Technical Transformation and Productive Practice of Mineral Processing Flowsheet about Jinchuan Copper-Nickel Sulfide Ore

-

摘要:

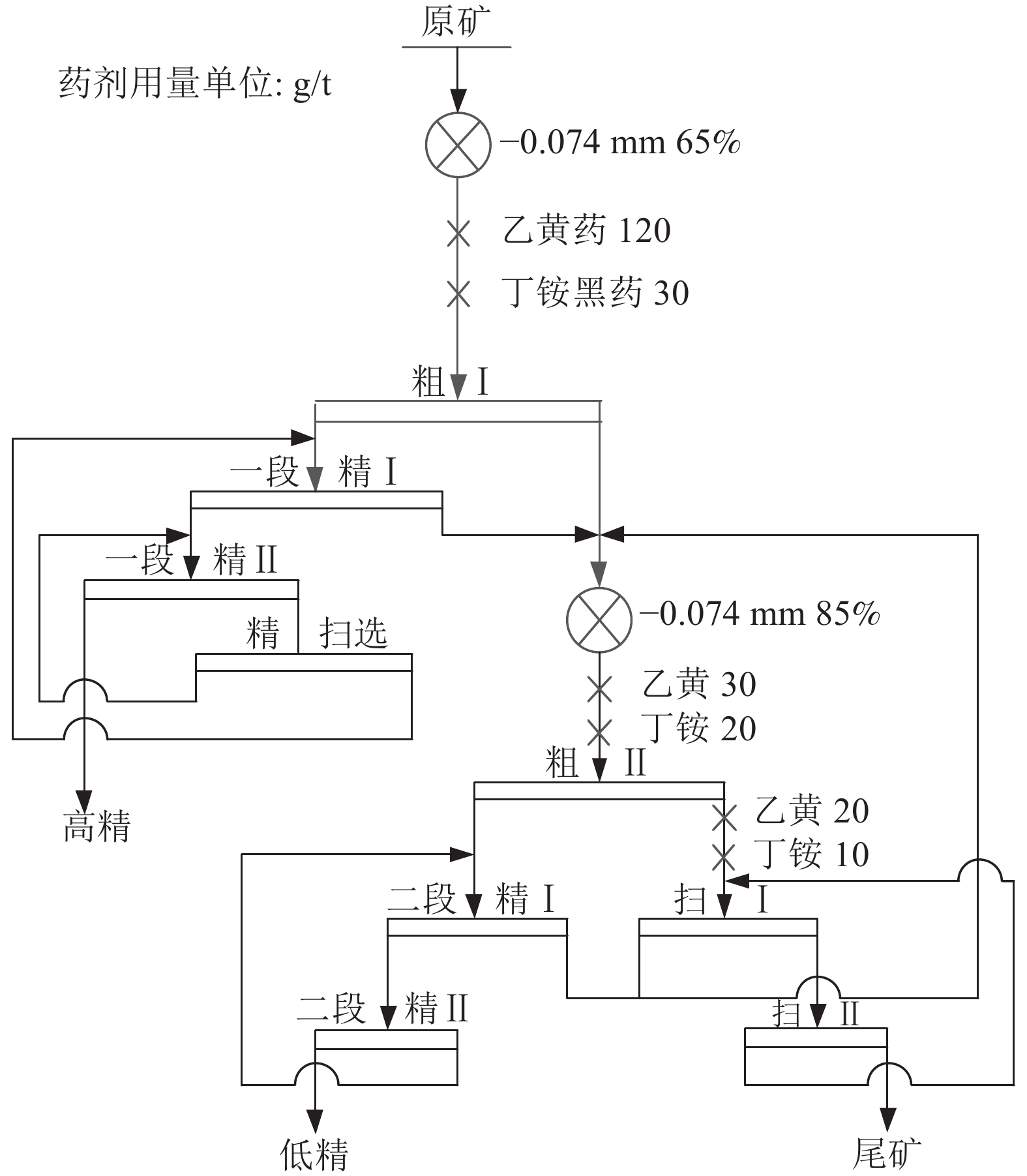

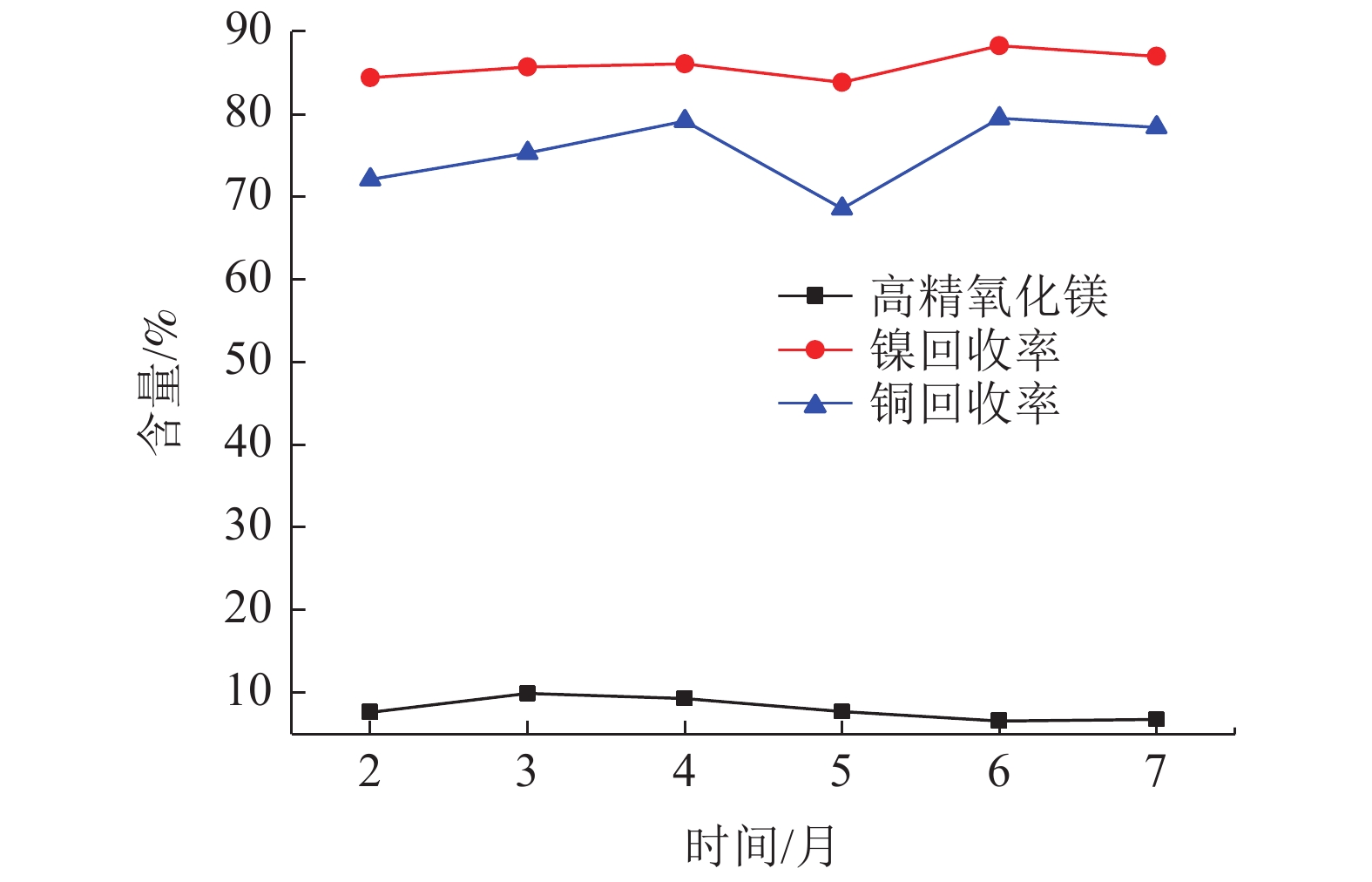

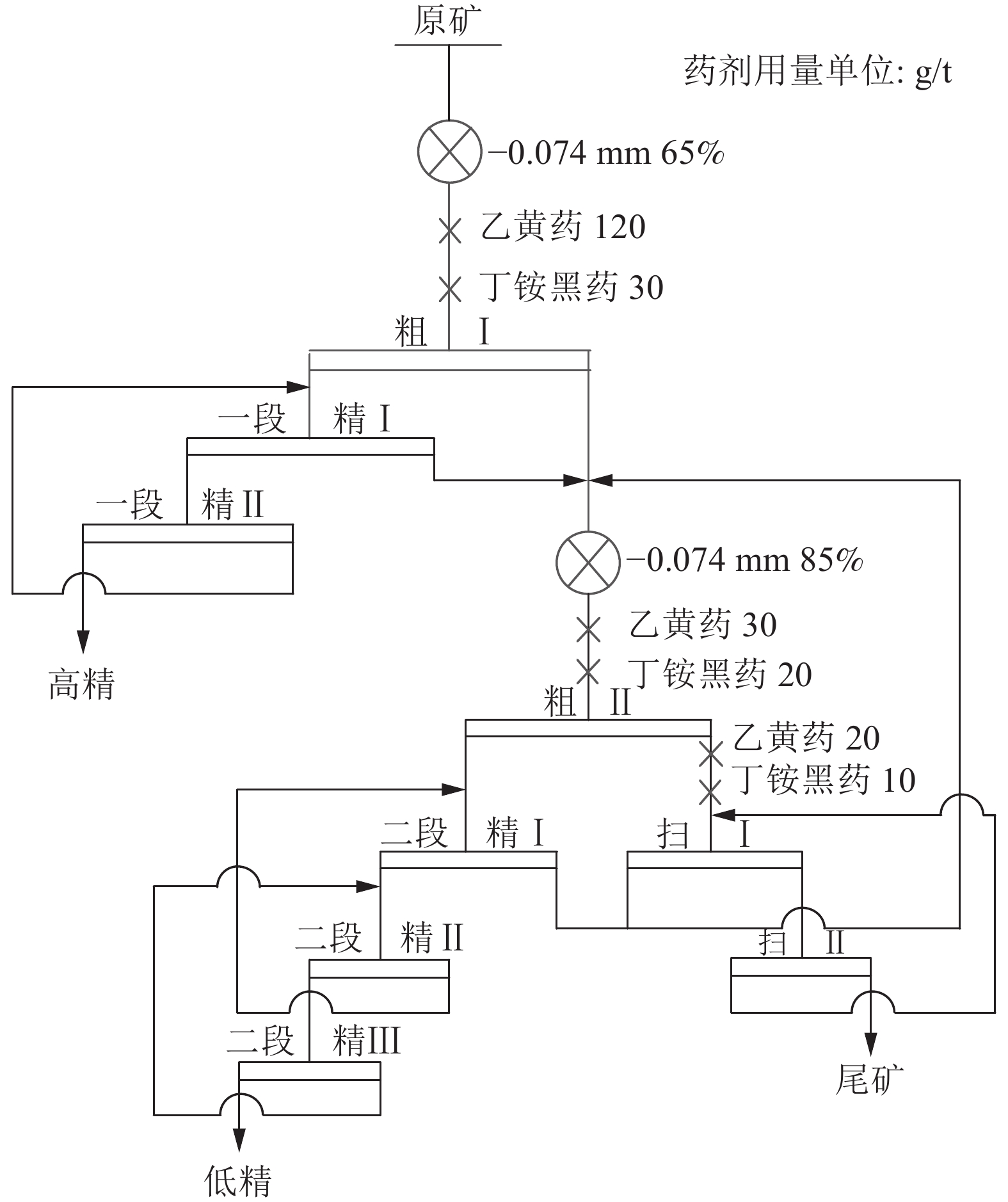

金川某矿区硫化铜镍矿中氧化镁含量高,主要以蛇纹石为主。生产实践表明,在现有的工艺流程下,精矿氧化镁含量波动大,超标严重,尾矿金属品位高、损失大,严重影响选矿厂的经济效益。为提高生产指标,在流程考察基础上对现有的工艺流程进行技术改造。改造后生产结果表明,高精氧化镁含量小于6.8%,镍回收率提高至87%以上,铜回收率提高至79%左右,精矿品质和金属回收率都有较大提高,给选矿厂带来良好的经济效益。

Abstract:Content of MgO in Jinchuan copper-nickel sulfide ore is high, mainly serpentine. The production quota show that the content of MgO was fluctuates greatly in concentrate and exceeds the standard seriously, and the metal grade is high in tailings and the metal loss is large under the current technological process, which seriously affects the economic benefits of the concentrator. In order to improve the production target, the existing process flow was reformed on the basis of process investigation. The production results show that the content of MgO in high grade concentrate is less than 6.8%, the nickel recovery rate is increased to more than 87%, and the copper recovery rate is increased to about 79% after technical transformation. The concentrate quality and metal recovery rate are greatly improved, which brings good economic benefits to the concentrator.

-

-

表 1 低品位矿石多组分分析结果/%

Table 1. Multi component analysis results of low grade ore

Ni Cu Co Fe Mn Ti Cr SiO2 0.82 0.63 0.025 11.29 0.087 0.16 0.22 34.51 Al2O3 CaO MgO C S Na2O P / 5.23 5.66 21.95 0.99 4.06 0.75 0.022 / 表 2 低品位矿石镍化学物相

Table 2. Chemical phases of nickel in low grade ores

物相 氧化镍 硫化镍 其他镍 总镍 含量/% 0.001 0.79 0.034 0.825 占有率/% 0.12 95.76 4.12 100.00 表 3 低品位矿石铜化学物相

Table 3. Chemical phases of copper in low grade ores

物相 氧化铜 墨铜矿 硫化铜 其他铜 总铜 含量/% 0.001 0.027 0.593 0.011 0.632 占有率/% 0.16 4.27 93.83 1.74 100.00 表 4 高品位矿石多组分分析结果/%

Table 4. Multi component analysis results of high grade ore

Ni Cu Co Fe Mn Ti Cr SiO2 1.47 1.26 0.024 14.23 0.1 0.13 0.26 29.72 Al2O3 CaO MgO C S Na2O P / 3.00 2.81 25.78 0.93 5.48 0.16 0.047 / 表 5 高品位矿石镍化学物相

Table 5. Chemical phases of nickel in high grade ores

物相 氧化镍 硫化镍 其他镍 总镍 含量/% 0.003 1.46 0.016 1.479 占有率/% 0.20 98.72 1.08 100.00 表 6 高品位矿石铜化学物相

Table 6. Chemical phases of copper in high grade ores

物相 氧化铜 墨铜矿 硫化铜 其他铜 总铜 含量/% 0.003 0.17 1.09 0.002 1.265 占有率/% 0.24 13.44 86.17 0.16 100.00 表 7 工艺改造前生产指标

Table 7. Production index before process transformation

时间 高精 低精 尾矿 回收率/% 镍品位/% 铜品位/% 氧化镁/% 镍品位/% 铜品位/% 镍品位/% 铜品位/% 镍 铜 二月 7.11 5.78 7.64 3.92 2.33 0.21 0.33 84.43 72.12 三月 6.56 4.99 9.93 4.32 3.28 0.19 0.28 85.7 75.3 四月 6.35 5.49 9.3 4.18 2.06 0.19 0.25 86.11 79.18 五月 7.66 6.09 7.7 5.21 2.17 0.2 0.34 83.83 68.55 表 8 一段二次精选作业分析结果

Table 8. Analysis results of secondary cleaning operation in Section one

采样点 第一次指标分析/% 第二次指标分析/% 第三次指标分析/% Ni Cu MgO Ni Cu MgO Ni Cu MgO 一段二精1 9.91 8.32 4.97 9.43 7.65 3.84 10.16 9.66 3.39 一段二精2 8.23 5.25 8.59 9.95 6.46 4.87 10.28 8.24 3.7 一段二精3 7.59 2.77 9.36 9.53 5.15 6.45 11.03 6.92 4.03 一段二精4 6.07 1.72 12.3 8.62 4.14 7.94 11.23 6.19 4.27 一段二精5 4.75 1.29 13.42 5.9 2.29 9.91 9.21 2.83 6.52 一段二精6 3.88 1.06 13.54 4.32 1.84 15.9 7.64 2 7.3 一段二精7 3.6 1.06 14.19 2.29 1.3 20.22 5.41 1.34 9.4 表 9 二段精选作业分析结果

Table 9. Analysis results of second stage cleaning operation

采样点 第一次指标分析/% 第二次指标分析/% 第三次指标分析/% Ni Cu Ni Cu Ni Cu 二段二精1 4.33 2.62 2.26 1.52 7.47 3.11 二段二精2 3.11 1.98 2.04 1.39 4.35 1.76 二段二精3 2.75 1.8 2.14 1.45 3.32 1.2 二段二精4 2.95 1.85 1.71 1.25 2.45 0.97 二段二精5 3.17 2.02 1.67 1.25 2.45 0.93 二段三精1 2.72 1.68 4.8 2.5 6.12 2.46 二段三精2 2.39 1.55 2.98 1.72 4.59 1.75 二段三精3 1.8 1.34 2.2 1.45 3.76 1.4 低精 6.8 3.79 3.47 2.05 5.2 1.42 表 10 工艺改造后生产指标

Table 10. Production index after process transformation

时间 高精 低精 尾矿 回收率/% 镍品位/% 铜品位/% 氧化镁/% 镍品位/% 铜品位/% 镍品位/% 铜品位/% 镍 铜 六月 7.99 7.04 6.57 4.46 3.06 0.17 0.28 88.28 79.49 七月 7.18 6.49 6.75 5.43 2.43 0.18 0.26 87.01 78.38 -

[1] 殷仁述, 杨沿平, 谢林明, 等. 新能源汽车动力电池对有色金属资源需求预测[J]. 资源与产业, 2016, 18(5):85-91.

YIN R S, YANG Y P, XIE L M, et al. New energy vehicle power battery demand forecast for non-ferrous metal resources[J]. Resources and Industry, 2016, 18(5):85-91.

[2] 邹邦坤, 丁楚雄, 陈春华. 锂离子电池三元正极材料的研究进展[J]. 中国科学:化学, 2014, 44(7):1104-1115.

ZOU B K, DING C X, CHEN C H. Research progress of ternary cathode materials for lithium-ion batteries[J]. Science in China:Chemistry, 2014, 44(7):1104-1115.

[3] 谢杰, 胡春梅. 国内外硫化铜镍矿选矿现状及未来发展方向[J]. 矿产保护与利用, 2018(5):149-156.

XIE J, HU C M. Current status and future development direction of copper-nickel sulfide ore beneficiation at home and abroad[J]. Conservation and Utilization of Mineral Resources, 2018(5):149-156.

[4] 刘钊, 张明, 刘洋, 等. φ5.5 m×8.5 m大型溢流球磨机衬板结构优化研究[J]. 矿山机械, 2020(8):71-73.

LIU Z, ZHANG M, LIU Y, et al. Research on the optimization of the liner structure of the φ5.5m×8.5m large overflow ball mill[J]. Mining Machinery, 2020(8):71-73.

[5] 杨文彪, 张永梅. 粗精再磨工艺在某高铜镍比矿石选矿中的研究及应用[J]. 矿产综合利用, 2020(3):121-125. doi: 10.3969/j.issn.1000-6532.2020.03.020

YANG W B, ZHANG Y M. Research and application of rough concentrate and regrinding technology in beneficiation of a high copper nickel ratio ore[J]. Multipurpose Utilization of Mineral Resources, 2020(3):121-125. doi: 10.3969/j.issn.1000-6532.2020.03.020

[6] 陈伟, 吴越. 六偏磷酸钠对低品位硫化铜镍矿浮选降镁的影响[J]. 矿冶, 2020, 29(2):34-37. doi: 10.3969/j.issn.1005-7854.2020.02.007

CHEN W, WU Y. Effect of sodium hexametaphosphate on magnesium reduction by flotation of low-grade copper-nickel sulfide ore[J]. Mining and Metallurgy, 2020, 29(2):34-37. doi: 10.3969/j.issn.1005-7854.2020.02.007

[7] 刘广龙. 金川硫化镍铜贫矿石选矿工艺研究[J]. 铜业工程, 2011(4):1-11. doi: 10.3969/j.issn.1009-3842.2011.04.001

LIU G L. Study on the beneficiation process of Jinchuan nickel-copper sulfide lean ore[J]. Copper Industry Engineering, 2011(4):1-11. doi: 10.3969/j.issn.1009-3842.2011.04.001

-

下载:

下载: