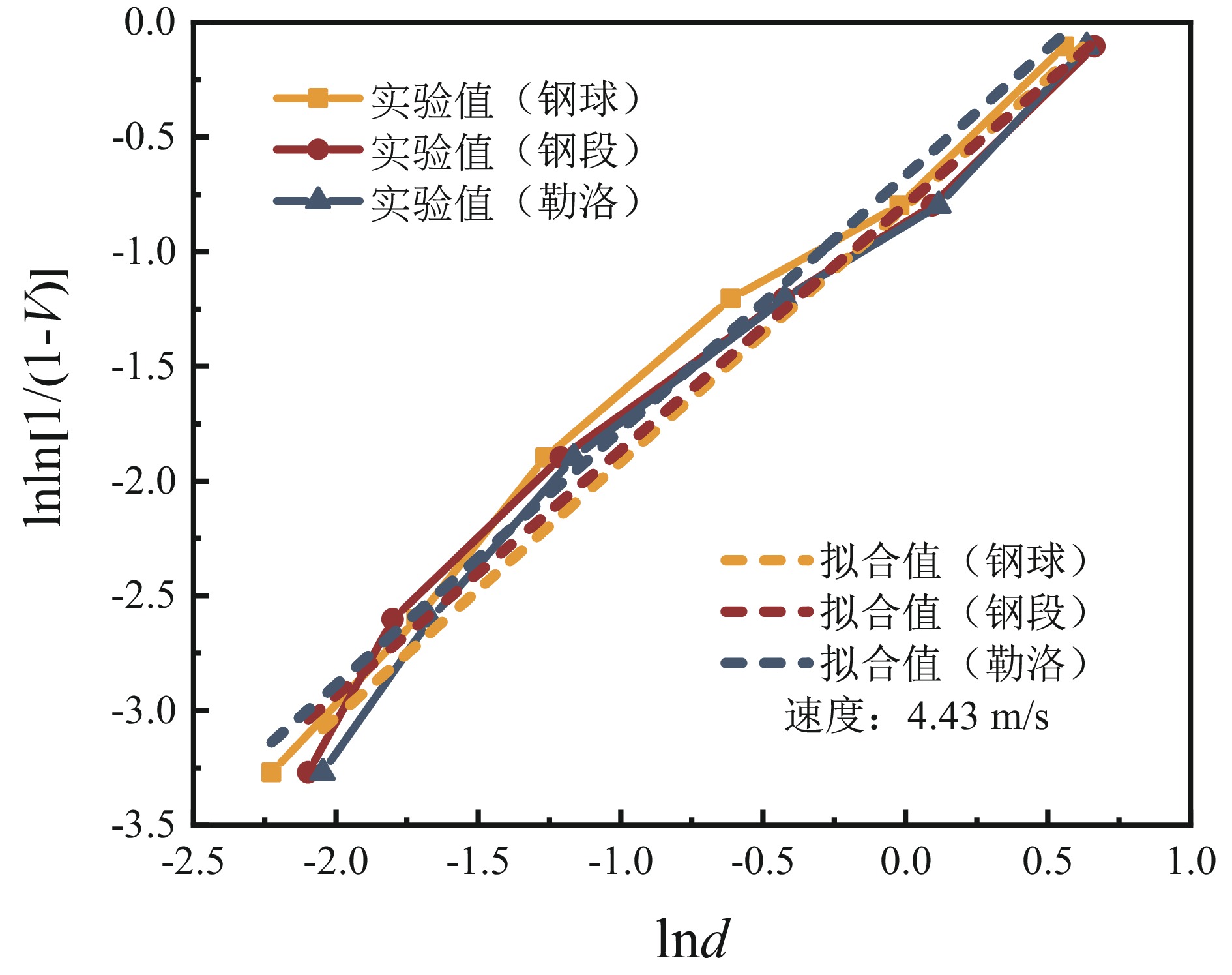

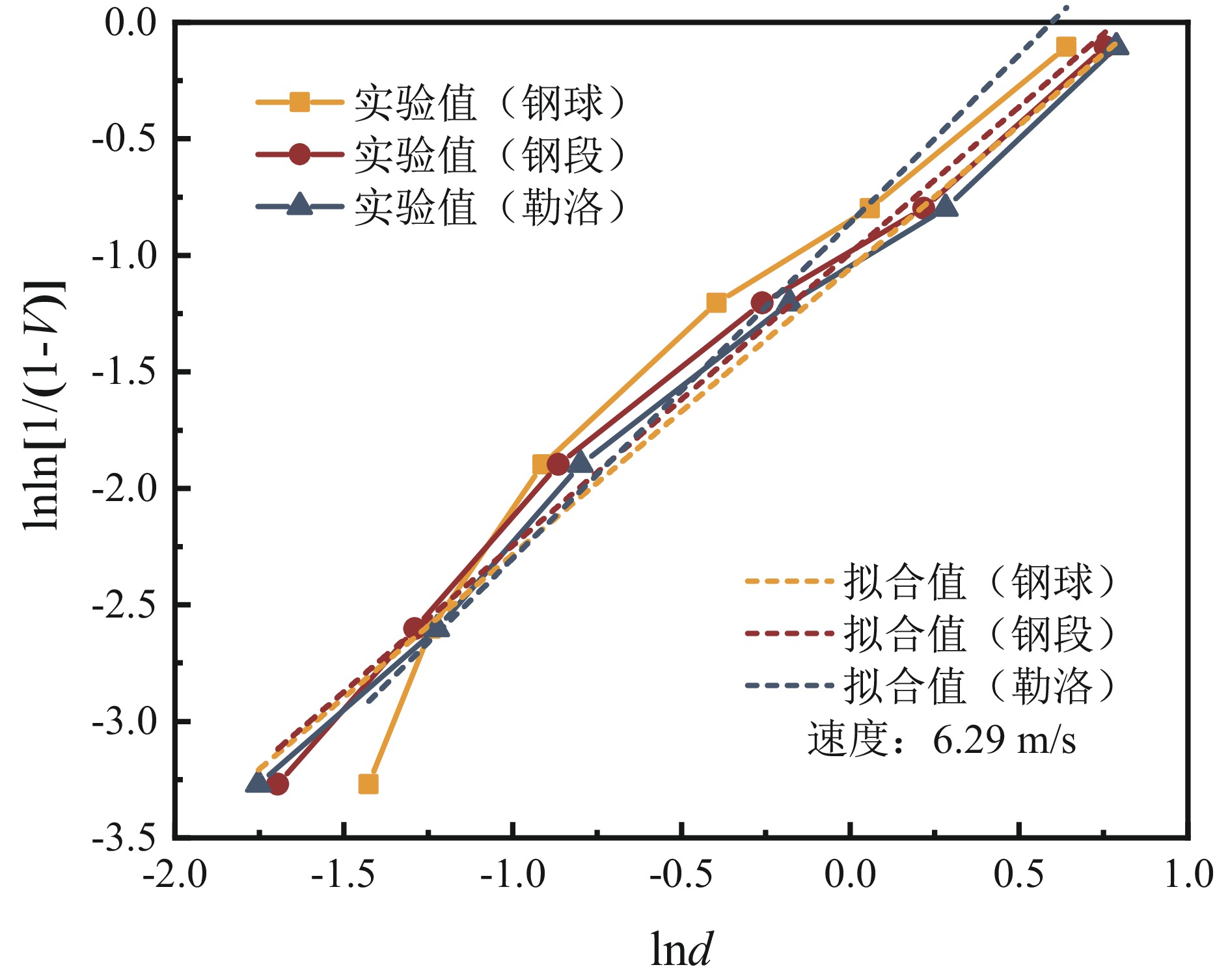

针对传统介质磨矿产品粒度特性差的问题,进行不同介质形状(球体、勒洛四面体、圆柱体)对料层的破碎粒度特性影响研究。采用落重实验仪模拟不同介质形状在不同高度(0.5 m、1.0 m、1.5 m、2.0 m)对料层的冲击效果。研究结果表明:利用威布尔分布计算出铜矿破碎特性指数与冲击速度成正比例关系拟合的方程拟合系数范围在0.96~0.99内,证实利用威布尔分布函数来描述铜矿冲击破碎的粒度分布规律是可靠、可行的;研究表明,冲击速度对铜矿冲击破碎粒度分布规律影响很小,2 m高度(速度6.29 m/s)的勒洛四面体介质比钢球和钢段的破碎特性指数分别提高了0.22和0.18;勒洛四面体介质冲击2 m高度(速度6.29 m/s)的料层与钢球和钢段相比,+0.15 mm级别产率分别比钢球和钢段介质降低3.14和1.85百分点、−0.074+0.038 mm产率分别提高5.86和2.26百分点、−0.074 mm级别产率分别提高0.4和1.41百分点、过粉碎级别−0.01 mm产率分别降低4.52和2.64百分点;验证了勒洛四面体介质形状能有效改善料层的粒度特性。

Abstract:Aiming at the problem of poor particle size characteristics of traditional medium grinding products, the influence of different medium shapes (sphere, Leroy tetrahedron, and cylinder) on the crushing particle size characteristics of the material layer was studied. The impact effect of different medium shapes at different heights (0.5 m, 1.0 m, 1.5 m, and 2.0 m) on the material bed was simulated by using drop weight tester. The results showed that the fitting coefficients of the equation fitted by Weibull distribution were in the range of 0.96~0.99, which proved that Weibull distribution function was reliable and feasible to describe the particle size distribution law of impact crushing of copper ore. The results showed that it was reliable and feasible to use Weibull distribution function to describe the particle size distribution law of impact crushing of copper ore; the results showed that the impact velocity had little effect on the particle size distribution of impact crushing of copper ore, and the crushing characteristic index of 2 m height (6.29 m/s) Leroy tetrahedral medium was 0.22 and 0.18 higher than that of steel ball and steel segment, respectively. Compared with steel ball and steel segment, the yields of +0.15 mm, −0.074 +0.038 mm, −0.074 mm and−0.01 mm were decreased by 3.14 and 1.85 percentage points, 5.86 and 2.26 percentage points, 0.4 and 1.41 percentage points, 4.52 and 2.64 percentage points, respectively. It was verified that the shape of Leroy tetrahedron medium can effectively improve the particle size characteristics of the material layer.

-

Key words:

- drop weight /

- ball mill /

- grinding media /

- Leroy tetrahedral media /

- particle size characteristics

-

-

表 1 落重实验方案

Table 1. Weight drop test scheme

介质方案 冲击高度/m 矿层质量/g Φ60 mm钢球方案 0.5 150 Φ60 mm钢段方案 0.5 150 Φ60 mm勒洛方案 0.5 150 Φ60 mm钢球方案 1.0 150 Φ60 mm钢段方案 1.0 150 Φ60 mm勒洛方案 1.0 150 Φ60 mm钢球方案 1.5 150 Φ60 mm钢段方案 1.5 150 Φ60 mm勒洛方案 1.5 150 Φ60 mm钢球方案 2.0 150 Φ60 mm钢段方案 2.0 150 Φ60 mm勒洛方案 2.0 150 表 2 铜矿冲击破碎产品质量累积概率

Table 2. Cu ore impact crushing product quality cumulative probability

冲击速度/(m·s−1) 冲击高度/m 介质种类 铜矿破碎后粒度不大于d(mm)的碎铜矿占试样总量的比例/% <0.01 mm <0.038 mm <0.074 mm <0.15 mm <0.3 mm <0.45 mm 3.13 0.5 钢球 4.18 6.54 10.13 14.15 25.95 73.23 钢段 3.96 7.06 9.79 23.14 48.66 69.19 勒洛 5.18 6.57 7.89 13.06 23.37 39.85 4.43 1.0 钢球 8.40 10.23 16.43 24.61 41.80 62.48 钢段 9.73 11.56 12.54 25.79 47.98 66.65 勒洛 9.47 12.13 17.16 26.83 48.05 67.47 5.42 1.5 钢球 9.72 13.49 16.53 30.05 52.27 71.79 钢段 8.65 11.09 13.69 25.81 45.99 65.65 勒洛 8.04 13.51 19.89 30.73 52.72 70.17 6.29 2.0 钢球 14.75 21.37 25.09 33.11 49.01 65.35 钢段 12.87 16.76 24.08 34.40 53.75 71.17 勒洛 10.23 15.91 25.49 36.25 56.62 73.43 表 3 铜矿质量累积分布拟合函数

Table 3. Copper ore mass cumulative distribution fitting function

冲击方案(高度+介质) 冲击速度/(m·s−1) 威布尔分布拟合函数 拟合度 0.5 m+钢球 3.13 F(d)=ln ln[1/(1−V)]=0.80lnd−0.80ln(0.42) 0.96 0.5 m+钢段 3.13 F(d)=ln ln[1/(1−V)]=1.05lnd−1.05ln(0.41) 0.99 0.5 m+勒洛 3.13 F(d)=ln ln[1/(1−V)]=1.07lnd−1.07ln(0.51) 0.98 1.0 m+钢球 4.43 F(d)=ln ln[1/(1−V)]=1.07lnd−1.07ln(0.47) 0.99 1.0 m+钢段 4.43 F(d)=ln ln[1/(1−V)]=1.07lnd−1.07ln(0.42) 0.98 1.0 m+勒洛 4.43 F(d)=ln ln[1/(1−V)]=1.12lnd−1.12ln(0.42) 0.99 1.5 m+钢球 5.42 F(d)=ln ln[1/(1−V)]=1.11lnd−1.11ln(0.38) 0.98 1.5 m+钢段 5.42 F(d)=ln ln[1/(1−V)]=1.11lnd−1.11ln(0.39) 0.98 1.5 m+勒洛 5.42 F(d)=ln ln[1/(1−V)]=1.16lnd−1.16ln(0.39) 0.99 2.0 m+钢球 6.29 F(d)=ln ln[1/(1−V)]=1.22lnd−1.22ln(0.43) 0.98 2.0 m+钢段 6.29 F(d)=ln ln[1/(1−V)]=1.26lnd−1.26ln(0.38) 0.98 2.0 m+勒洛 6.29 F(d)=ln ln[1/(1−V)]=1.44lnd−1.44ln(0.36) 0.99 -

[1] 母福生. 破碎及磨矿技术在国内外的技术发展和行业展望(一)[J]. 矿山机械, 2011, -11: 58−65. doi: 10.16816/j.cnki.ksjx.2011.11.016

MU F S. Technical Development and Industry outlook of crushing and grinding technology at home and abroad (1)[J]. Mining Machinery, 2011, -11: 58−65. doi: 10.16816/j.cnki.ksjx.2011.11.016

[2] BARRERA D, CERRILLO L, GONGORA F, et al. Design of a wear estimator for liners in SAG mills using ANFIS modeling[C]//IEEE International Conference on Automation/Congress of the Chilean Association of Automatic Control. IEEE, 2021. DOI: 10.1109/ICAACCA51523.2021.9465187.

[3] AARH, B M M, C H Z ,et al.On dry SAG mills end liners: Physical modeling, DEM−based characterization and industrial outcomes of a new design[J]. Minerals Engineering, 2019, 141: 105835−. DOI:10.1016/j.mineng.2019.105835.

[4] 李同清, 彭玉兴. 研磨介质形状对铁矿石磨矿动力学研究[J]. 有色金属(选矿部分), 2018(1): 84−89.

LI T Q, PENG Y X. Study on the grinding kinetics of iron ore by the shape of grinding media[J]. Non ferrous Metals (Mineral Processing Part), 2018 (1): 84−89.

[5] SUN X, XIE W, HE Y, et al. Analyses of the energy−size reduction of mixtures of narrowly sized coals in a ball-and-race mill[J]. Advanced Powder Technology, 2018, 29(6).

[6] DÍAZ E, VOISIN L, KRACHT W, et al. Using advanced mineral characterisation techniques to estimate grinding media consumption at laboratory scale[J]. Minerals Engineering, 2018, 121

[7] SHI, F. Comparison of grinding media−cylpebs versus balls[J]. Minerals Engineering, 2004, 17(11/12): 1259−1268. DOI: 10.1016/j.mineng.2004.05.019.

[8] LPEK H. Effect of grinding media shapes on breakage parameters[J]. Particle & particle systems characterization: measurement and description of particle properties and behavior in powders and other disperse systems, 2007, 24(3).

[9] 陈宗明, 朱定武. 新型胶囊球研磨介质: CN2498157[P]. 2002−7−03.

CHEN Z M, ZHU D W. New capsule ball grinding medium: CN2498157 [P]. 2002−07−03.

[10] 罗春梅, 肖庆飞, 郭永杰等. 锡矿石细磨介质形状的选择[J]. 昆明理工大学学报(理工版), 2008, 152(1): 1−4.

LUO C M, XIAO Q F, GUO Y J, et al. Selection of medium shape for fine grinding of tin ores[J]. Journal of Kunming University of Technology (Science and Technology Edition), 2008, 152(1): 1−4.

[11] ROSIN. P, RAMMLER. E. The laws governing the fineness of powdered coal[J]. J. inst. fuel, 1933, 7: 29−36.DOI.

[12] WEIBULL W. A statistical theory of the strength of materials[J]. Proceedings of the American Mathematical Society [2023-11-23].

[13] 刘送永, 杜长龙, 李建平. 煤截割粒度分布规律的分形特征[J]. 煤炭学报, 2009, 34(7): 977−982. doi: 10.3321/j.issn:0253-9993.2009.07.023

LIU S Y, DU C L, LI J P. Fractal characteristics of coal cutting particle size distribution[J]. Journal of Coal Science, 2009, 34(7): 977−982. doi: 10.3321/j.issn:0253-9993.2009.07.023

[14] 江红祥, 杜长龙, 刘送永. 冲击速度对煤岩破碎能量和粒度分布的影响[J]. 煤炭学报, 2013, 38(4): 604−609. doi: 10.13225/j.cnki.jccs.2013.4.022

JIANG H Y, DU C L, LIU S Y. The effect of impact velocity on the energy and particle size distribution of coal rock fragmentation[J]. Journal of Coal Science, 2013, 38(4): 604−609. doi: 10.13225/j.cnki.jccs.2013.4.022

[15] Shi F. Comparison of grinding media−Cylpebs versus balls[J]. Minerals Engineering, 2004(11/12). DOI: 10.1016/S0892-6875(04)00188-8.

[16] LAMECK N S, MOYS M H. Effects of media shape on milling kinetics[J]. Minerals Engineering, 2006, 19(13): 1377−1379. doi: 10.1016/j.mineng.2005.12.008

[17] CLOOS U. CYLPEBS: AN ALTERNATIVE TO BALLS AS GRINDING MEDIA[J]. 1983.

[18] N. HLABANGANA, DANHA G , GLASSER D .Use of the attainable region approach to determine major trends and optimize particle breakage in a laboratory mill[J]. Powder Technology, 2016. DOI: 10.1016/j.powtec.2016.01.001.

[19] BARRY KEAN ATKINSON. Fracture mechanics of rock[M]. London:Ac-ademic Press, 1987.

[20] LIU L, KAFUI K D, THORNTON C. Impact breakage of spherical, cuboidal and cylindrical agglomerates[J]. Powder Technology, 2010, 199(2): 189−196. DOI: 10.1016/j.powtec.2010.1.007.

[21] THORNTON C, LIU L. How do agglomerates break[J]. Powder Technology, 2004, 143(none): 110−116. DOI: 10.1016/j.powtec.2004.4.035.

-

下载:

下载: