Composition and Content of Fluorophlogopite Polytypes by X-ray Diffraction with Rotation-spraying Method

-

摘要:

合成氟金云母多型种类与含量对云母的物理化学性质具有重要的影响。然而在X射线粉晶衍射(XRD)制样过程中云母00l基面极易产生择优取向,严重制约了云母多型组成和含量的分析。传统撒样法可促使晶体取向随机分布,但制备的试样表面不够平坦。本文对传统撒样法进行改进,在撒样过程中使样品架均匀旋转,从而获得表面平坦的试样。XRD测试结果表明,旋转撒样法取向指数(OI=I001/I060)为3.9,与无择优取向的理论值4.5接近,明显优于正压法和侧装法(OI值分别为38.7和18.1),表明旋转撒样法能够显著减弱云母择优取向。这主要是由于旋转撒样法使晶体颗粒之间形成犬牙交错分布,提高了云母各晶面随机分布概率。Rietveld全图拟合分析显示,旋转撒样法获得的XRD数据精修效果较好,计算出本文合成的氟金云母样品中1M和2M1多型含量分别为86%和14%,8个工业合成的氟金云母样品中1M和2M1多型含量分别为57%~72%和28%~43%,并且存在较多的堆垛层错。总之,旋转撒样法减弱择优取向效果显著,为研究云母晶体生长、多型成因以及结构与性能之间的关系提供了技术支撑。

Abstract:BACKGROUND The polytype species and the content of synthetic fluorophores have a considerable influence on the physiochemical properties of fluorphlogopites. However, conventional methods (e.g., front loading and side loading) of sample preparation tend to generate a strongly preferred orientation on the 00l basal plane, limiting the X-ray diffraction (XRD) analysis of the composition and content of fluorphlogopite polytypes. The conventional spraying method was utilized to prepare samples with random orientations for XRD analysis. However, the sample surface was not flat enough to perform the analysis.

OBJECTIVES To decrease the preferred orientation and develop a method for quantitative analysis of fluorphlogopite polytypes.

METHODS In this study, the conventional spraying method was improved. The sample holder was rotated evenly during the spraying process to obtain a flat surface sample.

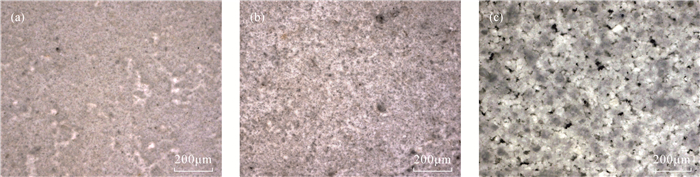

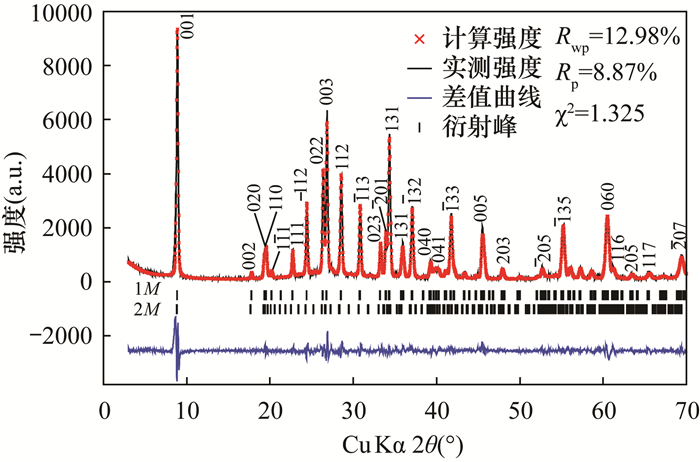

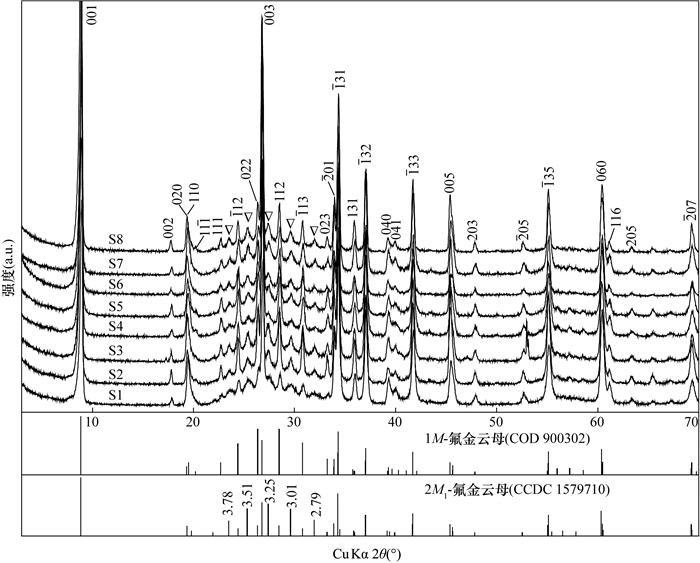

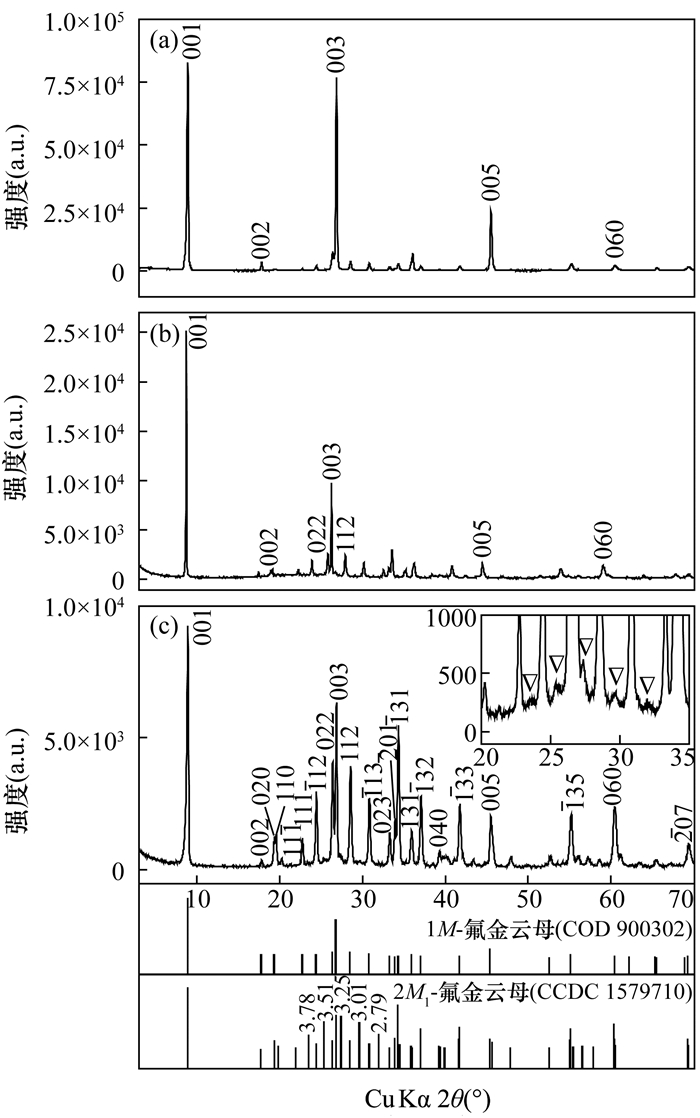

RESULTS XRD data suggested that the orientation index (OI=I001/I060) obtained by the rotation-spraying method was 3.9, which was close to the theoretical value (4.5). The OIs of the front and side loading methods were 38.7 and 18.1, respectively, which were significantly larger than the theoretical value (4.5). The results showed that the rotation-spraying method significantly decreased the preferred orientation of mica along the 00l basal plane compared with the front and side loading methods. Microscopic observations revealed that the surface of the sample prepared by the rotation-spraying method exhibited a canine tooth staggered distribution. This increased the random distribution between the crystal particles and reduced the preferred orientation. Rietveld quantitative phase analyses of fluorphlogopites were successfully performed based on the XRD data for the samples prepared by the rotation-spraying method. In this study, Rietveld refinement showed that the contents of 1M and 2M1 polytypes of synthetic fluorphlogopites were 86% and 14%, respectively. The systematic investigations of eight commercial fluorphlogopites revealed that these samples were composed of 28%-43% 2M1 polytype and 57%-72% 1M polytype. In addition, significant stacking faults were observed in these eight commercial samples.

CONCLUSIONS The rotation-spraying method significantly weakened the effect of preferential orientation. This study provides technical support for understanding the mica crystal growth, polymorphism, and structure-performance relationship.

-

Key words:

- preferred orientation /

- rotation-spray method /

- X-ray powder diffraction /

- fluorophlogopite /

- polytype

-

-

表 1 工业合成氟金云母样品1M和2M1多型含量

Table 1. Content of 1M and 2M1 fluorophlogopite of commercial samples

样品编号 多型含量(%) 1M型 2M1型 S1 68 32 S2 64 36 S3 60 39 S4 72 28 S5 61 39 S6 65 35 S7 57 43 S8 61 39 -

[1] 徐扬群. 合成云母的制造、加工与应用[M]. 北京: 化学工业出版社, 2012: 1-5.

Xu Y Q. Manufacuring, processing and application of synthetic mica[M]. Beijing: Chemical Industry Press, 2012: 1-5.

[2] Casasola R, Pérez J, Romero M. Crystal growth of F-phlogopite from glasses of the SiO2-Al2O3-MgO-K2O-F system[J]. Journal of the American Ceramic Society, 2016, 99(2): 484-491. doi: 10.1111/jace.13995

[3] Ma L J, Sun Z C, Zhang L, et al. Study on mechanism and theoretical model of tool wear in fluorophlogopite glass-ceramics turning[J]. Journal of Materials Processing Technology, 2020, 275: 1-10. http://www.sciencedirect.com/science/article/pii/S0924013619302560

[4] Fregola R A, Capitani G C, Scandale E, et al. Chemical control of 3T stacking order in a Li-poor biotite mica[J]. American Mineralogist, 2009, 94: 334-344. doi: 10.2138/am.2009.3004

[5] Capitani G C, Schingaro E, Lacalamita M, et al. Structural anomalies in tobelite-2M2 explained by high resolution and analytical electron microscopy[J]. Mineralogical Magazine, 2016, 80(1): 143-156. doi: 10.1180/minmag.2015.079.7.14

[6] Kuo C L, Huang Y H, Fan S J. X-ray topography study on imperfections in synthetic mica (fluorophlogopite) crystal[J]. Journal of Material Science, 1981, 16(4): 877-882. doi: 10.1007/BF00542730

[7] Bloss F D, Gibbs G V, Cummings D. Polymorphism and twinning in synthetic fluorophlogopite[J]. Journal of Geology, 1963, 71(5): 537-548. doi: 10.1086/626931

[8] Shell H R, Ivey K H. Fluorine micas[M]. Washington: U.S. Department of the Interior, Bureau of Mines, 1969: 152-154.

[9] Sunagawa I, Endo Y, Daimon N, et al. Nucleation, growth and polytypism of flour-phlogopite from the vapour phase[J]. Journal of Crystal Growth, 1968, 3(4): 751. http://www.sciencedirect.com/science/article/pii/0022024868902595

[10] Hammouda T, Pichavant M, Barbey P, et al. Synthesis of fluorphlogopite single crystals. Applications to experi-mental studies[J]. European Journal of Mineralogy, 1995, 7: 1381-1387. doi: 10.1127/ejm/7/6/1381

[11] 李中和, 秦关华, 翁臻培. 人造氟金云母的多型[J]. 人工晶体学报, 1982(增刊): 144. https://www.cnki.com.cn/Article/CJFDTOTAL-RGJT1982Z1196.htm

Li Z H, Qin G H, Weng Z P. Polytype of synthetic fluorophlogopite[J]. Journal of Synthetic Crystals, 1982(Supplement): 144. https://www.cnki.com.cn/Article/CJFDTOTAL-RGJT1982Z1196.htm

[12] Hillier S. Use of an air brush to spray dry samples for X-ray powder diffraction[J]. Clay Minerals, 1999, 34: 127-135. doi: 10.1180/000985599545984

[13] Moore D M, Reynolds R C J. X-ray diffraction and the identification and analysis of clay minerals[M]. New York: Oxford University Press, 1997: 204-225.

[14] Grathoff G H, Moore D M. Illite polytype quantification using WILDFIRE® calculated X-ray diffraction patterns[J]. Clays and Clay Minerals, 1996, 44(6): 835-842. doi: 10.1346/CCMN.1996.0440615

[15] Kleeberg R, Monecke T, Hillier S. Preferred orientation of mineral grains in sample mounts for quantitative XRD measurements: How random are powder samples?[J]. Clays and Clay Minerals, 2008, 56(4): 404-415. doi: 10.1346/CCMN.2008.0560402

[16] 马礼敦. X射线粉末衍射仪用试样的制作[J]. 上海计量测试, 2008(5): 2-6. doi: 10.3969/j.issn.1673-2235.2008.05.001

Ma L D. Preparation of the samples for X-ray powder diffractometers[J]. Shanghai Measurement and Testing, 2008(5): 2-6. doi: 10.3969/j.issn.1673-2235.2008.05.001

[17] Zhou X, Liu D, Bu H, et al. XRD-based quantitative analysis of clay minerals using reference intensity ratios, mineral intensity factors, Rietveld, and full pattern summation methods: A critical review[J]. Solid Earth Sciences, 2018, 3: 16-29. doi: 10.1016/j.sesci.2017.12.002

[18] 冉敬, 郭创锋, 杜谷, 等. X射线衍射全谱拟合法分析蓝晶石的矿物含量[J]. 岩矿测试, 2019, 38(6): 660-667. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201902220025

Ran J, Guo C F, Du G, et al. Quantitative analysis of mineral composition of kyanite by X-ray diffraction with Rietveld refinement method[J]. Rock and Mineral Analysis, 2019, 38(6): 660-667. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201902220025

[19] Toby B H. EXPGUI, a graphical user interface for GSAS[J]. Journal of Applied Crystallography, 2001, 34: 210-213. doi: 10.1107/S0021889801002242

[20] 陈爱清, 薛雍, 徐洪柳, 等. Rietveld定量方法在蒸发岩矿物组分分析中的精确度评价和误差来源[J]. 岩矿测试, 2017, 36(4): 374-381. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201608020111

Chen A Q, Xue Y, Xu H L, et al. Assessment of accuracy and error sources of the Rietveld quantitative phase analysis method in mineral contents of evaporites[J]. Rock and Mineral Analysis, 2017, 36(4): 374-381. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201608020111

[21] Zhang G, Germaine J T, Martin R T, et al. A simple sample-mounting method for radndom powder X-ray diffraction[J]. Clays and Clay Minerals, 2003, 51(2): 218-225. doi: 10.1346/CCMN.2003.0510212

[22] 彭观良, 杨建坤, 兰勇, 等. 择优取向对X射线衍射积分强度的影响[J]. 大学物理实验, 2007, 20(3): 56-58. doi: 10.3969/j.issn.1007-2934.2007.03.016

Peng G L, Yang J K, Lan Y, et al. The effect of preferred orientation on X-ray diffraction integral intensity[J]. Physical Experimental of College, 2007, 20(3): 56-58. doi: 10.3969/j.issn.1007-2934.2007.03.016

[23] Jenkins R, Fawcett T G, Smith D K, et al. JCPDS-International centre for diffraction data sample preparation methods in X-ray powder diffraction[J]. Powder Diffraction, 1986, 1(2): 51-63. doi: 10.1017/S0885715600011581

[24] Schingaro E, Lacalamita M, Scordari F, et al. 3T-phlogopite from Kasenyi kamafugite (SW Uganda): EPMA, XPS, FTIR, and SCXRD study[J]. American Mineralogist, 2013, 98: 709-717. doi: 10.2138/am.2013.4283

[25] Scordari F, Schingaro E, Ventruti G, et al. Fluorophlogopite from Piano delle Concazze (Mt. Etna, Italy): Crystal chemistry and implications for the crystallization conditions[J]. American Mineralogist, 2013, 98: 1017-1025. doi: 10.2138/am.2013.4225

[26] Brindley G W, Brown G. Crystal structures of clay minerals and their X-ray identification[M]. London: Mineralogical Society, 1980: 46-56.

[27] 郑振环, 李强. X射线多晶衍射数据Rietveld精修及GSAS软件入门[M]. 北京: 中国建材工业出版社, 2016: 20-23.

Zheng Z H, Li Q. Introduction to Rietveld refinement with X-ray powder diffraction data and GSAS software[M]. Beijing: China Building Material Industry Publishing House, 2016: 20-23.

[28] 陈昊鸿, 雷芳. 粉末衍射理论与实践[M]. 北京: 高等教育出版社, 2016: 158-160.

Chen H H, Lei F. Powder diffraction theory and practice[M]. Beijing: Higher Education Press, 2016: 158-160.

[29] Toby B H. R factors in Rietveld analysis: How good is good enough?[J]. Powder Diffraction, 2006, 21(1): 67-70. doi: 10.1154/1.2179804

[30] Mottana E A, Sassi F P, Thompson J B, et al. Micas: crystal chemistry and metamorphic petrology, reviews in mineralogy and geochemistry[M]. Washington: Mineralogical Society of America and the Geochemical Society, 2002: 1-90.

[31] Pignatelli I, Faure F, Mosser-Ruck R. Self-mixing magma in the Ruiz Peak rhyodacite (New Mexico, USA): A mechanism explaining the formation of long period polytypes of mica[J]. Lithos, 2016, 266: 332-347.

[32] 陈爱清. 熔体中氟金云母生长机制与多型成因[D]. 北京: 中国科学院大学, 2019.

Chen A Q. Growth mechanism and polytype genesis of synthetic fluorophlogopite from melt[D]. Beijing: University of Chinese Academy of Sciences, 2019.

-

下载:

下载: