Determination of Chromium, Iron, Molybdenum and Silicon in Ti-Al Alloy by Inductively Coupled Plasma-Optical Emission Spectrometry with Sodium Peroxide Alkali Fusion

-

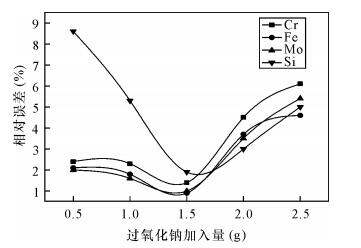

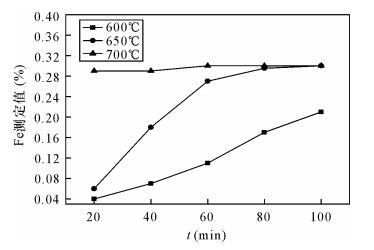

摘要: 应用电感耦合等离子体发射光谱法(ICP-OES)测定高钛含量的钛铝合金中铬铁钼硅时,单一酸不能使钛铝合金完全溶解;混合酸溶解样品后仍会出现少量杂质、溶解不完全的现象,且复溶时易出现沉淀现象,即使用浓王水也难以将沉淀再溶解。本实验在700℃温度下,采用过氧化钠进行碱熔20 min,盐酸酸化,建立了应用ICP-OES测定钛铝合金中的铬铁钼硅的方法。实验中采用钛基体匹配的方法降低了试液中钛浓度大于200 μg/mL时的钛基体干扰,通过控制过氧化钠使用量来降低待测溶液中的盐分含量保证了测定的稳定性。方法检出限为0.002~0.005 μg/mL,测定下限为0.007~0.017 μg/mL;采用国家标准物质(GBW02501)进行验证,方法的相对标准偏差(RSD)为0.90%~4.89%,相对误差为1.2%~3.6%,回收率为91.6%~103.8%。本方法与酸溶法相比,样品溶解完全,测定准确、可靠,适用于高钛含量的钛铝合金多元素测定。

-

关键词:

- 钛铝合金 /

- 钛基体干扰 /

- 过氧化钠碱熔 /

- 电感耦合等离子体发射光谱法

Abstract: Single acid cannot completely dissolve Ti-Al alloy with high Ti content when determining chromium, iron, molybdenum and silicon by Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES). A small amount of impurity remains after dissolving the samples by mixed acid. Furthermore, the precipitation occurs readily during re-dissolution, even if using concentrated aqua regia. In this study, the Ti-Al alloys were fused with sodium peroxide for 20 min at 700℃ and were acidified by hydrochloric acid. The method for the determination of chromium, iron, molybdenum and silicon in Ti-Al alloy by ICP-OES was established. The interference from the titanium matrix in samples was improved by the titanium matrix matching method when the concentration of titanium was greater than 200 μg/mL. Additionally, the amount of salt content in solution was controlled by sodium peroxide to ensure the stability of determination. The detection limits and lower determination limits are 0.02-0.05 μg/mL and 0.07-0.17 μg/mL, respectively. The method has been verified by analyzing the national standard material (GBW02501). The relative standard deviations (RSDs) are 0.90%-4.89%, the relative errors are 1.2%-3.6% and the recoveries are 91.6%-103.8%. Compared with acid solution, the dissolution of the samples is complete using the proposed method. Moreover, the method is accurate, reliable, and suitable for multi-element determination of Ti-Al alloy with high titanium content. -

-

表 1 标准溶液中待测元素的浓度

Table 1. Concentration of determined elements in standard solution

标准溶液编号 各元素浓度(μg/mL) Cr Fe Mo Si STD0 0.00 0.00 0.00 0.00 STD1 0.50 0.50 1.00 0.10 STD2 1.00 1.00 5.00 0.50 STD3 5.00 5.00 10.00 1.00 STD4 10.00 10.00 20.00 5.00 STD5 20.00 15.00 40.00 10.00 表 2 钛元素干扰实验测定结果

Table 2. Interference tests of Ti element

Ti浓度(μg/mL) Cr Fe Mo Si 测定值(μg/mL) 相对误差(%) 测定值(μg/mL) 相对误差(%) 测定值(μg/mL) 相对误差(%) 测定值(μg/mL) 相对误差(%) 0 10.00 0 10.00 0 10.01 0.1 10.01 0.1 50 9.99 0.1 9.99 0.1 9.99 0.1 10.00 0 100 9.86 1.4 9.89 1.1 9.90 1.0 9.91 0.09 200 9.77 2.3 9.78 2.2 9.66 3.4 9.70 3.0 300 9.61 3.9 9.60 4.0 9.62 3.8 9.59 4.1 400 9.51 4.9 9.52 4.8 10.67 6.7 9.43 5.7 500 9.37 6.3 9.11 8.9 11.74 7.4 9.28 7.2 表 3 方法精密度、准确度及加标回收率

Table 3. Precision, accuracy and recovery tests of the method

元素 标准值(%) 测定平均值(%) 加入量(μg) 测定总值(μg) 回收率(%) 相对误差(%) RSD (%) Cr 1.55 1.52 1000 2457 93.7 1.9 1.16 Fe 0.47 0.48 1000 1396 91.6 1.5 3.08 Mo 2.53 2.56 1000 3598 103.8 1.2 0.90 Si 0.28 0.27 1000 1248 97.8 3.6 4.89 -

[1] Chen R R, Ding H S, Yang J R, et al.Temperature field calculation on cold crucible continuous melting and directional solidifying Ti50Al alloys[J].Rare Metal Materials & Engineering, 2012, 22(3):647-653. http://d.wanfangdata.com.cn/Periodical_zgysjsxb-e201203025.aspx

[2] Chen X, Xie F Q, Ma T J, et al.Microstructure evolution and mechanical properties of linear friction welded Ti2AlNb alloy[J].Journal of Alloys & Compounds, 2015, 646:490-496. https://www.sciencedirect.com/science/article/pii/S0925838815300992

[3] 陈学源.溴化碲分光光度法测定钛铝合金中微量碲[J].稀有金属材料与工程, 1997, 26(4):56-59. http://www.cnki.com.cn/Article/CJFDTOTAL-COSE704.012.htm

Chen X Y.TeBr4 spectrophotometric determination of trace Te in TiAl alloy[J].Rare Metal Materials and Engineering, 1997, 26(4):56-59. http://www.cnki.com.cn/Article/CJFDTOTAL-COSE704.012.htm

[4] 牛金龙, 陈学源.铀试剂光度法测定钛铝合金中微量锑[J].稀有金属材料与工程, 1997, 26(6):56-59. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=cose706.018&dbname=CJFD&dbcode=CJFQ

Niu J L, Chen X Y.5-Br-PADAP extraction spectro-photometric determination of trace antimony in TiAl alloy[J].Rare Metal Materials and Engineering, 1997, 26(6):56-59. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=cose706.018&dbname=CJFD&dbcode=CJFQ

[5] 陈学源, 牛金龙.钛铝合金中微量磷的测定[J].稀有金属材料与工程, 1998, 27(2):119-121. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=cose802.013&dbname=CJFD&dbcode=CJFQ

Chen X Y, Niu J L.Determination of trace phosphorus in titanium-aluminium alloys[J]. Rare Metal Materials and Engineering, 1998, 27(2):119-121. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=cose802.013&dbname=CJFD&dbcode=CJFQ

[6] 高颂, 庞晓辉, 王桂军.电感耦合等离子体原子发射光谱法测定高铌钛铝合金中硼硅钨锰[J].冶金分析, 2013, 33(11):59-62. http://industry.wanfangdata.com.cn/yj/Detail/Conference?id=Conference_7839667

Gao S, Pang X H, Wang G J.Determination of boron, silicon, tungsten and manganese in high niobium titanium aluminum alloy by inductively coupled plasma atomic emission spectrometry[J].Metallurgical Analysis, 2013, 33(11):59-62. http://industry.wanfangdata.com.cn/yj/Detail/Conference?id=Conference_7839667

[7] 杜米芳.电感耦合等离子体原子发射光谱法测定钛合金中钼锆铌[J].冶金分析, 2015, 35(10):77-81. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yjfx201510020&dbname=CJFD&dbcode=CJFQ

Du M F.Determination of molybdenum, zirconium and niobium in titanium alloy by inductively coupled plasma atomic emission spectrometry[J].Metallurgical Analysis, 2015, 35(10):77-81. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yjfx201510020&dbname=CJFD&dbcode=CJFQ

[8] 高颂, 庞晓辉, 梁红玲.电感耦合等离子体原子发射光谱法测定TG6钛合金中镁钒铬铁钴铜锰钼钨[J].冶金分析, 2015, 35(3):51-55. https://wuxizazhi.cnki.net/qikan-YJFX201602014.html

Gao S, Pang X H, Liang H L.Determination of magnesium, vanadium, chromium, iron, cobalt, copper, manganese, molybdenum and tungsten in TG6 titanium alloy by inductively coupled plasma atomic emission spectrometry[J].Metallurgical Analysis, 2015, 35(3):51-55. https://wuxizazhi.cnki.net/qikan-YJFX201602014.html

[9] 王卿, 赵伟, 张会堂, 等.过氧化钠碱熔-电感耦合等离子体发射光谱法测定钛铁矿中铬磷钒[J].岩矿测试, 2012, 31(6):971-974. http://www.ykcs.ac.cn/article/id/ykcs_20120611

Wang Q, Zhao W, Zhang H T, et al.Determination of Cr, V and P in ilmenite by inductively coupled plasma atomic emission spectrometry with sodium peroxide fusion[J].Rock and Mineral Analysis, 2012, 31(6):971-974. http://www.ykcs.ac.cn/article/id/ykcs_20120611

[10] 王小强, 夏辉, 秦九红, 等.过氧化钠碱熔-电感耦合等离子体发射光谱法测定多金属矿中的锡钨钛等主次量成分[J].岩矿测试, 2017, 36(1):52-58. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.2017.01.008

Wang X Q, Xia H, Qin J H, et al.Determination of Sn, W, Ti and other elements in polymetallic ore by inductively coupled plasma atomic emission spectrometry with sodium peroxide fusion[J].Rock and Mineral Analysis, 2017, 36(1):52-58. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.2017.01.008

[11] 马兰, 余琼, 覃广河, 等.电感耦合等离子体原子发射光谱法测定硼铁合金中的硼[J].理化检验(化学分册), 2015, 51(4):478-479. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=lhjh201504016&dbname=CJFD&dbcode=CJFQ

Ma L, Yu Q, Qin G H, et al.Determination of boron in ferroboron alloy by ICP-AES[J].Physical Testing and Chemical Analysis (Part B:Chemical Analysis), 2015, 51(4):478-479. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=lhjh201504016&dbname=CJFD&dbcode=CJFQ

[12] 聂富强, 杜丽丽, 李景滨, 等.碱熔-电感耦合等离子体发射光谱法(ICP-OES)测定高碳高硅钢中的硅含量[J].中国无机分析化学, 2015, 5(4):74-78. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_zgwjfxhxwz201504017

Nie F Q, Du L L, Li J B, et al.Determination of silicon content in high carbon and high silicon steel by inductively coupled plasma atomic emission spectrometry with sodium peroxide fusion[J].Chinese Journal of Inorganic Analytical Chemistry, 2015, 5(4):74-78. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_zgwjfxhxwz201504017

[13] 仝晓红, 刘攀, 聂富强.碱熔-电感耦合等离子体原子发射光谱法测定高碳铬铁中铬[J].冶金分析, 2015, 35(9):36-41. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yjfx201509009&dbname=CJFD&dbcode=CJFQ

Tong X H, Liu P, Nie F Q.Determination of chromium in high-carbon ferrochrome by alkali fusion-inductively coupled plasma atomic emission spectrometry[J].Metallurgical Analysis, 2015, 35(9):36-41. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yjfx201509009&dbname=CJFD&dbcode=CJFQ

[14] 赵庆令, 李清彩.电感耦合等离子体发射光谱法测定锆钛砂矿中铪钛锆[J].岩矿测试, 2013, 32(6):883-886. http://www.ykcs.ac.cn/article/id/c47cff27-d31e-48fb-a4cd-b7b8df6b5f6f

Zhao Q L, Li Q C.Determination of Hf, Ti and Zr in zirconium-titanium placer by inductively coupled plasma atomic emission spectrometry[J].Rock and Mineral Analysis, 2013, 32(6):883-886. http://www.ykcs.ac.cn/article/id/c47cff27-d31e-48fb-a4cd-b7b8df6b5f6f

[15] 李红光, 王雪, 王哲, 等.电感耦合等离子体原子发射光谱法测定锆钛砂矿中锆钛铁钍铪[J].冶金分析, 2014, 34(2):62-65. http://d.wanfangdata.com.cn/Periodical_yjfx201402014.aspx

Li H G, Wang X, Wang Z, et al.Determination of zirconium, titanium, iron, thorium and hafnium in zirconium-titanium placer by inductively coupled plasma atomic emission spectrometry[J].Metallurgical Analysis, 2014, 34(2):62-65. http://d.wanfangdata.com.cn/Periodical_yjfx201402014.aspx

[16] 成勇.ICP-AES测定钛合金中硅钒铁铝镍钼铬[J].稀有金属材料与工程, 2012, 41(10):183-186. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=cose201210039&dbname=CJFD&dbcode=CJFQ

Cheng Y.Determination of the silicon, vanadium, iron, aluminum, nickel, molybdenum and chromium in titanium alloy by ICP-AES[J].Rare Metal Materials and Engineering, 2012, 41(10):183-186. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=cose201210039&dbname=CJFD&dbcode=CJFQ

-

下载:

下载: