Study on Comprehensive Utilization of Phosphorus Slag Modified Asphalt Mixture

-

摘要:

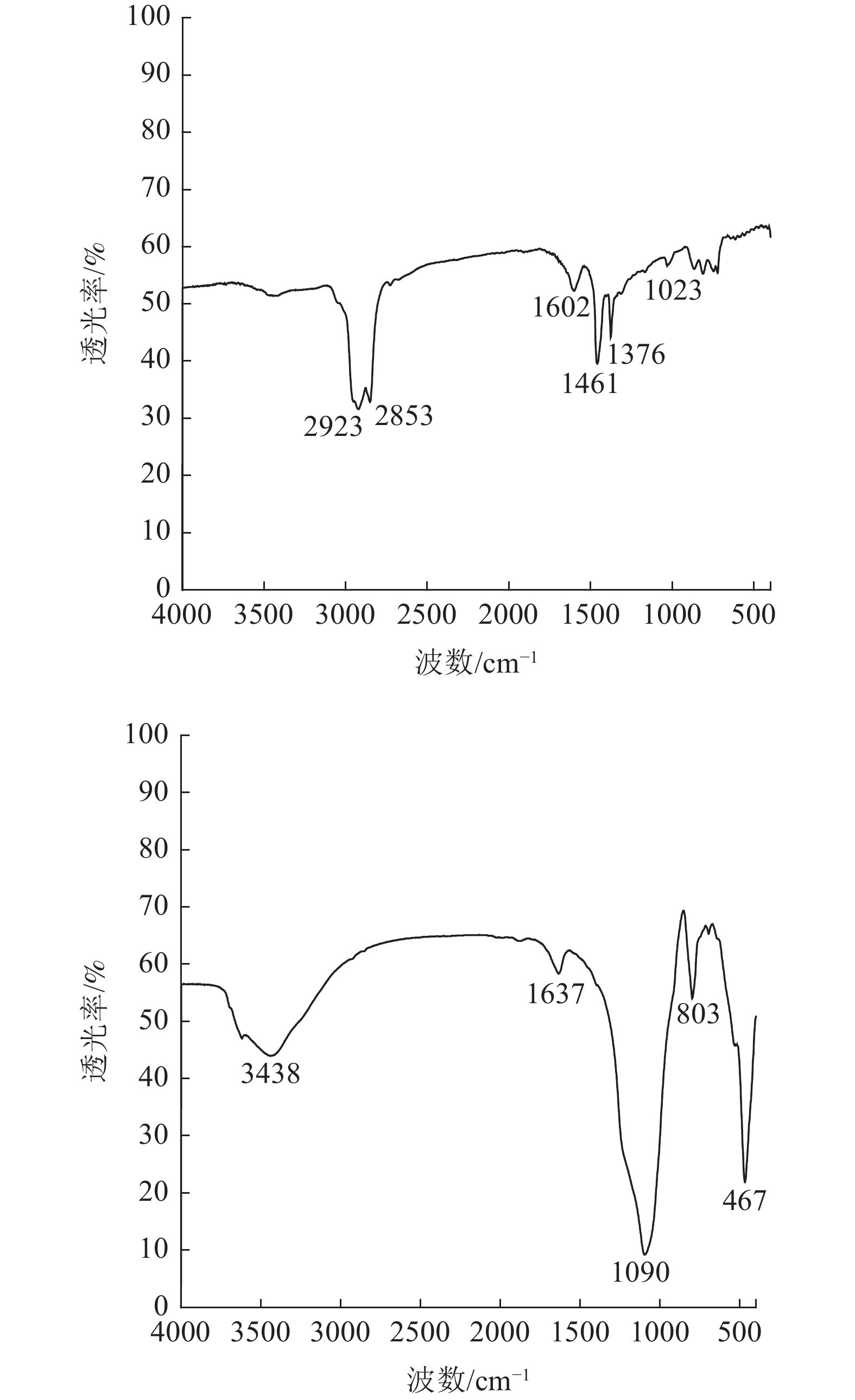

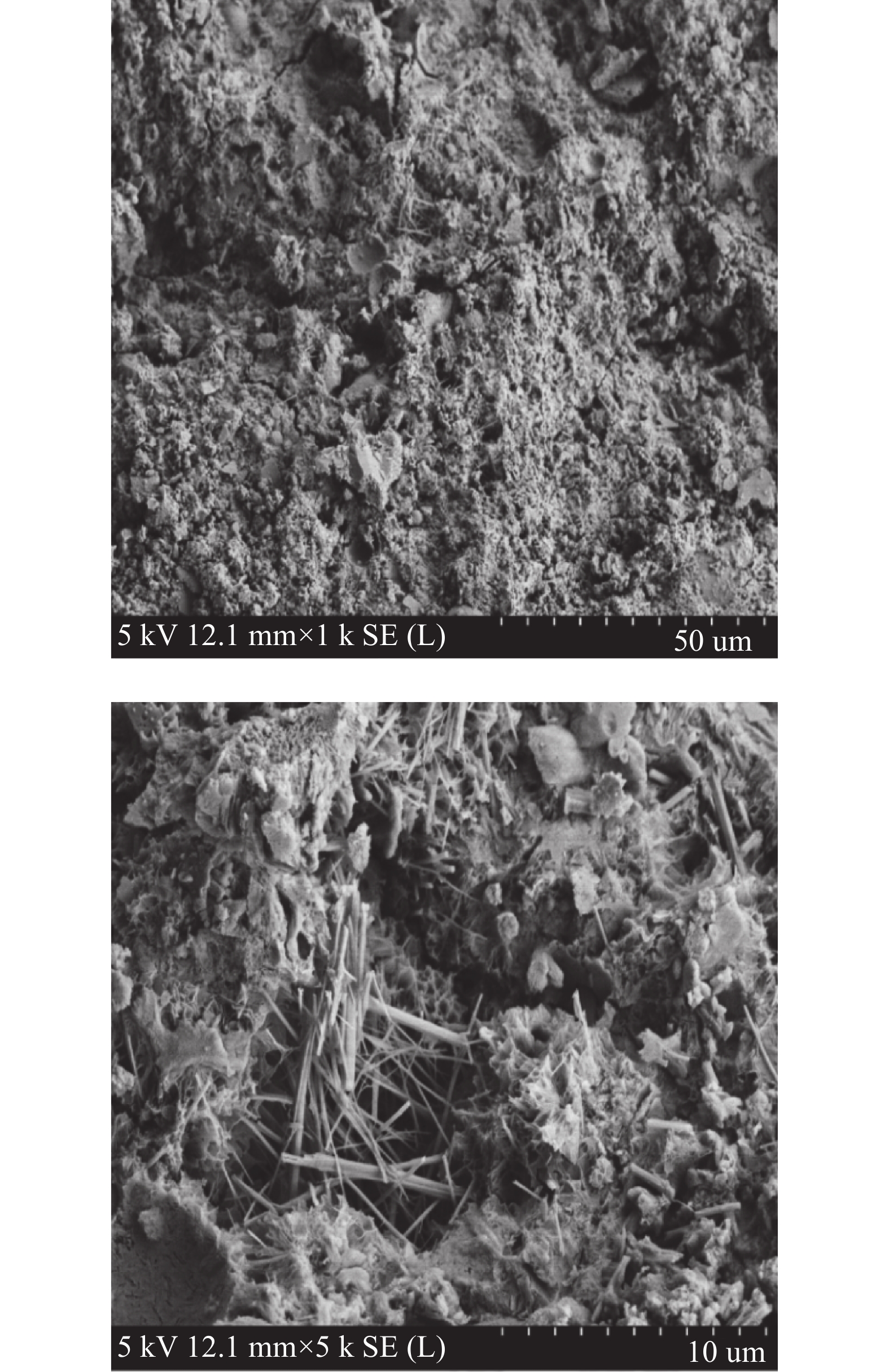

为了解决生产黄磷时排放的水淬磷酸盐类工业废渣难题,提高废弃物资源的再利用率。通过实验研究不同磷渣掺量下沥青混合料的高温稳定性和水稳定性,对基质沥青混合料及磷渣改性沥青混合料分别进行了马歇尔实验、车辙实验以及浸水马歇尔实验,结果表明:当磷渣掺量为9%时,磷渣改性沥青混合料的高温稳定性能和水稳定性能达到较佳。并通过采用电镜扫描、红外光谱等技术手段对磷渣改性沥青混合料的改性效果进行了具体分析。分析结果表明:在基质沥青中掺加磷渣能够明显提高沥青混合料的基本路用性能。按照本文的实验研究,得出当磷渣以9%的粉油比掺加到基质沥青中时改性效果较佳的结论。综合分析得出,磷渣改性沥青研究具有一定的研究价值,能够解决水淬磷酸盐类工业废渣难题以及资源再利用,并为延伸产业链等提供了新途径。

Abstract:In order to solve the problem of water quenched phosphate industrial waste residue discharged during the production of yellow phosphorus and improve the reuse rate of waste resources, high temperature stability and water stability of asphalt mixture with different phosphorus slag content are studied by experiment. Marshall test, rutting test and immersion Marshall test are carried out for matrix asphalt mixture and phosphorus slag modified asphalt mixture respectively. The results show that when phosphorus slag content is 9%, the high temperature stability and water stability performance of phosphorus slag modified asphalt mixture reach a better level. Modification effect of phosphorus slag modified asphalt mixture was analyzed by means of electron microscope scanning and infrared spectroscopy. Analysis results show that the basic road performance of asphalt mixture can be significantly improved by adding phosphorus slag into base asphalt. According to the experimental study in this paper, it is concluded that a better modification effect is obtained when phosphorus slag is added into base asphalt with 9% powder oil ratio. Comprehensive analysis shows that the research on phosphorus slag modified asphalt has certain research value, which can solve the problem of water quenched phosphate industrial waste residue and resource reuse, and provides a new way to extend the industrial chain.

-

-

表 1 基质沥青基本技术性质

Table 1. Basic technical properties of matrix asphalt

项目 规范要求 实验结果 实验方法 针入度(25℃)/ 0.1 mm 60~80 65 T0604-2011 延度(15℃)/cm ≥100 104.52 T0605-2011 软化点/℃ ≥46 48.5 T0606-2011 闪点/℃ ≥260 299 T0611-2011 溶解度/% ≥99.5 99.88 T0607-2011 表 2 石灰岩集料筛分结果

Table 2. Sieving results of limestone aggregate

粒径指标/cm 16~13.2 13.2~9.5 9.5~4.75 4.75~2.36 2.36~1.18 1.18~0.6 0.6~0.3 0.3~0.15 0.15~0.075 规范值 表观相对密度/(g·cm-3) 2.732 2.709 2.665 2.718 2.723 2.721 2.694 2.728 2.722 ≥

2.6毛体积相对密度/(g·cm-3) 2.721 2.697 2.658 2.718 - - - - - ≥

2.5吸水率/% 0.42 0.48 0.61 0.69 - - - - - ≤

3.0压碎值/% 19.4 18.6 20.1 - - - - - - ≤

28针片状含量/% 6.1 8.2 6.9 - - - - - - ≤

18+0.075 mm颗粒含量/% 0.42 ≤

1.0表 3 石灰岩粗集料技术指标与要求

Table 3. Technical indicators and requirements of limestone coarse aggregate

各项技术指标 实验结果 规范要求 压碎值/% 18.5 ≤28 针片状含量/% 6.4 ≤18 与沥青粘附性 5级 不小于4级 表观相对密度/(g·cm-3) 2.7162 ≥2.50 吸水率/% 0.4982 ≤3.0 +0.075 mm颗粒含量/% 0.42 ≤1 表 4 矿粉技术指标检测结果

Table 4. Test results of mineral powder technical indicators

各项技术指标 规范要求 实验检测结果 实验方法 含水量,不大于/% 1 0.18 T 0103 烘干法 表观密度,不小于/(t·m-3) 2.50 2.685 T 0352-2000 粒度范围<0.6 mm/% 100 100.0 T 0351-2000 粒度范围<0.15 mm/% 90~100 94.8 T 0351-2000 粒度范围<0.075 mm/% 75~100 86.7 T 0351-2000 外观 无团粒结块 无团粒结块 - 亲水系数 <1 0.7 T 0353-2000 塑性指数/% <4 - T 0354-2000 加热安定性 实测记录 与加热前矿粉

颜色一致T 0355-2000 表 5 AC-13沥青混合料级配设计

Table 5. Gradation design of AC-13 asphalt mixture

方孔筛/mm 通过的质量百分数/% 合成级配 级配上限 级配下限 目标级配 16 100 100 100 100 13.2 96.7 100 90 95 9.5 69.8 85 68 70.5 4.75 40.9 68 38 40.5 2.36 30 50 24 30.5 1.18 20.8 38 15 20.5 0.6 15.4 28 10 15 0.3 12.2 20 7 12 0.15 9.8 15 5 8.5 0.075 6.5 8 4 6 表 6 不同沥青混合料的车辙实验结果

Table 6. Rutting test results of different asphalt mixtures

混合料类型 动稳定度/(次·mm-1) 基质沥青 1001 掺加3%磷渣 2097 掺加5%磷渣 2485 掺加7%磷渣 2988 掺加9%磷渣 3203 掺加11%磷渣 2499 表 7 磷渣改性沥青混合料的浸水马歇尔实验结果

Table 7. Immersion Marshall test results of phosphorus slag modified asphalt mixture

混合料类型 试件浸水

30 min后的

稳定度MS1/

KN试件浸水

48 h后的

稳定度

MS2/kN试件的浸

水残留稳

定度MS0/

%基质 8.6 7.56 87.91 掺加3%磷渣 10.39 9.55 91.92 掺加5%磷渣 10.77 9.78 90.81 掺加7%磷渣 11.01 10.14 92.09 掺加9%磷渣 11.21 10.46 93.31 掺加11%磷渣 10.82 9.99 92.33 -

[1] 王圳, 张均, 陈芳, 等. 贵州省磷矿固体废弃物治理现状与建议[J]. 矿产综合利用, 2019(1):11-15. doi: 10.3969/j.issn.1000-6532.2019.01.003

WANG Z, ZHANG J, CHEN F, et al. Present situation and suggestion of management of phosphate rock solid waste[J]. Multipurpose Utilization of Mineral Resources, 2019(1):11-15. doi: 10.3969/j.issn.1000-6532.2019.01.003

[2] 包明, 吴雄, 杨文, 等. 黄磷渣改性对水泥复合胶凝材料性能的影响[J]. 矿产综合利用, 2019(4):122-125. doi: 10.3969/j.issn.1000-6532.2019.04.026

BAO M, WU X, YANG W, et al. Influence of the modification phosphorus slag on the properties of cement composite cementitious materials[J]. Multipurpose Utilization of Mineral Resources, 2019(4):122-125. doi: 10.3969/j.issn.1000-6532.2019.04.026

[3] 黄安冲. 利用吉安电厂废渣和锰渣制备复合混凝土掺合料的研究[D]. 南昌: 南昌大学, 2015.

HUANG A C. Research on the preparation of composite concrete admixtures using waste slag and manganese slag from Ji'an Power Plant[D]. Nanchang: Nanchang University, 2015.

[4] 王曦林, 程松波, 余剑英, 等. 不同单体接枝SBS改性沥青的性能研究[J]. 石油沥青, 2008(4):26-29. doi: 10.3969/j.issn.1006-7450.2008.04.007

WANG X L, CHENG S B, YU J Y, et al. Study on the performance of different monomers grafted SBS modified asphalt[J]. Petroleum Asphalt, 2008(4):26-29. doi: 10.3969/j.issn.1006-7450.2008.04.007

[5] 薛小刚. 沥青混合料级配优化及配合比设计方法研究[D]. 西安: 长安大学, 2005.

XUE X G. Research on asphalt mixture gradation optimization and mix design method[D]. Xi'an: Chang'an University, 2005.

[6] 孙雅珍, 侯艳妮, 王金昌, 等. 橡胶沥青应力吸收层抗疲劳作用机理研究[J]. 广西大学学报(自然科学版), 2020, 45(1):10-16. doi: 10.13624/j.cnki.issn.1001-7445.2020.0010

SUN Y Z, HOU Y N, WANG J C, et al. Research on anti-fatigue mechanism of rubber asphalt stress absorption layer[J]. Journal of Guangxi University (Natural Science Edition), 2020, 45(1):10-16. doi: 10.13624/j.cnki.issn.1001-7445.2020.0010

[7] 孙吉书, 许宁乾, 李宁利, 等. 沥青基有机膨润土纳米复合材料的作用机理与应用[J]. 硅酸盐通报, 2019, 38(2):530-536+542. doi: 10.16552/j.cnki.issn1001-1625.2019.02.039

SUN J S, XU N Q, LI L N, et al. Mechanism and application of asphalt-based organobentonite nanocomposites[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(2):530-536+542. doi: 10.16552/j.cnki.issn1001-1625.2019.02.039

-

下载:

下载: