Identification of Sericite in Graphite Tailing of Heilongjiang Provice by X-ray Diffraction, Scanning Electron Microscopy and Optical Microscope

-

摘要:

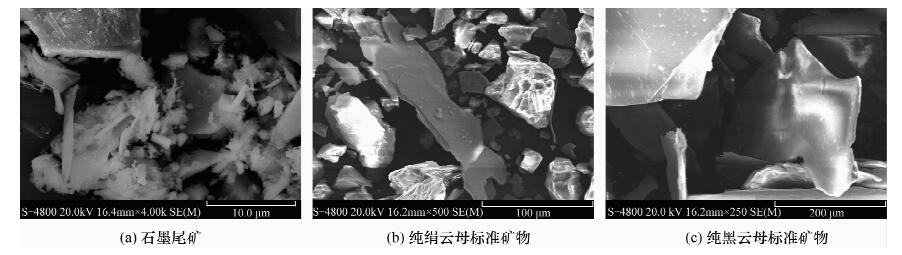

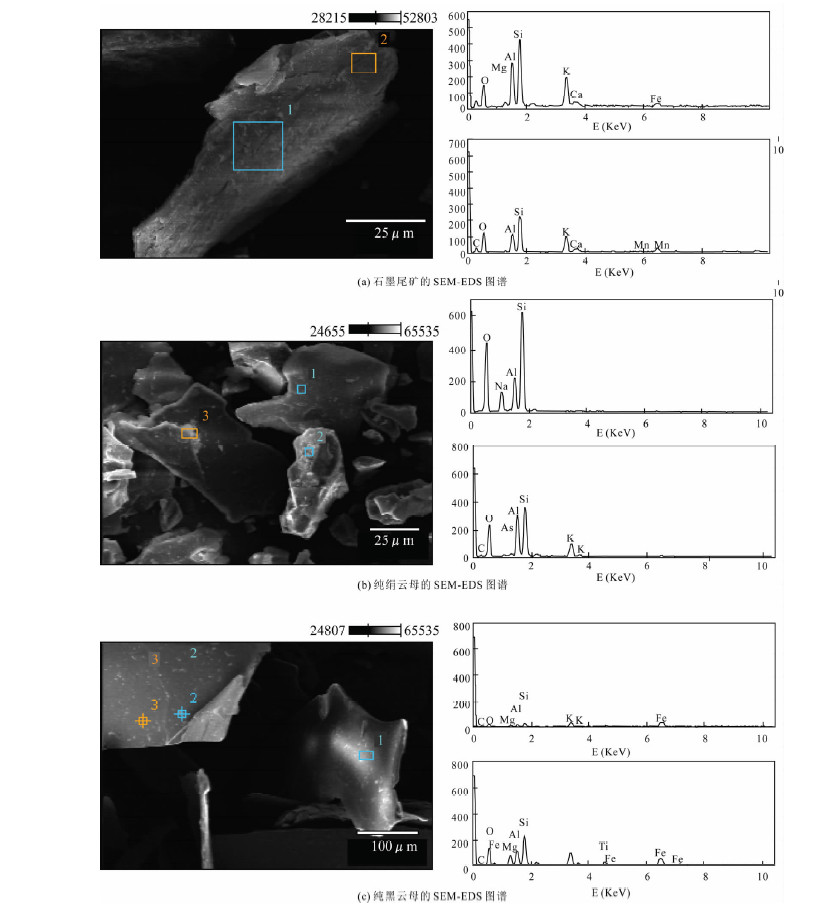

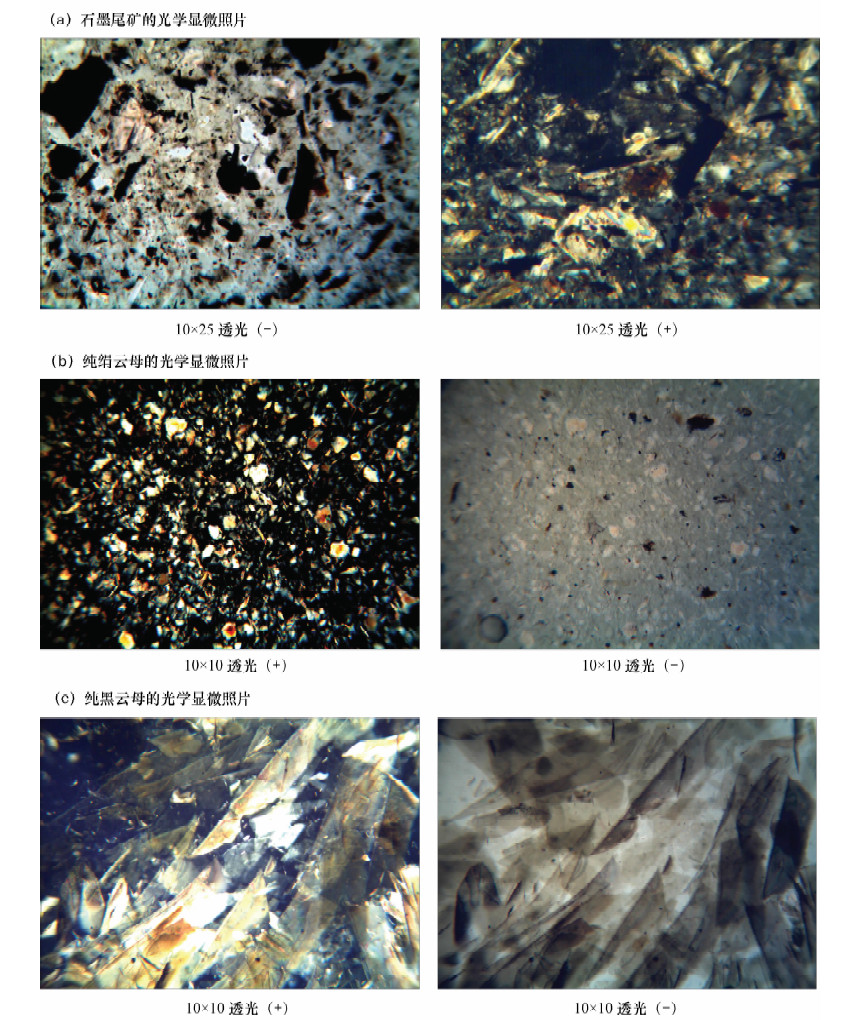

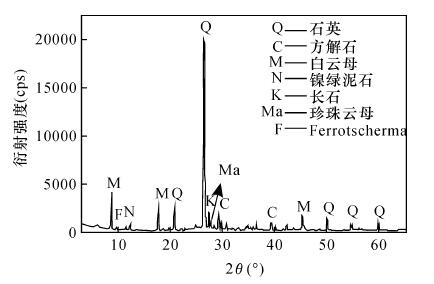

石墨尾矿作为一类二次资源, 当云母类矿物的含量在10%以上时, 具有回收利用价值。黑龙江某地石墨尾矿中含有10%以上的云母类矿物, 但其细度(500~800目)低于常规的云母矿, 本文采用X射线衍射(XRD)分析矿物组成, 再结合化学分析、扫描电镜-能谱、光学显微镜与纯矿物进行对比, 由此鉴定云母类矿物种属。XRD研究初步表明石墨尾矿含有的云母族矿物属于白云母亚类或黑云母亚类。扫描电镜分析表明尾矿中的云母矿物与纯绢云母矿物均以片状和鳞片状为主要存在形态, 而纯黑云母主要以片状形式存在。尾矿的SiO2含量为5%~13%, Al2O3含量为4%~8%, 与纯绢云母接近。光学显微镜鉴定显示在正交偏光下石墨尾矿中的云母颜色和纯绢云母类似, 而与纯黑云母截然不同。综合以上结果最终可确定该地石墨尾矿中的云母族矿物为白云母亚类中的绢云母。本研究为后续石墨尾矿的选矿工艺奠定了基础, 也可应用于类似细度绢云母的鉴定。

Abstract:Graphite tailing is a secondary resource, and could be be recovered when the mica mineral content in tailing is higher than 10%. Graphite tailings in Heilongjiang Province contain >10% mica minerals that are 500-800 mesh. These minerals are finer than conventional mica minerals making it difficult to identify its mineral species. In order to resolve this problem, X-ray Diffraction (XRD) was used to analysis mineral composition of the graphite tailing, along with chemical analysis, Scanning Electron Microscopy-Energy-Dispersive Spectrometry (SEM-EDS) and Optical Microscopy. XRD analysis shows that mica minerals can be recovered and chemical analysis indicates that these minerals are possibly muscovite or biotite. Morphology studies indicate that mica minerals in graphite tailing and pure sericite minerals are mainly schistic and scaled, whereas pure biotite is mainly schistic. EDS analysis shows that graphite tailing contains 5%-13% SiO2 and 4%-8% Al2O3. Mica mineral in graphite tailing has color similar to that of pure sericite but different from that of pure biotite, indicated by Optical Microscope. It is concluded that the mica mineral in graphite tailing is sericite of muscovite subtype. This research will provide reliable information for the subsequent mineral processing of graphite tailing and identification of sericite with similar fineness.

-

-

表 1 石墨尾矿、纯绢云母、纯黑云母的SEM-EDS图像(图 3) 中对应点位的成分

Table 1. Compositions of points in SEM-EDS micrographs of graphite tailing (Fig.3a), pure sericite (Fig.3b) and pure biotite (Fig.3c)

图 3a对应

的点位元素含量(%) C O Mg Al Si K Ca Mn Fe pt1 32.09 36.10 0.78 7.80 12.41 7.84 1.10 - 1.89 pt2 40.06 40.06 - 4.11 8.58 5.28 1.44 0.48 - 图 3b对应的

点位C O Na Al Si K Fe As pt2 - 57.63 10.19 8.04 24.14 - - - pt3 19.13 52.84 - 10.20 13.06 4.76 - 0.00 图 3c对应的

点位C O Mg Al Si K Ti Fe pt1 40.53 24.79 2.73 2.04 3.04 6.45 - 20.42 pt2 21.42 41.37 4.17 4.91 9.96 5.59 1.34 11.23 -

[1] [2] [3] [4] [5] [6] [7] 马鸿文编著.工业矿物与岩石(第三版)[M].北京:化学工业出版社,2011.

Ma H W. Industrial Minerals and Rocks(the Third Edition)[M].Beijing: Chemical Industry Press,2011.

[8] [9] [10] 李凤. 石墨尾矿中回收石墨和绢云母的选矿工艺研究[D]. 北京: 北京有色金属研究总院, 2014.

Li F. Research of Mineral Processing Technology Recycle Graphite and Sericite from Graphite Tailings[D]. Beijing: Beijing General Research Institute for Nonferrous Metals, 2014.

[11] [12] [13] [14] [15] [16] [17] doi: 10.1346/CCMN

[18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] [29] [30] [31] -

下载:

下载: