Effect of Suspension Magnetization Roasting Temperature on the Properties of Roasted Products of Chongqing Jielong Iron Mine

-

摘要:

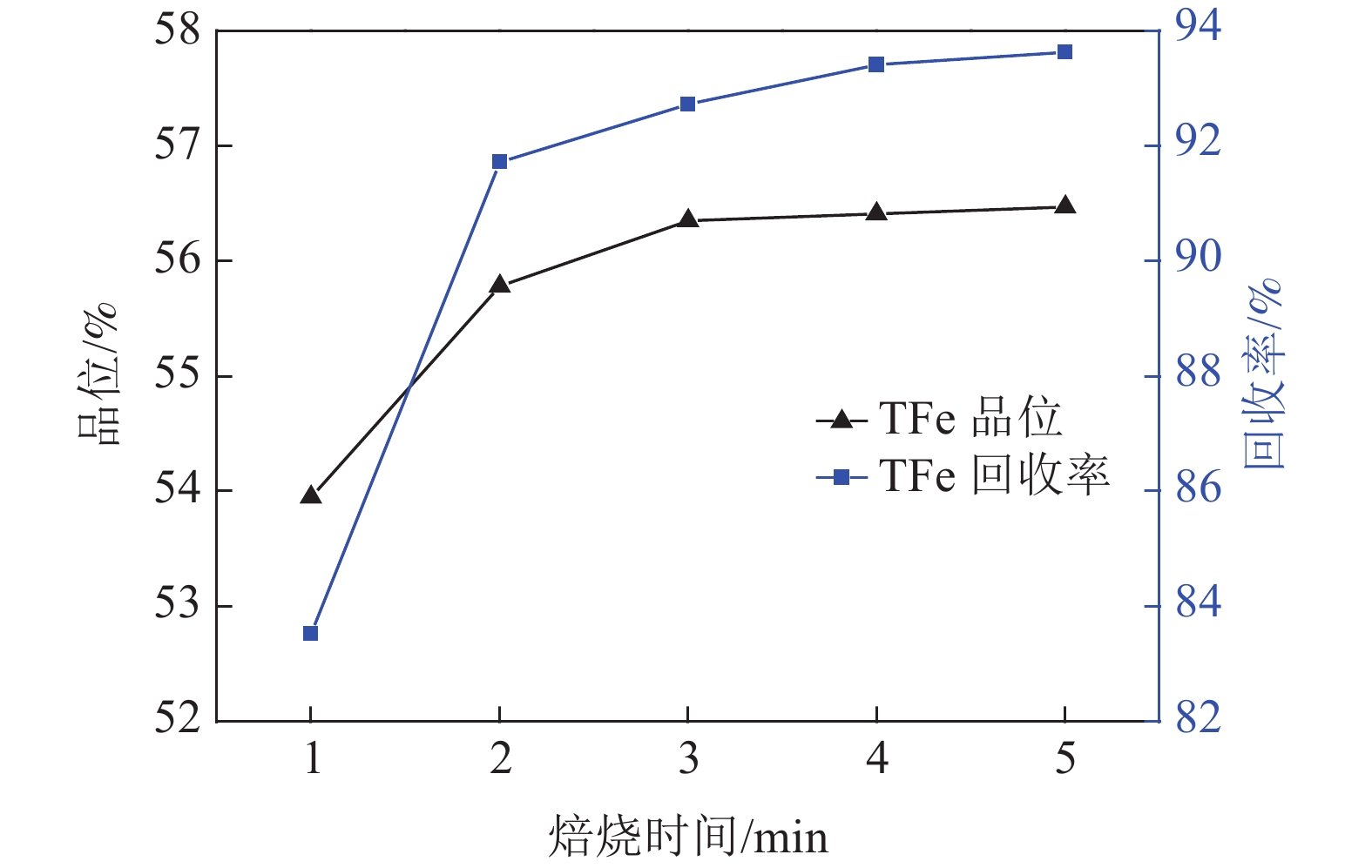

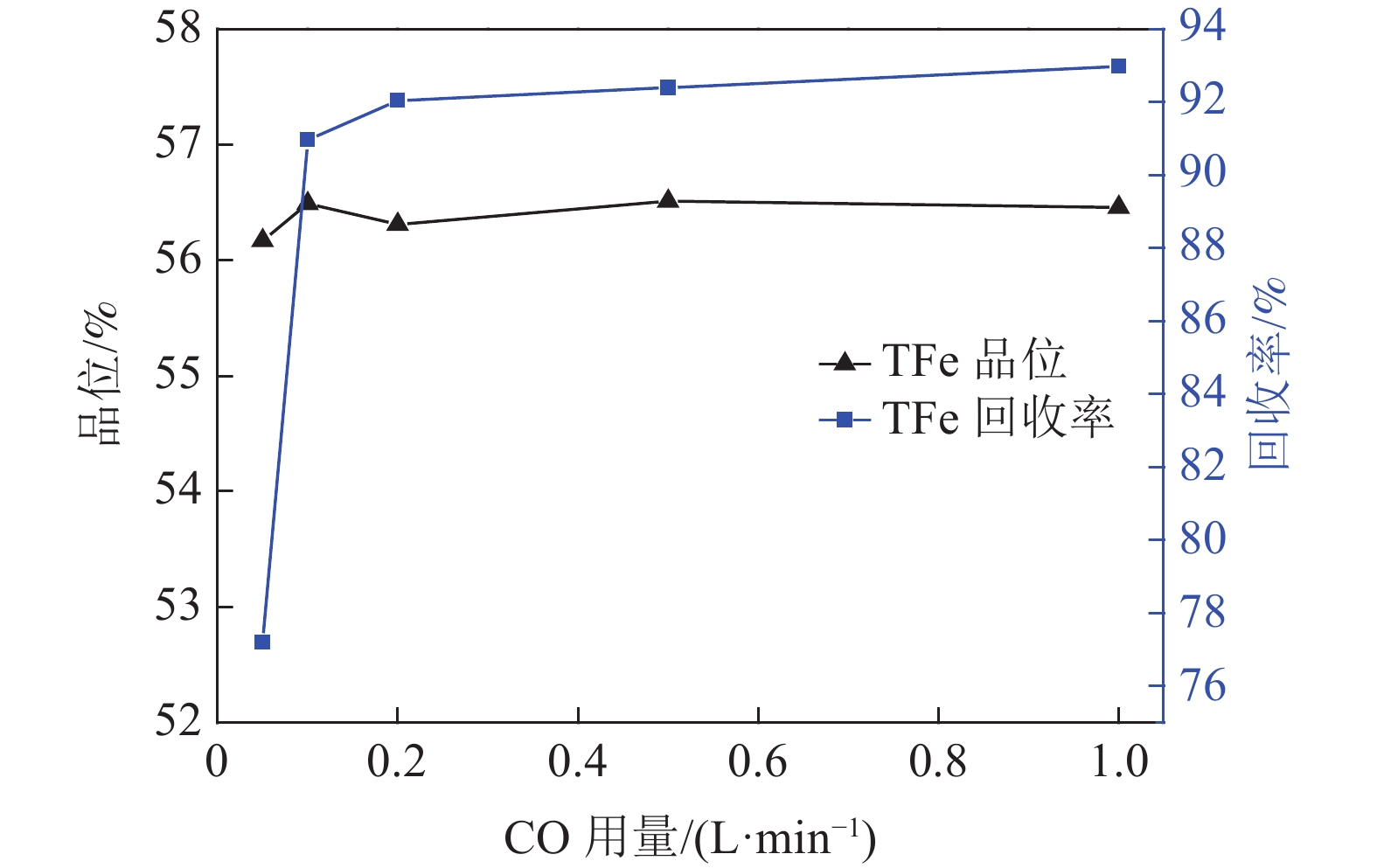

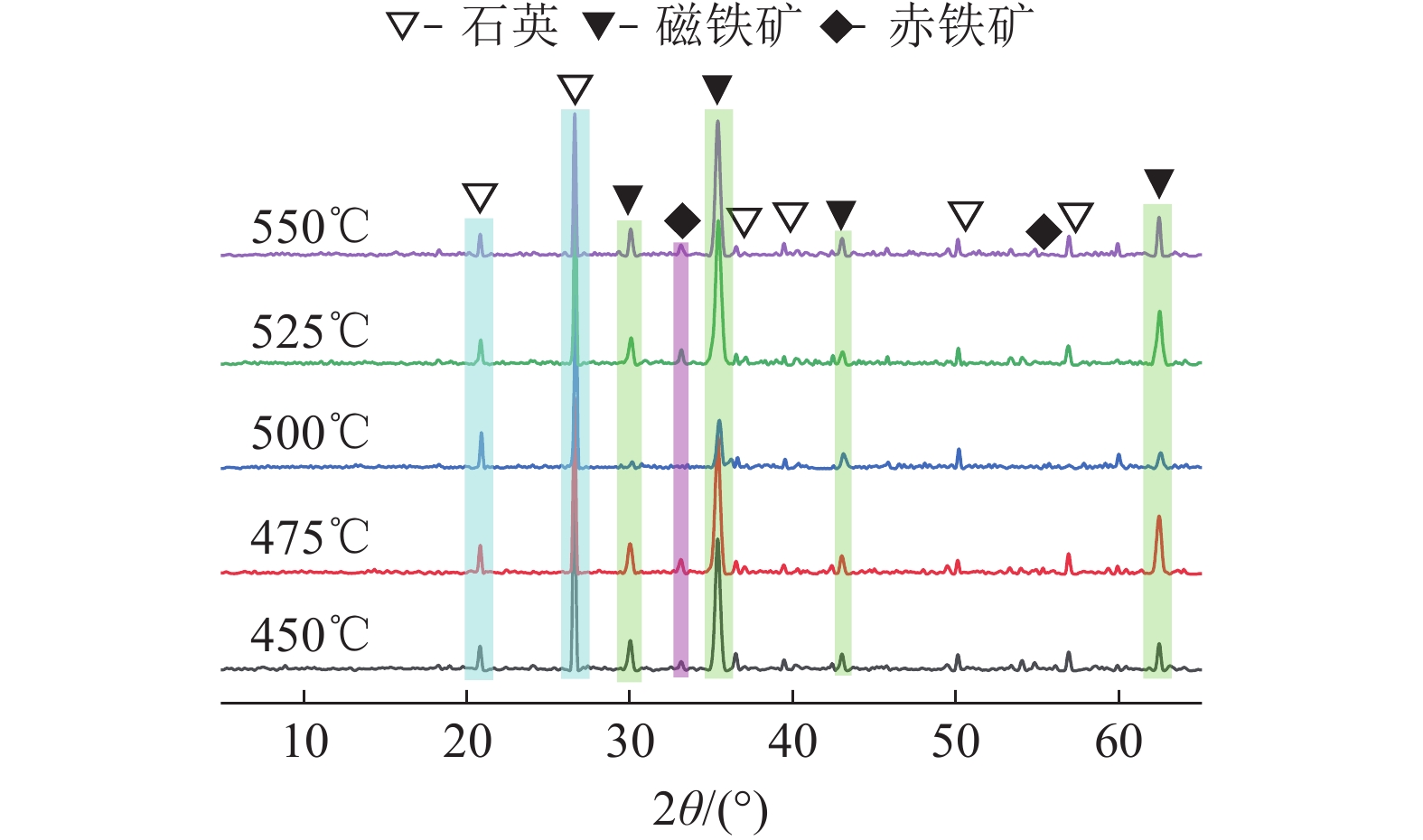

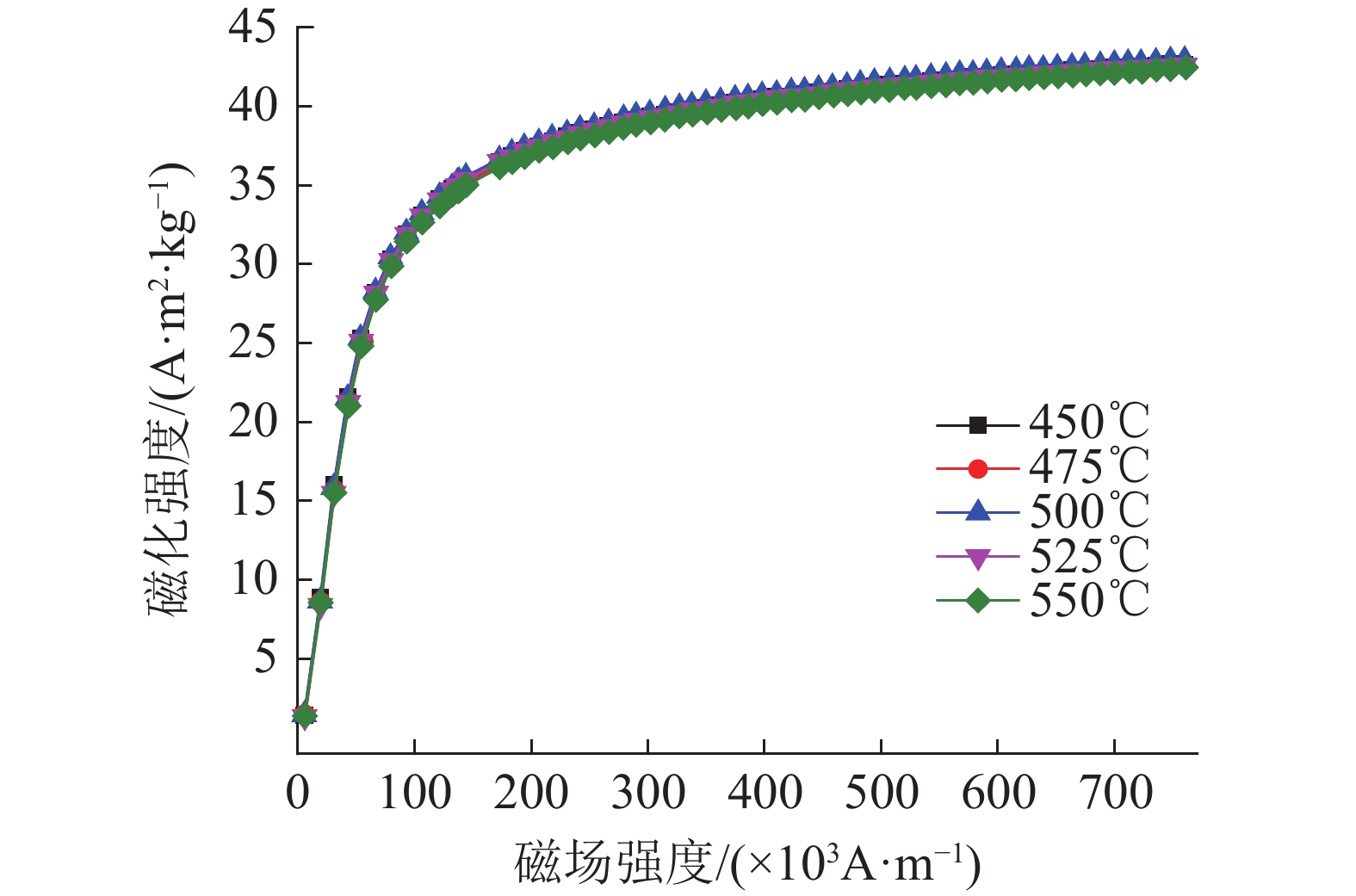

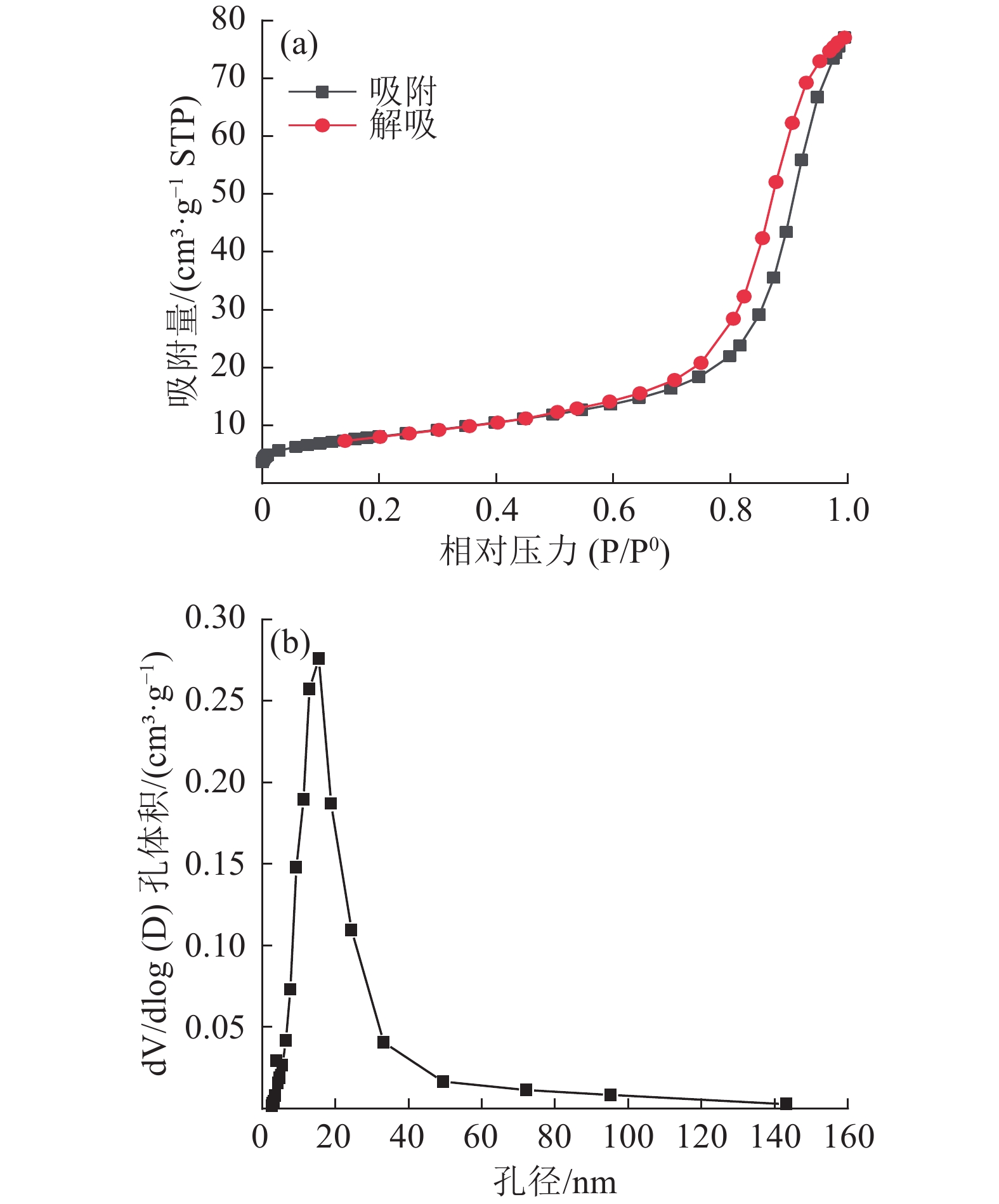

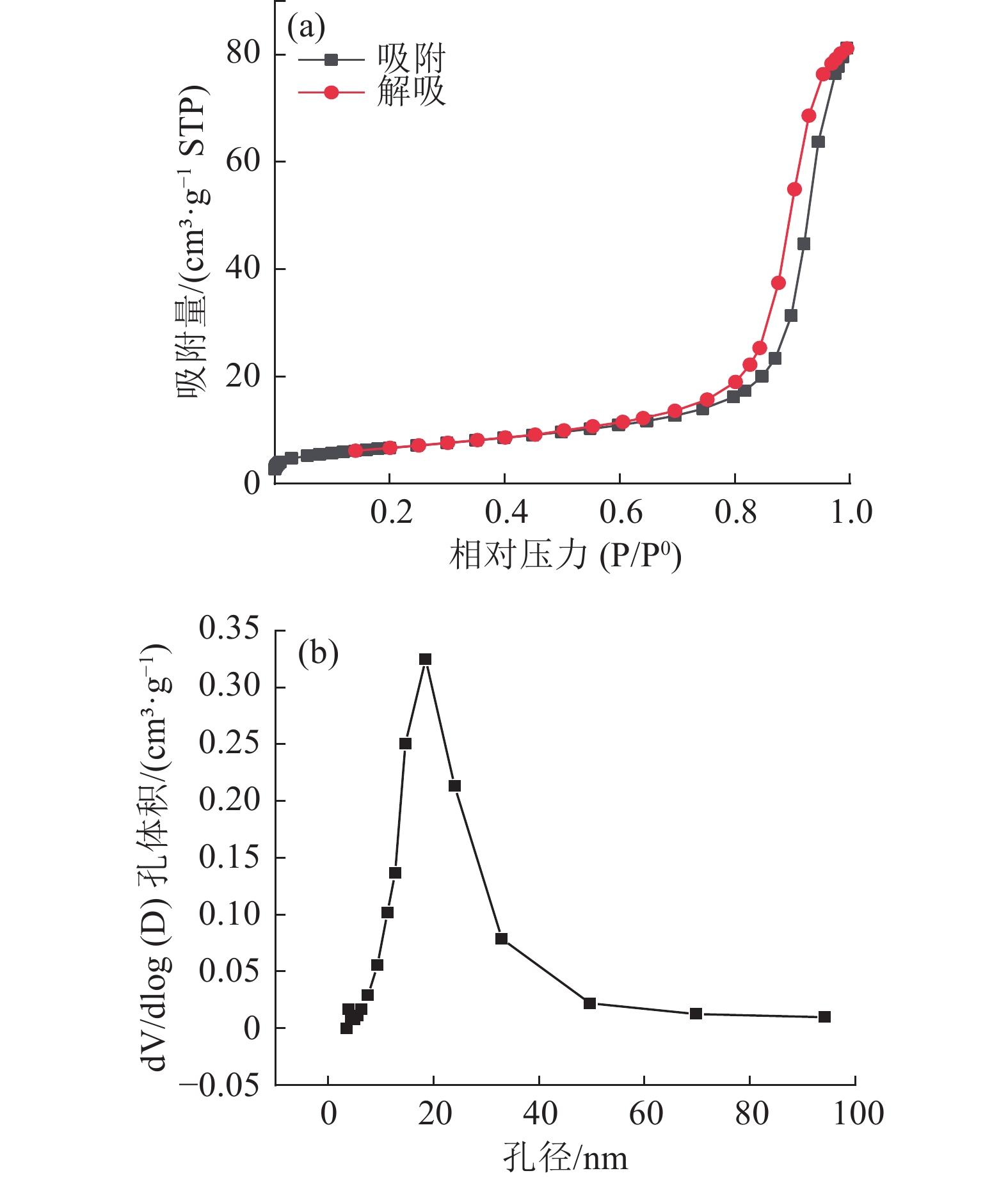

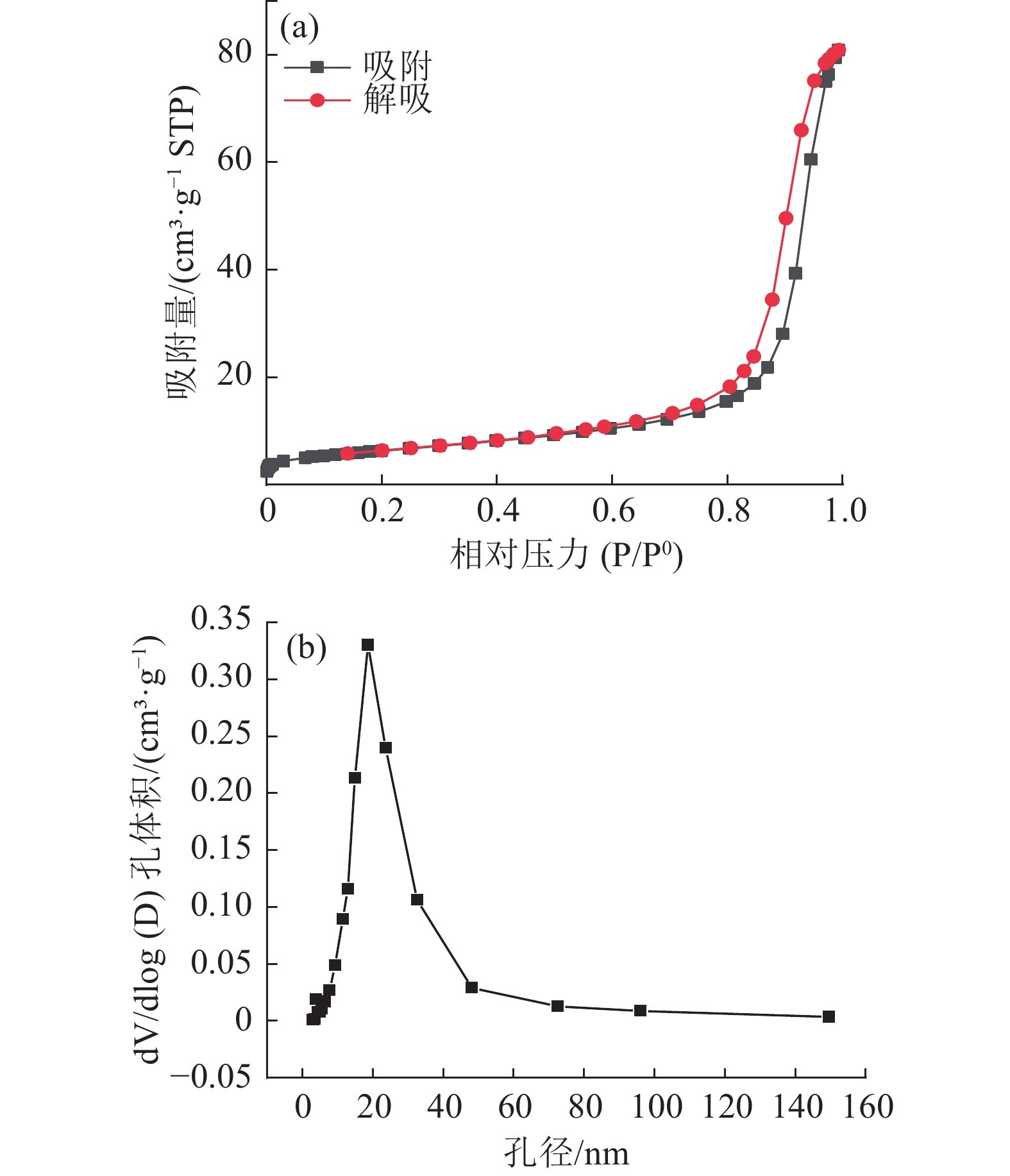

菱铁矿是我国重要的铁矿石资源,悬浮磁化焙烧是处理复杂难选铁矿的有效方法。本文采用实验室小型悬浮磁化焙烧装置,针对重庆接龙铁矿,开展悬浮磁化焙烧工艺优化及焙烧温度对磁化焙烧产品性能的研究。研究结果表明,接龙铁矿预氧化产品在焙烧温度为500℃、焙烧时间为3 min,CO用量为0.2 L/min的条件下,获得了铁精矿品位56.31%,回收率92.05%的试验指标。XRD分析表明,在450~550℃范围内,还原焙烧3 min,均可实现大部分的赤铁矿转变为磁铁矿,提高温度有利于赤铁矿还原更彻底,还原温度对焙烧产品的磁性影响较小。预氧化样品经还原焙烧后,比表面积降低,存在孔结构坍塌破坏后被填充的现象,导致孔尺寸增加。孔结构的改变,可能对后续的磨矿磁选造成一定的影响。研究结果对认识悬浮磁化焙烧规律有一定的意义。

Abstract:Siderite is an important iron ore resource in China. Suspension magnetization roasting is an effective method to deal with complex refractory iron ores. In this paper, a small laboratory suspension magnetization roasting device is used to carry out the research on the optimization of suspension magnetization roasting process and the effect of roasting temperature on the performance of magnetized roasted products for Chongqing Jielong iron mine. The results show that under the conditions of roasting temperature of 500℃, roasting time of 3 min and CO dosage of 0.2 L/min, the iron concentrate grade of 56.31% and recovery rate of 92.05% were obtained. XRD analysis shows that in the range of 450~550℃, most hematite can be transformed into magnetite by reduction roasting for 3 min. Increasing the temperature is conducive to the more thorough reduction of hematite, and the reduction temperature has little effect on the magnetism of roasted products. After reduction roasting, the specific surface area of the pre oxidized sample decreases, and the pore structure collapses and is filled, resulting in the increase of pore size. The change of pore structure may have a certain impact on the subsequent grinding and magnetic separation. The research results have certain significance for understanding the law of suspension magnetization roasting.

-

Key words:

- Suspension roasting /

- Product performance /

- Siderite /

- Roasting temperature

-

-

表 1 矿样的多项分析/%

Table 1. Multi-component analysis of iron ore sample

TFe FeO P S SiO2 Al2O3 CaO MgO K2O Na2O H2O+ 总C 烧失 35.68 33.78 0.10 0.36 20.73 3.23 1.22 1.21 0.14 0.060 1.61 6.51 21.05 表 2 矿样中铁化学物相分析

Table 2. Iron phase analysis of iron ore sample

名称 磁性铁中的Fe 赤(褐)铁矿中的Fe 菱铁矿中的Fe 硫化铁中的Fe 硅酸铁中的Fe 合计 含量/% 0.87 8.99 25.32 0.263 0.137 35.58 分布率/% 2.45 25.27 71.16 0.74 0.39 100.00 表 3 矿石矿物组成及其含量

Table 3. Mineral composition and contents of the ore

矿物 含量/% 矿物 含量/% 菱铁矿 51.20 高岭石 2.38 赤铁矿 9.60 黄铁矿 0.43 铁矿和绿泥石或

高岭石的混合物13.38 磷灰石 0.30 石英或玉髓 12.56 方解石 0.20 云母 5.30 白云石 0.18 绿泥石 4.45 其他 0.02 表 4 预氧化产品主要成分组成/%

Table 4. Main components of pre oxidation products

TFe FeO P S SiO2 Al2O3 CaO MgO K2O Na2O 44.60 0.02 0.10 0.15 25.96 4.02 1.51 1.46 0.17 0.07 表 5 焙烧产品主要成分组成/%

Table 5. Main components of roasted products

样品 TFe FeO P S SiO2 Al2O3 CaO MgO K2O Na2O 磁选精矿 56.31 24.11 0.09 0.28 13.12 2.42 2.38 1.92 0.06 0.07 磁选尾矿 13.12 2.12 0.12 0.12 67.58 8.78 1.03 0.76 0.44 0.11 表 6 不同焙烧温度对孔结构的影响

Table 6. Effect of different roasting temperatures on pore structure

样品 BET表面积/(m2·g−1) BJH总孔容/(cm3·g−1) BJH平均孔径/nm 预氧化样品 28.7821 0.126929 12.9666 450℃焙烧产品 23.3981 0.133270 16.8417 475℃焙烧产品 24.4172 0.128822 16.6092 500℃焙烧产品 22.1561 0.135887 18.7878 525℃焙烧产品 23.5988 0.130330 16.6781 550℃焙烧产品 22.4714 0.131200 17.4992 -

[1] 陈超, 张裕书, 李潇雨, 等. 钛磁铁矿选矿技术研究进展[J]. 矿产综合利用, 2021(3):99-105.

CHEN C, ZHANG Y S, LI X Y, et al. Research progress in titanium-magnetite beneficiation technology[J]. Multipurpose Utilization of Mineral Resources, 2021(3):99-105.

[2] 崔立伟, 夏浩东, 王聪, 等. 中国铁矿资源现状与铁矿实物地质资料筛选[J]. 地质与勘探, 2012, 48(5):894-905.

CUI L W, XIA H D, WANG C, et al. Current situation of iron ore resources in China and screening of physical geological data of iron ore[J]. Geology and Exploration, 2012, 48(5):894-905.

[3] 王岩, 邢树文, 张增杰, 等. 我国查明低品位铁矿资源储量分析[J]. 矿产综合利用, 2014(5):15-17. doi: 10.3969/j.issn.1000-6532.2014.05.004

WANG Y, XING S W, ZHANG Z J, et al. Reserves analysis of identified low-grade iron resources in China[J]. Multipurpose Utilization of Mineral Resources, 2014(5):15-17. doi: 10.3969/j.issn.1000-6532.2014.05.004

[4] 李艳军, 杨光, 赵瑞超, 等. 含菱铁矿难选铁矿石的特点及选矿技术研究趋势[J]. 矿产综合利用, 2015(2):12-17. doi: 10.3969/j.issn.1000-6532.2015.02.002

LI Y J, YANG G, ZHAO R C, et al. Feature of refractory iron ore containing siderite and its research trends of beneficiation technology[J]. Multipurpose Utilization of Mineral Resources, 2015(2):12-17. doi: 10.3969/j.issn.1000-6532.2015.02.002

[5] 何威, 廖德华. 某菱铁矿块矿直接还原-磁选制备铁粉[J]. 矿产综合利用, 2019(5):70-74. doi: 10.3969/j.issn.1000-6532.2019.05.015

HE W, LIAO D H. Preparation of iron powder from siderite by direct reduction and magnetic separation[J]. Multipurpose Utilization of Mineral Resources, 2019(5):70-74. doi: 10.3969/j.issn.1000-6532.2019.05.015

[6] 胡虹, 宋春燕, 胡桂渊. 菱铁矿基础性能及单独烧结试验研究[J]. 矿产综合利用, 2018(6):85-89. doi: 10.3969/j.issn.1000-6532.2018.06.017

HU H, SONG C Y, HU G Y. Study on basic properties and sintering of siderite ore[J]. Multipurpose Utilization of Mineral Resources, 2018(6):85-89. doi: 10.3969/j.issn.1000-6532.2018.06.017

[7] 刘明宝, 杨超普, 闫赞, 等. 基于Box-Behnken试验设计的柞水菱铁尾矿最佳回收工艺参数[J]. 矿产综合利用, 2018(4):152-157. doi: 10.3969/j.issn.1000-6532.2018.04.035

LIU M B, YANG C P, YAN Z, et al. Optimum recovery process parameters of siderite tailings in Zhashui based on the box-behnken center-united experimental method[J]. Multipurpose Utilization of Mineral Resources, 2018(4):152-157. doi: 10.3969/j.issn.1000-6532.2018.04.035

[8] Zhu D Q, Zhao Q, Qiu G Z, et al. Magnetizing roasting-magnetic separation of limonite ores from Anhui Province in east China[J]. Journal of University of Science and Technology Beijing, 2010, 32(6):713-718.

[9] 韩跃新, 李艳军, 高鹏, 等. 复杂难选铁矿石悬浮磁化焙烧-高效分选技术[J]. 钢铁研究学报, 2019, 31(2):1-4.

HAN Y X, LI Y J, GAO P, et al. Innovative and efficient beneficiation technology of refractory iron ores based on suspended magnetization roasting[J]. Journal of Iron and Steel Research, 2019, 31(2):1-4.

-

下载:

下载: