Determination of Beryllium and Tin in Beryllium Ore by Inductively Coupled Plasma-Mass Spectrometry with Alkali Fusion

-

摘要:

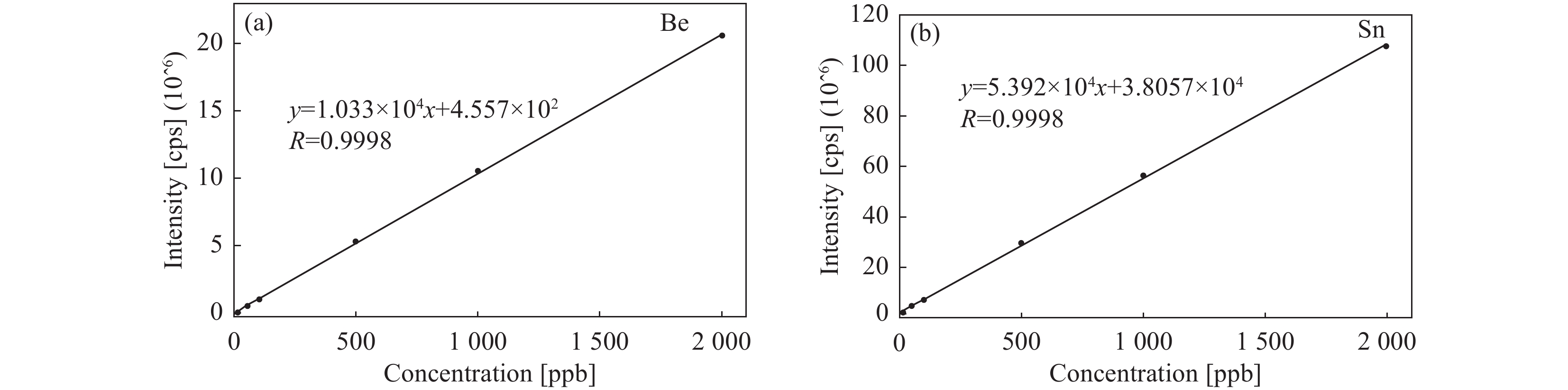

稀有金属矿物组成复杂,且矿物成分多样化,现有质谱方法对铍的测定以地质样品中或矿石样品中的低含量铍分析为主,也很少应用于分析铍矿石中伴生的难溶锡元素。本文以新疆大红柳滩高品位铍矿石并伴生较高含量锡元素的样品为研究对象,建立了铍矿石中难溶元素铍和锡同时测定的方法。利用高温熔融态过氧化钠强的复分解能力,将矿物中的坚固晶格破坏,使目标物转换为易溶盐被提取,通过10倍稀释降低样品基体盐分含量,保证长期测量的稳定性RSD低于5%,并对校准曲线进行基体匹配,以电感耦合等离子体质谱(ICP-MS)测定,铍和锡在5~2000ng/mL浓度范围内线性关系良好,相关系数均大于0.999,检出限为铍0.20μg/g、锡0.17μg/g;测量精密度高(RSD≤5%),测量上限为氧化铍5.6%,锡2%。本文方法线性范围宽,适合各种高品位铍矿石中铍和锡的分析。将建立的方法应用于分析新疆大红柳滩高品位铍矿等多金属稀有金属矿,氧化铍含量达到0.85%、锡含量达到0.078%的样品测量精密度良好;还适用于分析铍矿石中其他稀有元素锂铷铯铌钽和稀土元素。

-

关键词:

- 碱熔 /

- 铍矿石 /

- 铍 /

- 锡 /

- 电感耦合等离子体质谱法

Abstract:Due to the complex composition of rare metal minerals and the diversity of mineral components, the existing mass spectrometry methods for the determination of beryllium mainly focus on the analysis of low content beryllium in geological samples or ore samples, and rarely study and analyze the associated insoluble tin element in beryllium ores. A method for simultaneous determination of insoluble elements beryllium and tin in beryllium ores with high grade beryllium ore and associated high tin content in Dahongliutan, Xinjiang was established. The strong complex decomposition ability of molten sodium peroxide at high temperature was used to destroy the solid crystal lattice in the mineral, so that the target object was converted into soluble salt and extracted. The salt content of the sample matrix was reduced by 10 times dilution to ensure the long-term measurement stability of RSD below 5%. The matrix matching of the calibration curve was performed and determined by inductively coupled plasma-mass spectrometry. The linear relationship between beryllium and tin was good in the concentration range of 5−2000ng/mL, and the correlation coefficients were greater than 0.999. The detection limits of beryllium and tin were 0.20μg/g and 0.17μg/g respectively. High measurement stability (RSD)≤5%, the upper limit of measurement of beryllium oxide was 5.6%, tin was 2%. Compared with the existing methods, this method has a wide linear range and is suitable for the analysis of beryllium and tin in various high grade beryllium ores. The established method was applied to polymetallic rare metals such as high-grade beryllium ore in Dahongliutan, Xinjiang, and it was found that the precision of the samples with beryllium oxide content above 0.85% and tin content above 0.078% was good. This method is also suitable for the determination of other rare elements such as lithium, rubidium, cesium, niobium, tantalum and rare earth in beryllium ores.

-

Key words:

- alkali fusion /

- beryllium ore /

- beryllium /

- tin /

- inductively coupled plasma-mass spectrometry

-

-

表 1 电感耦合等离子体质谱仪主要工作参数

Table 1. Main working parameters of ICP-MS instrument

工作参数 设定值 工作参数 设定值 等离子体气体流速 13L/min 测量模式 标准 辅助气流速 0.8L/min 测量间隔 0.2s 雾化器气体流速 0.84L/min 泵速 40r/min 分辨率模式 Normal 驻留时间 0.001s 测量方式 单点跳峰 扫描次数 50 表 2 稀释倍数对铑内标信号的抑制程度对比

Table 2. Comparison of inhibition degree of Rh internal standard signal by different dilution ratios

稀释倍数 不同分析时间内标回收率(%) 10min 20min 30min 40min 50min 60min 5.0倍 21.2 20.1 18.7 17.2 15.4 12.9 7.5倍 35.9 34.5 32.0 29.9 27.8 25.7 10倍 39.4 40.3 38.8 41.1 39.5 39.0 15倍 53.9 52.5 50.4 51.8 49.7 50.2 20倍 68.4 66.7 65.9 67.2 68.3 66.8 表 3 连续高盐基体进样对铍和锡元素的测定准确度影响

Table 3. Effect of continuous high salt matrix injection on accuracy of Be and Sn determination

测量时间

间隔混合标准溶液校验点30ng/mL 混合标准溶液校验点800ng/mL Be含量

(ng/mL)相对误差

(%)Sn含量

(ng/mL)相对误差

(%)Be含量

(ng/mL)相对误差

(%)Sn含量

(ng/mL)相对误差

(%)10min 29.3 −2.3 30.1 0.33 807 0.88 787 −1.6 20min 30.4 1.3 30.3 1.0 799 −0.13 793 −0.88 30min 31.2 4.0 30.0 0.0 791 −1.1 806 0.75 40min 29.7 −1.0 30.2 0.67 810 1.3 794 −0.75 50min 29.5 −1.7 31.0 3.3 819 2.4 791 −1.1 60min 30.8 2.7 31.2 4.0 809 1.1 790 −1.3 RSD(%) 2.54 ‒ 1.66 ‒ 1.20 ‒ 0.83 ‒ 表 4 盐酸加入量对铍和锡检测结果的稳定性影响

Table 4. Effect of adding amount of hydrochloric acid on stability of Be and Sn determination

组分 测定项目 盐酸加入量 5.0mL 10.0mL 15.0mL 20.0mL 25.0mL BeO 测定平均值(%) 0.84 0.87 0.86 0.85 0.86 RSD(%) 7.2 3.3 2.0 1.9 2.2 Sn 测定平均值(%) 0.078 0.079 0.079 0.078 0.077 RSD(%) 8.3 4.1 2.4 2.5 2.6 注:为符合标准物质中铍和锡的结果表示形式和矿石类样品实际工作中报出要求,本文对样品测定结果铍均以BeO、锡以单质形式展示。 表 5 国家一级标准物质中铍和锡的测定结果误差

Table 5. Determination error of Be and Sn in national first-class standard materials

标准物质

编号BeO Sn 标准值(%) 测定值(%) RSD(%) 相对误差(%) 标准值(%) 测定值(%) RSD(%) 相对误差(%) GBW07150 0.060±0.006 0.060 4.1 0.0 − − − − GBW07151 0.365±0.026 0.359 2.3 −2.6 − − − − GBW07152 0.018±0.001 0.019 4.7 5.6 0.0036 0.0034 4.9 −5.6 GBW07153 0.026±0.003 0.026 3.5 0.0 0.0097±0.0005 0.0093 4.4 −4.1 GBW07154 0.033±0.002 0.033 3.9 0.0 0.0052 0.0055 3.6 5.8 GBW07155 0.033(0.032~0.009) 0.035 4.0 6.1 0.0063 0.0066 4.1 4.8 GBW07311 0.0026±0.005 0.0025 4.8 −3.8 0.037±0.0068 0.037 3.8 0.0 GBW07282 − − − − 1.27±0.001 1.22 1.3 −3.9 注:“−”表示没有定值;GBW07311中铍结果为单质。 表 6 实际样品中氧化铍和锡的测定精密度

Table 6. Precision of BeO and Sn in actual samples

铍矿石实际样品

编号BeO Sn 测定值

(%)RSD

(%)测定值

(%)RSD

(%)样品1 0.052 5.0 0.021 4.3 样品2 0.171 2.5 0.029 2.6 样品3 0.350 3.4 0.040 3.7 样品4 0.549 3.1 0.054 2.5 样品5 0.850 3.0 0.078 1.2 表 7 国家一级标准物质中伴生的稀有金属测定准确度和精密度

Table 7. Determination accuracy and precision of associated rare metals in national first-class standard materials

元素 GBW07151 GBW07152 标准值

(μg/g)测定值

(μg/g)RSD

(%)相对误差

(%)标准值

(μg/g)测定值

(μg/g)RSD

(%)相对误差

(%)Li2O − − − − 0.46±0.01* 0.47 0.7 2.17 Rb2O3 − − − − 0.145±0.011* 0.147 1.1 1.38 Cs2O3 − − − − 0.037±0.003* 0.038 2.3 2.70 Nb2O5 − − − − 27.0±2.1 27.0 4.2 0.00 Ta2O5 − − − − 49.4±4.7 46.6 5.1 −5.67 Y2O3 28.9±2.9 30.8 4.2 6.6 16.9±1.8 16.4 2.8 −2.96 La2O3 7.7±0.7 7.2 5.0 −6.5 5.1±0.5 5.4 5.5 5.88 CeO2 14.8±1.4 14.4 4.7 −2.7 9.0±0.7 8.6 5.5 −4.44 Pr6O11 2.0±0.2 2.0 4.1 0.0 1.3±0.3 1.4 3.9 7.69 Nd2O3 7.6±0.7 7.8 5.4 2.6 5.0±0.6 5.1 4.1 2.00 Sm2O3 2.7±0.2 2.9 4.8 7.4 1.6±0.2 1.4 6.8 −12.50 Eu2O3 0.15 0.12 10.2 −20.0 0.14 0.12 13.2 −14.29 Gd2O3 3.8±0.4 4.1 5.2 7.9 2.1±0.3 2.3 5.7 9.52 Tb4O7 0.8±0.1 0.84 3.7 5.0 0.43±0.05 0.46 3.8 6.98 Dy2O3 4.6±0.5 4.9 1.9 6.5 2.5±0.3 2.5 3.3 0.00 Ho2O3 0.87±0.16 0.92 3.4 5.7 0.45±0.10 0.45 5.3 0.00 Er2O3 2.2±0.4 2.5 0.9 13.6 1.2±0.2 1.3 4.3 8.33 Tm2O3 0.36±0.06 0.36 3.9 0.0 0.18±0.03 0.19 6.8 5.56 Yb2O3 2.5±0.5 2.4 0.3 −4.0 1.3±0.03 1.4 2.2 7.69 Lu2O3 0.31±0.05 0.34 2.5 9.7 0.18±0.04 0.20 4.4 11.11 注:标注“*”数据单位为百分含量(%)。 表 8 实际样品中伴生的稀有金属测定精密度

Table 8. Determination precision of associated rare metals in actual samples

铍矿石实际样品

编号Li2O Rb203 Cs2O3 Nb2O5 Ta2O5 测定值

(%)RSD

(%)测定值

(%)RSD

(%)测定值

(%)RSD

(%)测定值

(μg/g)RSD

(%)测定值

(μg/g)RSD

(%)样品1 0.53 2.3 0.133 1.1 0.013 1.7 92.9 2.0 42.8 3.4 样品2 1.04 0.9 0.114 2.5 0.014 3.0 107 4.9 47.5 4.5 样品3 1.76 1.9 0.088 1.9 0.013 1.4 117 4.9 56.7 4.1 样品4 2.83 2.3 0.074 1.2 0.012 2 129 3.6 63.2 5.0 样品5 4.30 2.0 0.045 3.5 0.007 1.2 152 3.6 79.6 2.2 -

[1] 梁飞, 赵汀, 王登红, 等. 中国铍资源供需预测与发展战略[J]. 中国矿业, 2018, 27(11): 6−10. doi: 10.12075/j.issn.1004-4051.2018.11.011

Liang F, Zhao T, Wang D H, et al. Situation, supply and demand forecast and development strategy of beryllium resources in China[J]. China Mining Magazine, 2018, 27(11): 6−10. doi: 10.12075/j.issn.1004-4051.2018.11.011

[2] 梁飞. 我国铍资源特征、供需预测与发展探讨[D]. 北京: 中国地质科学院, 2018.

Liang F. Characteristics, supply and demand forecast and development of beryllium resources in China[D]. Beijing: Chinese Academy of Geological Sciences, 2018.

[3] 林博磊, 尹丽文, 崔荣国, 等. 全球铍资源分布及供需格局[J]. 国土资源情报, 2018(1): 13−17.

Lin B L, Yin L W, Cui R G, et al. Global beryllium resource distribution and supply and demand pattern[J]. Land and Resources Information, 2018(1): 13−17.

[4] 王仁财, 邢佳韵, 彭浩. 美国铍资源战略启示[J]. 中国矿业, 2014, 23(10): 21−24. doi: 10.3969/j.issn.1004-4051.2014.10.006

Wang R C, Xing J Y, Peng H. Enlightenment of United States’beryllium resources strategy[J]. China Mining Magazine, 2014, 23(10): 21−24. doi: 10.3969/j.issn.1004-4051.2014.10.006

[5] 王登红, 王成辉, 孙艳, 等. 我国锂铍钽矿床调查研究进展及相关问题简述[J]. 中国地质调查, 2017, 4(5): 1−8. doi: 10.19388/j.zgdzdc.2017.05.01

Wang D H, Wang C H, Sun Y, et al. New progresses and discussion on the survey and research of Li,Be,Ta ore deposits in China[J]. Geological Survey of China, 2017, 4(5): 1−8. doi: 10.19388/j.zgdzdc.2017.05.01

[6] 邓伟, 颜世强, 谭洪旗, 等. 我国铍矿资源概况及选矿技术研究现状[J]. 矿产综合利用, 2023(1): 148−154. doi: 10.3969/j.issn.1000-6532.2023.01.020

Deng W, Yan S Q, Tan H Q, et al. General situation of beryllium mineral resources and research status of mineral processing technology in China[J]. Comprehensive Utilization of Mineral Resources, 2023(1): 148−154. doi: 10.3969/j.issn.1000-6532.2023.01.020

[7] 周仕林, 刘芳, 高明慧, 等. 稀土元素测定方法的研究进展[J]. 理化检验(化学分册), 2014, 50(3): 392−396.

Zhou S L, Liu F, Gao M H, et al. Recent Advances of Researches on Determination of Rare-Earth Elements[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2014, 50(3): 392−396.

[8] 陈波, 胡兰, 陈园园, 等. 地质样品中总锡测定方法的研究进展[J]. 理化检验(化学分册), 2017, 53(2): 236−241. doi: 10.11973/lhjy-hx201702026

Chen B, Hu L, Chen Y Y, et al. Recent progress of research on methods for determination of total tin in geological samples[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2017, 53(2): 236−241. doi: 10.11973/lhjy-hx201702026

[9] 夏传波, 成学海, 姜云, 等. 密闭酸溶-电感耦合等离子体发射光谱/质谱法测定花岗伟晶岩中32种微量元素[J]. 岩矿测试, 2019, 43(2): 247−258. doi: 10.15898/j.ykcs.202307310105

Xia C B, Cheng X H, Jiang Y, et al. Determination of 32 trace elements in granite pegmatite by inductively coupled plasma-optical emission spectrometry and mass spectrometry with closed acid dissolution[J]. Rock and Mineral Analysis, 2019, 43(2): 247−258. doi: 10.15898/j.ykcs.202307310105

[10] 于亚辉, 刘军, 李小辉, 等. 高压密闭消解-电感耦合等离子体质谱法测定地球化学样品中的50种元素[J]. 理化检验(化学分册), 2019, 55(7): 833−839. doi: 10.11973/lhjy-hx201907017

Yu Y H, Liu J, Li X H, et al. High pressure sealed digestion-determination of 50 elements in geochemical samples by inductively coupled plasma mass spectrometry[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2019, 55(7): 833−839. doi: 10.11973/lhjy-hx201907017

[11] 张玉芹, 彭艳, 韦时宏, 等. 高压密闭消解-电感耦合等离子体质谱法测定地质样品中稀土元素[J]. 实验室研究与探索, 2021, 40(3): 29−32. doi: 10.19927/j.cnki.syyt.2021.03.007

Zhang Y Q, Peng Y, Wei S H, et al. Determination of rare earth elements in geological samples by high-pressure closed digestion and ICP-MS[J]. Research and Exploration in Laboratory, 2021, 40(3): 29−32. doi: 10.19927/j.cnki.syyt.2021.03.007

[12] 程祎, 李志伟, 于亚辉, 等. 高压密闭消解-电感耦合等离子体质谱法测定地质样品中铌、钽、锆、铪和16种稀土元素[J]. 理化检验(化学分册), 2019, 56(7): 782−787. doi: 10.11973/lhjy-hx202007007

Cheng Y, Li Z W, Yu Y H, et al. Determination of niobium, tantalum, zirconium, hafnium and 16 rare earth elements in geological samples by high-pressure closed digestion and inductively coupled plasma mass spectrometry[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2019, 56(7): 782−787. doi: 10.11973/lhjy-hx202007007

[13] 王记周, 燕洲泉, 徐磊, 等. 新疆大红柳滩地区伟晶岩型锂铍资源潜力分析[J]. 黄金科学技术, 2019, 27(6): 802−815. doi: 10.11872/j.issn.1005-2518.2019.06.802

Wang J Z, Yan Z Q, Xu L, et al. Potential evaluation of pegmatite-type lithium-beryllium mineral resources in Dahongliutan,Xinjiang[J]. Gold Science and Technology, 2019, 27(6): 802−815. doi: 10.11872/j.issn.1005-2518.2019.06.802

[14] 常学东. 测定稀有金属矿中锂、铍、铌、钽的方法选择[J]. 新疆有色金属, 2016, 39(3): 64−66. doi: 10.16206/j.cnki.65-1136/tg.2016.03.026

Chang X D. Selection of methods for the determination of lithium, beryllium, niobium and tantalum in rare metal ores[J]. Xinjiang Nonferrous Metals, 2016, 39(3): 64−66. doi: 10.16206/j.cnki.65-1136/tg.2016.03.026

[15] Brügmann G, Berger D, Pernicka E. Determination of the tin stable isotopic composition in tin-bearing metals and minerals by MC-ICP-MS[J]. Geostandards and Geoanalytical Research, 2017, 41(3): 437−448. doi: 10.1111/ggr.12166

[16] 郭琳, 于汀汀, 孙红宾, 等. 偏硼酸锂熔融-电感耦合等离子体发射光谱法测定铍矿石中的铍及主量元素[J]. 岩矿测试, 2019, 43(2): 356−365. doi: 10.15898/j.ykcs.202308070129

Guo L, Yu T T, Sun H B, et al. Determination of beryllium and major elements in beryllium ores by inductively coupled plasma-optical emission spectrometry with lithium metaborate melting[J]. Rock and Mineral Analysis, 2019, 43(2): 356−365. doi: 10.15898/j.ykcs.202308070129

[17] 刘环, 康佳红, 王玉学. 碱熔-电感耦合等离子体质谱法测定地质样品中铍铯镓铊铌钽锆铪铀钍[J]. 冶金分析, 2019, 39(3): 26−32. doi: 10.13228/j.boyuan.issn1000-7571.010574

Liu H, Kang J H, Wang Y X. Determination of beryllium, cesium, gallium, thallium, niobium, tantalum, zirconium, hafnium, uranium and thorium in geological sample by inductively coupled plasma mass spectrometry with alkali fusion[J]. Metallurgical Analysis, 2019, 39(3): 26−32. doi: 10.13228/j.boyuan.issn1000-7571.010574

[18] 罗艳, 杨侨. 碱熔、分离沉淀-电感耦合等离子体质谱法快速测定地球化学样品中的锡[J]. 分析试验室, 2017, 36(7): 827−830. doi: 10.13595/j.cnki.issn1000-0720.2017.0178

Luo Y, Yang Q. Alkaline fusion, separate precipitation-inductively coupled plasma spectrometry and rapid measurement of tin from planet chemical samples[J]. Chinese Journal of Analysis Laboratory, 2017, 36(7): 827−830. doi: 10.13595/j.cnki.issn1000-0720.2017.0178

[19] 郝冬梅, 张翼明, 许涛, 等. ICP-MS法测定稀土铌钽矿中铍、铀、铌、钽、锆、铪量[J]. 稀土, 2010, 31(5): 67−69. doi: 10.16533/j.cnki.15-1099/tf.2010.05.020

Hao D M, Zhang Y M, Xu T, et al. Determination of beryllium, uranium, niobium, tantalum, zirconium and hafnium in rare earth-niobium-tantalum mineralby by ICP-MS[J]. Chinese Rare Earths, 2010, 31(5): 67−69. doi: 10.16533/j.cnki.15-1099/tf.2010.05.020

[20] 雷占昌, 韩斯琴图, 蒋常菊, 等. 过氧化钠碱熔-电感耦合等离子体质谱法测定原生矿石中的锡[J]. 岩矿测试, 2019, 38(3): 326−332. doi: 10.15898/j.cnki.11-2131/td.201812030127

Lei Z C, Han S Q T, Jang C J, et al. Determination of tin in primary ore by inductively coupled plasma mass spectrometry with sodium peroxide alkali fusion[J]. Rock and Mineral Analysis, 2019, 38(3): 326−332. doi: 10.15898/j.cnki.11-2131/td.201812030127

[21] 王凤祥. 电感耦合等离子体原子发射光谱法测定锡矿石中锡[J]. 冶金分析, 2017, 37(11): 59−63. doi: 10.13228/j.boyuan.issn1000-7571.010155

Wang F X. Determination of tin in tin ore by inductively coupled plasma atomic emission spectrometry[J]. Metallurgical Analysis, 2017, 37(11): 59−63. doi: 10.13228/j.boyuan.issn1000-7571.010155

[22] 孙孟华, 李晓敬, 王文娟, 等. 过氧化钠碱熔-电感耦合等离子体质谱法测定地质样品 中锆铌铪钽锂铍钒磷铀锰[J]. 冶金分析, 2022, 42(1): 78−84. doi: 10.13228/j.boyuan.issn1000-7571.011455

Sun M H, Li X J, Wang W J, et al. Determination of zirconium, niobium, hafnium, tantalum, lithium, beryllium, vanadium, phosphorous uranium-manganese in geological samples by inductively coupled plasma mass spectrometry with sodium peroxide alkali fusion[J]. Metallurgical Analysis, 2022, 42(1): 78−84. doi: 10.13228/j.boyuan.issn1000-7571.011455

[23] 马龙, 付东磊, 马明, 等. 过氧化钠熔融-电感耦合等离子体质谱法测定锡矿石中锡[J]. 冶金分析, 2020, 40(8): 50−54. doi: 10.13228/j.boyuan.issn1000-7571.011020

Ma L, Fu D L, Ma M, et al. Determination of tin in tin ore by inductively coupled plasma mass spectrometry after fusion with sodium peroxide[J]. Metallurgical Analysis, 2020, 40(8): 50−54. doi: 10.13228/j.boyuan.issn1000-7571.011020

[24] 杨林, 邹国庆, 周武权, 等. 碱熔-电感耦合等离子体发射光谱(ICP-OES)法测定钨锡矿石中钨锡钼铜铅锌硫砷[J]. 中国无机分析化学, 2019, 13(11): 1191−1196. doi: 10.3969/j.issn.2095-1035.2023.11.005

Yang L, Zou G Q, Zhou W Q, et al. Determination of W, Sn, Mo, Cu, Pb, Zn, S and As in tungsten-tin ore by inductively coupled plasma optical emission spectro-metry (ICP-OES) with alkali fusion[J]. Chinese Journal of Inorganic Analytical Chemistry, 2019, 13(11): 1191−1196. doi: 10.3969/j.issn.2095-1035.2023.11.005

[25] 孔庆玲, 沈领兄, 曹开科. 电感耦合等离子体发射光谱法(ICP-OES)测定钨铋矿石中的 锡[J]. 矿产与地质, 2017, 31(4): 817−819. doi: 10.3969/j.issn.1001-5663.2017.04.026

Kong Q L, Shen L X, Cao K K. Application of inductively coupled plasma atomic emission spectro-metry in determining tin from tungsten and bismuth ores[J]. Minerals Resources and Geology, 2017, 31(4): 817−819. doi: 10.3969/j.issn.1001-5663.2017.04.026

[26] Daniel L, Laird D W, Hefter G T. Sodium peroxide fusion for reliable determination of gold in ores and metallurgical samples[J]. International Journal of Mineral Processing, 2017, 168: 35−39. doi: 10.1016/j.minpro.2017.09.001

[27] 李振, 钟莅湘, 崔承洋, 等. 碱熔-电感耦合等离子体质谱法测定铌钽矿中铌钽锂铍[J]. 矿产综合利用, 2024, 45(3): 200−204. doi: 10.3969/j.issn.1000-6532.2024.03.031

Li Z, Zhong L X, Cui C Y, et al. Determination of niobium-tantalum lithium beryllium in niobium-tantalum ore by alkali fusion-inductively coupled plasma mass spectrometry[J]. Multipurpose Utilization of Mineral Resources, 2024, 45(3): 200−204. doi: 10.3969/j.issn.1000-6532.2024.03.031

[28] 郑大中, 李小英, 郑若锋, 等. 过氧化钠超强熔矿能力的新认识[J]. 四川地质学报, 2010, 30(4): 488−492, 499. doi: 10.3969/j.issn.1006-0995.2010.04.031

Zheng D Z, Li X Y, Zheng R F, et al. New acquaintances of super strong melting ore capacity of Na2O2[J]. Acta Geologica Sichuan, 2010, 30(4): 488−492, 499. doi: 10.3969/j.issn.1006-0995.2010.04.031

[29] 李文渊, 高永宝, 任广利, 等. 新疆大红柳滩伟晶岩型锂矿深部结构与区域成矿模型解释[J]. 地质学报, 2024, 98(5): 1440−1451. doi: 10.19762/j.cnki.dizhixuebao.2024063

Li W Y, Gao Y B, Ren G L, et al. Deep structure and interpretation of regional metallogenic model of the dahongliutan pegmatite lithium ore deposit in Xinjiang , Western China[J]. Acta Geologica Sinica, 2024, 98(5): 1440−1451. doi: 10.19762/j.cnki.dizhixuebao.2024063

-

下载:

下载: