Quantitative Detection of Gas-Liquid Inclusions in High-Purity Quartz Sand by Double Extreme Case Analysis

-

摘要:

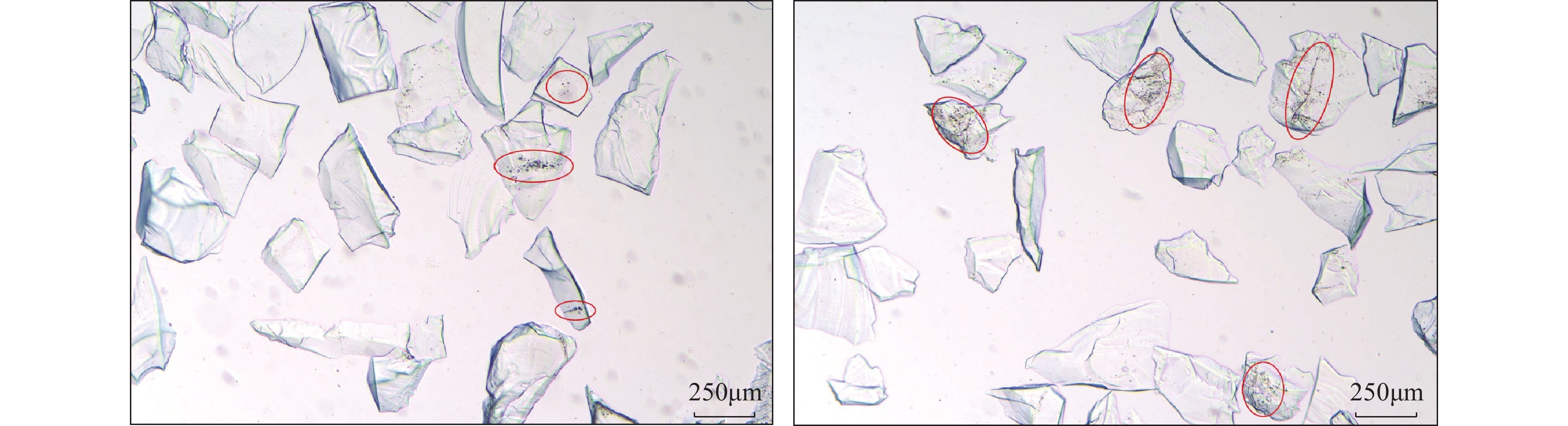

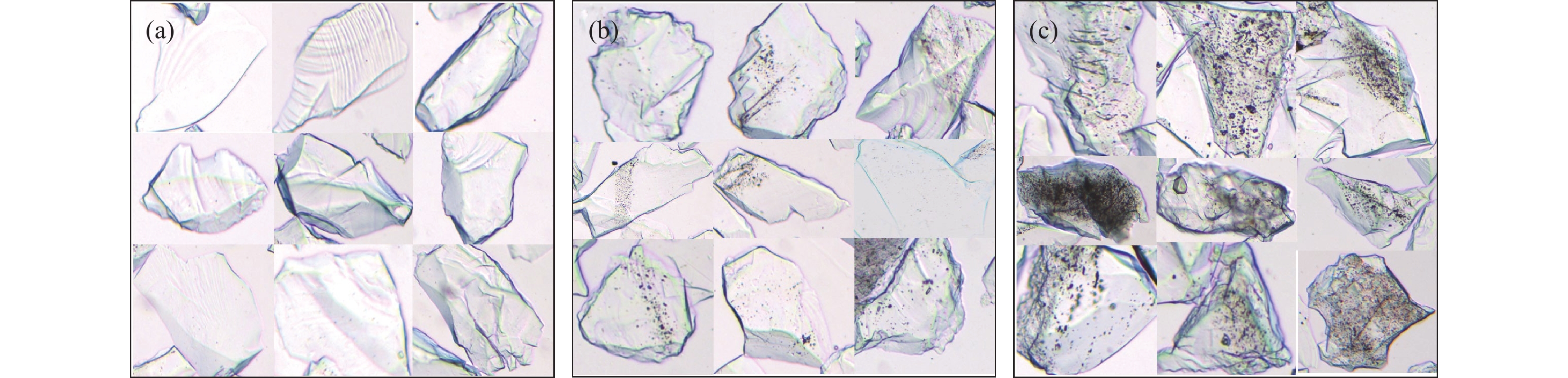

高纯石英砂作为半导体、光伏等战略新兴行业的关键材料,其质量对单晶硅坩埚、石英管等产品的应用至关重要。除杂质元素外,气液包裹体是影响高纯石英质量的重要因素之一,但目前对石英气液包裹体的检测方法多为定性描述,缺乏高效精确的定量分析手段。本文提出了一种双极端对比(Double extreme case analysis,DECA)检测法,能够快速、定量地评估气液包裹体含量。具体流程包括:将药剂浸泡石英砂片置于显微镜下观察并拍摄,总计获取不少于300个石英砂颗粒的显微照片,其中石英砂呈透明状,而气液包裹体呈黑色,通过图像统计计算得到石英砂通透颗粒(T)和不通透颗粒(NT)比例两个数据,以此来评价石英砂品质。通过研究不同石英砂DECA检测结果及坩埚能力,结果表明,T比例较高、NT比例较低的石英砂制备的坩埚透明度优良;而T比例较低、NT比例较高的石英砂制品透明层质量显著下降。该方法有效地解决了气液包裹体检测中定量化不足的难题,为高纯石英砂品质评估提供了可靠依据。

Abstract:High-purity quartz sand serves as a critical material in various strategic emerging industries, such as semiconductors and photovoltaics. The quality of quartz sand is crucial for the application of products like single crystal silicon crucibles and quartz tubes. Besides impurity elements, gas-liquid inclusions are a significant factor affecting quartz quality. However, current detection methods for gas-liquid inclusions are mainly qualitative, lacking efficient and precise quantitative analysis techniques. The double extreme case analysis (DECA) method is innovatively proposed here to quantitatively assess the content of gas-liquid inclusions. The process involves quartz sand slices treated with reagent and put under a microscope for observation and photographing, obtaining at least 300 images of quartz particles where the quartz appears transparent and the inclusions appear black. By statistically analyzing the images, the ratio of transparent (T) to non-transparent (NT) particles is calculated to evaluate quartz quality. The crucible study of different quartz sands using DECA shows that quartz sand with a high T ratio and low NT ratio produces crucibles of excellent transparency, while quartz sand with a low T ratio and high NT ratio results in poor transparency. This method effectively addresses the challenge of quantitative gas-liquid inclusion detection and provides a reliable basis for evaluating high-purity quartz sand quality.

-

-

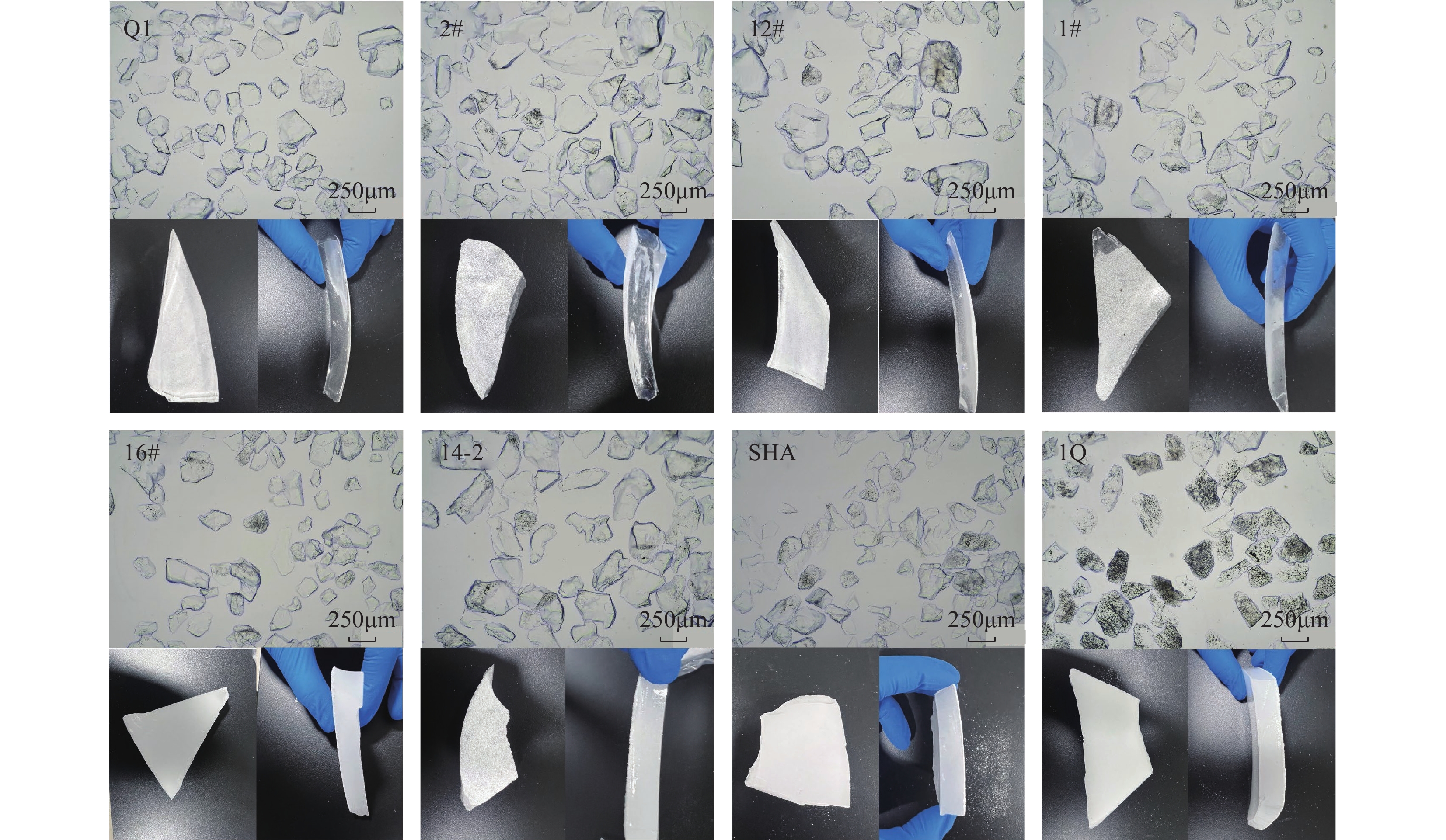

表 1 不同石英砂气液包裹体检测及坩埚测试结果

Table 1. Detection of gas-liquid inclusions and crucible test results of different quartz sands

样品编号 通透颗粒

含量T(%)不通透颗粒

含量NT(%)坩埚说明 Q1 79 1 坩埚透明度好,没有气泡 2# 68 5 坩埚透明度较好,气泡含量极少 12# 41 10 坩埚透明度较差,含有一定量气泡 1# 34 16 坩埚透明度较差,含有一定量气泡 16# 32 20 坩埚透明度差,气泡含量较多 14-2 23 18 坩埚透明度差,气泡含量多 SHA 22 28 坩埚几乎不透明 1Q 1 92 坩埚呈沙状,完全不透明 -

[1] 赵海波, 张倩, 张勇, 等. 天然石英矿物微量元素赋存特征研究进展及对高纯石英找矿的指示[J]. 西北地质, 2024, 57(5): 106−119. doi: 10.12401/j.nwg.2023180

Zhao H B, Zhang Q, Zhang Y, et al. A review of the impurity element chemistry and textures of natural quartz and its application to the prospect of high purity quartz deposit[J]. Northwestern Geology, 2024, 57(5): 106−119. doi: 10.12401/j.nwg.2023180

[2] 汪灵. 高纯石英的概念及其原料品级划分[J]. 矿产保护与利用, 2022, 42(5): 55−63. doi: 10.13779/j.cnki.issn1001-0076.2022.05.009

Wang L. Concept of high purity quartz and classification of its raw materials[J]. Conservation and Utilization of Mineral Resources, 2022, 42(5): 55−63. doi: 10.13779/j.cnki.issn1001-0076.2022.05.009

[3] 郝文俊, 冯书文, 詹建华, 等. 全球高纯石英资源现状、生产、消费及贸易格局[J]. 中国非金属矿工业导刊, 2020(5): 15−19. doi: 10.3969/j.issn.1007-9386.2020.05.005

Hao W J, Feng S W, Zhan J H, et al. Current situation, production, consumption and trade pattern of high purity quartz in the world[J]. China Non-metallic Mining Industry, 2020(5): 15−19. doi: 10.3969/j.issn.1007-9386.2020.05.005

[4] 武志超, 张海啟, 谭秀民, 等. 高纯石英应用及化学提纯技术研究进展[J]. 化工矿物与加工, 2023, 52(9): 72−80. doi: 10.16283/j.cnki.hgkwyjg.2023.09.012

Wu Z C, Zhang H Q, Tan X M, et al. Research progress on the application of high-purity quartz and its chemical refinement technology[J]. Industrial Minerals & Processing, 2023, 52(9): 72−80. doi: 10.16283/j.cnki.hgkwyjg.2023.09.012

[5] 马超, 冯安生, 刘长淼, 等. 高纯石英原料矿物学特征与加工技术进展[J]. 矿产保护与利用, 2019, 39(6): 48−57. doi: 10.13779/j.cnki.issn1001-0076.2019.06.008

Ma C, Feng A S, Liu C M, et al. Mineralogical characteristics and progress in processing technology of raw materials of high purity quartz[J]. Conservation and Utilization of Mineral Resources, 2019, 39(6): 48−57. doi: 10.13779/j.cnki.issn1001-0076.2019.06.008

[6] 杨晓勇, 孙超, 曹荆亚, 等. 高纯石英的研究进展及发展趋势[J]. 地学前缘, 2022, 29(1): 231−244. doi: 10.13745/j.esf.sf.2021.8.1

Yang X Y, Sun C, Cao J Y, et al. High purity quartz: Research progress and perspective review[J]. Earth Science Frontiers, 2022, 29(1): 231−244. doi: 10.13745/j.esf.sf.2021.8.1

[7] 张亮, 刘磊, 朱黎宽, 等. 关于高纯石英原料矿石地质学评价方法的探讨[J]. 岩石学报, 2024, 40(4): 1311−1326. doi: 10.18654/1000-0569/2024.04.16

Zhang L, Liu L, Zhu L K, et al. Discussion on the geological evaluation for high purity quartz raw material[J]. Acta Petrologica Sinica, 2024, 40(4): 1311−1326. doi: 10.18654/1000-0569/2024.04.16

[8] 魏玉燕. 脉石英显微结构与包裹体特征及其与高纯石英加工提纯的关系[D]. 成都: 成都理工大学, 2018.

Wei Y Y. Microstructure and inclusion characteristics of vein quartz and its’ relationship of making high purity quartz[D]. Chengdu: Chengdu University of Technology, 2018.

[9] 中国粉体技术网. 解析: 为什么美国尤尼明能够做出高纯石英砂[EB/OL]. (2018-3-15)[2019-6-12]. http://www.cnpowdertech.com/2018/jsjzt_0315/24824.html.

China Powder Technology Network. Analysis: Why Unimin can produce high-purity quartz sand[EB/OL]. (2018-3-15) [2019-6-12].http://www.cnpowdertech.com/2018/jsjzt_0315/24824.html.

[10] 贾德龙, 张万益, 陈丛林, 等. 高纯石英全球资源现状与我国发展建议[J]. 矿产保护与利用, 2019, 39(5): 111−117. doi: 10.13779/j.cnki.issn1001-0076.2019.05.011

Jia D L, Zhang W Y, Chen C L, et al. Global resource status and China’s development suggestions of high purity quartz[J]. Conservation and Utilization of Mineral Resources, 2019, 39(5): 111−117. doi: 10.13779/j.cnki.issn1001-0076.2019.05.011

[11] 李光惠, 王超峰, 詹建华, 等. 高纯石英原料作为战略性矿产的分析及建议[J]. 中国非金属矿工业导刊, 2020(5): 20−24.

Li G H, Wang C F, Zhan J H. Analysis and suggestions on high purity quartz raw material as strategic minerals[J]. China Non-Metallic Mining Industry, 2020(5): 20−24.

[12] 陶恭益. 石英包裹体中液相成分的测定[J]. 岩矿测试, 1996, 15(2): 143−146.

Tao G Y. Determination of liquid compositions in quartz inclusion[J]. Rock and Mineral Analysis, 1996, 15(2): 143−146.

[13] Shu L, Shen K, Yang R, et al. SEM-CL study of quartz containing fluid inclusions in Wangjiazhuang porphyry copper (-molybdenum) deposit, Western Shandong, China[J]. Journal of Earth Science, 2020, 31(4): 330−341.

[14] 蓝廷广, 胡瑞忠, 范宏瑞, 等. 流体包裹体及石英LA-ICP-MS分析方法的建立及其在矿床学中的应用[J]. 岩石学报, 2017, 33(10): 3239−3262.

Lan T G, Hu R Z, Fan H R, et al. In-situ analysis of major and trace elements in fluid inclusion and quartz: LA-ICP-MS method and applications to ore deposits[J]. Acta Petrologica Sinica, 2017, 33(10): 3239−3262.

[15] Lin M, Pei Z Y, Liu Y Y, et al. High-efficiency trace Na extraction from crystal quartz ore used for fused silica—A pretreatment technology[J]. Journal of Mineral Metallurgy and Materials, 2017(24): 1086. doi: 10.1007/s12613-017-1498-y

[16] 李康宁, 张江苏, 徐进, 等. 西秦岭甘南加甘滩金矿床流体包裹体及氢-氧-硫-铅同位素特征[J]. 地质通报, 2023, 42(6): 941−952. doi: 10.12097/j.issn.1671-2552.2023.06.007

Li K N, Zhang J S, Xu J, et al. Fluid inclusions and H-O-S-Pb isotopic characteristics of the Jiagantan gold deposit in Gannan, West Qinling[J]. Geological Bulletin of China, 2023, 42(6): 941−952. doi: 10.12097/j.issn.1671-2552.2023.06.007

[17] 唐春花, 张生辉, 袁晶, 等. 江西宁都白云母伟晶花岗岩型高纯石英用硅质原料矿床特征与资源潜力[J]. 地质通报, 2024, 43(5): 667−679. doi: 10.12097/gbc.2022.10.026

Tang C H, Zhang S H, Yuan J, et al. Deposit characteristics and potential resources of silicon material for high-purity quartz of muscovite-pegmatite-granite type in Ningdu, Jiangxi Province[J]. Geological Bulletin of China, 2024, 43(5): 667−679. doi: 10.12097/gbc.2022.10.026

[18] 赵毅, 王守敬, 郭理想, 等. 基于机器视觉的石英流体包裹体自动识别与指数计算[J]. 矿产保护与利用, 2022, 42(5): 28−34. doi: 10.13779/j.cnki.issn1001-0076.2022.05.005

Zhao Y, Wang S J, Guo L X, et al. Index calculation and automatic identification of quartz fluid inclusions based on machine vision[J]. Conservation and Utilization of Mineral Resources, 2022, 42(5): 28−34. doi: 10.13779/j.cnki.issn1001-0076.2022.05.005

[19] 王征, 韩东, 刘阳, 等. 石英砂包裹体含量的检测方法、设备及存储介质[P]. 中国:CN201911174246. X(2023-08-29).

Wang Z, Han D, Liu Y, et al. Detection methods, equipment, and storage media for quartz sand inclusions[P]. China: CN201911174246. X (2023-08-29).

[20] 张文淮, 陈紫英. 流体包裹体地质学[M]. 武汉: 中国地质大学出版社, 1993: 17−18.

Zhang W H, Chen Z Y. Geology of fluid inclusions[M]. Wuhan: China University of Geosciences Press, 1993: 17−18.

[21] 欧阳恒, 张术根, 谷湘平. 溆浦高纯硅矿床石英流体包裹体研究[J]. 中国非金属矿工业导刊, 2006(2): 55−57, 64. doi: 10.3969/j.issn.1007-9386.2006.02.018

Ouyang H, Zhang S G, Gu X P. Fluid inclusions in quartz of high purity silica deposit of Xupu, Hunan[J]. China Non-metallic Mining Industry, 2006(2): 55−57, 64. doi: 10.3969/j.issn.1007-9386.2006.02.018

[22] 李静. 微波和酸蚀作用去除石英砂中气液包裹体及机理研究[D]. 株洲: 湖南工业大学, 2014.

Li J. Study on removal fluid inclusions in quartz sand by microwave and acid leaching and removal mechanism[D]. Zhuzhou: Hunan University of Technology, 2014.

[23] 刘泰荣. 酸浸辅助微波场去除石英砂中气液包裹体的研究[D]. 株洲: 湖南工业大学, 2015.

Liu T R. Research on removal of fluid inclusions from quartz sand through acid leaching-aided microwave field[D]. Zhuzhou: Hunan University of Technology, 2015.

[24] 王旭东, 倪培, 袁顺达, 等. 赣南漂塘钨矿锡石及共生石英中流体包裹体研究[J]. 地质学报, 2013, 87(6): 850−859. doi: 10.3969/j.issn.0001-5717.2013.06.009

Wang X D, Ni P, Yuan S D, et al. Fluid inclusion studies on coexisting cassiterite and quartz from the Piaotang tungsten deposit, Jiangxi Province, China[J]. Acta Geologica Sinica, 2013, 87(6): 850−859. doi: 10.3969/j.issn.0001-5717.2013.06.009

[25] 张立, 胡修权, 彭兴华, 等. 高纯石英砂原料矿中流体包裹体研究[J]. 矿产综合利用, 2022, 43(3): 188−192. doi: 10.3969/j.issn.1000-6532.2022.03.033

Zhang L, Hu X Q, Peng X H, et al. Research on fluid inclusions in vein quartz as higher purity quartz sand[J]. Multipurpose Utilization of Mineral Resources, 2022, 43(3): 188−192. doi: 10.3969/j.issn.1000-6532.2022.03.033

[26] Ji Z, Ge C, Zhou M, et al. Quartz-hosted fluid inclusions characteristics and their implications for fluvial deposits along the Changjiang River[J]. Journal of Earth Science, 2020: 571−581.

[27] 汤中昉. 脉石英包裹体特征及其对高纯石英提纯效果的影响[D]. 成都: 成都理工大学, 2022.

Tang Z F. Characteristics of inclusions in vein quartz and its effect on purification of high-purity quartz [D]. Chengdu: Chengdu University of Technology, 2022.

[28] Yuan Y, Zhang L, Guan J, et al. Contribution on fluid inclusion abundance to activation of quartz flotation[J]. Physicochemical Problems of Mineral Processing, 2018.

[29] 赵动. 去除微小气液包裹体制备高纯石英砂的研究[D]. 广州: 华南理工大学, 2014.

Zhao D. Research on removing tiny fluid inclusions for preparation of high purity quartz sand[D]. Guangzhou: South China University of Technology, 2014.

[30] 王九一. 印度北部某4N8级高纯石英原料研究及其对我国的找矿启示[J/OL]. 岩石矿物学杂志[2024-04-28]. http://kns.cnki.net/kcms/detail/11.1966.p.20240419.1901.002.html.

Wang J Y. Investigation on a 4N8 grade high purity quartz deposit from Northern India: Implications for ore prospecting in China[J/OL]. Acta Petrologica Mineralogica [2024-04-28]. http://kns.cnki.net/kcms/detail/11.1966.p.20240419.1901.002.html.

[31] 唐宇, 孙红娟, 刘波, 等. 典型光伏坩埚用高纯石英砂工艺属性对比研究[J]. 非金属矿, 2024, 47(S5): 37−41. doi: 10.3969/j.issn.1000-8098.2024.05.009

Tang Y, Sun H J, Liu B, et al. Comparative study on high purity quartz sand used in typical photovoltaic crucible[J]. Non-Metallic Mines, 2024, 47(S5): 37−41. doi: 10.3969/j.issn.1000-8098.2024.05.009

-

下载:

下载: