Effect and Mechanism of Carboxymethyl Cellulose on Flotation Separation of Apatite Against Dolomite

-

摘要:

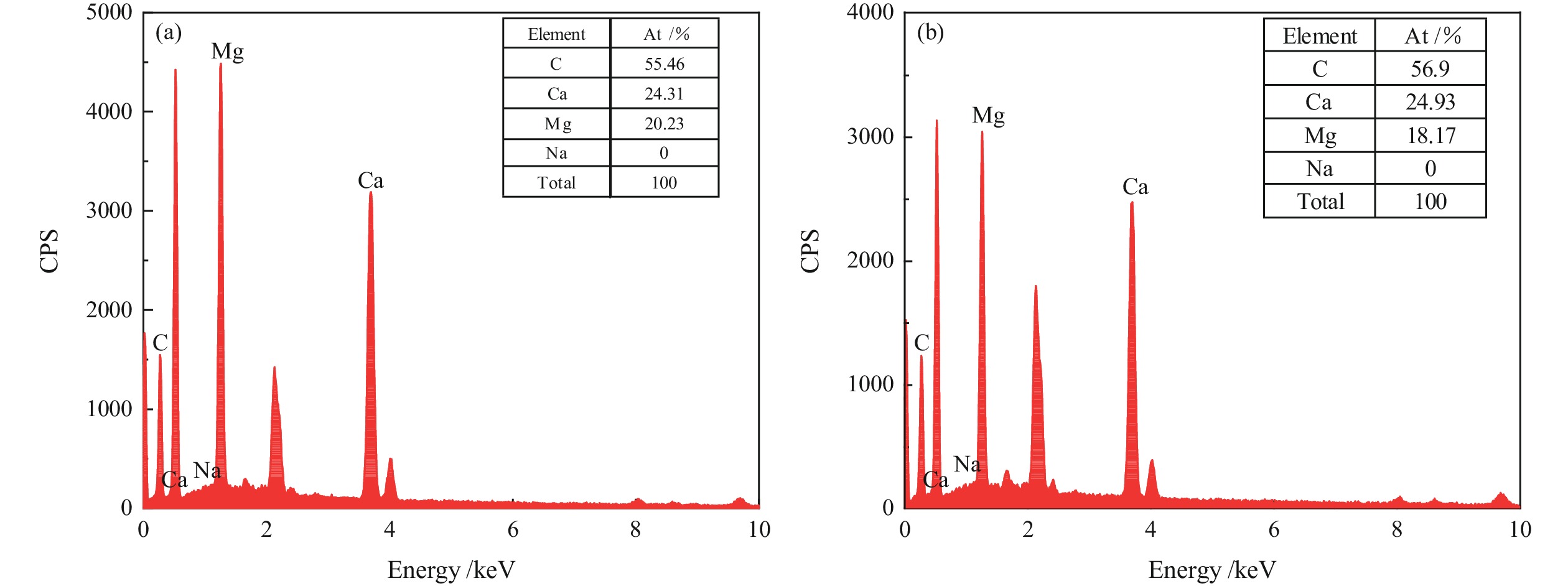

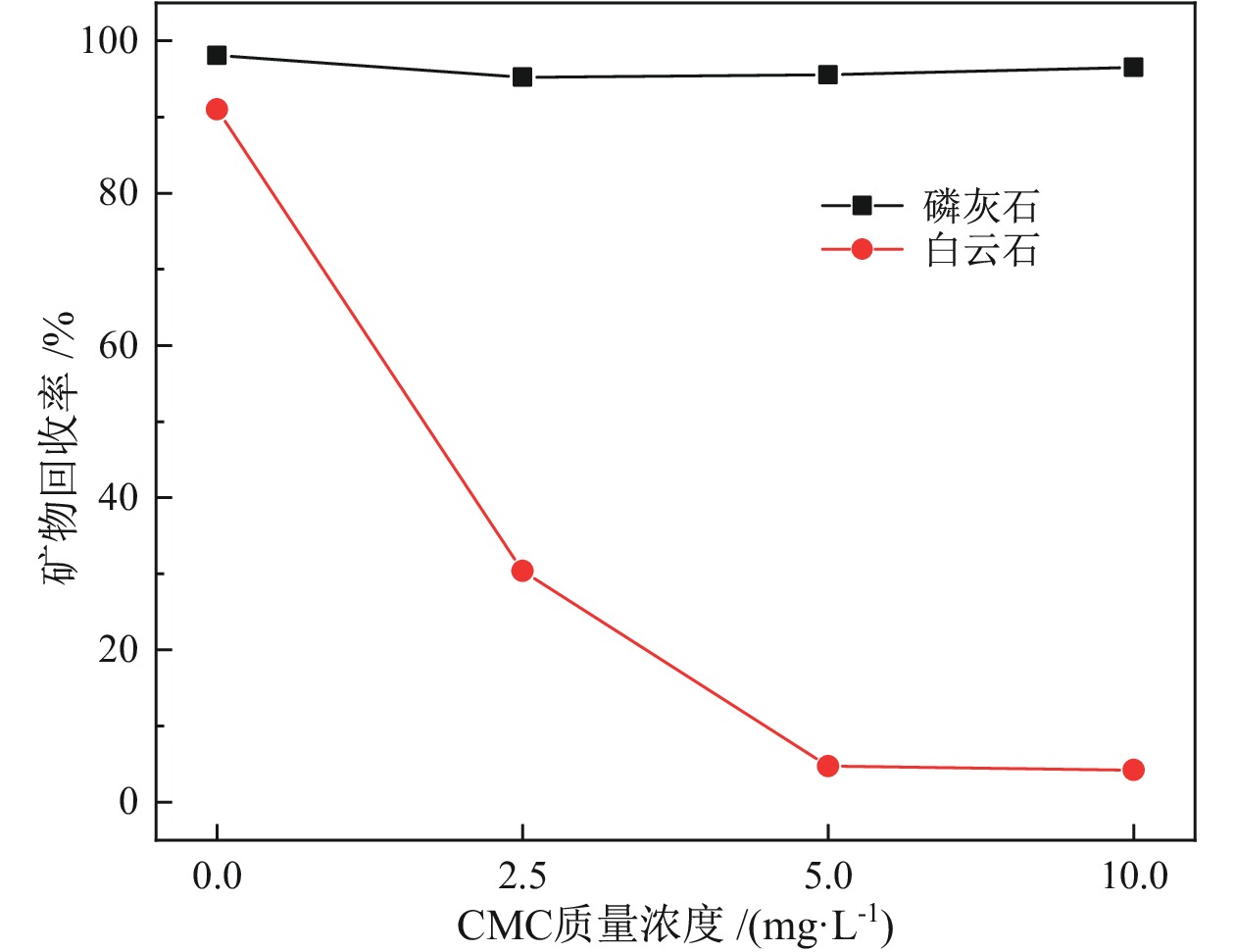

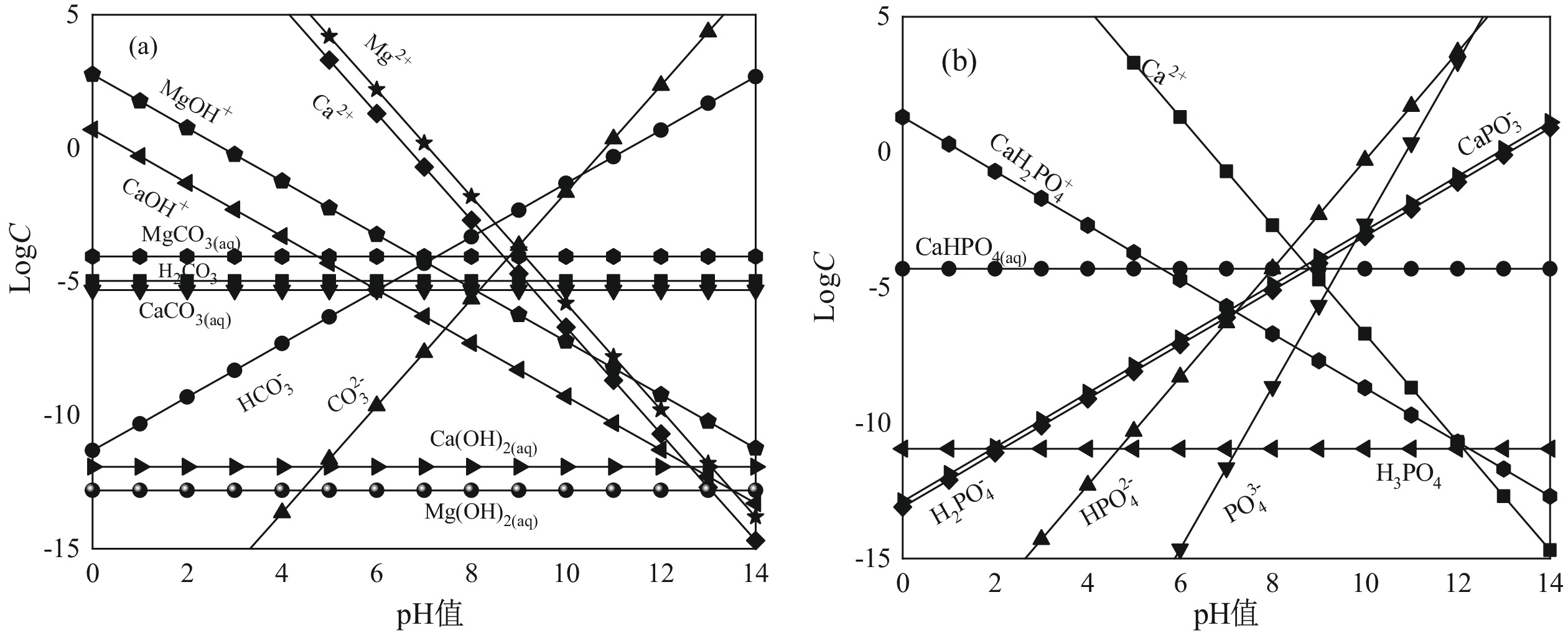

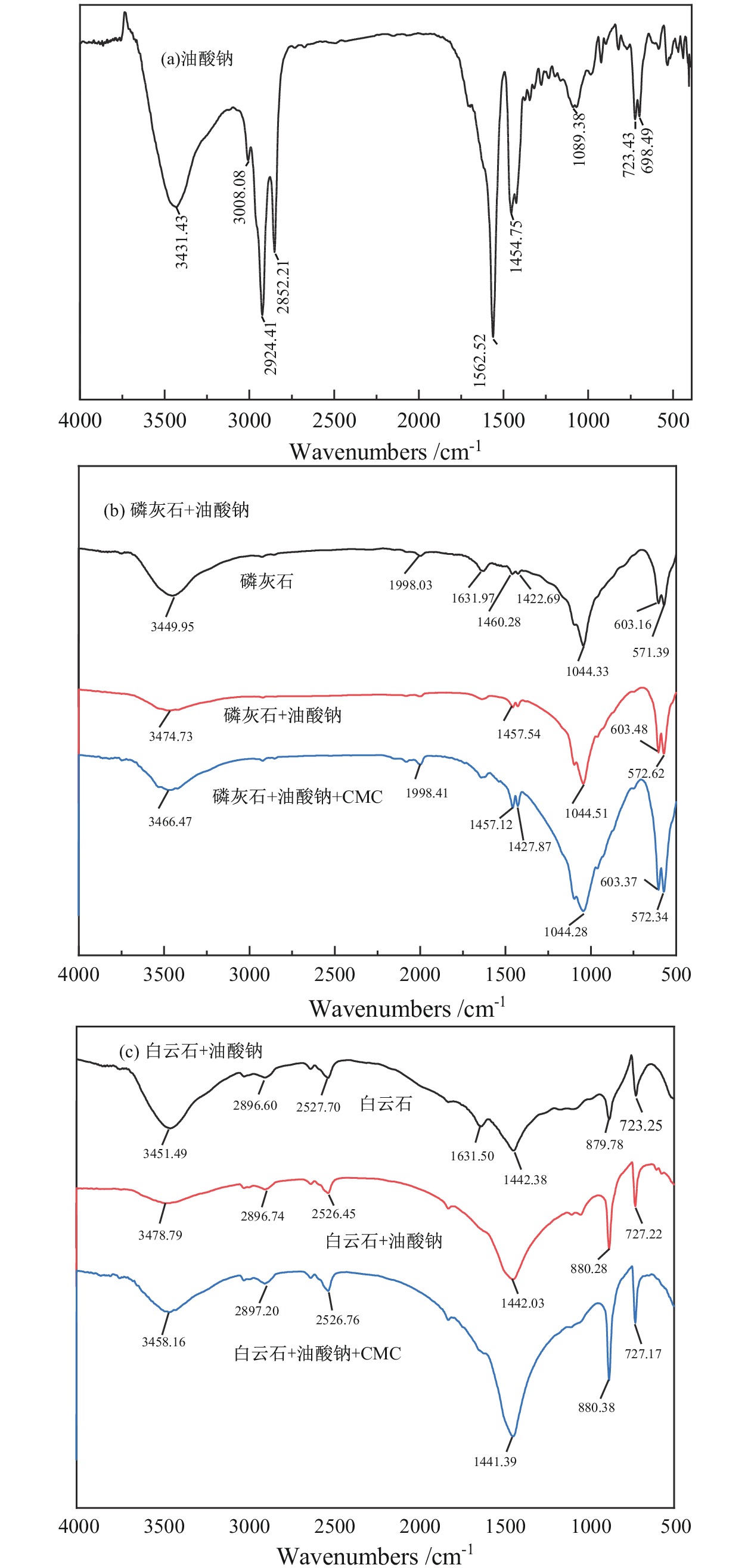

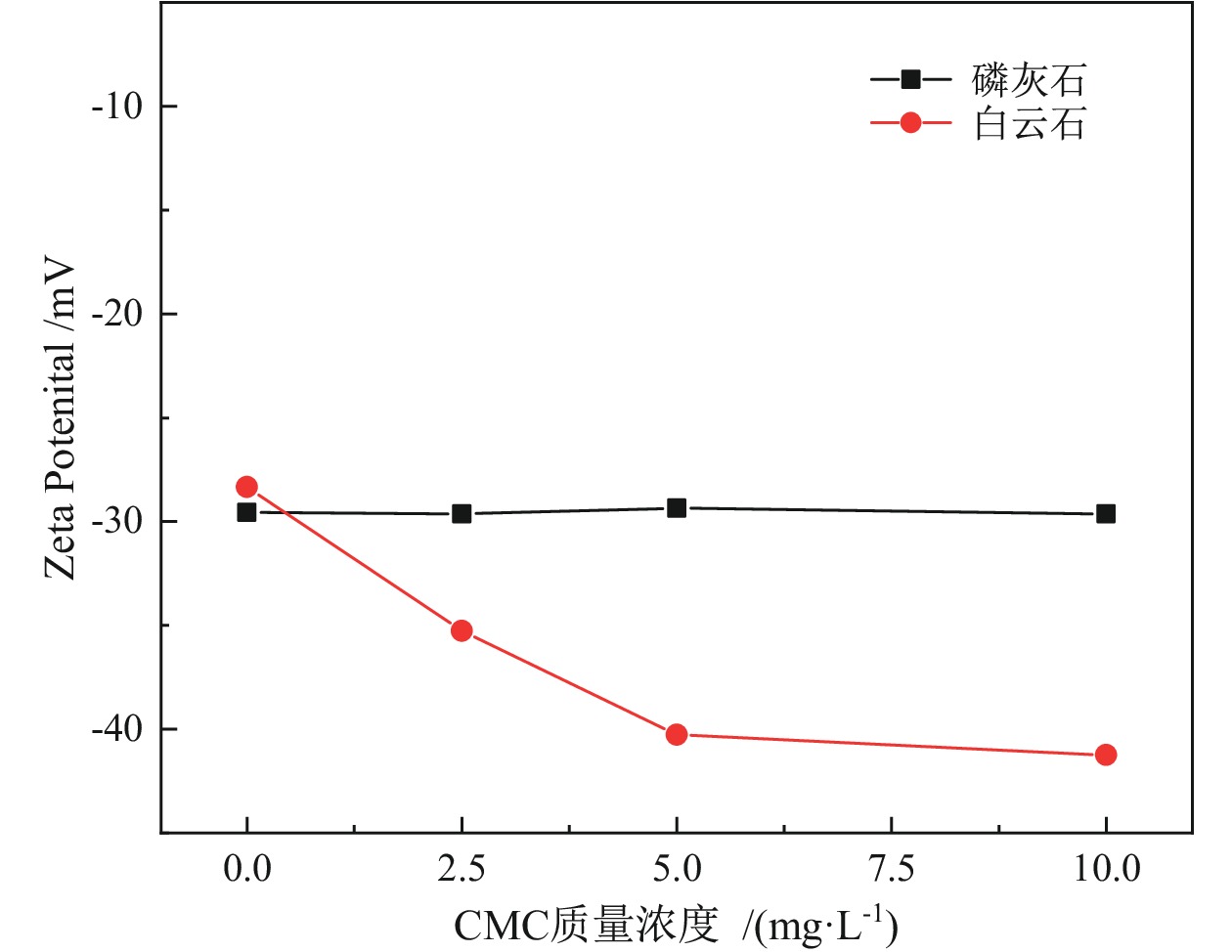

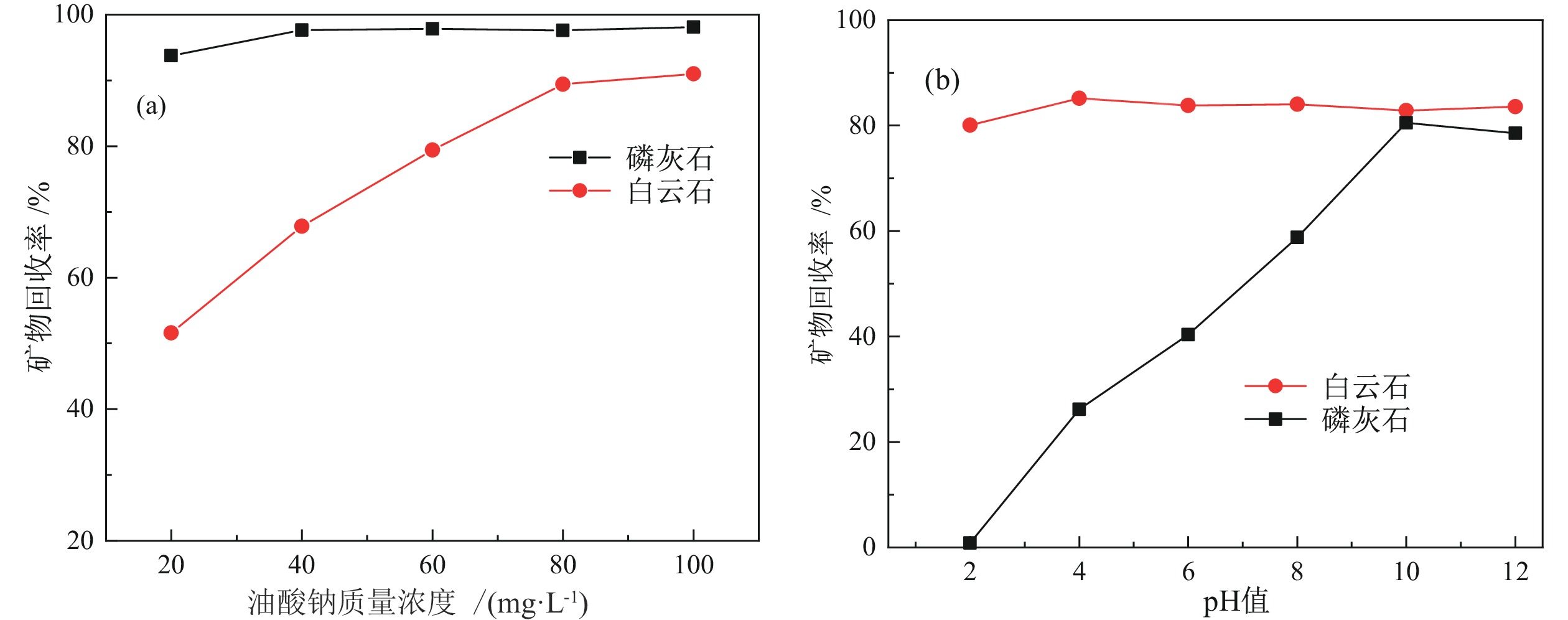

以磷灰石和白云石为研究对象,采用纯矿物浮选实验、红外光谱分析、Zeta电位分析等方法,探讨油酸钠体系中羧甲基纤维素(CMC)对两种矿物浮选分离的影响及作用机理。实验结果表明:油酸钠为捕收剂用量100 mg/L,在无抑制剂CMC时,白云石和磷灰石的回收率均在90%以上;而CMC质量浓度5 mg/L时,白云石与磷灰石的回收率分别为4.72%、95.52%,实现了白云石与磷灰石的高效分离。机理分析表明:油酸钠在磷灰石和白云石表面主要以物理吸附为主,而CMC可能与白云石表面的Mg2+“桥接”,阻碍了油酸钠在白云石表面的吸附,且其阻碍油酸钠在磷灰石表面吸附的能力很小,因此CMC对白云石具有较强的选择性抑制作用;在油酸钠体系中,随着CMC质量浓度的增大,磷灰石表面电位发生轻微负偏移,而白云石表面电位出现大幅负移,说明CMC能阻止油酸钠在白云石表面的吸附,却不影响油酸钠在磷灰石表面的吸附,因此能达到选择性抑制白云石浮选的效果。

Abstract:Effect of carboxymethyl cellulose (CMC) in sodium oleate system on the flotation separation of apatite against dolomite in single mineral experiments was investigated in this study, and its mechanism was further studied through infrared spectrum analysis and Zeta potential analysis. The recovery of apatite and dolomite both attained 90% with 100 mg/L sodium oleate, and changed to 95.52% and 4.72%, respectively with addition of 5 mg/L CMC. As a result, the efficient separation of apatite against dolomite was achieved. The adsorption of sodium oleate on the surface of apatite and dolomite was a physical process. CMC was connected with Mg2+ on the surface of dolomite like a "bridge", and hindered the adsorption of sodium oleate on the surface of dolomite. The ability of CMC to hinder the adsorption of sodium oleate on the surface of apatite was extremely limited, so CMC would not influence the flotation of apatite. The Zeta potential results indicated that the surface potential of apatite had a slight negative shift with the increase of CMC concentration, while that of dolomite had a significantly negative shift, indicating that CMC can prevent the adsorption of sodium oleate on the surface of dolomite, but cannot prevent the adsorption of sodium oleate on the surface of apatite.

-

Key words:

- apatite /

- dolomite /

- flotation separation /

- carboxymethyl cellulose /

- depression

-

-

表 1 白云石和磷灰石多元素分析结果

Table 1. Chemical compositions of dolomite and apatite

/% 矿物 MgO CaO P2O5 SiO2 CO2 F Al2O3 MnO2 Fe2O3 Na2O 白云石 21.22 30.32 — 4.77 10.39 — 0.15 0.007 0.42 0.08 磷灰石 — 40.98 38.93 1.14 10.83 2.93 0.27 0.013 0.44 0.37 表 2 磷灰石和白云石粒度分析测试结果

Table 2. Particle size analysis of dolomite and apatite

/μm 矿物种类 D10 D25 D50 D75 D90 白云石 2.07 7.45 22.99 42.96 62.17 磷灰石 1.46 16.11 28.31 48.60 67.52 -

[1] 崔荣国, 张艳飞, 郭娟, 等. 资源全球配置下的中国磷矿发展策略[J]. 中国工程科学, 2019, 21(1): 128−132.

CUI R G, ZHANG Y F, GUO J, et al. Development strategy of phosphate rock in China under global allocation of resources[J]. Strategic Study of Chinese Academy of Engineering, 2019, 21(1): 128−132.

[2] CAO Q, CHENG J, WEN S, et al. A mixed collector system for phosphate flotation[J]. Minerals Engineering, 2015, 78: 114−121. doi: 10.1016/j.mineng.2015.04.020

[3] 杨晓健, 胡国涛, 王诗瀚. 中低品位磷矿脱镁技术研究进展[J]. 矿产保护与利用, 2022, 42(2): 67−73.

YANG X J, HU G T, WANG S H. Research progress of magnesium removal technology from medium and low grade phosphate rocks[J]. Conservation and Utilization of Mineral Resources, 2022, 42(2): 67−73.

[4] 罗红莹. 油酸钠体系中锡石与绿泥石浮选选择性抑制作用研究[D]. 昆明: 昆明理工大学, 2021.

LUO H Y. Selective inhibition of cassiterite and chlorite flotation in sodium oleate system[D]. Kunming: Kunming University of Science and Technology, 2021.

[5] 任皞, 纪绯绯. 铌钙矿及其主要脉石矿物浮选的抑制与分离[J]. 有色金属, 2003(1): 96−98.

REN H, JI F F. Development strategy of phosphate rock in china under global allocation of resources[J]. Nonferrous Metals Engineering, 2003(1): 96−98.

[6] 邬海滨. 纤维素类抑制剂在白钨矿浮选体系中的吸附行为与机理研究[D]. 赣州: 江西理工大学, 2018.

WU H B. Adsorption behavior and mechanism of cellulose inhibitors in the system of scheelite flotation[D]. Ganzhou: Jiangxi University of Science and Technology, 2018.

[7] 张文谱. 高分子抑制剂对磷灰石与含钙碳酸盐矿物浮选行为的影响及机理研究[D]. 赣州: 江西理工大学, 2020.

ZHANG W P. Effects of macromolecular organic depressants on flotation behavior of apatite and calcium carbonate minerals and the mechanism [D]. Ganzhou: Jiangxi University of Science and Technology, 2020.

[8] 张书超. 磷灰石浮选体系中矿物的交互影响研究[D]. 福州: 福州大学, 2018.

ZHANG S C. Study on interaction of minerals in apatite flotation system [D]. Fuzhou: Fuzhou University, 2018.

[9] 唐云, 杨典奇, 王雪, 等. 羟肟酸协同脂肪酸分离磷灰石和白云石[J]. 金属矿山, 2016(4): 86−90.

TANG Y, YANG D Q, WANG X, et al. Synergistic effect of fatty acid and hydroxamic acid in flotation separation of apatite and dolomite[J]. Metal Mine, 2016(4): 86−90.

[10] 张国范, 冯寅, 朱阳戈, 等. 钙、镁离子对磷灰石与白云石浮选行为的影响[J]. 化工矿物与加工, 2011, 40(7): 1−4+10.

ZHANG G F, FENG Y, ZHU Y G, et al. Influence of Ca2+、Mg2+ on apatite and dolomite flotation[J]. Industrial Minerals & Processing, 2011, 40(7): 1−4+10.

[11] 马强, 李育彪, 李万青, 等. CMC浮选分离萤石与方解石作用机理研究[J]. 金属矿山, 2022(7): 187−192.

MA Q, LI Y B, LI W Q, et al. Study on the reaction mechanism of fluorite and calcite flotation separation by carboxymethyl cellulose[J]. Metal Mine, 2022(7): 187−192.

[12] Ló PEZ−VALDIVIESO A, LOZANO−LEDESMA L A, ROBLEDO−CABRERA A, et al. Carboxymethylcellulose (CMC) as PbS depressant in the processing of Pb−Cu bulk concentrates: Adsorption and floatability studies[J]. Minerals Engineering, 2017, 112: 77−83. doi: 10.1016/j.mineng.2017.07.012

[13] 张汉泉, 许鑫, 肖林波, 等. 油酸钠在细粒白云石表面吸附特性研究[J]. 矿冶工程, 2021, 41(2): 33−38.

ZHANG H Q, XU X, XIAO L B, et al. Adsorption characteristics of sodium oleate on fine dolomite[J]. Mining and Metallurgical Engineering, 2021, 41(2): 33−38.

[14] 李彩霞, 刘高全, 白阳, 等. 油酸钠体系中菱镁矿−白云石浮选实验研究[J]. 非金属矿, 2018, 41(4): 77−79.

LI C X, LIU G Q, BAI Y, et al. Study on flotation process of magnesite and dolomite in sodium oleate system[J]. Non−Metallic Mines, 2018, 41(4): 77−79.

[15] 印万忠, 唐远, 姚金, 等. 矿物浮选过程中的交互影响[J]. 矿产保护与利用, 2018(3): 55−60.

YIN W Z, TANG Y, YAO J, et al. Interactive effects in mineral flotation process[J]. Conservation and Utilization of Mineral Resources, 2018(3): 55−60.

[16] LIU X, LUO H H, CHENG R J, et al. Effect of citric acid and flotation performance of combined depressant on collophanite ore[J]. Minerals Engineering, 2017, 109: 162−168. doi: 10.1016/j.mineng.2017.03.010

[17] GUO F, LI J. Separation strategies for Jordanian phosphate rock with siliceous and calcareous gangues[J]. Mineral Processing, 2010, 97(1/4): 74−78.

[18] 阮耀阳, 罗惠华, 张泽强, 等. 难选硅钙质胶磷矿正反浮选研究[J]. 矿冶工程, 2017, 37(6): 38−41. doi: 10.3969/j.issn.0253-6099.2017.06.009

RUAN Y Y, LUO H H, ZHANG Z Q, et al. Direct−everse flotation of refractory siliceous−calcareous collophane ore[J]. Mining and Metallurgical Engineering, 2017, 37(6): 38−41. doi: 10.3969/j.issn.0253-6099.2017.06.009

[19] 刘朋, 葛英勇, 刘鸣, 等. 四川某磷矿双反浮选实验研究[J]. 矿冶工程, 2018, 38(3): 63−65+70. doi: 10.3969/j.issn.0253-6099.2018.03.015

LIU P, GE Y Y, LIU M, et al. Experimental research on double reverse flotation of phosphate ore from sichuan[J]. Mining and Metallurgical Engineering, 2018, 38(3): 63−65+70. doi: 10.3969/j.issn.0253-6099.2018.03.015

[20] DU W F, LI X B. Insight into the inhibition mechanism of carboxymethyl cellulose for flotation of dolomite and fluorapatite: experimental and DFT studies[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 604(5): 131957.

-

下载:

下载: