Effect of Ultrasonically Modified Cationic Polyacrylamide on the Flocculation Settlement and Dewatering Performance of Coal Slime Water

-

摘要:

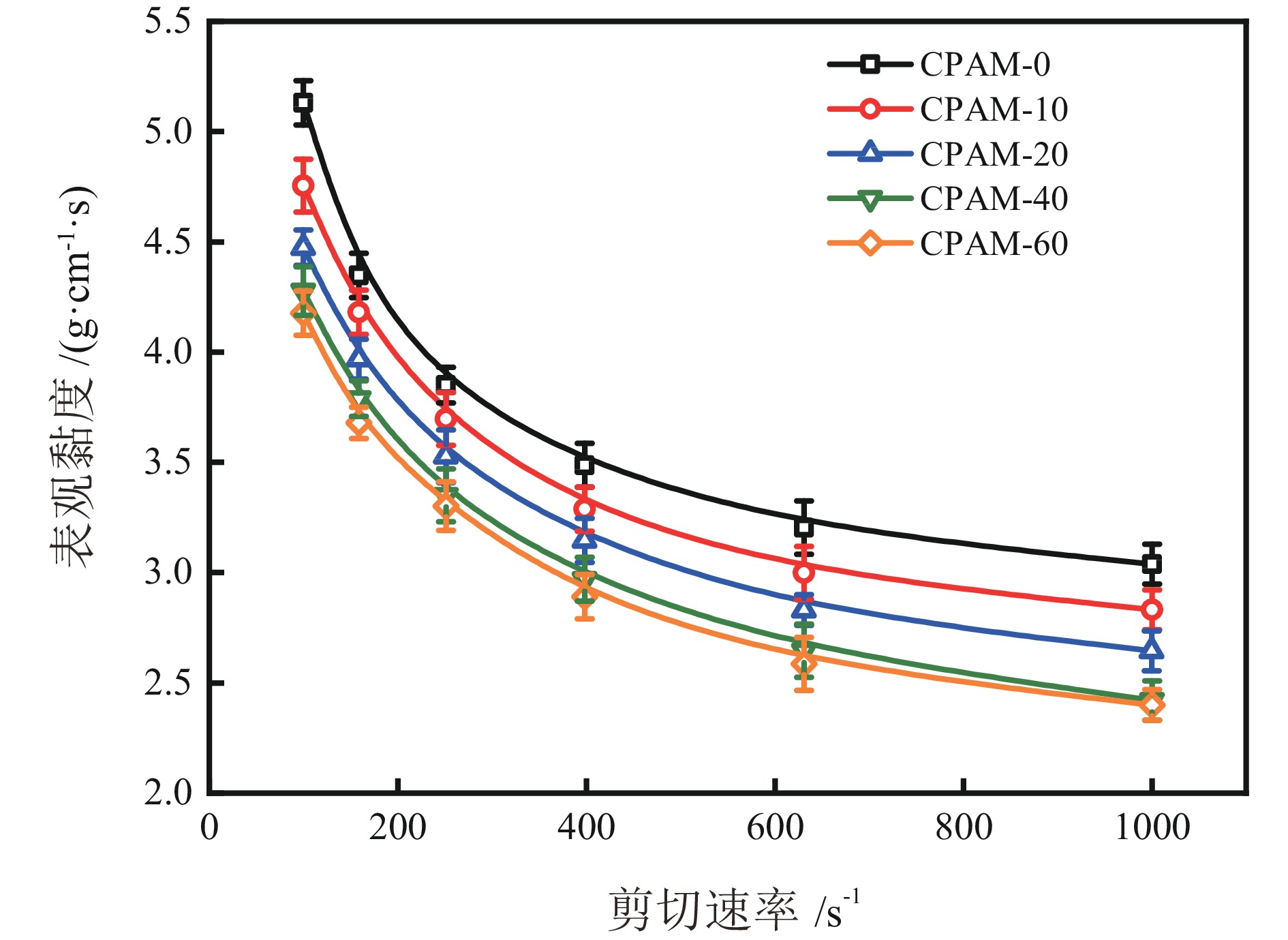

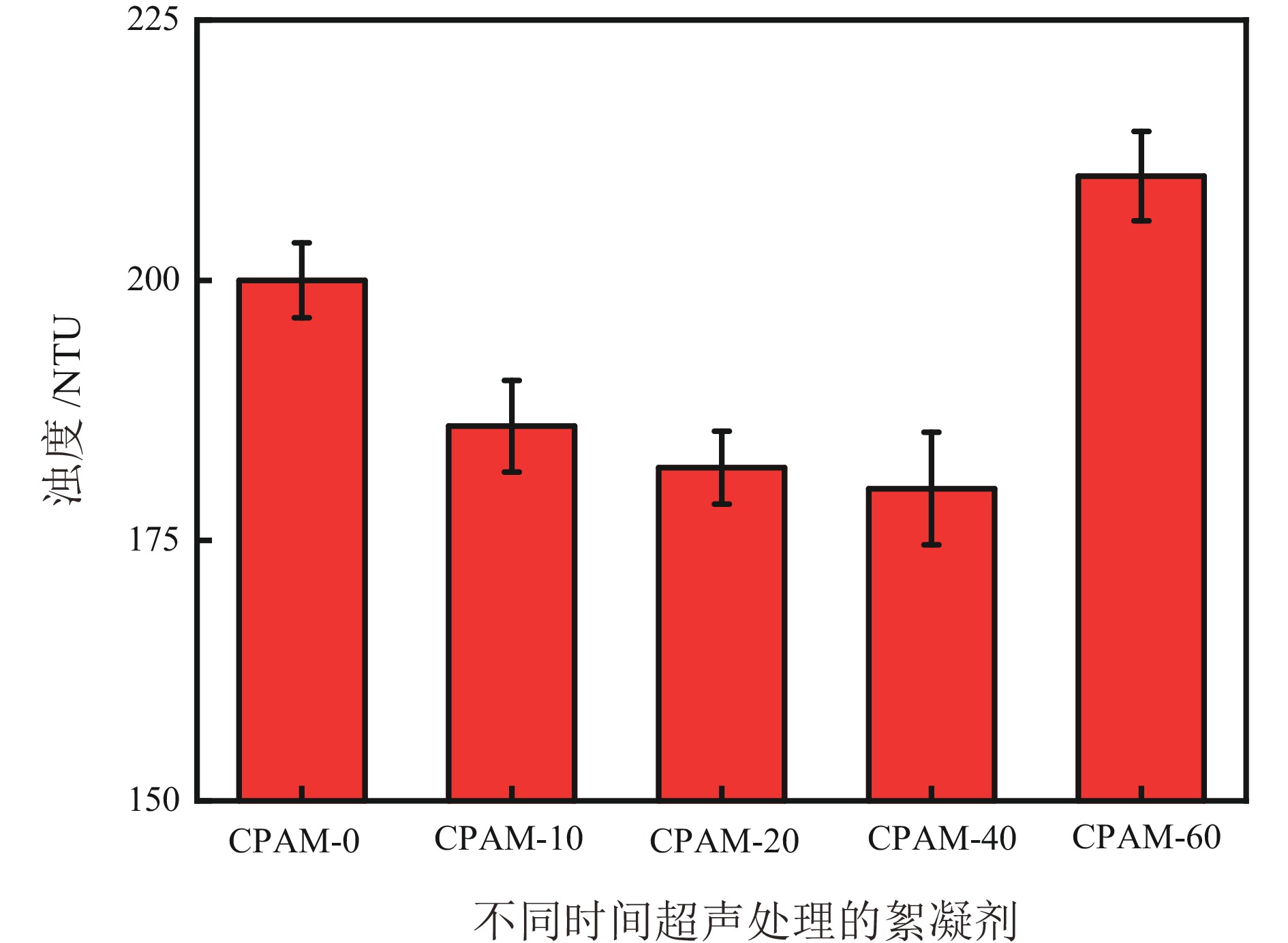

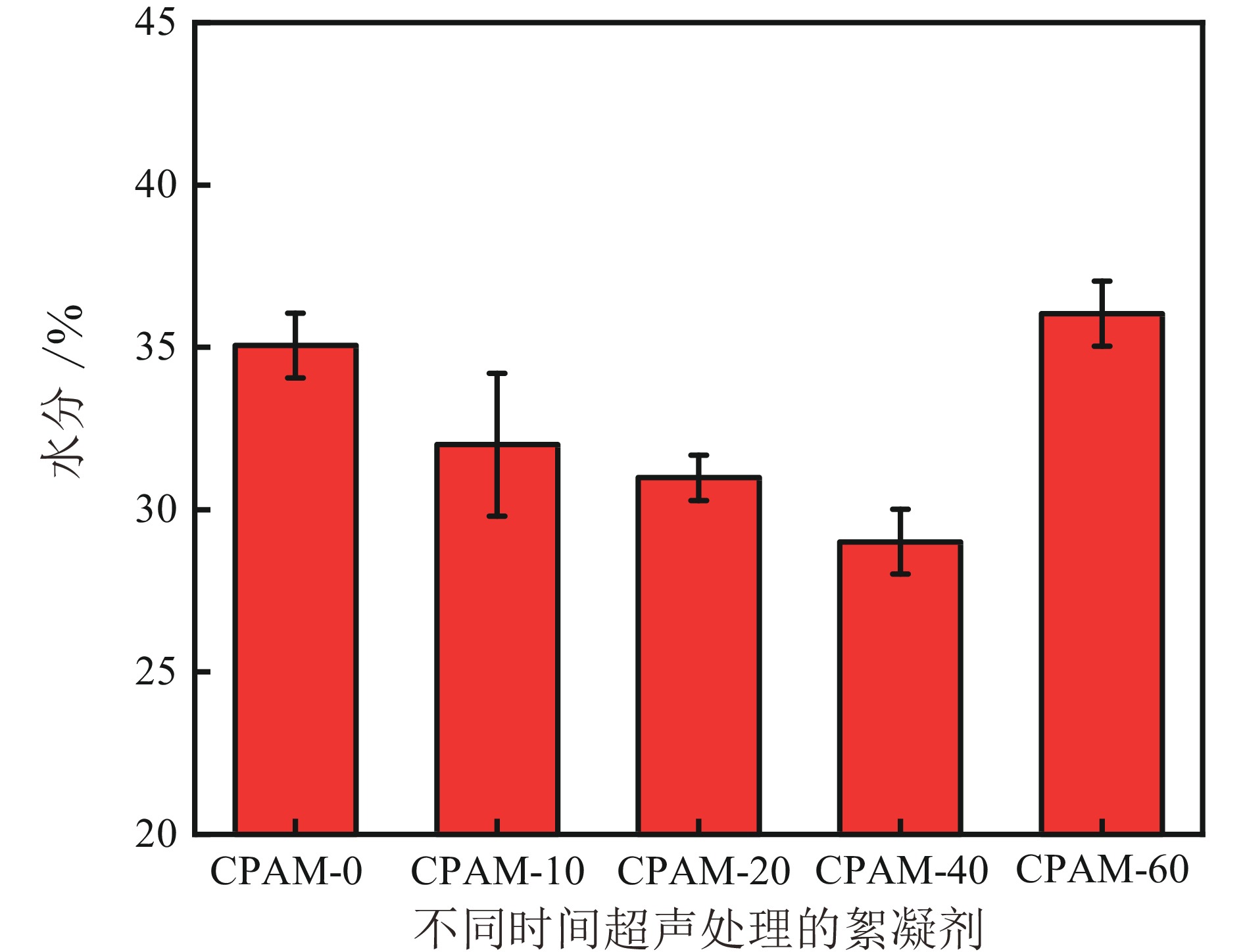

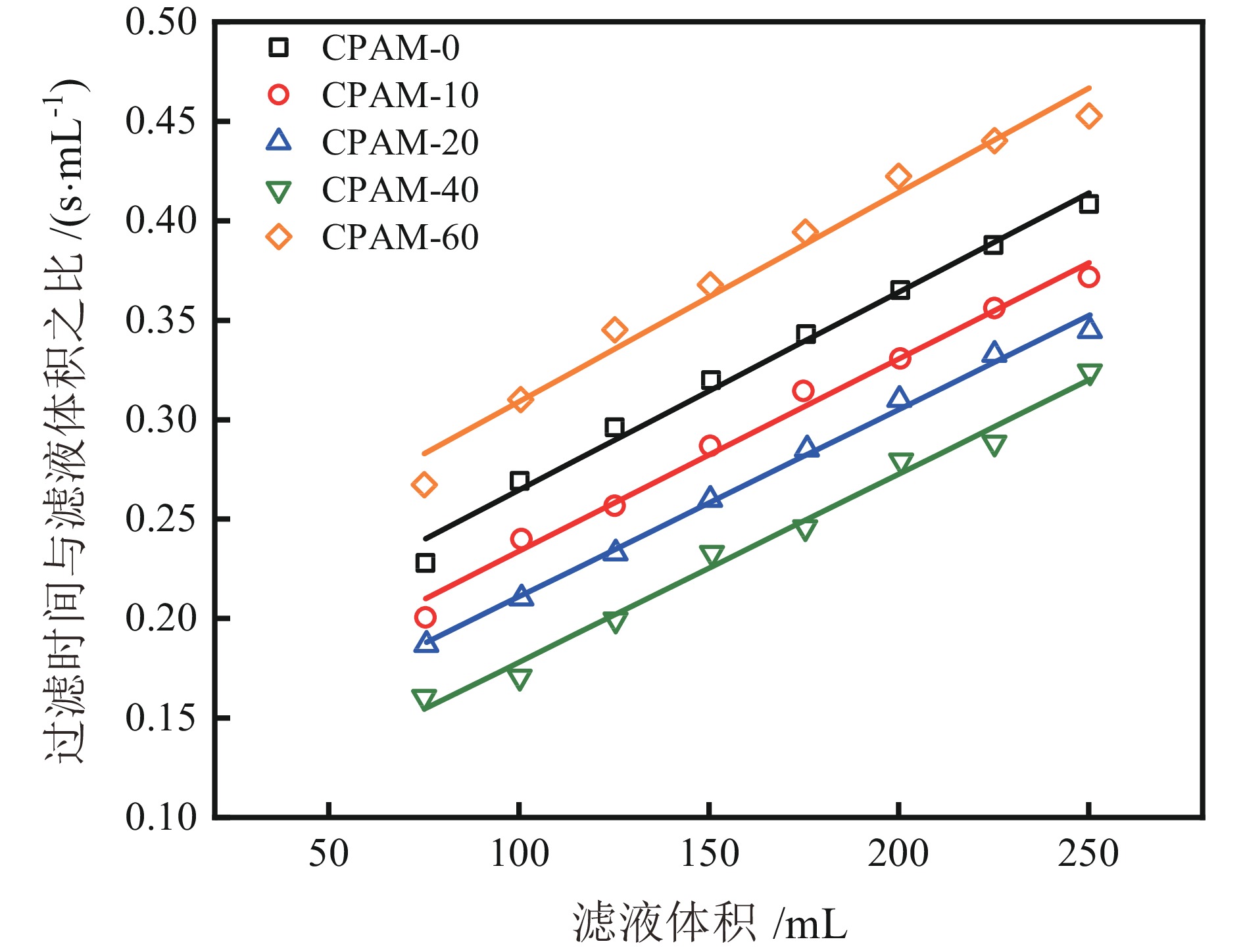

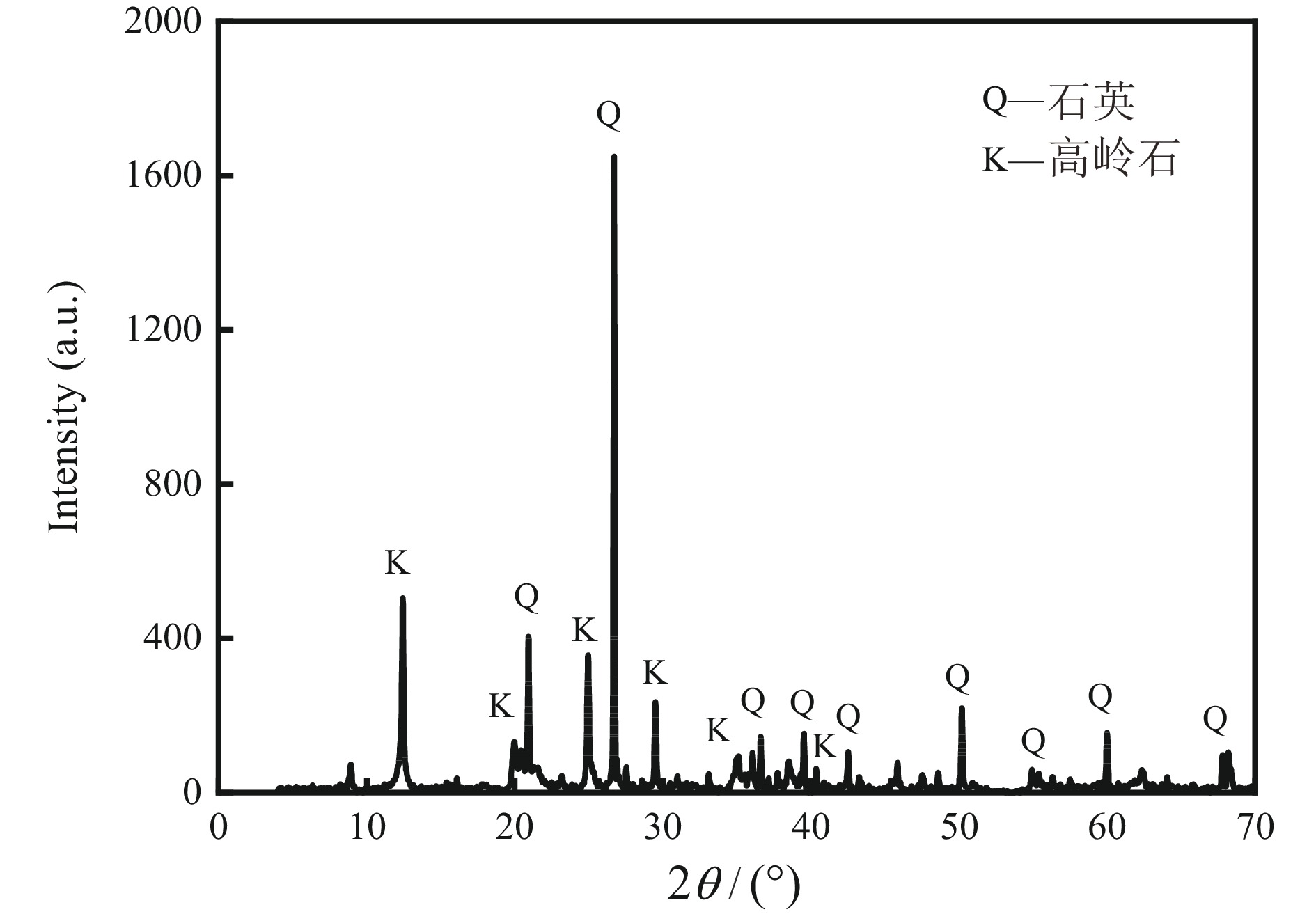

絮凝沉降和过滤脱水是煤泥水处理的常见方法。絮凝效果直接影响煤泥的脱水效果。提出了一种利用超声改性的阳离子聚丙烯酰胺(CPAM)强化煤泥水絮凝脱水过程的新技术。用流变仪研究了超声预处理不同时间的CPAM溶液的特性。通过沉降试验以及浊度测试分析了超声改性絮凝剂对煤泥水沉降的影响。使用聚焦光束反射率测量系统与颗粒观测系统观察不同改性CPAM处理煤泥水时的絮体特性。建立了絮体特性与煤泥水过滤过程所形成的滤饼特性的联系。实验结果表明,经过40 s超声处理的CPAM作用于煤泥水后,煤泥絮凝效果最好,上清液浊度最低,为180 NTU。在该条件下,煤泥的过滤速度最快,与未经超声处理的情况相比,过滤时间减少25 s。此外,在此条件下获得的滤饼水分含量也最低,为29%。因为经过40 s的超声处理后,部分CPAM分子链被超声产生的强烈的机械以及化学作用随机切断,这些被切断的CPAM分子链将煤泥颗粒逐渐聚集成微小絮体,而未被切断的CPAM分子链进一步将这些小絮体连接在一起。煤泥颗粒在聚合物内部通过多组分聚合物的复杂体系得以紧密结合。随着絮体的沉降,形成了更加致密的结构和沉积床。这些致密的絮体构建的沉积层具有较低的过滤阻力,从而有助于提高过滤速度,同时也导致过滤结束后的滤饼具有更低的水分含量。

Abstract:Flocculation settlement and dewatering through filtration are common methods used for treating slime water. The efficiency of flocculation directly impacts the dewatering process of coal slime. This paper introduces a novel technology to enhance the flocculation and dewatering process of coal slime water by utilizing ultrasonically modified cationic polyacrylamide (CPAM). The characteristics of CPAM solutions pretreated with ultrasonic treatment for different durations were examined using a rheometer. The impact of ultrasonically modified flocculants on the settling of coal slime water was analyzed through settlement and turbidity tests. Floc properties of various modified CPAMs in the treatment of slime water were observed using the focused beam reflectance measurement system and the particle observation system. Furthermore, a correlation was established between the floc properties and the characteristics of the filter cake formed during the filtration of coal slime water. Experimental results indicate that after 40 seconds of ultrasonic treatment, CPAM demonstrates the most effective slime flocculation with the lowest supernatant turbidity, approximately 180 NTU. Under these conditions, coal slime filtration occurs at the fastest rate, reducing filtration time by about 25 seconds compared to cases without ultrasonic treatment. Additionally, the moisture content of the filter cake obtained under these conditions is the lowest, around 29%. This phenomenon can be attributed to the formation of multi−molecular−weight polymers in the CPAM solution following 40 seconds of sonication. Low−molecular−weight agents gradually aggregate coal slime particles into small flocs, while high−molecular−weight agents further link these small flocs together. Coal slime particles become tightly bound within the polymer matrix through a complex system of multi−component polymers. As the flocs settle, they create a denser structure and sedimentary bed. This sediment layer, composed of dense flocs, offers lower filtration resistance, enhancing filtration speed, and resulting in a reduced moisture content in the filter cake post−filtration.

-

Key words:

- cationic /

- polyacrylamide /

- ultrasonic /

- flocculation /

- filtration

-

-

表 1 煤泥样品粒度组成

Table 1. Particle size composition of coal slime samples

粒级/mm 产率/% 灰分/% 累积产率/% 累积灰分/% −0.50+0.25 1.02 28.13 3.02 28.13 −0.25+0.125 3.86 29.69 6.88 29.01 −0.125+0.075 8.78 38.41 15.66 34.28 −0.075+0.045 21.08 40.1 36.74 37.62 −0.045 63.26 44.72 100 42.11 表 2 不同药剂作用下滤饼过滤阻力

Table 2. Filtration resistance of filter cake under different agents

药剂名称 过滤比阻α/10−8 过滤介质阻力Rm/10−4 R2 CPAM−0 6.61 16.57 0.9875 CPAM−10 6.44 13.71 0.9930 CPAM−20 6.26 11.72 0.9856 CPAM−40 6.20 8.34 0.9743 CPAM−60 7.01 20.37 0.9854 -

[1] 张志军, 孟齐, 刘炯天. 选煤水化学−循环煤泥水系统的水化学性质[J]. 煤炭学报, 2021, 46: 614−623.

ZHANG Z J, MENG Q, LIU J T. Water chemical properties of circulating coal slime water system[J]. Journal of China Coal Society, 2021, 46: 614−623.

[2] 董宪姝. 煤泥水处理技术研究现状及发展趋势[J]. 选煤技术, 2018, 3: 1−8.

DONG X S. Research status and development trend of coal slime water treatment technology[J]. Coal Preparation Technology, 2018, 3: 1−8.

[3] 陈军, 闵凡飞, 彭陈亮, 等. 煤泥水中微细粒在季铵盐作用下的疏水聚团特性[J]. 中国矿业大学学报, 2015, 44(2): 332−340.

CHENG J, MIN F F, PENG C L, et al. Hydrophobic aggregation characteristics of fine particles in coal slime water under the action of quaternary ammonium salt[J]. Journal of China University of Mining & Technology, 2015, 44(2): 332−340.

[4] P. OFORI, A. V. NGUYEN, B. FIRTH, C. MCNALLY, O. Ozdemir, Shear−induced floc structure changes for enhanced dewatering of coal preparation plant tailings[J], Chemical Engineering Journal, 2011, 172: 914−923.

[5] 杨彦斌, 屈进州, 朱子祺, 等. 难沉降煤泥水全流程处理技术研究进展[J]. 洁净煤技术, 2021, 27(5): 106−114.

YANG Y B, QU J Z, ZHU Z Q, et al. Research progress of the whole process treatment technology for difficult−to−settle slime water[J]. Clean Coal Technology, 2021, 27(5): 106−114.

[6] P. MPOFU, J. ADDAI−MENSAH, J. Ralston, Flocculation and dewatering behaviour of smectite dispersions: effect of polymer structure type[J]. Minerals Engineering, 2004, 17: 411−423.

[7] M. LEMANOWICZ, Z. JACH, E. KILIAN, A. Gierczycki, Ultra−fine coal flocculation using dual−polymer systems of ultrasonically conditioned and unmodified flocculant[J]. Chemical Engineering Journal, 2011, 168: 159−169. doi: 10.1016/j.cej.2010.12.057

[8] M. LEMANOWICZ, A. KUS, A. T. Gierczycki, Influence of ultrasonic conditioning of flocculant on the aggregation process in a tank with turbine mixer[J]. Chemical Engineering and Processing:Process Intensification, 2010, 49: 205−211. doi: 10.1016/j.cep.2009.12.007

[9] 孙浩. 超声波预处理—复合絮凝剂作用下铅锌尾矿颗粒聚集沉降行为研究[D]. 武汉: 武汉科技大学, 2021.

SUN H. Study on aggregation and settlement behavior of lead−zinc tailings particles under the action of ultrasonic pretreatment−compound flocculant[D]. Wuhan: Wuhan University of Science and Technology, 2021.

[10] G ANTTI, P PENTTI, K Hanna. Ultrasonic degradation of aqueous carboxymethylcellulose: effect of viscosity, molecular mass, and concentration[J]. Ultrasonics Sonochemistry, 2008, 15: 644−648. doi: 10.1016/j.ultsonch.2007.09.005

[11] A GRÖNROOS, P PIRKONEN, O Ruppert. Ultrasonic depolymerization of aqueous carboxymethylcellulose[J]. Ultrasonics Sonochemistry, 2004, 11: 9−12. doi: 10.1016/S1350-4177(03)00129-9

[12] 程效锐, 张舒研, 房宁. 超声空化技术在化工领域的应用研究进展[J]. 应用化工, 2018, 8: 1753−1757.

CHENG X R, ZHANG S Y, FANG N. Research progress and application situation of the ultrasonic cavitation technology in chemical industry field[J]. Applied Chemical Industry, 2018, 8: 1753−1757.

[13] ZHOU S, BU X, M. Alheshibri, et al. Floc structure and dewatering performance of kaolin treated with cationic polyacrylamide degraded by hydrodynamic cavitation[J]. Chemical Engineering Communications, 2022, 209(6): 798−807. doi: 10.1080/00986445.2021.1919652

[14] H. Anlauf, Wet Cake Filtration: Fundamentals, Equipment, and Strategies, John Wiley & Sons2019.

[15] HU P, LIANG L, WANG W, et al. Filtration of coal tailings aided by a novel physical conditioner carbon–containing fly ash[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020: 1−13.

[16] CAO B, ZHANG W, WANG Q. Wastewater sludge dewaterability enhancement using hydroxyl aluminum conditioning: Role of aluminum speciation[J]. Water Research, 2016, 105: 615−624. doi: 10.1016/j.watres.2016.09.016

-

下载:

下载: