Comparative Study of Nanobubble Flotation and Traditional Flotation for Micro-fine Flake Graphite

-

摘要:

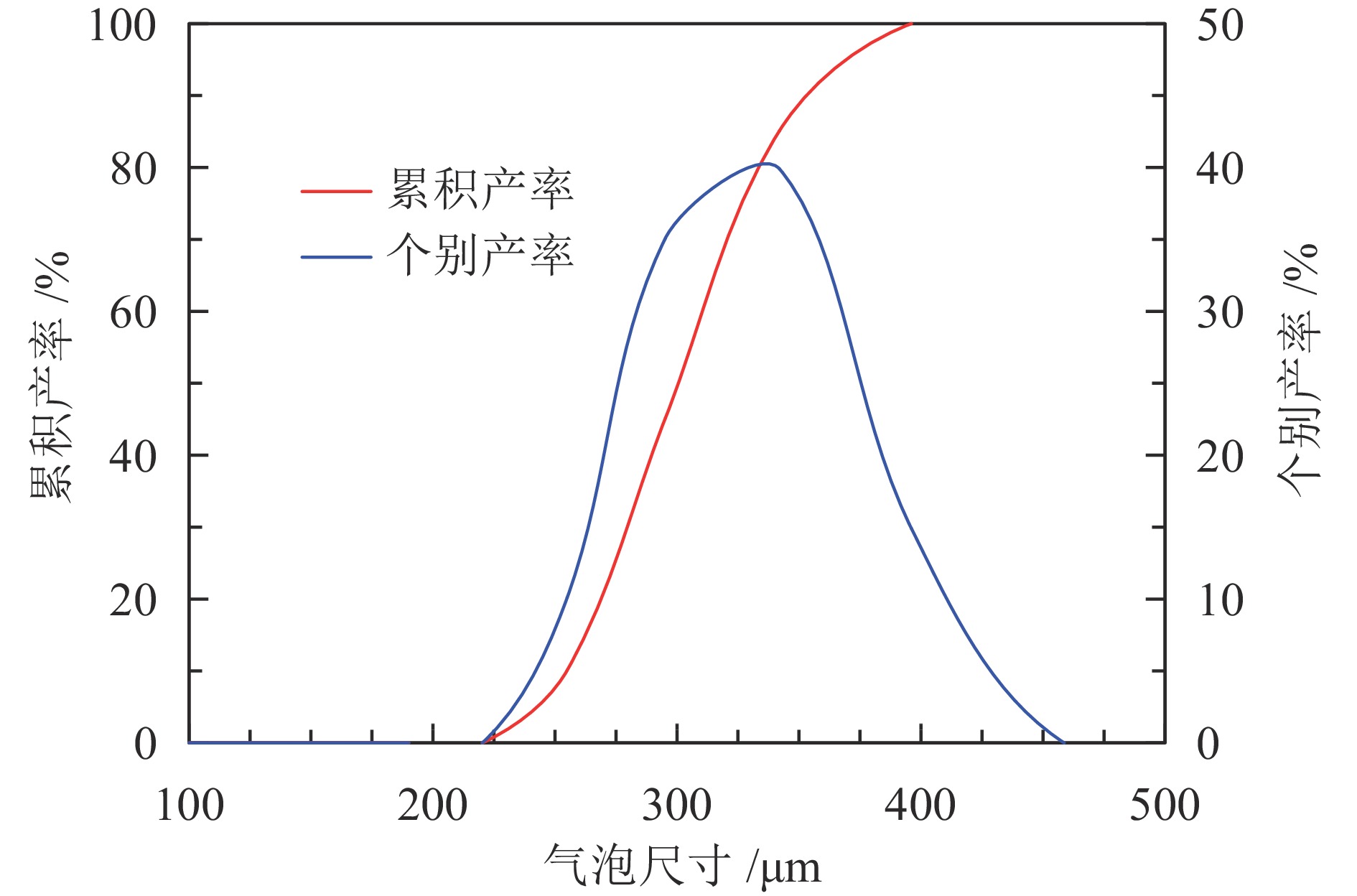

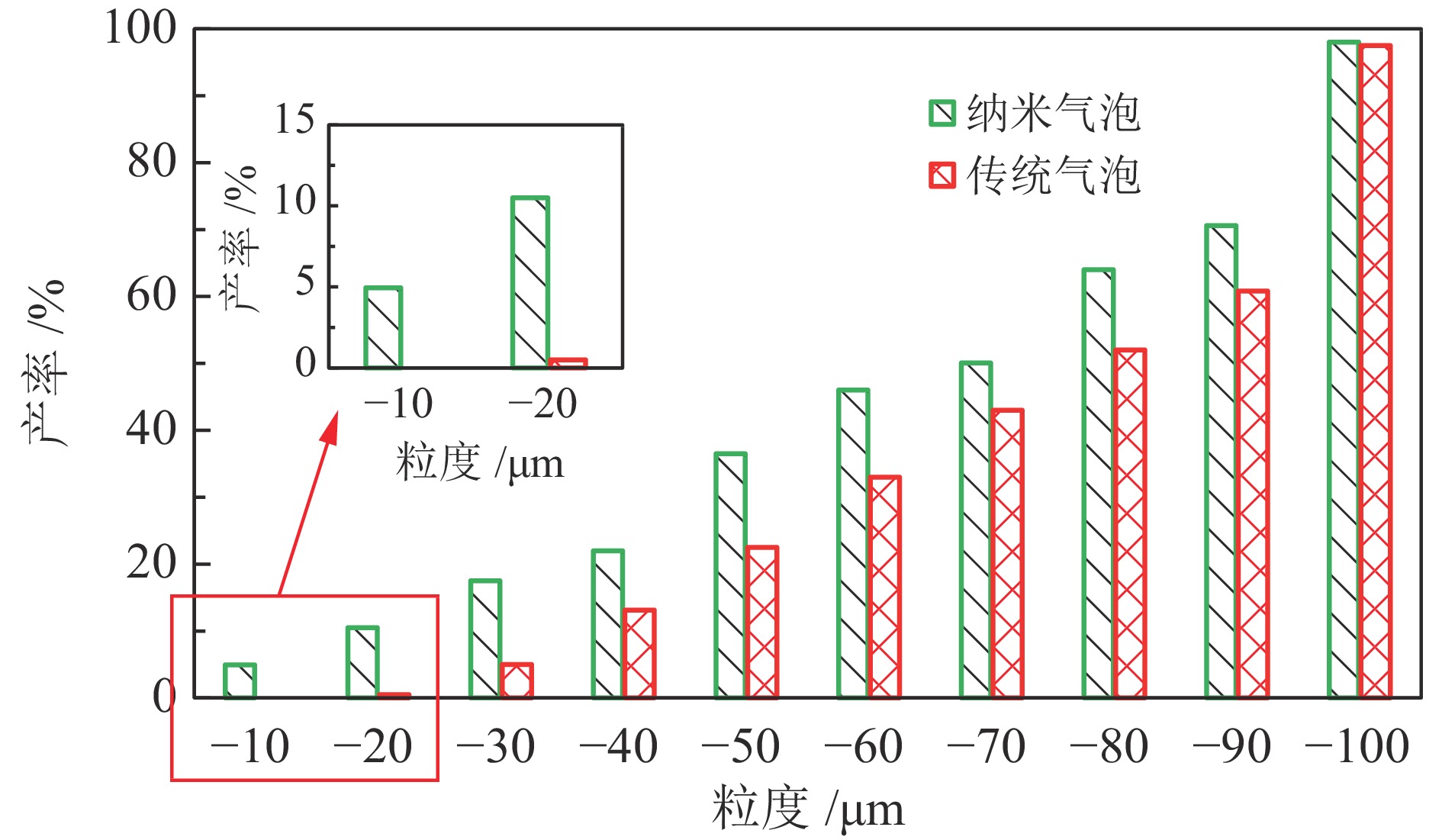

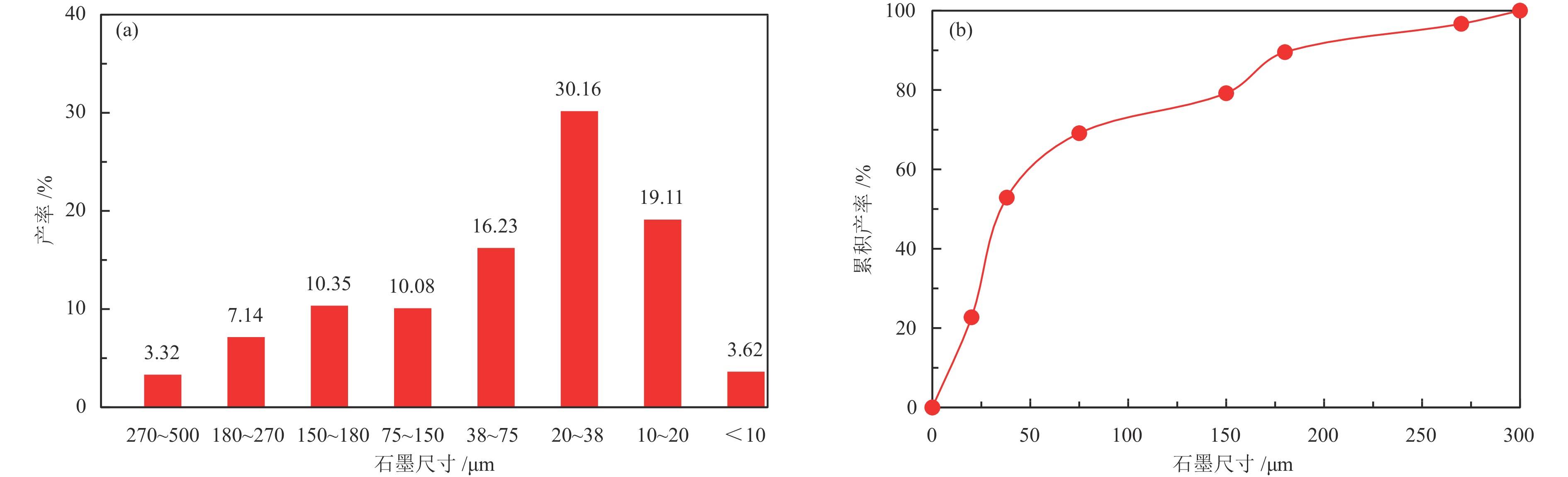

微细鳞片石墨资源将是未来利用的主要石墨资源,为了实现微细鳞片石墨高效回收,探究了纳米气泡对微细鳞片石墨浮选强化行为的影响。通过浮选动力学、激光粒度分析仪、Zeta电位仪以及接触角分析仪研究了纳米气泡浮选和传统浮选行为的差异。结果表明,纳米气泡比传统浮选提前25 s完成微细鳞片石墨浮选。传统浮选精矿回收率和碳含量分别为87.89%和72.31%,纳米气泡浮选精矿回收率和碳含量分别为92.91%和73.40%,相比传统浮选精矿回收率高约5百分点,碳含量高约1百分点。纳米气泡可以有效团聚微细鳞片石墨,增大其表观尺寸,改善浮选效果。纳米气泡可以回收传统浮选不能有效回收的10 μm以下微细鳞片石墨,进而提高了回收率。纳米气泡浮选精矿表面接触角比传统浮选精矿表面接触角高6.92°,有利于柴油在石墨表面的吸附,改善了石墨表面疏水性。纳米气泡降低了微细鳞片石墨颗粒间的静电斥力,有利于微细鳞片石墨疏水性团聚体的稳定结构,从而提高浮选概率。

Abstract:With the depletion of large flake graphite resources, micro−flake graphite resources will be the main graphite resources in the future, and it is imperative to develop micro−scale graphite ore separation technology. This work mainly investigated the effect of nanobubbles on the strengthening flotation behavior of fine flake graphite in order to achieve efficient recovery of micro−fine flake graphite. The differences between nanobubble flotation and conventional flotation were studied by flotation kinetics, laser particle size analyzer, Zeta potentiometer and contact angle analyzer. The results showed that the nano-bubble flotation time was 25 seconds earlier to complete the flotation of fine flake graphite compared with the traditional flotation. The recovery and carbon content of nanobubble flotation concentrate were 92.91% and 73.40%, respectively, which were about 5 percentage points and 1 percentage point higher than that of traditional flotation concentrate. The results of laser dynamic analysis of pulp showed that nanobubbles can effectively aggregate micro−fine flake graphite, increased its apparent size and improved the flotation effect. The results of particle size analysis of concentrate showed that nanobubbles can recover the micro−fine flake graphite below 10 μm which can not be recovered effectively by traditional flotation, thus improving the recovery of concentrate flotation. The contact angle analysis results showed that the surface contact angle of the nanobubble flotation concentrate was 6.92° higher than that of the traditional flotation concentrate, so the surface hydrophobicity of the graphite was improved. The Zeta potential test results showed that the nanobubbles reduced the electrostatic repulsion between the particles of micro−fine flake graphite, which was conducive to the stable aggregate structure of microscale graphite to improve the flotation probability.

-

Key words:

- micro−fine flake graphite /

- nanobubbles /

- particle size /

- flotation behavior

-

-

图 2 纳米气泡浮选与常规浮选实验装置示意图[7]

Figure 2.

表 1 样品主要矿物组成

Table 1. Main mineral composition of the sample

矿物 石墨 白云母 黄铁矿 石英 石榴石 高岭石 含量/% 29.86 17.29 8.20 22.12 4.36 7.26 -

[1] 马芳源. 石墨矿纳米气泡高效浮选及其机理研究[D]. 徐州: 中国矿业大学, 2022.

MA F Y. Study on high−efficiency nanobubble flotation of graphite ore and its mechanisms[D]. Xuzhou: China University of Mining and Technology, 2022.

[2] ZHANG D, MA F, TAO Y. Study on effect of nanobubble on ultra−fine flake graphite (UFG) flotation[J]. Particulate Science and Technology, 2023, 41(7): 1062−1070.

[3] KANG W, LI H. Enhancement of flaky graphite cleaning by ultrasonic treatment[J]. Royal Society Open Science, 2019, 6(12): 191160. doi: 10.1098/rsos.191160

[4] BU X, ZHANG T, CHEN Y, et al. Comparison of mechanical flotation cell and cyclonic microbubble flotation column in terms of separation performance for fine graphite[J]. Physicochemical Problems of Mineral Processing, 2018, 54(3): 732−740.

[5] BU X, ZHANG T, PENG Y, et al. Multi−stage flotation for the removal of ash from fine graphite using mechanical and centrifugal forces[J]. Minerals, 2018, 8(1): 15.

[6] SHI Q, LIANG X, FENG Q, et al. The relationship between the stability of emulsified diesel and flotation of graphite[J]. Minerals Engineering, 2015, 78: 89−92. doi: 10.1016/j.mineng.2015.04.014

[7] MA F, TAO D, TAO Y, et al. An innovative flake graphite upgrading process based on HPGR, stirred grinding mill, and nanobubble column flotation[J]. International Journal of Mining Science and Technology, 2021, 31(6): 1063−1074. doi: 10.1016/j.ijmst.2021.06.005

[8] ALHESHIBRI M, QIAN J, JEHANNIN M, et al. A history of nanobubbles[J]. Langmuir, 2016, 32: 11086−11100. doi: 10.1021/acs.langmuir.6b02489

[9] SADA E, Y ASUNISHI A, KATOH S, et al. Bubble formation in flowing liquid[J]. The Canadian Journal of Chemical Engineering, 1978, 56(6): 669–672.

[10] TANG C, MA F, WU T, et al. Study on surface physical and chemical mechanism of nanobubble enhanced flotation of fine graphite[J]. Journal of Industrial and Engineering Chemistry, 2023, 122: 389−396. doi: 10.1016/j.jiec.2023.02.039

[11] ZHANG X, WANG Q, WU Z, et al. An experimental study on size distribution and zeta potential of bulk cavitation nanobubbles[J]. International Journal of Minerals Metallurgy and Materials, 2021, 27(2): 152−161.

[12] MA F, TAO D. A study of mechanisms of nanobubble−enhanced flotation of graphite[J]. Nanomaterials, 2022, 12(19): 3361. doi: 10.3390/nano12193361

[13] LIU L, HU S, WU C, et al. Aggregates characterizations of the ultra−fine coal particles induced by nanobubbles[J]. Fuel, 2021, 297: 120765. doi: 10.1016/j.fuel.2021.120765

[14] ZHOU W, CHEN H, OU L, et al. Aggregation of ultra−fine scheelite particles induced by hydrodynamic cavitation[J]. International Journal of Mineral Processing, 2016, 157: 236−240. doi: 10.1016/j.minpro.2016.11.003

[15] MA F, TAO D, TAO Y. Effects of nanobubbles in column flotation of Chinese sub−bituminous coal[J]. International Journal of Coal Preparation and Utilization, 2022, 42(4): 1126−1142. doi: 10.1080/19392699.2019.1692340

[16] SOBHY A, TAO D. Nanobubble column flotation of fine coal particles and associated fundamentals[J]. International Journal of Mineral Processing, 2013, 124: 109−116. doi: 10.1016/j.minpro.2013.04.016

[17] CALGAROTO S, AZEVEDO A, RUBIO J. Flotation of quartz particles assisted by nanobubbles[J]. International Journal of Mineral Processing, 2015, 137: 64−70. doi: 10.1016/j.minpro.2015.02.010

-

下载:

下载: