Experimental Research on Reprocessing Fluorite from High Mud Tailings

-

摘要:

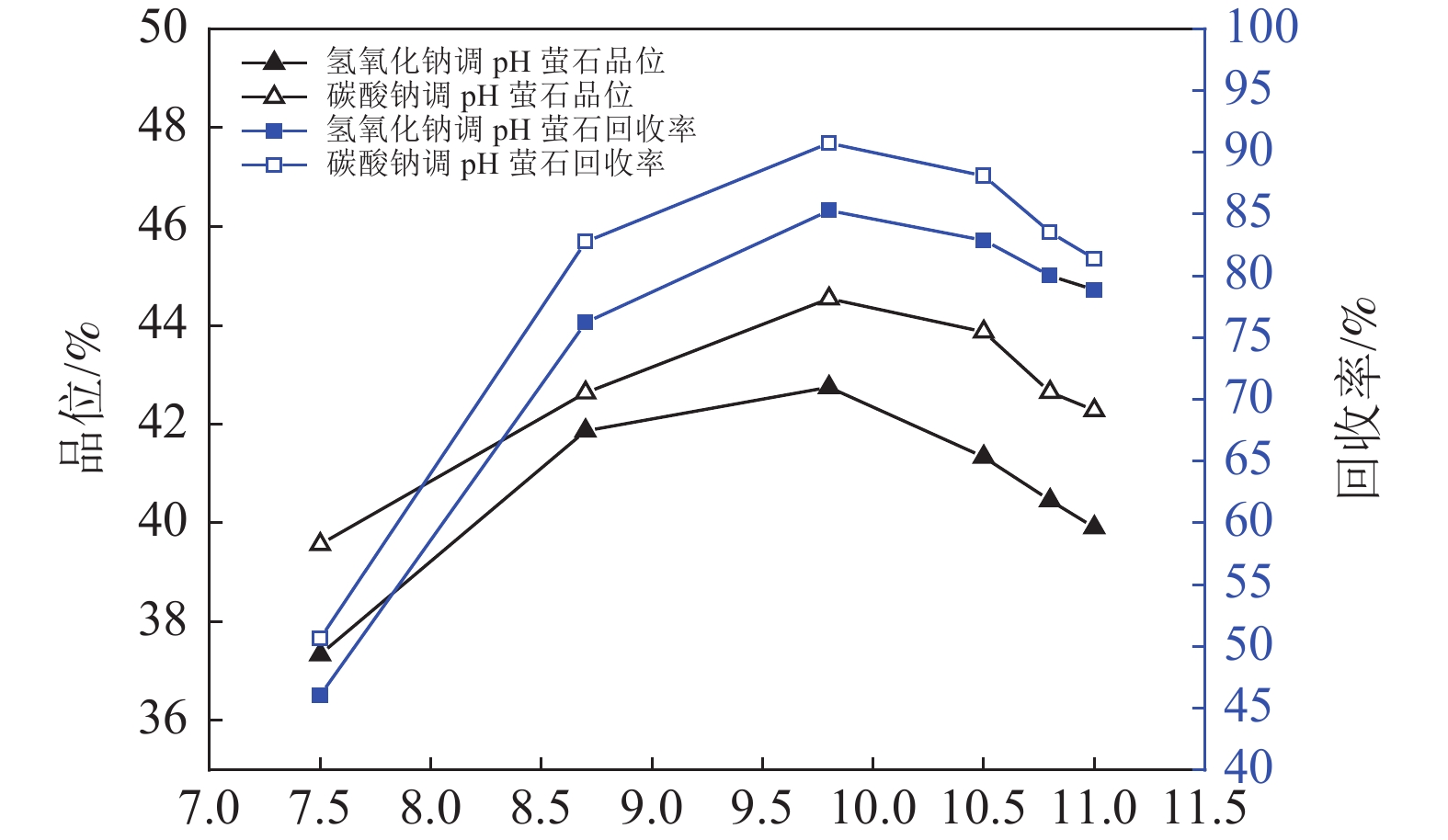

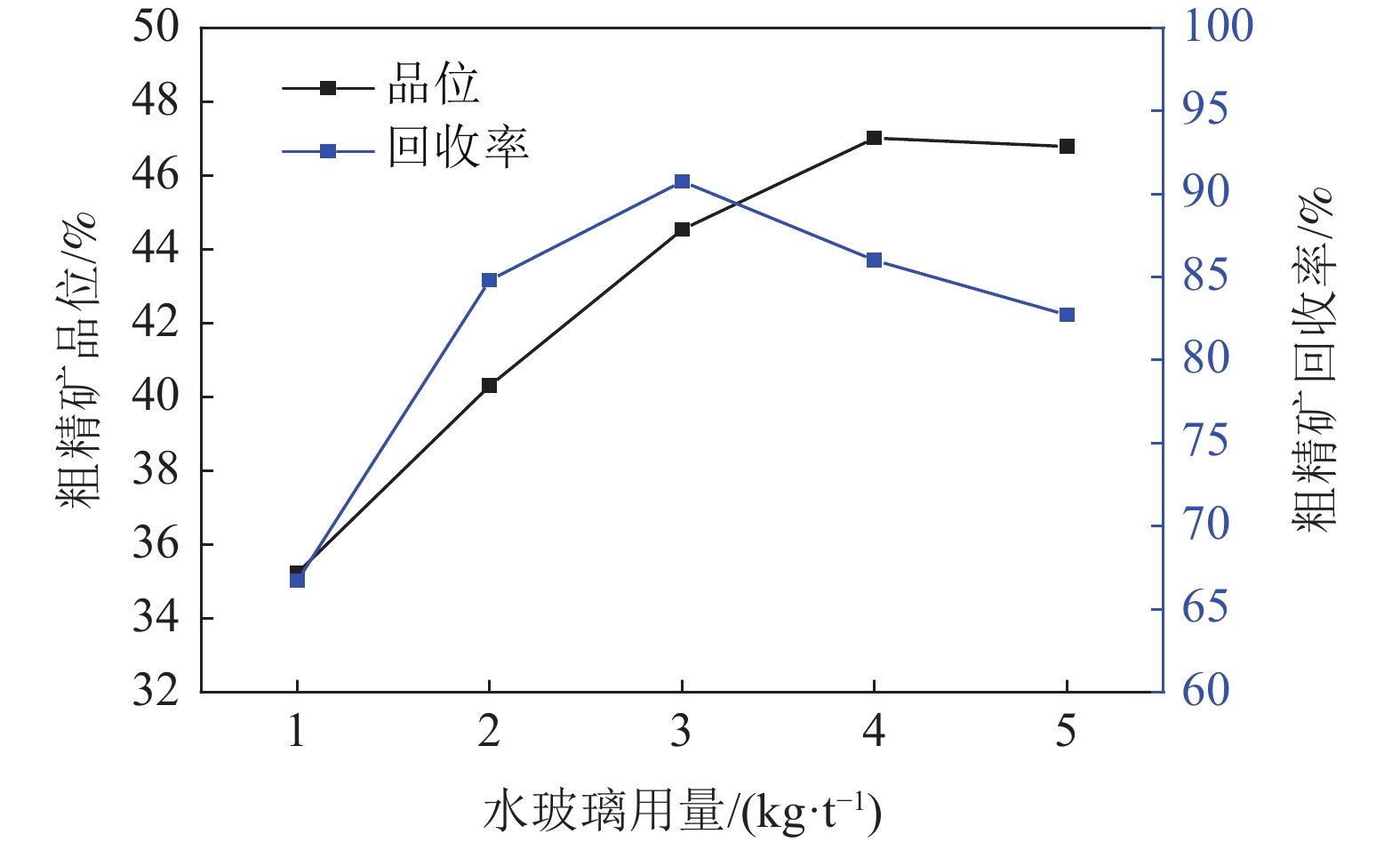

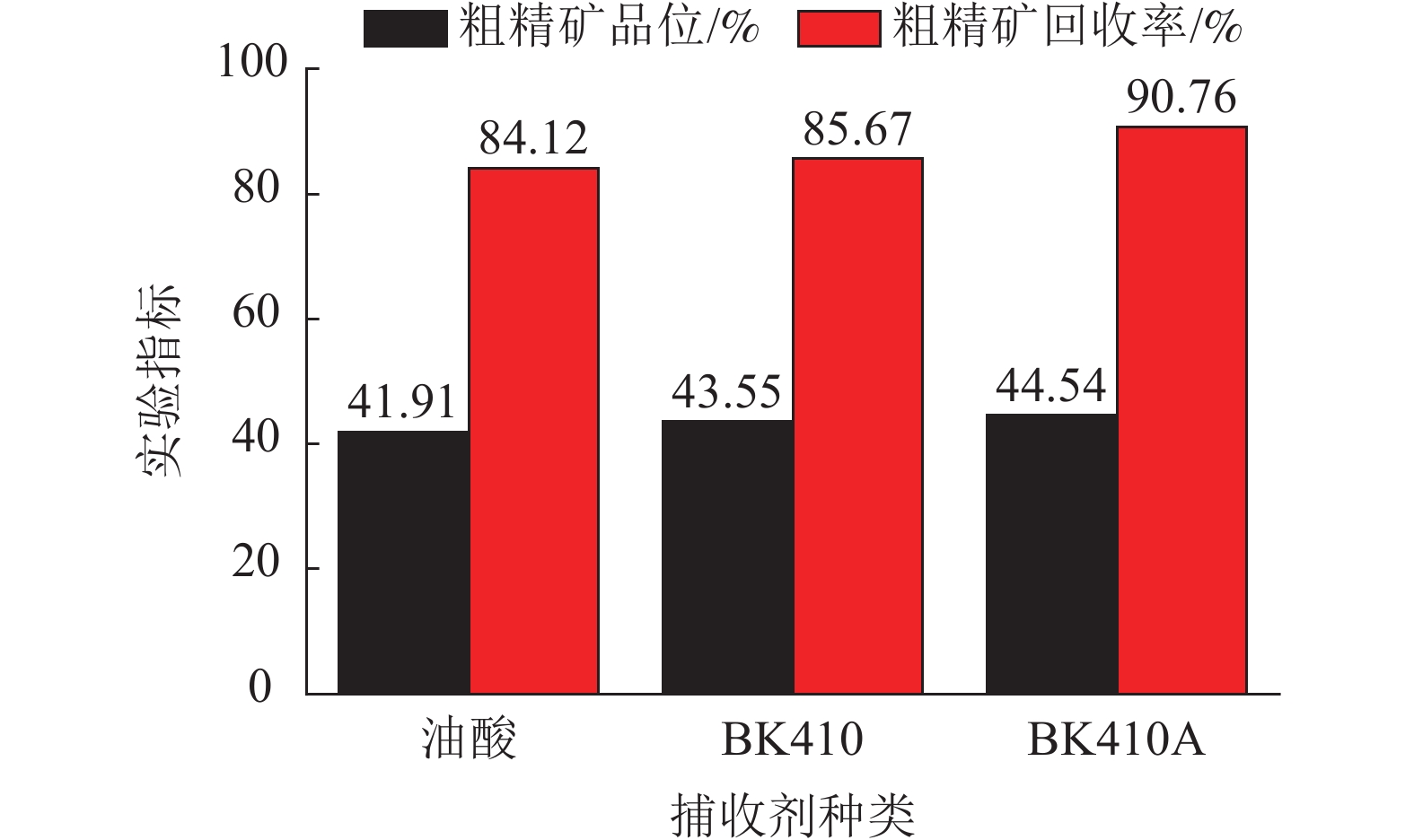

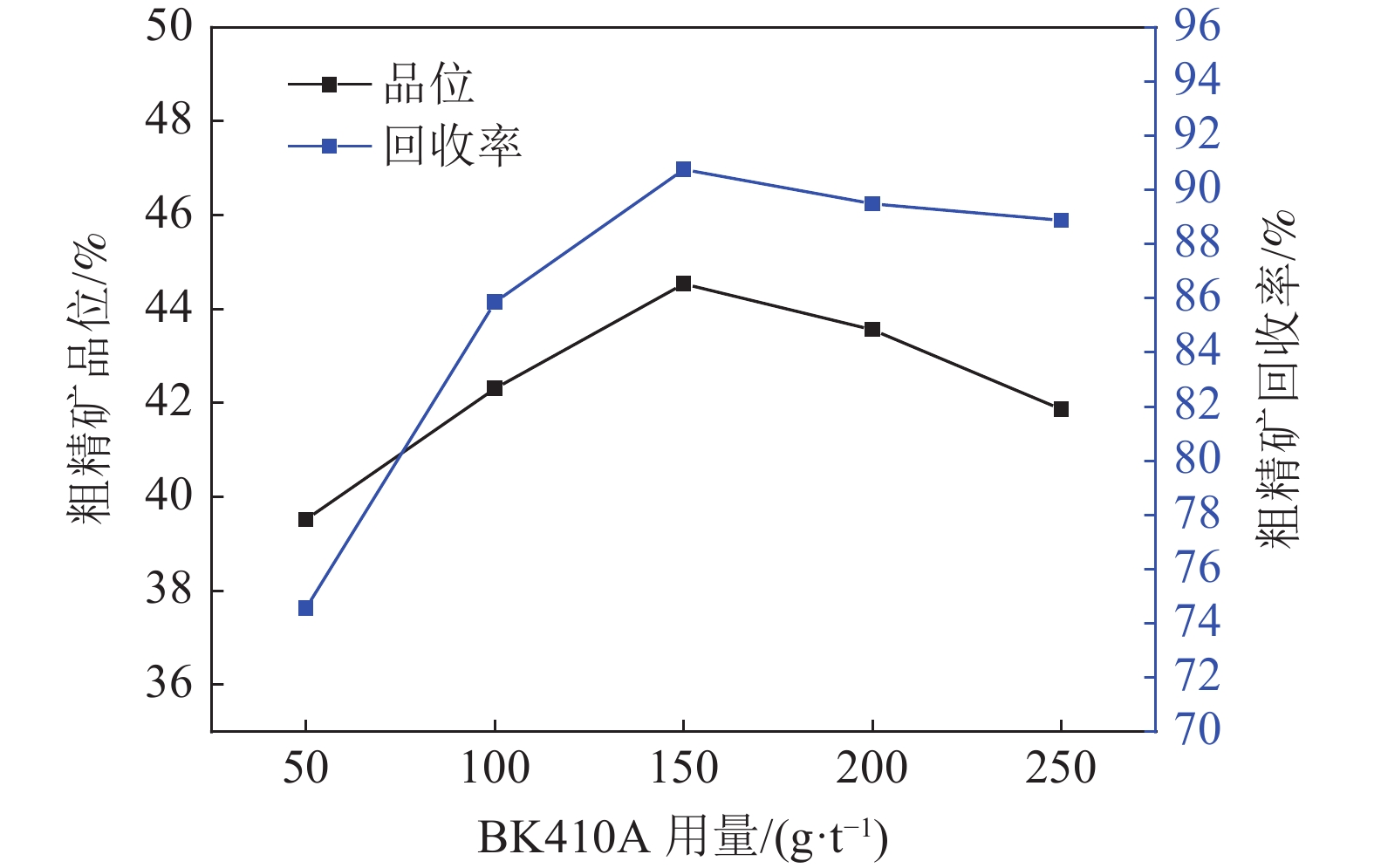

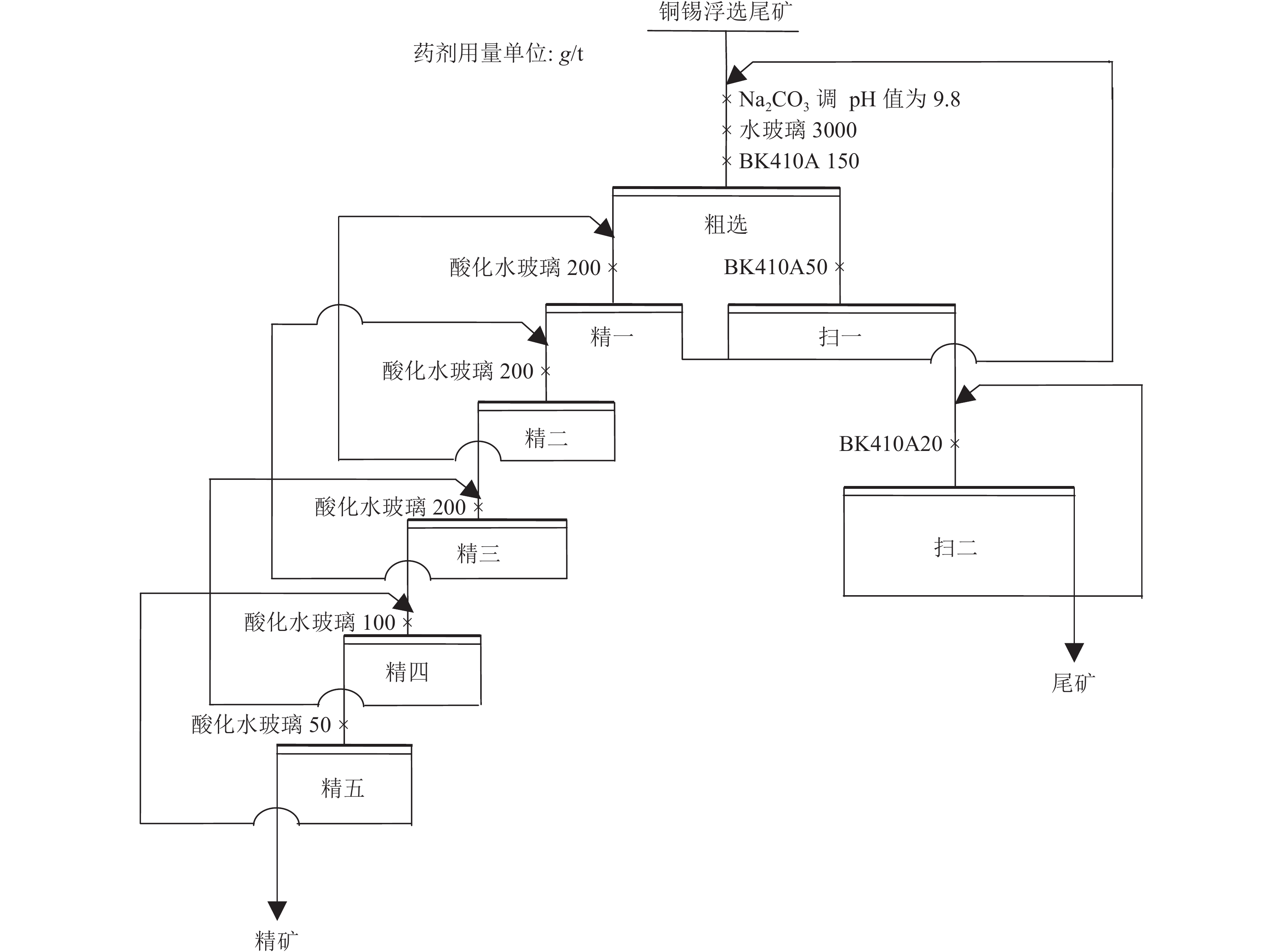

为提高某铜锡萤石矿资源利用率,对其浮铜—除硫—磁铁—选锡尾砂中的萤石资源进行再选。实验采用碳酸钠为pH值调整剂、水玻璃与酸化水玻璃为抑制剂、BK410A为捕收剂,经1粗5精2扫浮选闭路实验流程,最终得到萤石精矿中 CaF2品位90.51%、回收率66.13%。

Abstract:In order to improve the utilization rate of a copper-tin mine, The fluorite resources in floating copper-sulfur-removal-magnet-tin tailings were reselected.Sodium carbonate was used as pH agent, water glass and acidic water glass as inhibitors, BK410A as collector.a roughing test, two scavenging, five cleaning of flotation test process. Finally, the fluorite concentrate was obtained and the CaF2 grade and recovery was 90.51% and 66.13%.

-

-

表 1 矿样多元素分析结果 /%

Table 1. Multi-element analysis results of ore samples

CaF2 CaCO3 SiO2 Fe S Cu Sn WO3 Pb Zn 20.68 7.65 41.02 1.56 1.1 0.05 0.21 0.11 0.1 0.26 表 2 矿样筛析实验结果

Table 2. Screen analysis test results of ore samples

粒级/μm 产率/% CaF2品位/% CaF2分布率/% +74 6.61 14.71 4.70 -74+38 19.04 19.11 17.59 -38+10 44.34 21.27 45.61 -10 30.01 22.12 32.10 合计 100 20.68 100 表 3 闭路实验结果

Table 3. Closed-circuit test results

产品名称 CaF2产率/% CaF2品位/% CaF2回收率/% 铜锡浮选尾矿 100.00 20.68 100.00 萤石精矿 15.11 90.51 66.13 萤石尾矿 84.89 8.26 33.87 -

[1] 崔瑞, 王旭, 魏骞, 等. 湖北某重晶石-萤石型矿综合利用研究[J]. 矿产综合利用, 2019(2):70-74. doi: 10.3969/j.issn.1000-6532.2019.02.014

CUI R, WANG X, WEI Q, et al. Study on comprehensive utilization of a barite-fluorite ore in Hubei province[J]. Multipurpose Utilization of Mineral Resources, 2019(2):70-74. doi: 10.3969/j.issn.1000-6532.2019.02.014

[2] 艾光华, 梁焘茂, 袁勤智, 等. 某低品位方解石-石英型萤石浮选试验研究[J]. 非金属矿, 2018, 41(1):70-72. doi: 10.3969/j.issn.1000-8098.2018.01.021

AI G H, LIANG T M, YUAN Q Z, et al. Experimental study on flotation of a low-grade calcite and quartz fluorite[J]. Nonmetallic Ore, 2018, 41(1):70-72. doi: 10.3969/j.issn.1000-8098.2018.01.021

[3] 缪亚兵, 邓海波, 徐轲. 萤石在油酸和水玻璃体系中的浮选动力学模型及浮选行为研究[J]. 化工矿物与加工, 2015(7):13-17.

MIAO Y B, DENG H B, XU K. Flotation kinetics model and flotation behavior of fluorite in oleic acid and sodium silicate system[J]. Chemical Minerals and Processing, 2015(7):13-17.

[4] 凌石生, 王中明, 刘方, 等. 湖南某多金属矿尾矿萤石选矿新工艺研究[J]. 有色金属(选矿部分), 2018(6): 57-61.

LING S S, WANG Z M, LIU F, et al. Nonferrous Metals (Mineral Processing Section), 2018(6): 57-61.

[5] 冯胜雷. 湖南某白钨尾矿回收低品位萤石矿的试验研究[J]. 非金属矿, 2019, 42(4): 58-60.

FENG S L. Experimental study on recovery of low grade fluorite ore from a scheelite tailings in Hunan [J]. Nonmetallic Minerals, 219, 42(4): 58-60.

[6] 孙伟, 宋韶博. 水玻璃及其在白钨矿浮选中的应用和分析[J]. 中国钨业, 2013, 28(4):22-25. doi: 10.3969/j.issn.1009-0622.2013.04.006

SUN W, SONG S B. Silicate glass and its application and analysis in scheelite flotation[J]. China Tungsten Industry, 2013, 28(4):22-25. doi: 10.3969/j.issn.1009-0622.2013.04.006

[7] 张行荣, 朴永超, 尚衍波, 等. 一种耐低温型捕收剂在萤石浮选中的应用[J]. 矿产综合利用, 2015(3):28-31. doi: 10.3969/j.issn.1000-6532.2015.03.007

ZHANG X R, PIAO Y C, SHANG Y B, et al. Application of a low temperature resistant collector in fluorite flotation[J]. Multipurpose Utilization of Mineral Resources, 2015(3):28-31. doi: 10.3969/j.issn.1000-6532.2015.03.007

[8] 王长涛, 刘润清, 林上勇, 等. 湖南某萤石矿洗矿泥选矿工艺研究[J]. 矿冶工程2019, 39(4): 43-46.

WANG C T, LIU R Q, LIN S Y, et al. Study on beneficiation process of fluorite washing slime in Hunan [J]. Mining and Metallurgical Engineering, 219, 39(4): 43-46.

-

下载:

下载: