Optimization of Sulfur Determination in Vanadium-Titanium Magnetite Ore in the Panxi Area

-

摘要:

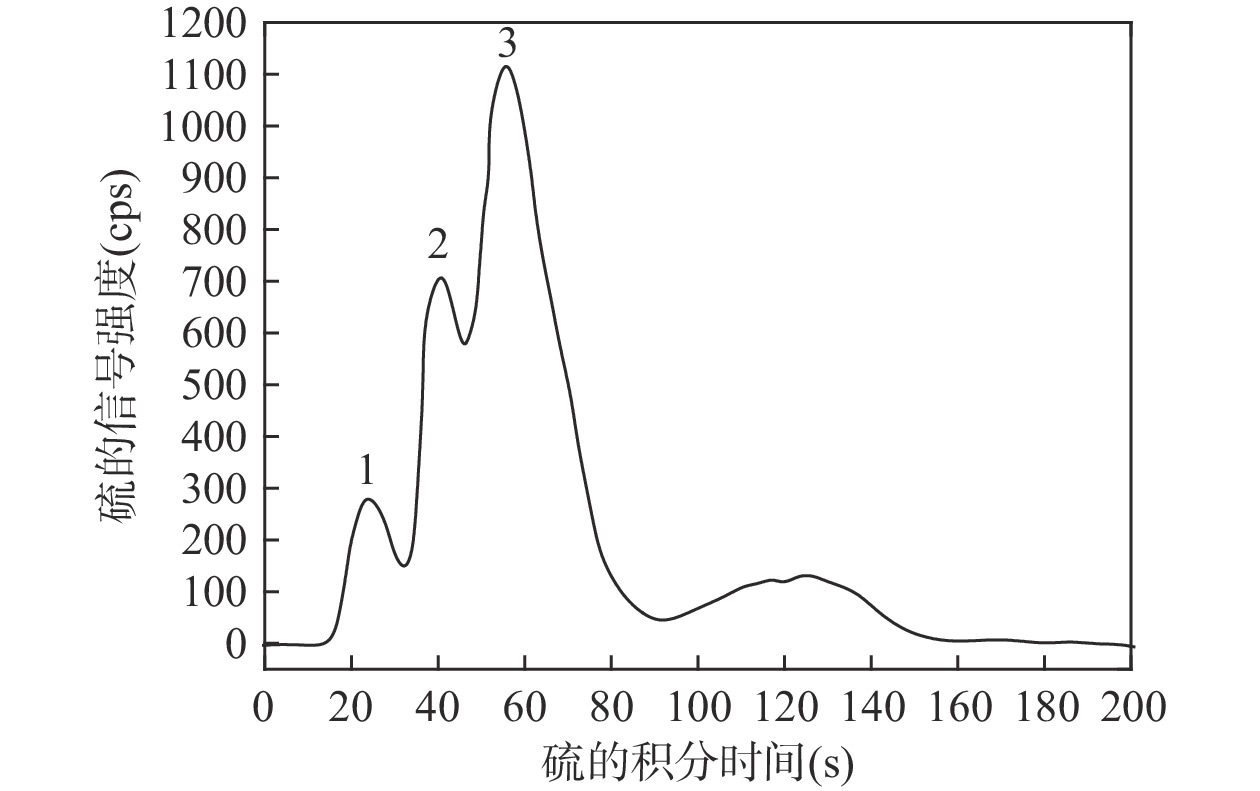

硫是钒钛磁铁矿中重要的质量和环保指标,准确测定其含量对后续工艺控制和污染评价具有重要意义。攀西地区钒钛磁铁矿中硫赋存形态多样且含量范围宽,采用高频燃烧红外吸收法测定硫时,部分矿区样品易出现积分延迟、低硫精密度差的问题。本文结合扫描电镜技术及红外碳硫仪的程序升温功能,通过大量实验,得出钒钛磁铁矿中硫化物形态及含量的差异是造成上述问题的主要原因,并通过优化仪器分析功率、助熔剂及添加顺序、样品质量等分析条件,实现高频燃烧红外吸收法对攀西地区钒钛磁铁矿中0.0004%~1.52%硫的测定。优化后的实验条件如下:样品质量0.30g、助熔剂为0.30g铁粒、0.20g铜粒和1.0g钨粒,助熔剂和样品的添加顺序为铁粒—铜粒—样品—钨粒,分析功率95%。采用不同硫含量的钒钛磁铁矿标准物质建立标准曲线,硫的质量分数为0.0004%~0.200%时(低硫),标准曲线线性方程为y=1.0028x−1.35×10−6 (r=0.9998);硫的质量分数为0.201%~1.52%时(高硫),标准曲线线性方程为y=1.0062x−1.49×10−6 (r=0.9998),方法检出限为0.0004%。采用本方法对标准物质及攀西地区钒钛磁铁矿实际样品进行测定,标准物质硫含量测定值在标准值的允许范围内,相对标准偏差(RSD)为0.72%~1.40%;实际样品硫含量测定值的RSD为0.40%~0.67%。

Abstract:Sulfur is an important quality and environmental indicator in vanadium-titanium magnetite ore, so the accurate measurement of sulfur is of great significance for subsequent process control and pollution evaluation. There are some problems such as integration delay and poor precision in low sulfur when measuring sulfur in vanadium-titanium magnetite ore with the high-frequency combustion infrared absorption method. To solve the problems, scanning electron microscope (SEM) and infrared absorption carbon-sulfur analyzer with programmed heating function were used, and the analysis conditions such as power, flux and addition sequence, and sample mass were optimized. The optimized experimental conditions were as follows: analysis power of 95%, iron particle flux of 0.30g, copper particle flux of 0.20g, and tungsten particle flux of 1.0g, sample mass of 0.30g. The order of addition is iron-copper-sample-tungsten. The optimized method was used to measure sulfur content, and the results of sulfur in the standard sample were within the allowable error, with satisfactory accuracy. The relative standard deviation (RSD) in samples was 0.40%−0.67%, with satisfactory precision. The range of the method was 0.0004%−1.52%, and the detection limit was 0.0004%.

-

-

表 1 助熔剂选择实验

Table 1. Selection test of flux

铜粒助熔剂 铁粒助熔剂 钨粒助熔剂 质量

(g)硫含量分次测定值

(%)硫含量

平均值

(%)质量

(g)硫含量分次测定值

(%)硫含量

平均值

(%)质量

(g)硫含量分次测定值

(%)硫含量

平均值

(%)0 0.521 0.537 0.535 0.531 0 0.521 0.545 0.544 0.537 0.5 0.521 0.554 0.557 0.544 0.1 0.545 0.552 0.557 0.551 0.3 0.537 0.554 0.553 0.548 1.0 0.537 0.558 0.544 0.546 0.2 0.544 0.553 0.557 0.551 0.6 0.535 0.558 0.557 0.550 1.5 0.535 0.545 0.553 0.544 SDCu(%) − 0.012 SDFe(%) − 0.007 SDW(%) − 0.001 表 2 助熔剂添加顺序对硫测定的影响

Table 2. The influence of flux addition sequence on sulfur measurement

助熔剂添加顺序 硫含量测定值

(%)SD

(%)硫含量测定

平均值(%)硫含量标准值

(%)样品及助熔剂在坩埚内燃烧情况 铁粒+样品+

铜粒+钨粒0.372 0.381 0.373 0.005 0.375 0.382 坩埚内熔渣表面较平滑,坩埚壁有少量飞溅残渣 铁粒+铜粒+

样品+钨粒0.379 0.381 0.380 0.001 0.380 0.382 坩埚内熔渣表面平滑,坩埚壁飞溅残渣较少 钨粒+铜粒+

样品+铁粒0.377 0.383 0.382 0.003 0.381 0.382 坩埚内熔渣表面有少许鼓包,坩埚壁飞溅残渣较多且坩埚有开裂现象 钨粒+样品+

铜粒+铁粒0.374 0.378 0.382 0.004 0.378 0.382 坩埚内熔渣表面有少许鼓包,坩埚壁飞溅残渣较多且坩埚有开裂现象 铜粒+铁粒+

样品+钨粒0.382 0.379 0.370 0.006 0.377 0.382 坩埚内熔渣表面较平滑,坩埚壁有少量飞溅残渣 表 3 不同矿区钒钛磁铁矿样品及标准物质重复测定结果(n=7)

Table 3. Repeated measurement results of vanadium-titanium magnetite ore samples from different mining areas and standard materials (n=7)

钒钛磁铁矿样品 硫含量分次测定值

(%)硫含量平均值

(%)SD

(%)RSD

(%)1#(攀枝花矿) 0.287 0.284 0.286 0.288 0.286 0.288 0.290 0.287 0.002 0.67 2#(红格矿) 0.308 0.311 0.312 0.309 0.307 0.311 0.310 0.310 0.002 0.58 3#(白马矿) 0.326 0.324 0.325 0.325 0.323 0.325 0.327 0.325 0.001 0.40 4#(太和矿) 1.38 1.39 1.39 1.37 1.38 1.39 1.38 1.38 0.008 0.55 YSBC19736-2017 0.204 0.203 0.206 0.208 0.204 0.204 0.211 0.206 0.003 1.4 GBW07227 0.441 0.443 0.442 0.443 0.448 0.449 0.447 0.445 0.003 0.72 -

[1] 王勋, 韩跃新, 李艳军, 等. 钒钛磁铁矿综合利用研究现状[J]. 金属矿山, 2019, 48(6): 33−37.

Wang X, Han Y X, Li Y J, et al. Research status on comprehensive development and utilization of vanadium-titanium magnetite[J]. Metal Mine, 2019, 48(6): 33−37.

[2] 肖仪武. 钒钛磁铁矿矿石基因特性及其对选铁的影响[J]. 矿产综合利用, 2021, 42(5): 198−201. doi: 10.3969/j.issn.1000-6532.2021.05.033

Xiao Y W. Ore genetic characteristics of vanadium-titanium magnetite and its influence for mineral processing[J]. Multipurpose Utilization of Mineral Resources, 2021, 42(5): 198−201. doi: 10.3969/j.issn.1000-6532.2021.05.033

[3] 梅燕, 单永奎, 何科瀚. 攀西钒钛磁铁矿分布特征及采矿选矿技术[J]. 西昌学院学报(自然科学版), 2023, 37(1): 58−65.

Mei Y, Shan Y K, He K H. Distribution features of vanadium-titano magnetite in Panxi regions and its mining and beneficiating techniques[J]. Journal of Xichang College (Natural Science Edition), 2023, 37(1): 58−65.

[4] 张贵山, 邱红信, 彭仁, 等. 扬子板块西缘攀西地区白草矿区黄铁矿标型元素特征及其指示意义[J]. 地球科学与环境学报, 2021, 43(2): 262−275.

Zhang G S, Qiu H X, Peng R, et al. Characteristics of pyrite typomorphic elements in Baicao mining area of Panzhihua—Xichang region, the western margin of Yangtze Plate, China and their indication[J]. Journal of Earth Sciences and Environment, 2021, 43(2): 262−275.

[5] 钟祥, 史志新, 高健. 攀西地区白马钒钛磁铁矿工艺矿物学探讨[J]. 冶金分析, 2021, 41(10): 29−35.

Zhong X, Shi Z X, Gao J. Discussion on process mineralogy of Baima vanadium-titanium magnetite in Panxi area[J]. Metallurgical Analysis, 2021, 41(10): 29−35.

[6] 薛忠言, 曾令熙, 刘应冬. 太和钒钛磁铁矿中硫化物的工艺矿物学研究[J]. 矿产综合利用, 2019, 40(3): 78−81. doi: 10.3969/j.issn.1000-6532.2019.03.018

Xue Z Y, Zeng L X, Liu Y D. Process mineralogy of the sulfide in the Taihe vanadium titano magnetite[J]. Multipurpose Utilization of Mineral Resources, 2019, 40(3): 78−81. doi: 10.3969/j.issn.1000-6532.2019.03.018

[7] 邱红信, 张贵山, 温汉捷, 等. 攀西会理县白草钒钛磁铁矿床磁黄铁矿矿物学特征及成因[J]. 矿物学报, 2021, 41(3): 245−257.

Qiu H X, Zhang G S, Wen H J, et al. Mineralogical characteristics and genesis of pyrrhotite in the Baicao V-Ti magnetite deposit in the Huili area of the Panzhihua—Xichang rift[J]. Acta Mineralogica Sinica, 2021, 41(3): 245−257.

[8] 罗金华, 武昭妤, 李俊翰, 等. 红格钒钛磁铁矿中硫化物的矿物学特征研究[J]. 钢铁钒钛, 2015, 36(3): 57−61. doi: 10.7513/j.issn.1004-7638.2015.03.012

Luo J H, Wu S Y, Li J H, et al. Mineralogical characteristics of sulfide in Hongge vanadium titano-magnetite[J]. Iron Steel Vanadium Titanium, 2015, 36(3): 57−61. doi: 10.7513/j.issn.1004-7638.2015.03.012

[9] 张贵山, 邱红信, 温汉捷, 等. 攀西红格钒钛磁铁矿矿田富钴硫化物中钴的地球化学特征及其地质意义[J]. 吉林大学学报(地球科学版), 2021, 51(6): 1740−1752.

Zhang G S, Qiu H X, Wen H J, et al. Geochemical characteristics and geological significance of cobalt in cobalt-rich sulfide of Hongge V-Ti magnetite ore field, Panxi[J]. Journal of Jilin University (Earth Science Edition), 2021, 51(6): 1740−1752.

[10] 吴宁. 攀西某钒钛磁铁精矿浮选脱硫实验[J]. 矿产综合利用, 2022, 43(3): 126−131. doi: 10.3969/j.issn.1000-6532.2022.03.022

Wu N. Experimental study on the flotation desulfurization of vanadium titanium magnetite concentrate in Panxi[J]. Multipurpose Utilization of Mineral Resources, 2022, 43(3): 126−131. doi: 10.3969/j.issn.1000-6532.2022.03.022

[11] 李潇雨, 周满赓, 王婧, 等. 攀西钒钛磁铁矿硫族元素工艺矿物学研究[J]. 中国矿业, 2016, 25(1): 118−124, 134. doi: 10.3969/j.issn.1004-4051.2016.01.025

Li X Y, Zhou M G, Wang Q, et al. Craft mineralogy research of chalcogens in Panxi vanadium-titanium magnetite[J]. China Mining Magazine, 2016, 25(1): 118−124, 134. doi: 10.3969/j.issn.1004-4051.2016.01.025

[12] 李磊, 金建文, 肖仪武, 等. 影响攀西某磁铁矿精矿品质的矿物学因素分析[J]. 矿产综合利用, 2021, 42(4): 193−196. doi: 10.3969/j.issn.1000-6532.2021.04.031

Li L, Jin J W, Xiao Y W, et al. Researches of mineralogical factors affecting the quality of a magnetite concentrate in Panxi area[J]. Multipurpose Utilization of Mineral Resources, 2021, 42(4): 193−196. doi: 10.3969/j.issn.1000-6532.2021.04.031

[13] 钟祥, 陈福林, 史志新, 等. 矿物自动分析系统在攀西某矿区钒钛磁铁矿工艺矿物学上的应用[J]. 冶金分析, 2022, 42(7): 62−70.

Zhong X, Chen F L, Shi Z X, et al. Application of advanced mineral identification and characterization system in the process mineralogy of vanadium-titanium magnetite in a mining area in Panxi[J]. Metallurgical Analysis, 2022, 42(7): 62−70.

[14] 翟雨可, 常自勇, 王晓莉, 等. 攀西地区钒钛磁铁矿石弱磁选工序前浮选硫钴的探讨[J]. 金属矿山, 2022, 51(11): 107−114.

Zhai Y K, Chang Z Y, Wang X L, et al. Discussion on the flotation recovery of sulfur and cobalt before low intensity magnetic separation of vanadium and titanium magnetite ore in Panxi area[J]. Metal Mine, 2022, 51(11): 107−114.

[15] 刘志雄. 白马钒钛磁铁矿提质降杂研究及工业实践[J]. 钢铁钒钛, 2022, 43(3): 104−110. doi: 10.7513/j.issn.1004-7638.2022.03.017

Liu Z X. Research and industrial practice on improving quality and reducing impurities of Baima vanadium-titanium magnetite[J]. Iron Steel Vanadium Titanium, 2022, 43(3): 104−110. doi: 10.7513/j.issn.1004-7638.2022.03.017

[16] 冀成庆, 杨耀辉, 徐璐, 等. 攀西钒钛磁铁矿伴生硫资源综合利用及其低碳发展意义[J]. 矿产综合利用, 2023, 44(4): 19−26.

Ji C Q, Yang Y H, Xu L, et al. Comprehensive utilization of associated sulfur resources of Panxi vanadium titanium magnetite and its significance for low-carbon development[J]. Multipurpose Utilization of Mineral Resources, 2023, 44(4): 19−26.

[17] 张耀, 孙刚, 王琪, 等. 钒钛磁铁矿区农用地污染特征及风险评价[J]. 环境科学与技术, 2022, 45(5): 217−225.

Zhang Y, Sun G, Wang Q, et al. Pollution characteristics of farmland in vanadium-titano magnetite mining area and relevant health risk assessment[J]. Environmental Science & Technology, 2022, 45(5): 217−225.

[18] 田松, 徐华, 唐碧玉, 等. 燃烧-碘量法测定金矿石中的硫含量[J]. 矿产与地质, 2023, 37(1): 191−196.

Tian S, Xu H, Tang B Y, et al. Determination of sulfur content in gold ore sample by combustion-iodine analysis method[J]. Mineral Resources and Geology, 2023, 37(1): 191−196.

[19] 乐胜锋, 王宁, 刘伟丽, 等. 管式炉燃烧-离子色谱法测定石墨烯粉体中氟、氯、溴、硫元素的含量[J]. 理化检验(化学分册), 2023, 59(1): 79−83.

Le S F, Wang N, Liu W L, et al. Determination of fluorine, chlorine, bromine and sulfur elements in grapheme powder by ion chromatography with tube furnace combustion[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2023, 59(1): 79−83.

[20] 石友昌, 陈贵仁, 赵萌生, 等. 酸溶-电感耦合等离子体发射光谱法和燃烧-红外吸收法测定不同类型地球化学样品中的硫[J]. 岩矿测试, 2022, 41(4): 663−672. doi: 10.3969/j.issn.0254-5357.2022.4.ykcs202204015

Shi Y C, Chen G R, Zhao M S, et al. Determination of sulfur in different types of geochemical samples by ICP-OES with acid dissolution and combustion-infrared absorption spectrometry[J]. Rock and Mineral Analysis, 2022, 41(4): 663−672. doi: 10.3969/j.issn.0254-5357.2022.4.ykcs202204015

[21] 聂高升, 石友昌, 阿米娜·胡吉, 等. 高频红外碳硫仪测定区域地球化学样品中的硫[J]. 中国无机分析化学, 2023, 13(11): 1215−1220. doi: 10.3969/j.issn.2095-1035.2023.11.009

Nie G S, Shi Y C, Amina H, et al. Determination of sulfur in regional geochemistry samples by high-frequency infrared carbon and sulfur analyzer[J]. Chinese Journal of Inorganic Analytical Chemistry, 2023, 13(11): 1215−1220. doi: 10.3969/j.issn.2095-1035.2023.11.009

[22] 冯丽丽, 王成林, 管嵩, 等. 高频燃烧红外吸收法测定萤石中的硫[J]. 中国无机分析化学, 2023, 13(5): 484−489. doi: 10.3969/j.issn.2095-1035.2023.05.012

Feng L L, Wang C L, Guan S, et al. Determination of sulfur in fluorite by high frequency combustion infrared absorption[J]. Chinese Journal of Inorganic Analytical Chemistry, 2023, 13(5): 484−489. doi: 10.3969/j.issn.2095-1035.2023.05.012

[23] 石象, 罗燕生. 高频燃烧红外吸收法测定钨精矿中硫含量[J]. 中国钨业, 2022, 37(6): 75−79. doi: 10.3969/j.issn.1009-0622.2022.06.011

Shi X, Luo Y S. Determination of sulfur contents in tungsten concentrate by high frequency combustion infrared absorption method[J]. China Tungsten Industry, 2022, 37(6): 75−79. doi: 10.3969/j.issn.1009-0622.2022.06.011

[24] 耶曼, 李婧, 马怡飞, 等. 高频红外碳硫仪快速测定镍铅锌矿石中的硫含量[J]. 岩矿测试, 2022, 41(4): 680−687. doi: 10.3969/j.issn.0254-5357.2022.4.ykcs202204017

Ye M, Li Q, Ma Y F, et al. Rapid determination of sulfur in nickel-lead-zinc ore by high-frequency infrared carbon and sulfur analyzer[J]. Rock and Mineral Analysis, 2022, 41(4): 680−687. doi: 10.3969/j.issn.0254-5357.2022.4.ykcs202204017

[25] 费发源, 马兴娟, 范志平, 等. 高频燃烧红外吸收光谱法测定一水硬铝石型高硫铝土矿中的硫[J]. 湿法冶金, 2022, 41(6): 558−561.

Fei F Y, Ma X J, Fan Z P, et al. Determination of sulfur in diaspore bauxite containing sulfur by high frequency combustion-infrared absorption spectrometry[J]. Hydrometallurgy of China, 2022, 41(6): 558−561.

[26] 董礼男, 周莉莉, 朱春要, 等. 高频感应燃烧红外吸收法测定轧钢含油污泥中硫含量[J]. 中国测试, 2022, 48(10): 68−72.

Dong L N, Zhou L L, Zhu C Y, et al. Determination of sulfur contents in rolling oily sludge by high frequency induction combustion infrared absorption method[J]. China Measurement & Testing Technology, 2022, 48(10): 68−72.

[27] 罗琼辉, 郑浩, 赵朝辉. 高频燃烧-红外吸收光谱法测定钒钛磁铁矿中硫的含量[J]. 理化检验(化学分册), 2023, 59(10): 1218−1220.

Luo Q H, Zheng H, Zhao C H. Determination of sulfur content in vanadium titanium magnetite by high-frequency combustion infrared absorption spectroscopy[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2023, 59(10): 1218−1220.

[28] 张高庆, 王录锋. 高频燃烧红外吸收法测定钒钛高炉渣中硫[J]. 冶金分析, 2022, 42(4): 14−18.

Zhang G Q, Wang L F. Determination of sulfur in vanadium-titanium bearing slag by high frequency combustion infrared absorption method[J]. Metallurgical Analysis, 2022, 42(4): 14−18.

[29] 惠博, 杨耀辉, 陈伟, 等. 安康地区某钒钛磁铁矿工艺矿物学研究[J]. 钢铁钒钛, 2020, 41(6): 88−93, 123. doi: 10.7513/j.issn.1004-7638.2020.06.016

Hui B, Yang Y H, Chen W, et al. Study on process mineralogy of a titanium magnetite in Ankang area[J]. Iron Steel Vanadium Titanium, 2020, 41(6): 88−93, 123. doi: 10.7513/j.issn.1004-7638.2020.06.016

[30] 王立平, 杨明灵, 赵海珍, 等. 承德钒钛磁铁矿钒和钛物相的联测分析方法[J]. 岩矿测试, 2013, 32(1): 84−89. doi: 10.3969/j.issn.0254-5357.2013.01.015

Wang L P, Yang M L, Zhao H Z, et al. Determination method of vanadium and titanium phases for Chengde vanadium titanium magnetite[J]. Rock and Mineral Analysis, 2013, 32(1): 84−89. doi: 10.3969/j.issn.0254-5357.2013.01.015

[31] 曾磊, 陈倩倩, 刘攀, 等. 高频燃烧红外吸收法在无机固体材料碳/硫分析标准中的应用[J]. 冶金分析, 2023, 43(5): 32−45.

Zeng L, Chen Q Q, Liu P, et al. Application of high frequency combustion infrared absorption method for analysis standard of carbon and sulfur in inorganic solid material[J]. Metallurgical Analysis, 2023, 43(5): 32−45.

-

下载:

下载: