Effect of Diatomite on Properties of Cement- Copper Tailing Powder Cementitious Materials

-

摘要:

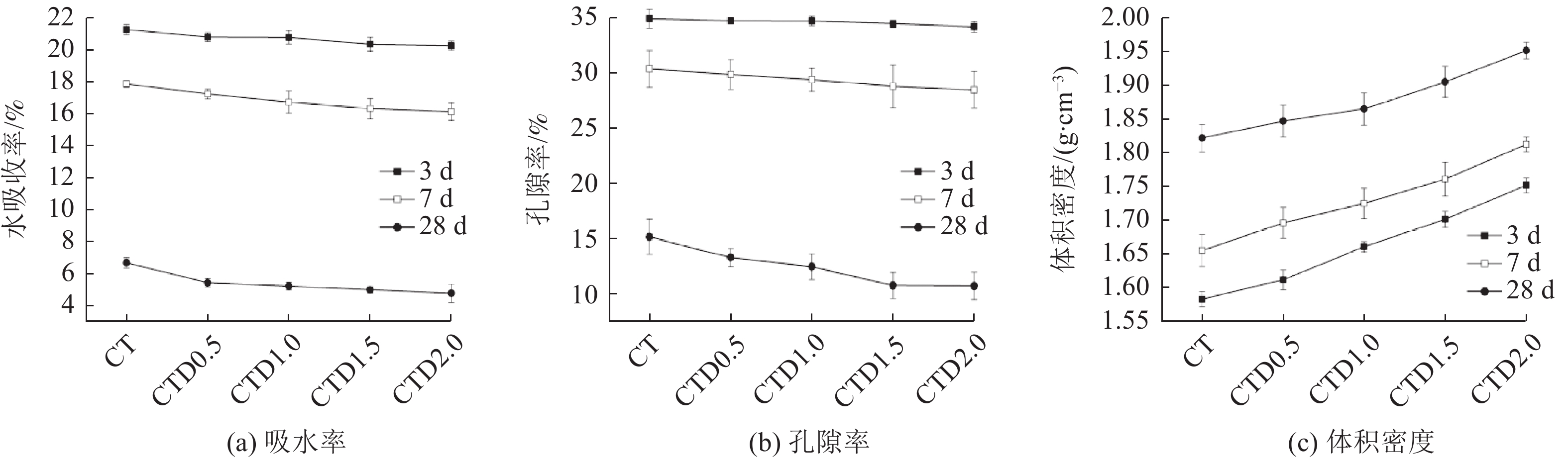

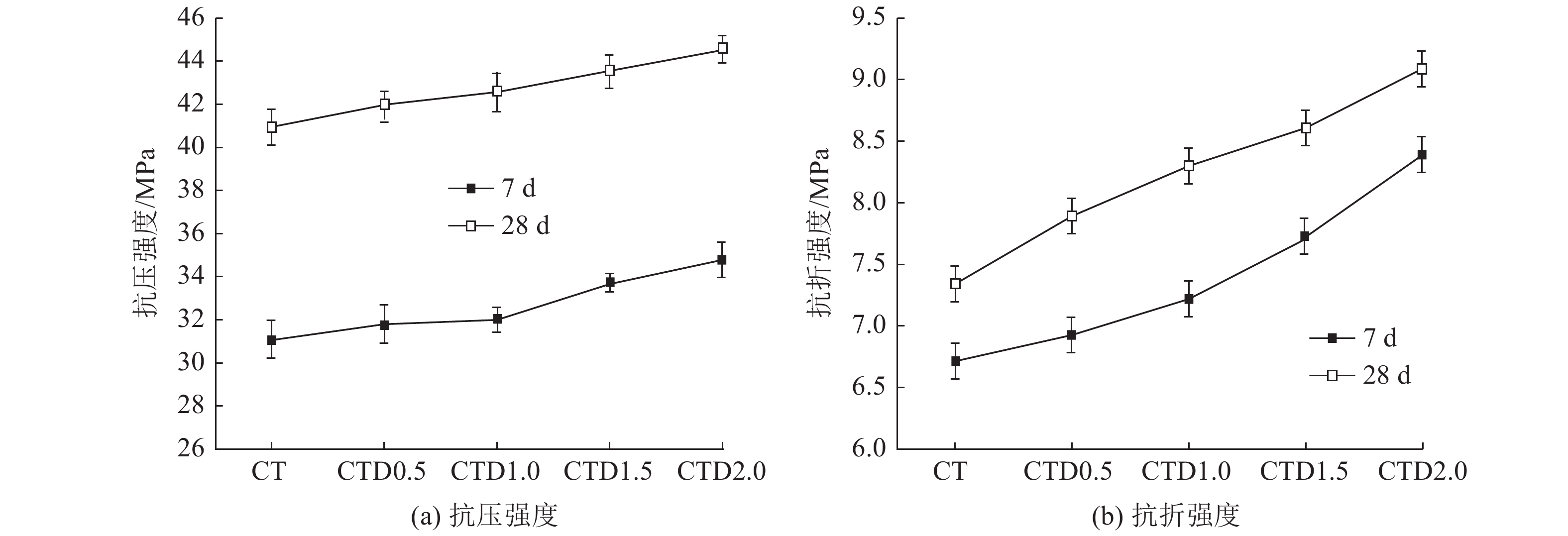

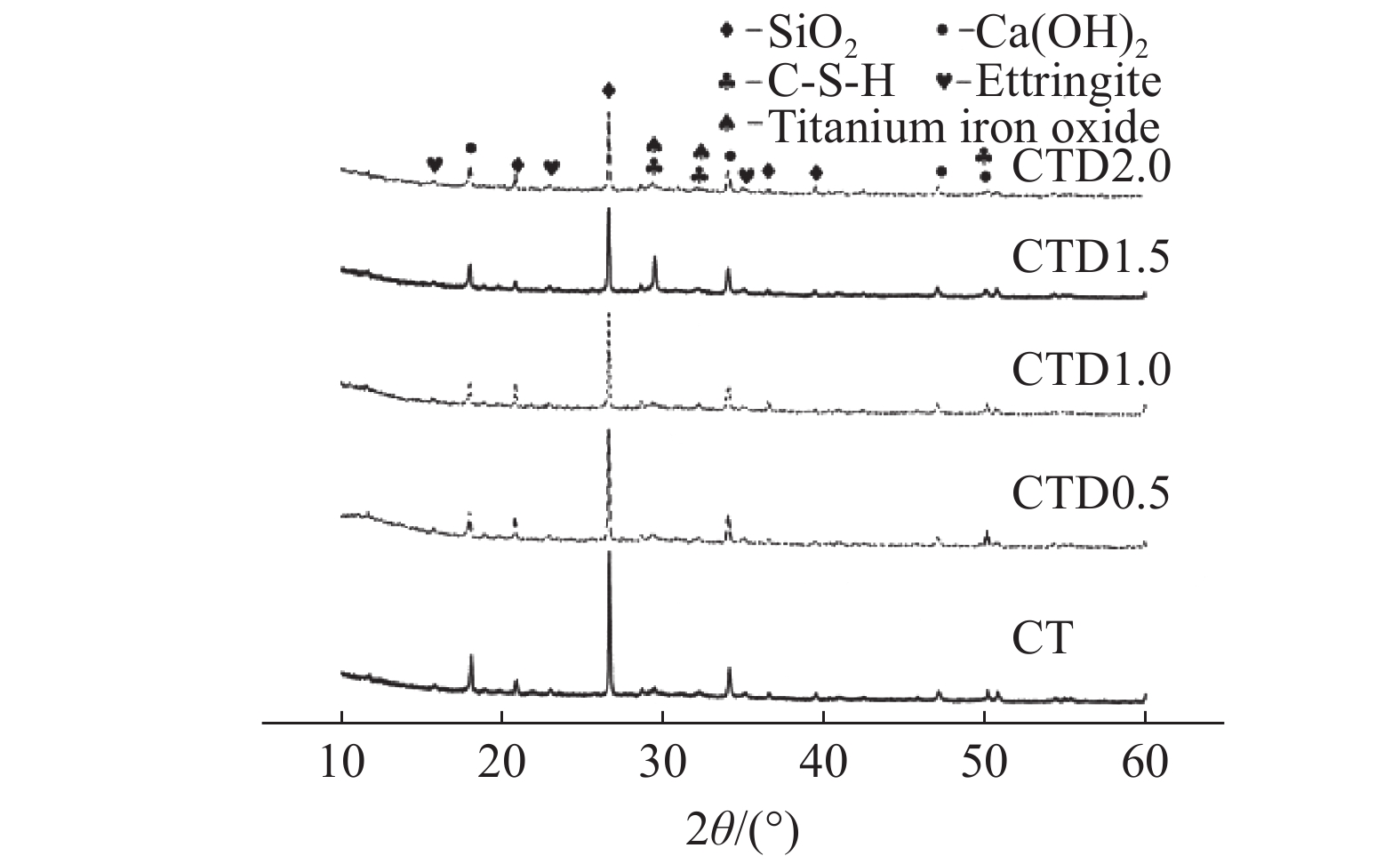

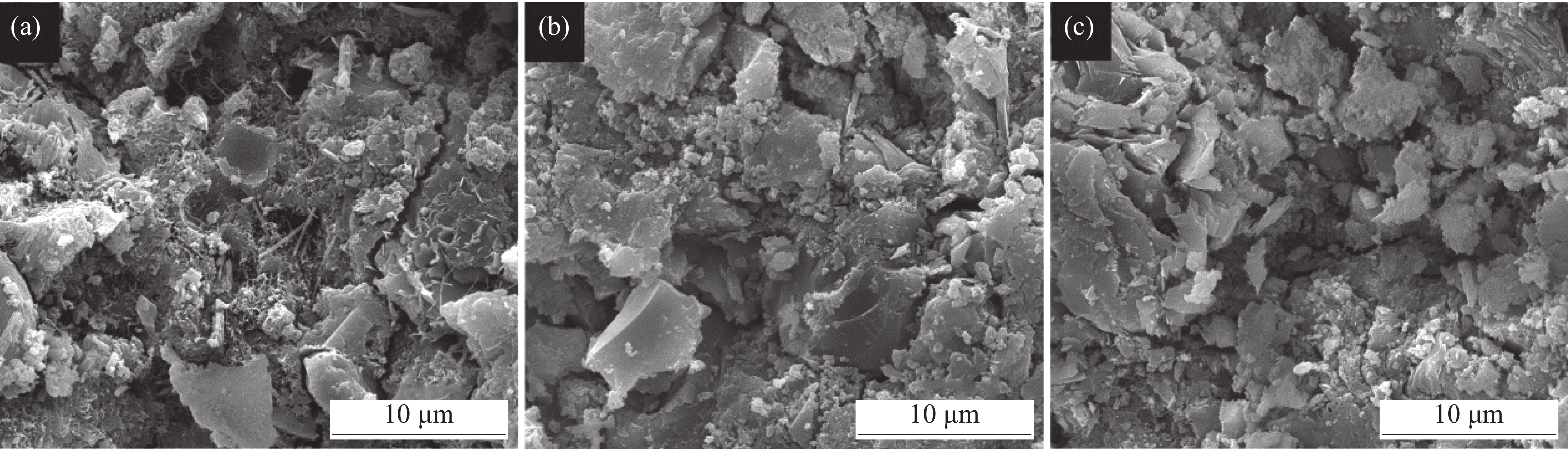

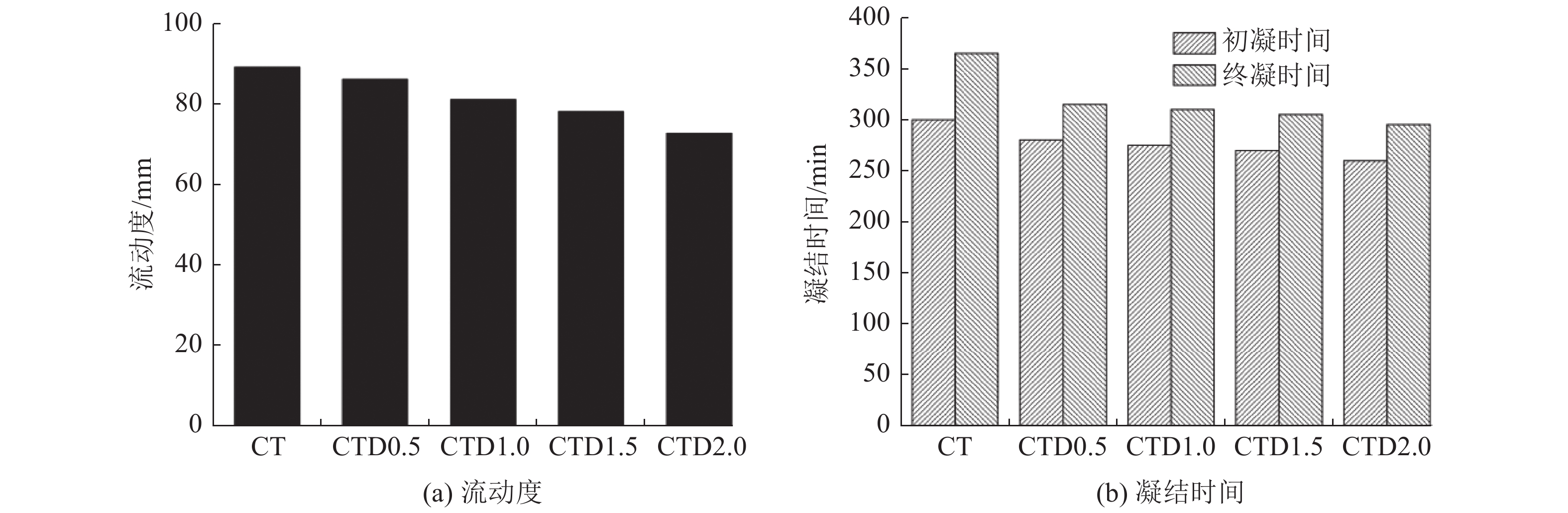

针对铜尾矿粉-硅酸盐水泥力学强度差的问题,本文拟将硅藻土加入到该胶凝体系中,硅藻土以0.5%,1.0%,1.5%和2.0%等质量替代铜尾矿粉-水泥,测试了复合胶凝材料的流动度、凝结时间、吸水率、孔隙率、体积密度、力学性能和微观性能。结果表明,随着硅藻土掺量的增加,净浆的流动度降低,凝结时间缩短,吸水率和孔隙率减小,体积密度增大,砂浆的抗压强度和抗折强度增加。净浆养护28 d后,硅藻土的加入使得净浆中的SiO2和Ca(OH)2晶体含量减少,C-S-H(水化硅酸钙)凝胶增多,整体比较致密。

Abstract:To overcome the poor mechanical strength of copper tailing powders- Portland cement, diatomite was added into this cementitious system.Diatomite replaced the copper tailing powders- Portland cement with 0.5%, 1.0%, 1.5% and 2.0% in weight.The fluidity, setting time, water absorption, porosity, bulk density, mechanical properties and microscopic properties of the composite cement materials were tested. The results showed that with the increase of the dosage of diatomite, the fluidities of the pastes decrease, the setting time shortens, water absorptions and porosities decrease, bulk densities increase, compressive strength and flexural strength of the mortars increase. After curing for 28 days, the addition of diatomite makes the SiO2 and Ca(OH)2 content in the hydration products decrease, the C-S-H (Calcium Silicate Hydrate) gels increase, and the whole is denser.

-

Key words:

- Diatomite /

- Copper tailing powder /

- Portland cement /

- Cementitious material /

- Mechanical strength

-

-

表 1 水泥、铜尾矿和硅藻土的化学组成/%

Table 1. Chemical composition of cement, copper tailing powder and diatomite

名称 SiO2 CaO Al2O3 Fe2O3 SO3 MgO P2O5 Na2O K2O LOI 水泥 20.87 62.66 4.14 5.12 2.32 4.08 0.08 0.11 0.28 0.34 铜尾矿 3.56 63.84 19.65 2.37 0.36 3.16 0.15 0.30 4.67 1.94 硅藻土 78.24 1.06 0.55 1.12 0.98 0.87 0.25 0.89 0.75 15.29 表 2 硅藻土-铜尾矿粉-水泥净浆的组成设计

Table 2. Composition design of diatomite- copper tailing powder- cement pastes

样品 水泥/g 铜尾矿粉/g 硅藻土/g 自来水/g CT 840 360 - 420 CTD0.5 835.8 358.2 6 420 CTD1.0 831.6 356.4 12 420 CTD1.5 827.4 354.6 18 420 CTD2.0 823.2 352.8 24 420 -

[1] 刘振宇. 硅藻土-钢渣基复合胶凝材料的制备及机理研究[D]. 邯郸: 河北工程大学, 2019.

LIU Z Y. Preparation and characterization of composite cementitious materials based on diatomite [D]. Handan: Hebei University of Engineering, 2019.

[2] 田键, 申盛伟, 叶斌, 等. 铜尾矿资源化利用与处置新工艺[J]. 矿产综合利用, 2016(3):5-9. doi: 10.3969/j.issn.1000-6532.2016.03.002

TIAN J, SHEN S W, YE B, et al. New technology for utilization and disposal of copper tailings[J]. Multipurpose Utilization of Mineral Resources, 2016(3):5-9. doi: 10.3969/j.issn.1000-6532.2016.03.002

[3] 陈甲斌, 李瑞军, 余良晖. 铜尾矿资源调查评价方法及其应用[J]. 自然资源学报, 2012, 27(8):1373-1381. doi: 10.11849/zrzyxb.2012.08.011

CHEN J B, LI R J, YU L H. Investigation and evaluation method of copper tailings resources and its application[J]. Journal of Natural Resources, 2012, 27(8):1373-1381. doi: 10.11849/zrzyxb.2012.08.011

[4] 宋军伟, 朱街禄, 刘方华, 等. 铜尾矿粉对复合胶凝体系强度和微结构的影响[J]. 建筑材料学报, 2019, 22(6):846-852. doi: 10.3969/j.issn.1007-9629.2019.06.002

SONG J W, ZHU J L, LIU F H, et al. Effect of copper-tailing powder on the strength and microstructure of composite cementification system[J]. Journal of Building Materials, 2019, 22(6):846-852. doi: 10.3969/j.issn.1007-9629.2019.06.002

[5] 成奖国. 球磨混合硅藻土/坡缕石的吸附性能研究[J]. 矿产综合利用, 2018(2):130-134. doi: 10.3969/j.issn.1000-6532.2018.02.029

CHENG J G. Study on the adsorption performance of mixed diatomite/palozozite by ball mill[J]. Multipurpose Utilization of Mineral Resources, 2018(2):130-134. doi: 10.3969/j.issn.1000-6532.2018.02.029

[6] Lamastra F R, Mori S, Cherubini V, et al. A new green methodology for surface modification of diatomite filler in elastomers[J]. Materials Chemistry and Physics, 2017, 194:253-260. doi: 10.1016/j.matchemphys.2017.03.050

[7] 任子杰, 高惠民, 柳溪. 硅藻土提纯及制备助滤剂研究进展[J]. 矿产综合利用, 2013(5):9-13+16.

REN Z J, GAO H M, LIU X. Research progress of purification of diatomite and preparation of filtration aid[J]. Multipurpose Utilization of Mineral Resources, 2013(5):9-13+16.

[8] Han L, Li F, Deng X, et al. Foam-gelcasting preparation, microstructure and thermal insulation performance of porous diatomite ceramics with hierarchical pore structures[J]. Journal of the European Ceramic Society, 2017, 37(7):2717-2725. doi: 10.1016/j.jeurceramsoc.2017.02.032

[9] 白春华, 徐志永, 李光辉, 等. 纳米TiO2负载硅藻土及改性研究进展[J]. 矿产综合利用, 2016(6):8-12. doi: 10.3969/j.issn.1000-6532.2016.06.002

BAI C H, XU Z Y, LI G H, et al. Research progress of nano-TiO2 supported diatomite and its modification[J]. Multipurpose Utilization of Mineral Resources, 2016(6):8-12. doi: 10.3969/j.issn.1000-6532.2016.06.002

[10] Aydin A C, Gül R. Influence of volcanic originated natural materials as additive on the setting time and some mechanical properties of concrete. Construction and Building Materials, 2007(21): 1277-1281.

[11] 罗小宝, 马芹永, 顾皖庆, 等. 硅藻土掺量和硅粉掺量对混凝土抗压强度影响的试验与分析[J]. 科学技术与工程, 2018(18):315-319.

LUO X B, MA Q Y, GU W Q, et al. Experimental and analysis of the influence of diatomite and silica powder on the compressive strength of concrete[J]. Science Technology and Engineering, 2018(18):315-319.

-

下载:

下载: