Study on Comprehensive Recovery of Gold, Silver and Copper Associated with Iron Ore in Qinghai

-

摘要:

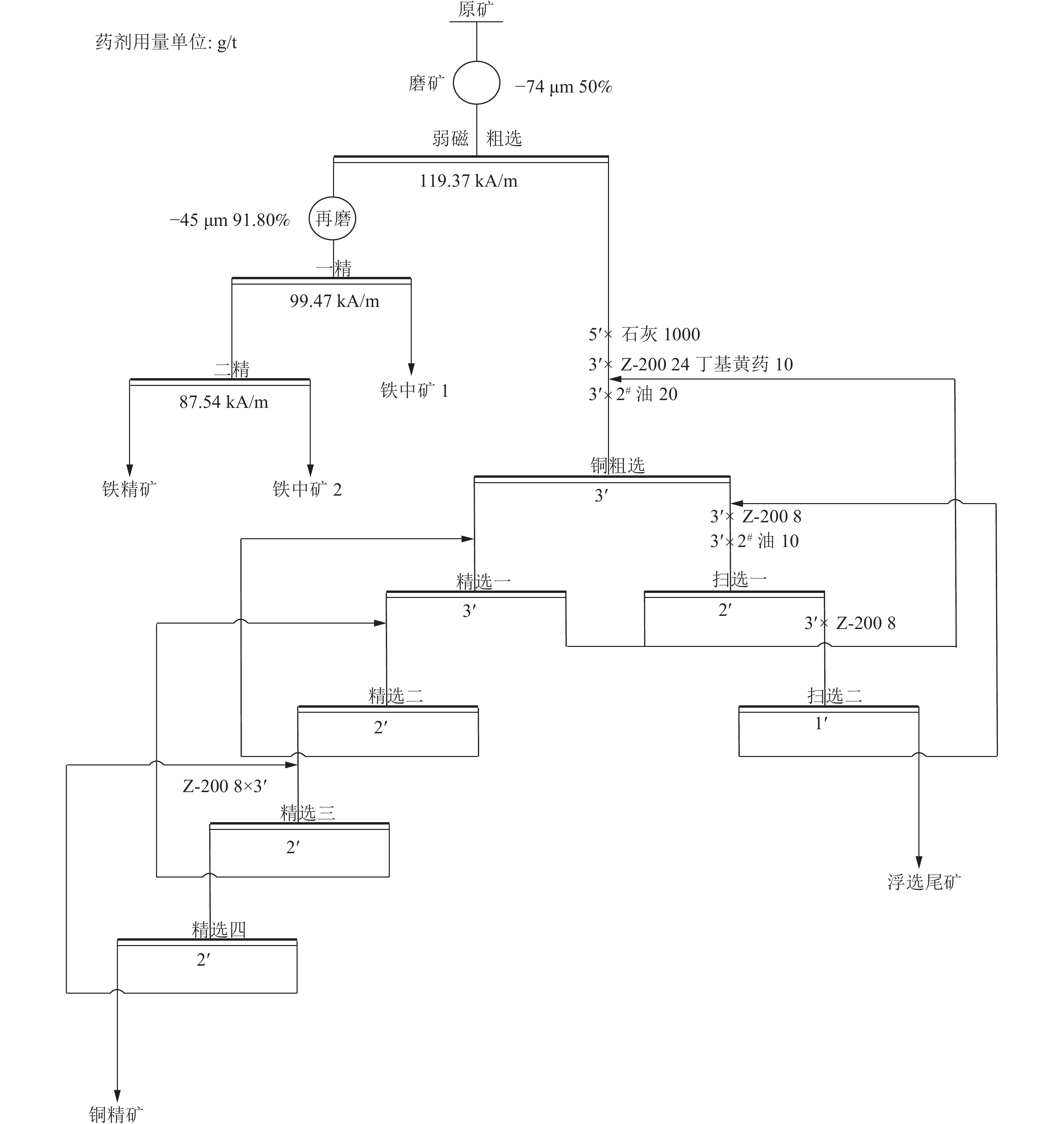

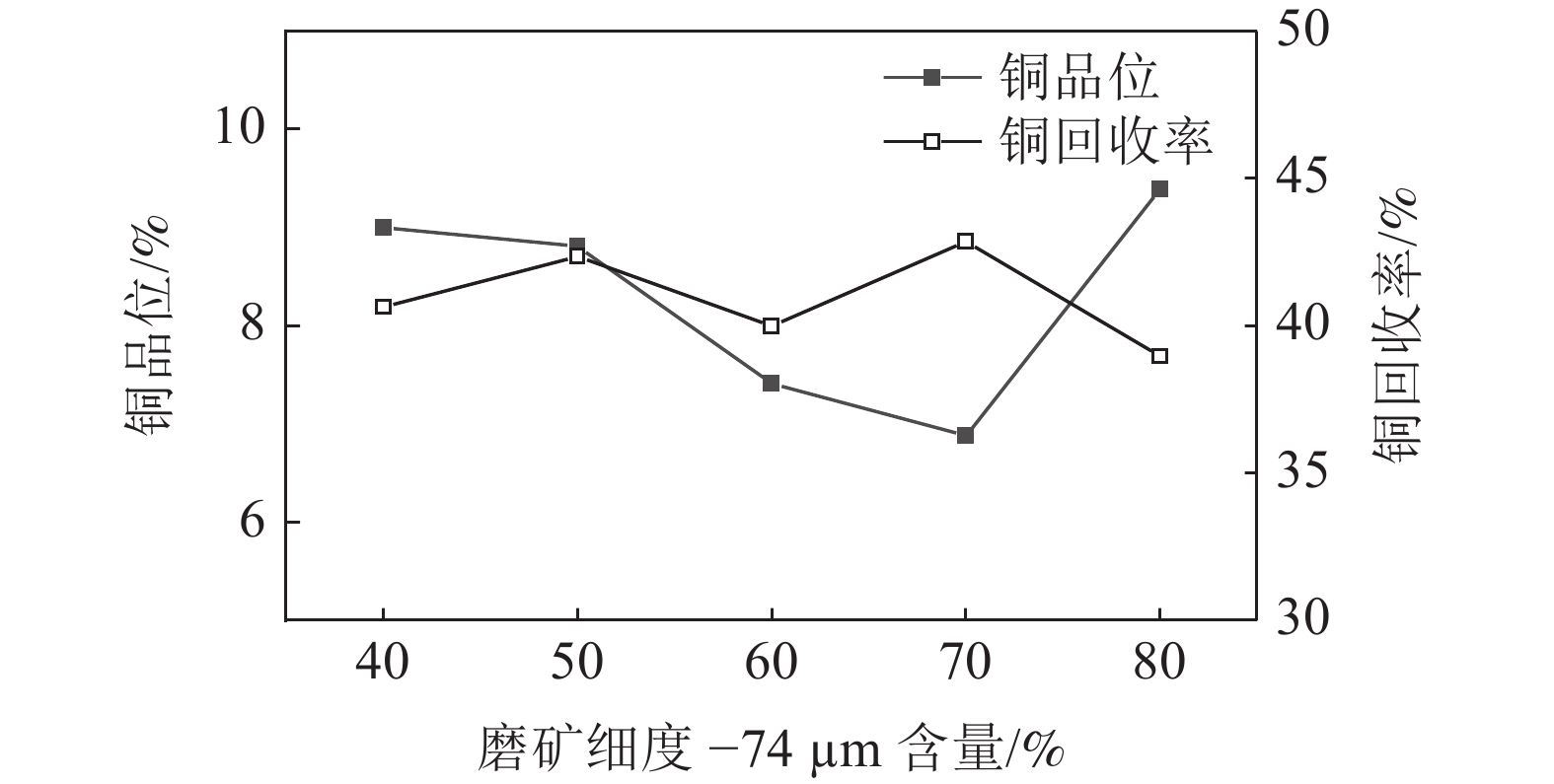

青海铁矿中伴生少量的金银铜,这些伴生矿物达到回收标准,实验采用先磁后浮及先浮后磁工艺流程进行对比实验研究,研究结果表明,采用先磁后浮流程可获得铁精矿含全铁68.25%,铁回收率77.48%,铜精矿含铜28.60%,铜回收率41.14%,铜精矿含金18.60 g/t,含银1127.91 g/t,金回收率44.44%,银回收率46.23%,实验指标较为理想,达到了伴生矿产资源综合利用的目的,对同类型矿产资源综合利用具有一定的参考价值。

Abstract:A small amount of gold and silver copper is associated with the iron ore of Qinghai, and the associated minerals reach the recovery standard; the test adopts the first magnetic rear floating and the first floating post-floating magnetic process flow; the first magnetic post-floating process can obtain the iron concentrate containing 68.25 percent of the total iron, 77.48 percent of the iron recovery rate, 28.60 percent of the copper concentrate and 41.14 percent of the copper recovery rate, The gold content of the copper concentrate is 18.60 g/ t, the silver content is 1127.91 g/ t, the recovery rate of gold is 44.44%, and the silver recovery rate is 46.23%.

-

Key words:

- Iron ore /

- Associated /

- Polymetallic ore /

- Comprehensive utilization

-

-

表 1 原矿化学多元素分析结果/%

Table 1. Results of chemical multielement analysis of raw ore

Fe2O3 TFe mFe Cu Pb Zn S As SiO2 K2O Na2O P CaO MgO MnO TiO2 Al2O3 Au* Ag* 烧失量 45.18 31.71 24.07 0.30 0.006 0.093 0.18 0.017 23.04 0.44 0.39 0.10 18.92 2.92 0.88 0.54 2.53 0.20 12.50 2.81 *单位为g/t。 表 2 原矿铁、铜物相分析结果

Table 2. Analysis results of iron and copper phase of raw ore

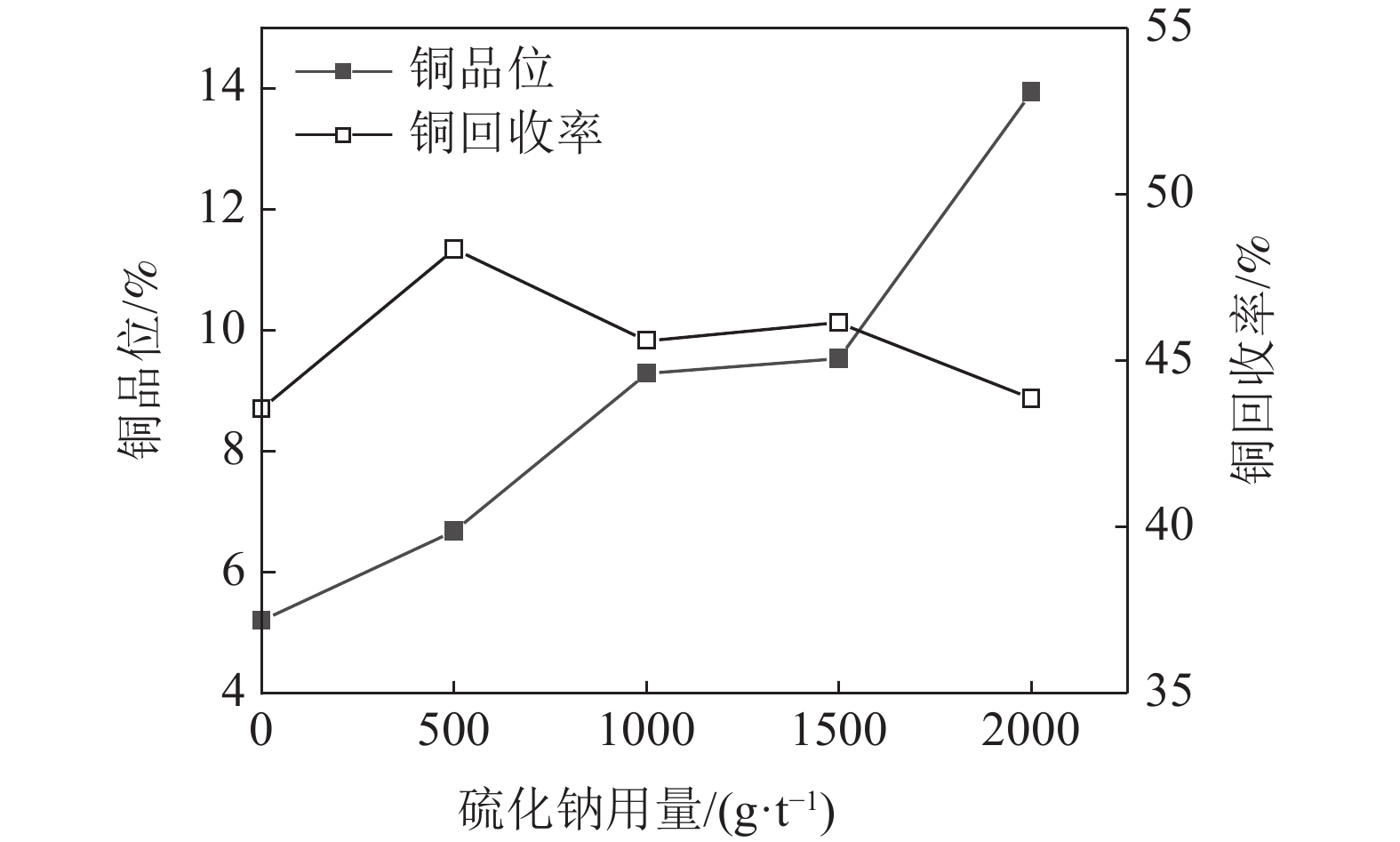

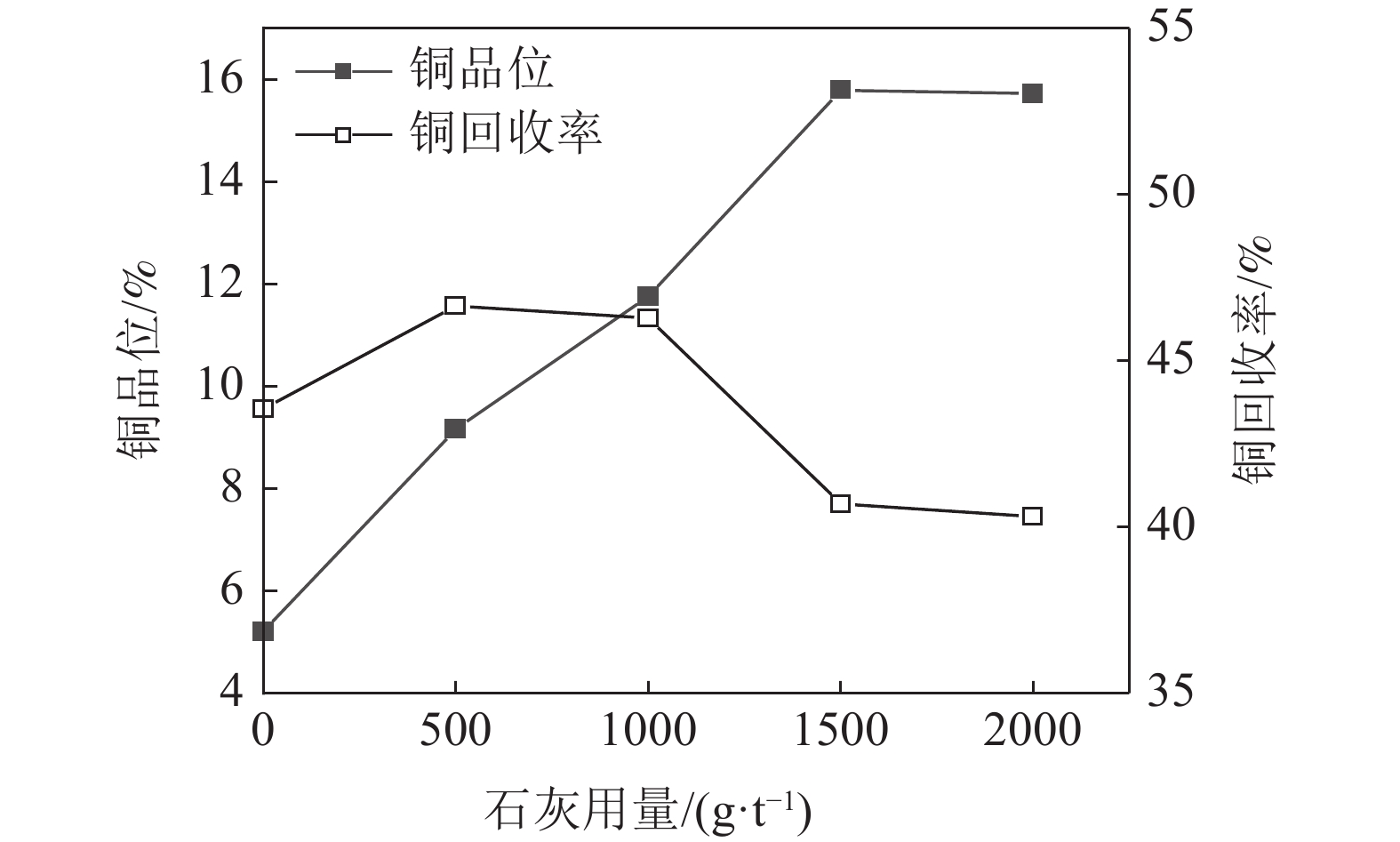

名称 TFe品位/% 分布率/% 名称 Cu品位/% 分布率/% 磁性铁中铁 24.11 75.82 硫化铜 0.11 36.18 碳酸铁中铁 0.11 0.35 氧化铜 0.19 62.50 赤褐铁中铁 2.45 7.70 结合铜 0.004 1.32 硅酸铁中铁 5.08 15.97 黄铁矿中铁 0.05 0.16 合计 31.80 100.00 合计 0.304 100.00 表 3 调整剂种类及用量实验结果

Table 3. Test results of type and dosage of adjuster

调整剂种类及

用量/(g·t−1)产品名称 产率/% Cu品位/% Cu回收率/% 不加

pH值6~7铜粗精矿 2.60 5.20 43.55 尾 矿 97.40 0.18 56.45 原 矿 100.00 0.31 100.00 石灰500

pH值7~8铜粗精矿 1.59 9.16 46.65 尾 矿 98.41 0.17 53.35 原 矿 100.00 0.313 100.00 硫酸铜500

pH值6~7铜粗精矿 1.53 8.13 37.58 尾 矿 98.43 0.21 62.42 原 矿 100.00 0.33 100.00 硫化钠500

pH值6~7铜粗精矿 2.19 6.67 48.34 尾 矿 97.81 0.16 51.66 原 矿 100.00 0.302 100.00 硅酸钠1000

pH值7铜粗精矿 1.06 9.75 35.40 尾 矿 98.94 0.19 64.60 原 矿 100.00 0.291 100.00 亚硫酸钠500

pH值7铜粗精矿 2.23 6.13 43.77 尾 矿 97.77 0.18 56.23 原 矿 100.00 0.313 100.00 碳酸钠1000

pH值7铜粗精矿 1.48 8.81 42.35 尾 矿 98.52 0.18 57.65 原 矿 100.00 0.307 100.00 表 4 捕收剂种类及用量实验结果

Table 4. Test results of type and dosage of collector

捕收剂种类及

用量/(g·t−1)产品名称 产率/% Cu品位/% Cu回收率/% Z-200 16 铜粗精矿 0.78 15.23 38.64 尾 矿 99.22 0.19 61.36 原 矿 100.00 0.308 100.00 Z-200 24 铜粗精矿 1.82 7.53 43.63 尾 矿 98.18 0.18 56.37 原 矿 100.00 0.314 100.00 Z-200 16

丁基黄药10铜粗精矿 1.65 8.99 46.98 尾 矿 98.35 0.17 53.02 原 矿 100.00 0.315 100.00 Z-200 24

丁基黄药10铜粗精矿 1.62 9.35 47.34 尾 矿 98.38 0.171 52.66 原 矿 100.00 0.319 100.00 丁基黄药50 铜粗精矿 0.77 15.16 38.24 尾 矿 99.23 0.19 61.76 原 矿 100.00 0.306 100.00 丁基黄药30

丁胺黑药20铜粗精矿 1.40 10.20 45.98 尾 矿 98.60 0.17 54.02 原 矿 100.00 0.311 100.00 丁基黄药10

羟肟酸30铜粗精矿 2.73 5.53 50.12 尾 矿 97.27 0.16 49.88 原 矿 100.00 0.302 100.00 表 5 闭路实验结果

Table 5. Closed circuit test results

工艺流程 产品名称 产率/% 品位/% 回收率/% Cu Au* Ag* TFe Cu Au Ag TFe 先浮后磁 铜精矿 0.74 18.38 10.0 876.35 20.95 44.59 40.44 51.71 0.49 铁精矿 34.34 0.11 0.09 5.46 67.83 12.46 16.94 14.95 73.29 中矿2 0.46 0.16 0.11 7.24 21.24 0.33 0.55 0.26 0.31 中矿1 4.26 0.14 0.13 6.88 11.57 1.97 3.28 2.34 1.55 尾 矿 60.20 0.20 0.12 6.40 12.89 40.65 38.79 30.74 24.36 原 矿 100.00 0.305 0.183 12.54 31.78 100.00 100.00 100.00 100.00 先磁后浮 铁精矿 34.35 0.12 0.10 5.39 68.25 13.71 18.89 14.81 73.94 中矿2 0.90 0.15 0.11 7.24 45.12 0.33 0.56 0.56 1.29 中矿1 4.25 0.13 0.12 6.80 18.05 2.01 2.78 2.32 2.43 铜精矿 0.43 28.60 18.60 1347.91 11.63 41.14 44.44 46.44 0.16 尾 矿 60.07 0.21 0.10 7.45 11.70 42.81 33.33 35.87 22.18 原 矿 100.00 0.299 0.18 12.49 31.70 100.00 100.00 100.00 100.00 *单位为g/t。 -

[1] 张铃, 蒋太国, 方建军, 等. 铜矿中伴生金银综合回收研究进展[J]. 贵金属, 2020(5):1-8. doi: 10.3969/j.issn.1004-0676.2020.01.014

ZHANG L, JIANG T G, FANG J J, et al. Research progress on comprehensive recovery of associated gold and silver in copper mines[J]. Precious Metals, 2020(5):1-8. doi: 10.3969/j.issn.1004-0676.2020.01.014

[2] 冯博, 朱贤文, 彭金秀, 等. 有色金属硫化矿中伴生金银资源回收研究进展[J]. 贵金属, 2016, 37(2):70-76. doi: 10.3969/j.issn.1004-0676.2016.02.014

FENG B, ZHU X W, PENG J X, et al. Research progress on recovery of associated gold and silver resources in nonferrous metal sulfide ores[J]. Precious Metals, 2016, 37(2):70-76. doi: 10.3969/j.issn.1004-0676.2016.02.014

[3] 宛鹤. 复杂多金属矿石共(伴)生金银综合利用的试验研究[D]. 西安: 西安建筑科技大学, 2009.

WAN H. Experimental study on the comprehensive utilization of gold and silver in complex polymetallic ores [D]. Xi'an: Xi'an University of Architecture and Technology, 2009.

[4] 徐莲芳. 我国有色金属及黄金的综合回收技术[J]. 世界有色金属, 1999(10):19-21.

XU L F. Comprehensive recovery technology of non-ferrous metals and gold in my country[J]. World Non-ferrous Metals, 1999(10):19-21.

[5] 孙长泉. 铜铁矿石伴生金银的综合回收[J]. 中国矿业, 1999(4):54-56.

SUN C Q. Comprehensive recovery of gold and silver associated with copper and iron ore[J]. China Mining Industry, 1999(4):54-56.

[6] 高洪山, 肖春泉. 浅析提高有色金属伴生金银综合回收水平的几个重要途径[J]. 矿产保护与利用, 1994(3):35-38+55.

GAO H S, XIAO C Q. Analysis on several important ways to improve the comprehensive recovery level of gold and silver associated with non-ferrous metals[J]. Mineral Protection and Utilization, 1994(3):35-38+55.

-

下载:

下载: