Application Research on Replacing Steel balls with Ceramic Balls under the "Double Carbon Target"

-

摘要:

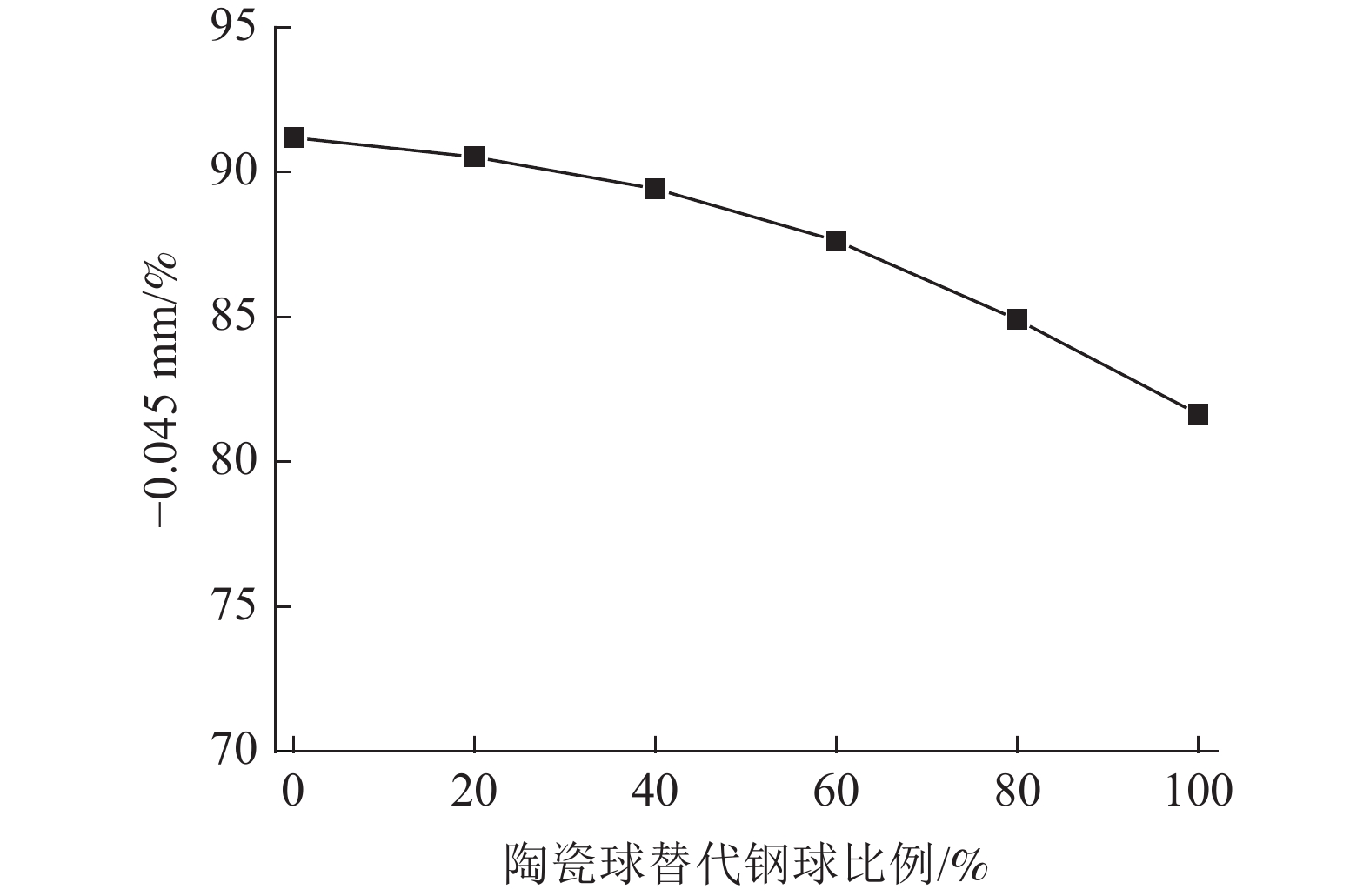

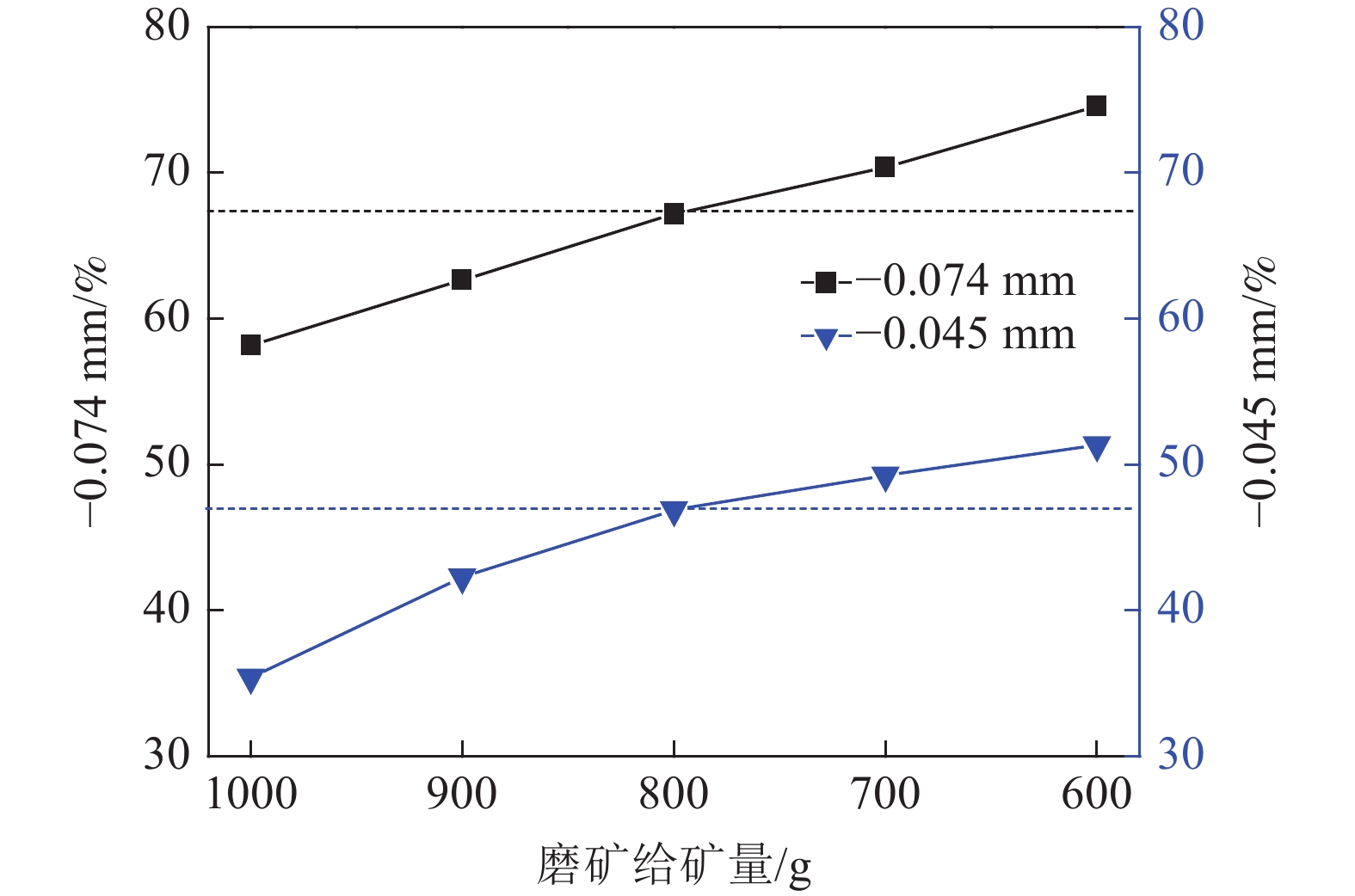

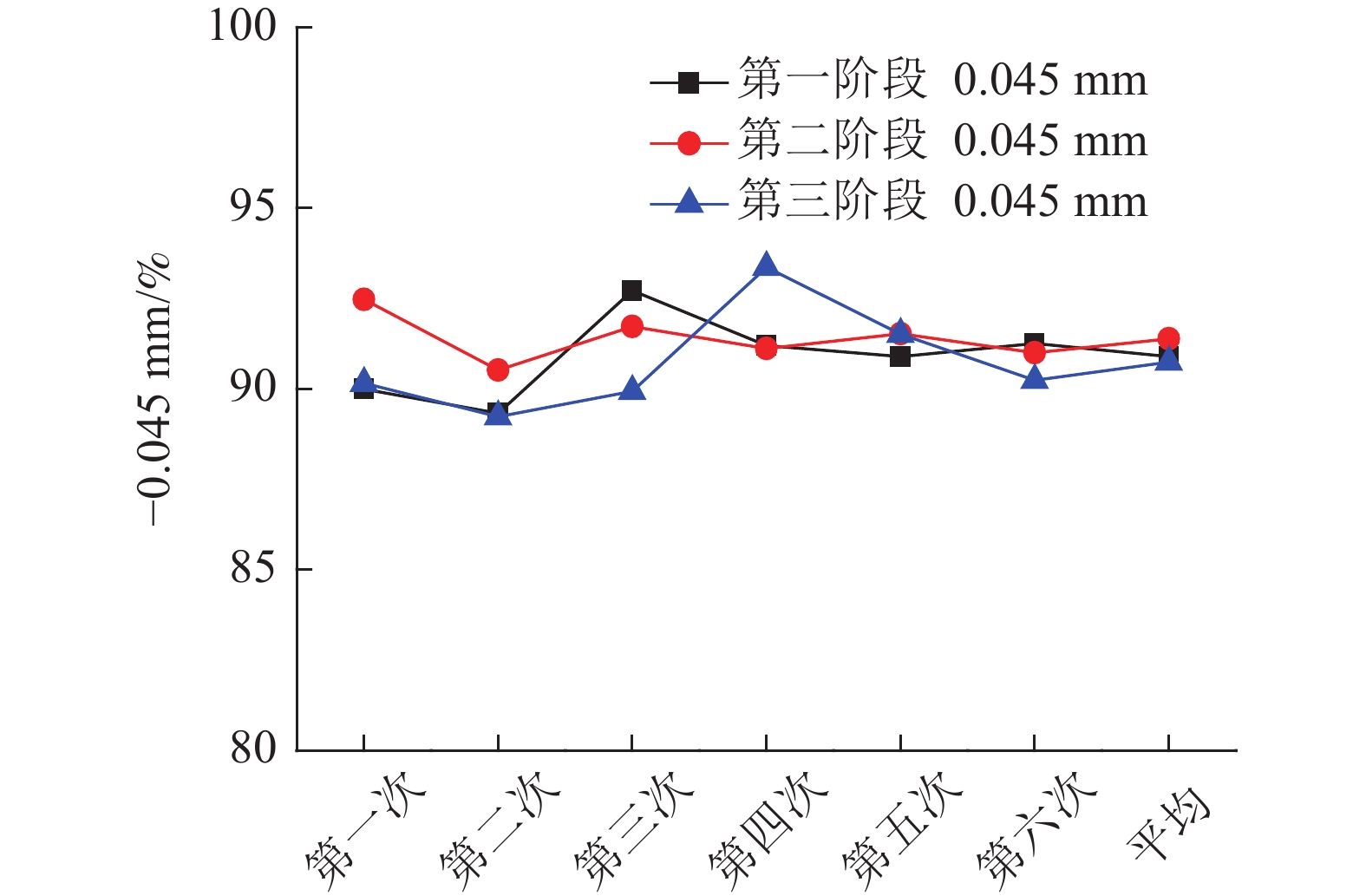

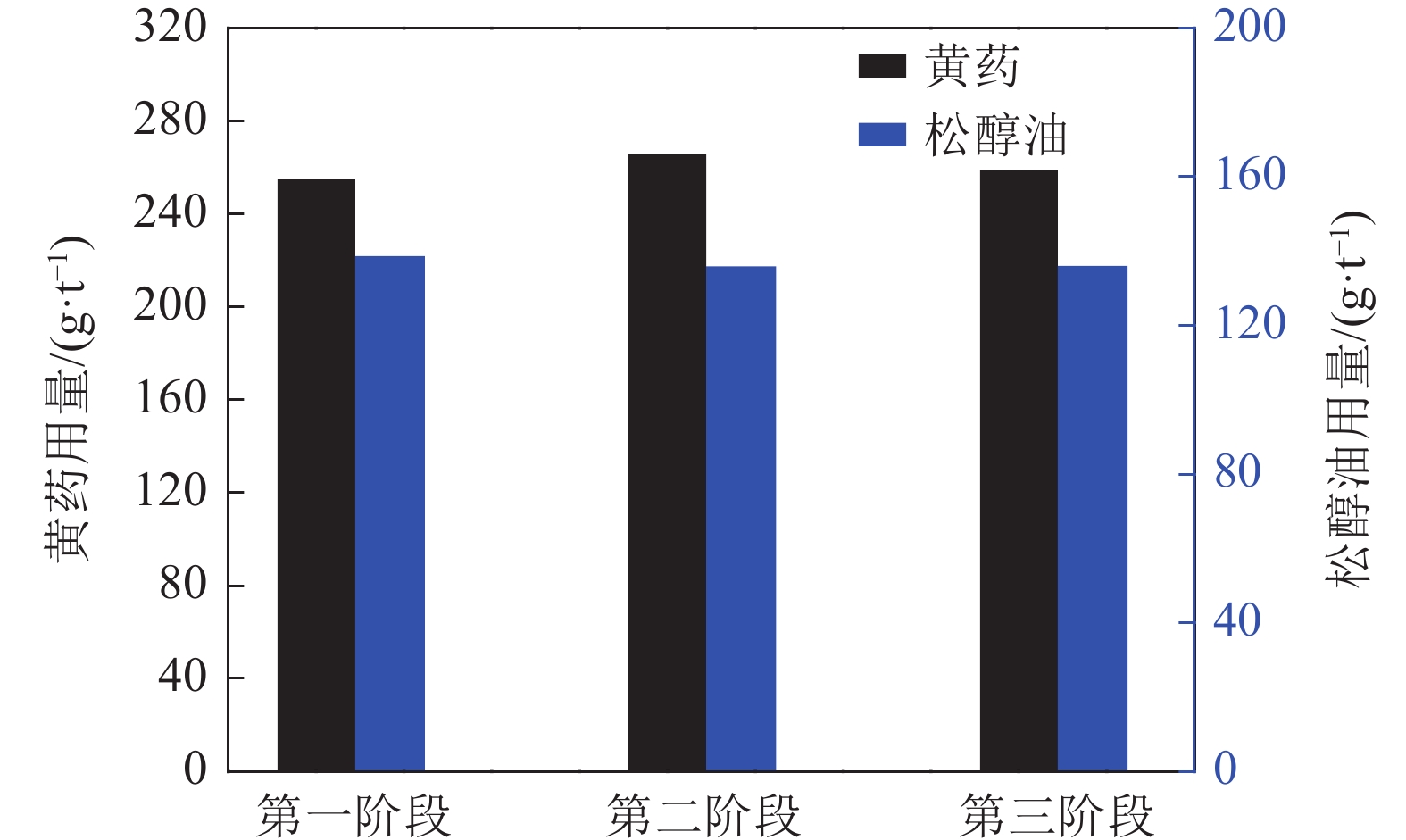

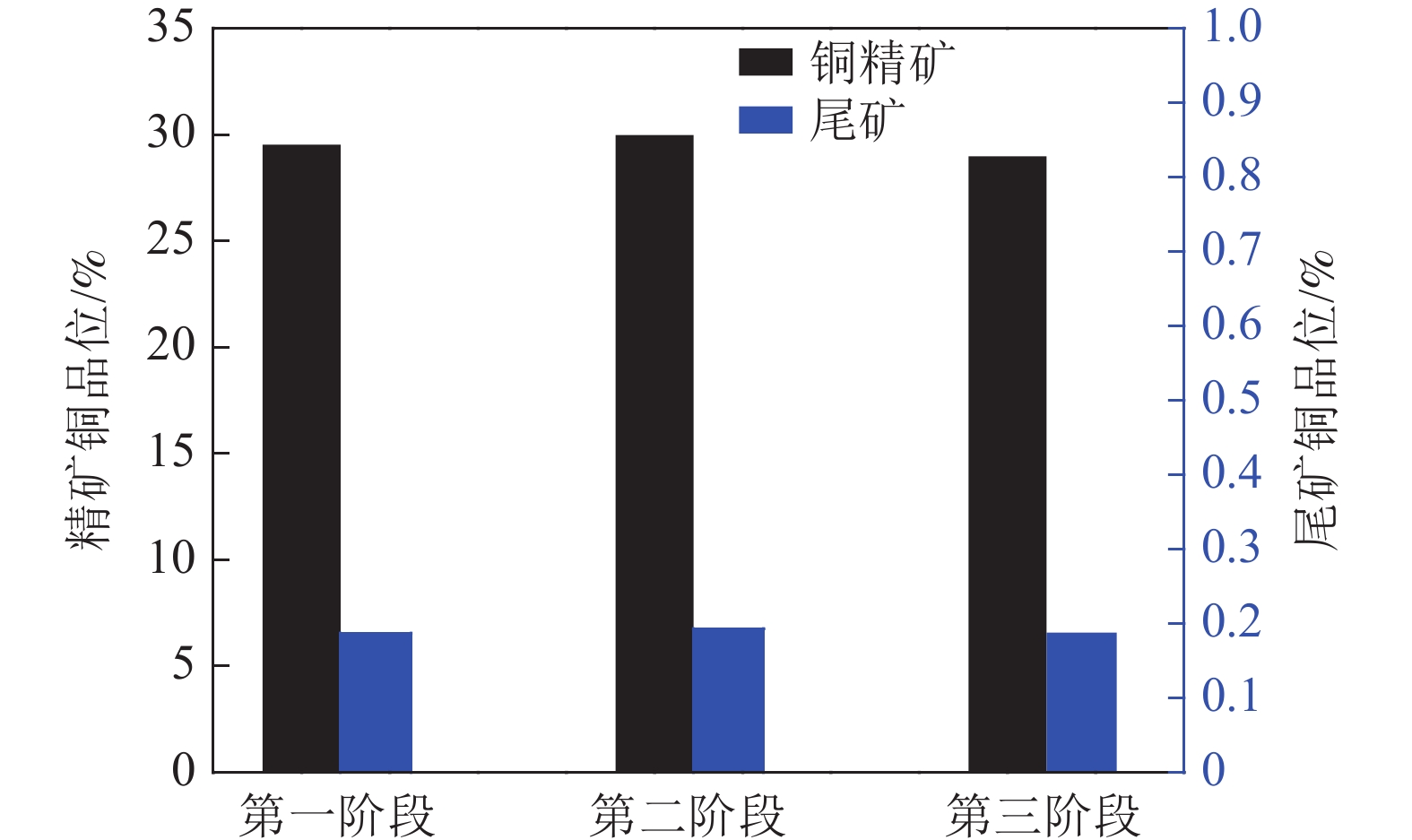

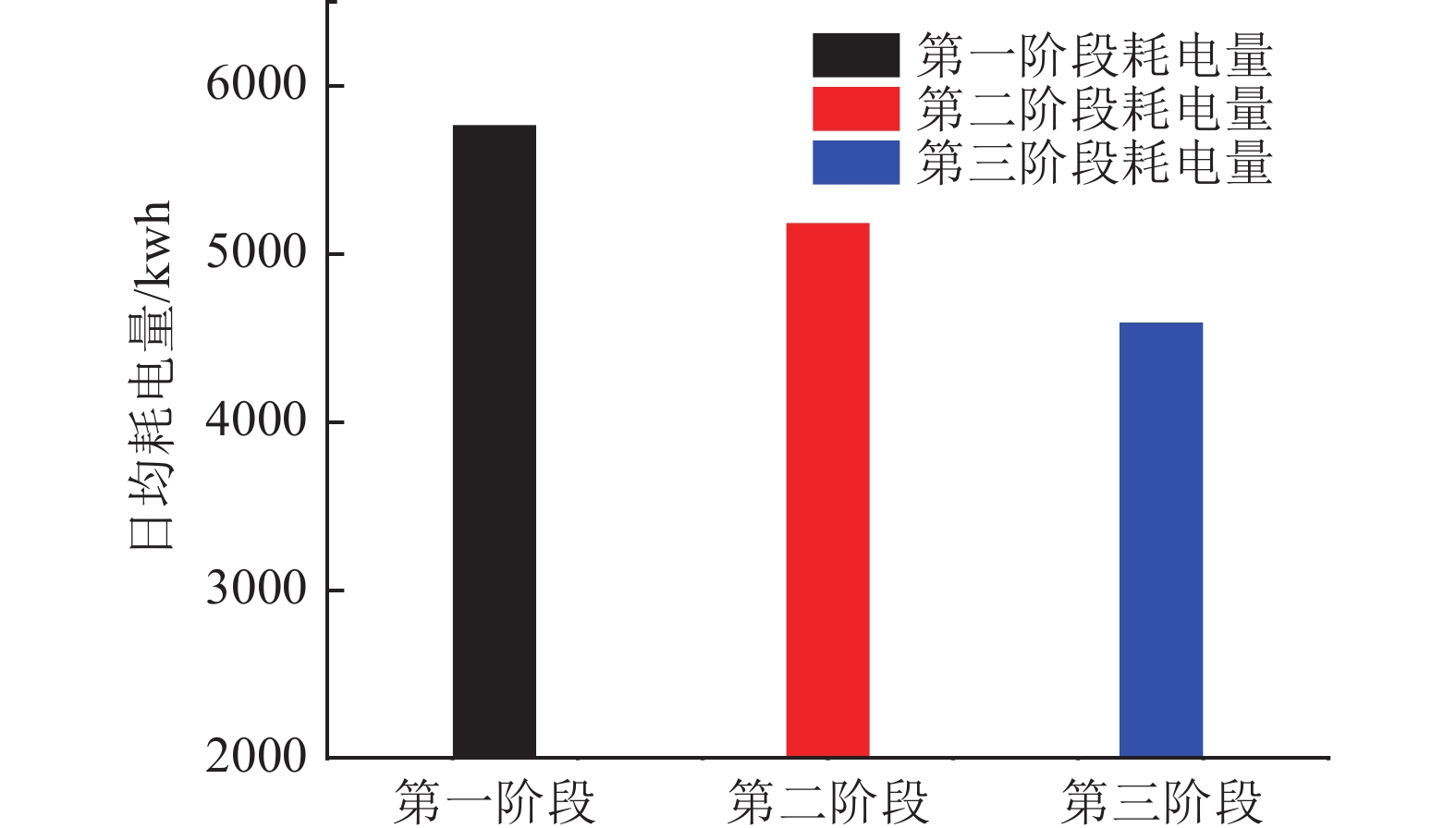

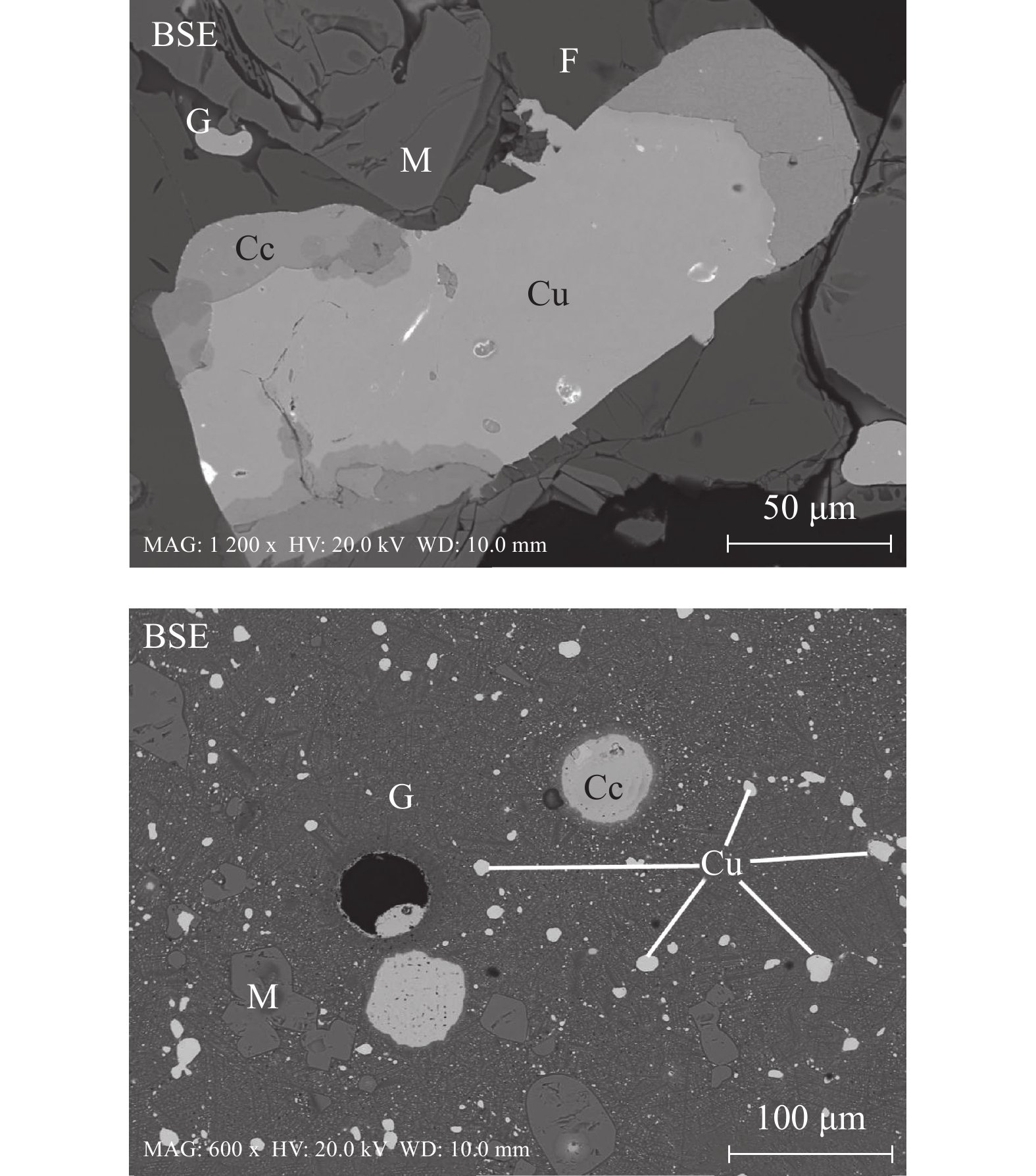

针对大冶诺兰达转炉渣磨矿过程,研究了陶瓷球替换钢球对磨矿效率、能耗、物耗及分选指标等的影响。实验室实验研究表明,一段二段磨矿过程中,磨矿效率随着陶瓷球替代比例增加而降低;但陶瓷球体积比例控制在40%以内时,对磨矿效率影响较小。而采用全陶瓷球磨矿,给矿量降低到全钢球的80%,可实现与全钢球时等同的磨矿效率。工业实验研究表明,当立磨机中陶瓷球比例14%为38%时,基本不影响磨矿效率、药剂消耗及铜精矿指标,但对磨矿过程中的能耗分别降低为全钢球的89.90%和79.60%,减少了磨矿过程中介质的消耗,研究结果为转炉渣选矿厂生产过程中节能降耗提供了新思路。

Abstract:In this paper, the effect of ceramic ball replacing steel ball on grinding efficiency, energy consumption, material consumption and separation index was studied for the grinding process of Daye Noranda converter slag. The laboratory studies presented that the grinding efficiency decreases with the increases of ceramic ball replacement ratio in the process of primary and secondary grinding, however, However, the grinding efficiency was hardly influenced when the ceramic ball volume proportion is controlled within 40%, and the ore feed need to be reduced to 80% of the whole steel ball which can achieve the same grinding efficiency as the whole steel ball in the case of all-ceramic ball grinding. The industrial test results showed that grinding efficiency, reagent consumption and copper concentrate index are not affected when the proportion of ceramic balls in vertical mill is 14% to 38%, but the energy consumption is reduced to 89.90% and 79.60% respectively of the whole steel ball during grinding, and the loss of grinding medium is reduced in this process. This The research results provide a new idea for energy saving and consumption reduction in the production process of converter slag concentrator.

-

Key words:

- Ceramic ball /

- Converter slag /

- Grinding efficiency /

- Energy Conservation

-

-

表 1 试样化学多元素分析结果 /%

Table 1. Results of multielement chemical analysis of sample

Cu Au* Ag* Pb Zn Mo Fe 4.29 0.55 31.72 2.29 5.53 0.055 42.05 SiO2 TiO2 Al2O3 CaO MgO MnO Na2O 24.54 0.085 1.22 0.66 0.81 0.13 0.11 K2O As Sb S P C 烧失 0.25 0.0094 0.032 0.54 0.014 0.048 4.26 *单位为g/t。 表 2 不同磨矿细度铜矿物的解离度

Table 2. Dissociation degree of copper minerals under different grinding fineness

磨矿细度 单 体/% 连生体/% >3/4 3/4~1/2 1/2~1/4 <1/4 -0.074 mm 90% 61.09 10.46 5.63 6.23 16.59 -0.045 mm 65% 65.42 17.14 4.24 4.07 9.13 -0.045 mm 85% 68.01 20.33 4.59 1.95 5.12 -0.045 mm 90% 75.01 13.84 5.74 2.27 3.14 -

[1] 张建文, 马崇振, 梁汉, 等. 磨矿细度对湖南某方解石矿加工技术性能的影响研究[J]. 矿产综合利用, 2021(6):81-84. doi: 10.3969/j.issn.1000-6532.2021.06.014

ZHANG J W, MA C Z, LIANG H, et al. Research on the effect of grinding fineness on the processing technology performance of a calcite mine in Hunan[J]. Multipurpose Utilization of Mineral Resources, 2021(6):81-84. doi: 10.3969/j.issn.1000-6532.2021.06.014

[2] 孙文瀚. 基于JKSimMet模拟的某选矿厂矿石碎磨特性及流程优化研究[D]. 南宁: 广西大学, 2019.

SUN W H. Research on ore grinding characteristics and process optimization of a concentrator based on JKSimMet simulation [D]. Nanning: Guangxi University, 2019.

[3] 钟晋, 郭永杰, 杜令攀, 等. 球磨机磨矿介质优化实验研究[J]. 化工矿物与加工, 2016, 45(5):28-30.

ZHONG J, GUO Y J, DU L P, et al. Experimental research on optimization of grinding medium of mill[J]. Chemical Minerals and Processing, 2016, 45(5):28-30.

[4] 杨俊龙, 郭艳华, 郭海宁. 冶炼废弃渣综合回收金银新工艺实验研究[J]. 矿产综合利用, 2021(5):172-176. doi: 10.3969/j.issn.1000-6532.2021.05.028

YANG J L, GUO Y H, GUO H N. Experimental study on a new technology for comprehensive recovery of gold and silver from smelting waste residue[J]. Multipurpose Utilization of Mineral Resources, 2021(5):172-176. doi: 10.3969/j.issn.1000-6532.2021.05.028

[5] 任朋, 田应忠, 郭鑫. 河南某冶炼铜渣浮选回收铜的实验研究[J]. 矿产综合利用, 2021(6):155-157+154. doi: 10.3969/j.issn.1000-6532.2021.06.026

REN P, TIAN Y Z, GUO X. Experimental study on recovery of copper by flotation of copper slag in a south smelting[J]. Multipurpose Utilization of Mineral Resources, 2021(6):155-157+154. doi: 10.3969/j.issn.1000-6532.2021.06.026

[6] 左更. "双碳"要求下未来中国金属矿业行业产业布局猜想[J]. 冶金管理, 2021(22):24-29.

ZUO G. Conjecture on the future industrial layout of China's metal mining industry under the requirements of "double carbon"[J]. Metallurgical Management, 2021(22):24-29.

[7] 景宇, 徐国华. 球磨机陶瓷球与钢球混合替代研究及应用[J]. 铜业工程, 2021(3):32-35. doi: 10.3969/j.issn.1009-3842.2021.03.009

JING Y, XU G H. Research and application of mixing substitution of ceramic balls and steel balls in ball mills[J]. Copper Industry Engineering, 2021(3):32-35. doi: 10.3969/j.issn.1009-3842.2021.03.009

-

下载:

下载: