Current Situation and Development Trend of Comprehensive Utilization of Zinc Smelting Slag

-

摘要:

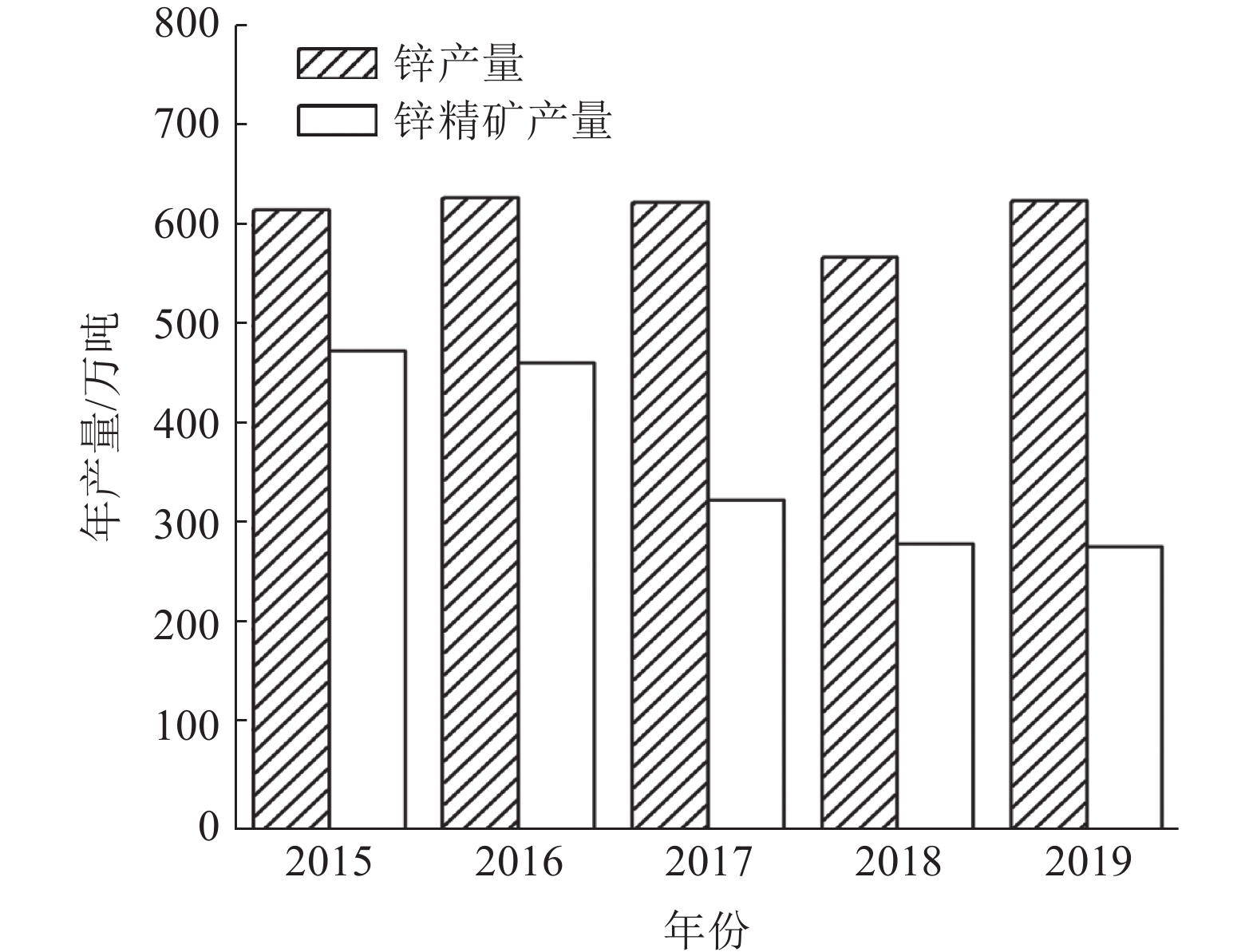

为了顺应国家发展需求,对锌资源的不断开发使高品位矿石日益枯竭,并产生了大量的含锌冶炼渣,且由于锌的生产方式多样,含锌冶炼渣成分及性质各不相同,后续的处理难度也显著提升。含锌冶炼渣的大量堆存不仅会对周围环境造成严重危害,还会导致有价金属资源浪费。本文总结了含锌冶炼渣的危害及现行的利用方式,并着重介绍了回收含锌冶炼渣中有价金属的主要处理工艺的原理、优缺点及研究现状。最后指出了含锌冶炼渣资源化处理技术可加强的研究方向。

Abstract:In order to meet the needs of the national development, the continuous development of zinc resources has increasingly depleted high-grade ore and produced a large amount of zinc smelting slag. Due to the diverse production methods of zinc, the composition and properties of zinc smelting slag are different. The processing difficulty is also significantly increased. Storage of zinc smelting slag will not only cause serious harm to the surrounding environment, but also cause waste of valuable metal resources. This article summarizes the harm of zinc smelting slag and the current utilization methods, and focuses on the principle advantages and disadvantages and research status of the main treatment processes for recovering valuable metals from zinc smelting slag. Finally, it points out the research direction that can be strengthened in the resource treatment technology of zinc smelting slag.

-

Key words:

- Zinc smelting slag /

- Resource utilization /

- Comprehensive utilization

-

-

冶炼分类 冶炼工艺 技术介绍 湿法炼锌 常规浸出法 浮选硫化锌精矿抛入沸腾焙烧炉焙烧后得焙砂,送至中性浸出,浸出后的上清液采用三段锌粉置换法获得硫酸锌溶液,再熔炼出锌锭或合金锌。由于环境保护,节能减排等方面有明显缺陷,2000年以来新冶炼厂很少采用。 热酸浸出法 增添了高酸、高温浸出工艺,有利于浸出过程不溶解的有价金属富集,方便后续回收处理。 氧压直接浸出法(OPL) 选用高压釜,在高温高压和富氧条件下浸出,取消了硫化锌精矿常压浸出、焙烧和制酸过程,能使难以溶解的硫化锌溶解,并以元素硫的方式代替了二氧化硫的生成,削减了对周围环境的危害。 常压富氧浸出法(APOL) 以氧压浸出为工艺基础,采用高温常压,在立式玻璃钢反应器内用废电解液连续浸出硫化锌精矿。 火法炼锌 电炉炼锌 可分为电阻电热竖炉和电弧电阻矿热炉,该工艺以电能为能源,并转化成热能冶炼氧化锌物料,锌挥发后冷凝可得到粗锌产品。 密封鼓风炉炼锌(ISP) 对原料适应性强,能很好处理铅锌难以分选的精矿,但污染较为严重,逐渐被弃用。 竖罐炼锌 主要包括团矿制备、还原蒸馏及锌蒸汽冷凝三部分,该工艺能耗高,且伴生金属回收效果差。 -

[1] 代涛, 陈其慎, 于汶加. 全球锌消费及需求预测与中国锌产业发展[J]. 资源科学, 2015, 37(5):951-960.

DAI T, CHEN Q S, YU W J. Global zinc consumption and demand forecast and development of China's zinc industry[J]. Resources Science, 2015, 37(5):951-960.

[2] 中国资源综合利用年度报告(2014)[R]. 再生资源与循环经济, 2014, 7(10): 3-8.

China annual report on comprehensive utilization of resources(2014)[R]. Recyclable Resources and Cyclular Economy, 2014, 7(10): 3-8.

[3] 郭天立, 高良宾. 当代竖罐炼锌技术述评[J]. 中国有色冶金, 2007(1):5-6. doi: 10.3969/j.issn.1672-6103.2007.01.002

GUO T L, GAO L B. Review on today's zinc vertical retorting technology[J]. China Nonferrous Metallurgy, 2007(1):5-6. doi: 10.3969/j.issn.1672-6103.2007.01.002

[4] 胡丕成. 电炉炼锌工艺[J]. 中国有色冶金, 2018, 47(4):1-3.

HU P C. Zinc smelting process by submerged arc furnace[J]. China Nonferrous Metallurgy, 2018, 47(4):1-3.

[5] 白桦. 密闭鼓风炉炼铅锌[J]. 工程设计与研究, 2005(1):6-9.

BAI H. Lead and zinc smelting in closed blast furnace[J]. Engineering Design and Research, 2005(1):6-9.

[6] 张飞, 曾科. 铅冶炼行业现状及重金属污染防治对策分析[J]. 世界有色金属, 2018(9):1-3. doi: 10.3969/j.issn.1002-5065.2018.09.001

ZHANG F, ZENG K. Analysis of lead smelting industry situation countermeasures for prevention and treatment of heavy metal pollution[J]. World Nonferrous Metal, 2018(9):1-3. doi: 10.3969/j.issn.1002-5065.2018.09.001

[7] 黄兰青, 白堂谋. 锌冶炼技术现状及发展探讨[J]. 企业科技与发展, 2015(5):41-42. doi: 10.3969/j.issn.1674-0688.2015.05.015

HUANG L Q, BAI T M. Discussion on the status and development of zinc smelting technology[J]. Sci-Tech & Development of Enterprise, 2015(5):41-42. doi: 10.3969/j.issn.1674-0688.2015.05.015

[8] 王成彦, 陈永强. 中国铅锌冶金技术状况及发展趋势: 锌冶金[J]. 有色金属科学与工程, 2017, 8(1):1-7.

WANG C Y, CHEN Y Q. Lead and zinc metallurgy technology situation and development treads of China: zinc metallurgy[J]. Nonferrous Metals Science and Engineering, 2017, 8(1):1-7.

[9] 缑明亮, 夏丹. 陕西某锌冶炼厂锌冶炼渣综合利用[J]. 矿产综合利用, 2020(4):147-151. doi: 10.3969/j.issn.1000-6532.2020.04.025

GOU M L, XIA D. Study on comprehensive utilization of zinc smelting slag in a zinc smelter in Shaanxi province[J]. Multipurpose Utilization of Mineral Resources, 2020(4):147-151. doi: 10.3969/j.issn.1000-6532.2020.04.025

[10] 闫亚楠, 晏拥华, 贺深阳. 利用炼锌尾渣生产混凝土路面砖性能研究[J]. 混凝土, 2013(7):121-123. doi: 10.3969/j.issn.1002-3550.2013.07.034

YAN Y N, YAN Y H, HE S Y. Study on performances of the concrete pavement brick from zincilate[J]. Concrete, 2013(7):121-123. doi: 10.3969/j.issn.1002-3550.2013.07.034

[11] 王生辉, 刘荣进, 陈平, 等. 铅锌尾矿和冶炼渣双掺制备复合水泥的试验研究[J]. 水泥工程, 2020(1):21-24.

WANG S H, LIU R J, CHEN P, et al. Experimental study on the preparation of composite cement by combining lead-zinc tailings with smelting slag[J]. Cement Engineering, 2020(1):21-24.

[12] 张深根, 杨健, 刘波, 等. 一种危险固废制备微晶玻璃的方法: 中国, CN201410783923.9 [P]. 2015-03-25.

ZHANG S G, YANG J, LIU B, et al. Method for preparing glass-ceramics from hazardous solid waste: China, CN201410783923.9[P]. 2015-03-25.

[13] 石振武, 杨海东, 宋娟, 等. 利用铅锌废渣制备银修饰纳米复合材料的研究[J]. 稀有金属材料与工程, 2018, 47(7):2257-2261.

SHI Z W, YANG H D, SONG J, et al. Silver modified composite nanomaterials from metallurgical lead and zinc slag[J]. Rare Metal Materials and Engineering, 2018, 47(7):2257-2261.

[14] 王艳君, 潘梦雅, 张择瑞, 等. 锌渣与膏状氨基酸应用于生产复合螯合氨基酸锌的综合利用[J]. 广州化工, 2019, 47(16):71-74. doi: 10.3969/j.issn.1001-9677.2019.16.030

WANG Y J, PAN M Y, ZHANG Z D, et al. Comprehensive utilization of zinc slag and paste-like amino acids for producing complex chelated amino acidic zinc(II) bompounds[J]. Guangzhou Chemical Industry, 2019, 47(16):71-74. doi: 10.3969/j.issn.1001-9677.2019.16.030

[15] 郝晓平, 韩进文, 高志强, 等. 锌冶炼废渣的综合利用[J]. 无机盐工业, 2017, 49(7):55-58.

HAO X P, HAN J W, GAO Z Q, et al. Comprehensive utilization of zinc smelting residue[J]. Inorganic Chemicals Industry, 2017, 49(7):55-58.

[16] 谭聪, 肖筱瑜, 孙伟, 等. 锌行业重金属废渣固化/稳定化应用研究[J]. 矿产与地质, 2019, 33(3):562-566.

TAN C, XIAO X Y, SUN W, et al. Study on solidification/stabilization of heavy metal slag in zinc industry[J]. Mineral Resources and Geology, 2019, 33(3):562-566.

[17] 申坤, 程言君, 高国龙, 等. 某冶炼废渣的稳定化处理[J]. 有色金属工程, 2013, 3(3):45-49. doi: 10.3969/j.issn.2095-1744.2013.03.010

SHEN K, CHENG Y J, GAO G L, et al. Stabilization of a smelting residue[J]. Nonferrous Metals Engineering, 2013, 3(3):45-49. doi: 10.3969/j.issn.2095-1744.2013.03.010

[18] 柴立元, 柯勇, 梁彦杰, 等. 重金属冶炼废渣稳定化/固化处理技术研究进展[C]. 重金属污染防治及风险评价研讨会暨重金属污染防治专业委会学术年会. 长沙: 中国环境科学学会, 2013.

CHAI L Y, KE Y, LIANG Y J, et al. Research advances on stabilization/solidification treatment technology of heavy metal-containing smelting s1ag[C]. Seminar on heavy metal pollution prevention and risk assessment and annual conference of the professional committee on heavy metal pollution prevention and control. Changsha: Chinese Society For Environmental Sciences, 2013.

[19] 赵金艳, 王金生, 郑骥. 有色金属冶炼废渣有价金属湿法回收技术及现状[J]. 矿产综合利用, 2012(4):7-12. doi: 10.3969/j.issn.1000-6532.2012.04.002

ZHAO J Y, WANG J S, ZHENG J. Non-ferrous metal smelting waste slag and valuable metal wet recovery technology and current situation[J]. Multipurpose Utilization of Mineral Resources, 2012(4):7-12. doi: 10.3969/j.issn.1000-6532.2012.04.002

[20] 黄柱成, 蔡江松, 杨永斌, 等. 浸锌渣中有价元素的综合利用[J]. 矿产综合利用, 2002(3):46-49.

HUANG Z C, CAI J S, YANG Y B, et al. Comprehensive recovery of valuable elements from zinc-leaching residue[J]. Multipurpose Utilization of Mineral Resources, 2002(3):46-49.

[21] 朱军, 李维亮, 刘曼博, 等. 锌湿法冶炼渣的污染物分析及综合利用技术[J]. 矿产综合利用, 2020(4):59-65. doi: 10.3969/j.issn.1000-6532.2020.04.009

ZHU J, LI W L, LIU M B, et al. Analysis of contaminants and comprehensive utilization technology of zinc hydrometallurgical slag[J]. Multipurpose Utilization of Mineral Resources, 2020(4):59-65. doi: 10.3969/j.issn.1000-6532.2020.04.009

[22] 赵成, 朱军, 王正民, 等. 重要有色金属冶炼废渣的特征及处理技术[J]. 矿产综合利用, 2019(6):1-6. doi: 10.3969/j.issn.1000-6532.2019.06.001

ZHAO C, ZHU J, WANG Z M, et al. Characteristics and treatment technology of non-ferrousheavy metal smelting slag[J]. Multipurpose Utilization of Mineral Resources, 2019(6):1-6. doi: 10.3969/j.issn.1000-6532.2019.06.001

[23] 王超, 郭宇峰, 杨凌志, 等. 含锌渣尘中有价金属回收利用现状与研究进展[J]. 金属矿山, 2019(3):21-29. doi: 10.19614/j.cnki.jsks.201903003

WANG C, GUO Y F, YANG L Z, et al. Situation and research development of recovery valuable metals inzinc dust and residue[J]. Metal Mine, 2019(3):21-29. doi: 10.19614/j.cnki.jsks.201903003

[24] 何启贤, 周裕高, 覃毅力, 等. 锌浸出渣回转窑富氧烟化工艺研究[J]. 中国有色冶金, 2017, 46(3):49-54. doi: 10.3969/j.issn.1672-6103.2017.03.014

HE Q X, ZHOU Y G, QIN Y L, et al. Study on oxygen-enriched fuming process of zinc leaching residue with rotary kiln[J]. China Nonferrous Metallurgy, 2017, 46(3):49-54. doi: 10.3969/j.issn.1672-6103.2017.03.014

[25] 张帆, 程楚, 王海北, 等. 铅银渣综合利用研究现状[J]. 中国资源综合利用, 2015, 33(3):37-41. doi: 10.3969/j.issn.1008-9500.2015.03.023

ZHANG F, CHENG C, WANG H B, et al. Research status of lead-silver residue comprehensive utilization[J]. China Resources Comprehensive Utilization, 2015, 33(3):37-41. doi: 10.3969/j.issn.1008-9500.2015.03.023

[26] 孙明生. 铁闪锌矿湿法冶炼浸出渣的资源综合利用无害化处理技术与应用[J]. 中国资源综合利用, 2019, 37(9):53-56. doi: 10.3969/j.issn.1008-9500.2019.09.016

SUN M S. Technology and application of the innocent treatment and comprehensive utilization of the iron sphalerite hydrometallurgical leaching residue[J]. China Resources Comprehensive Utilization, 2019, 37(9):53-56. doi: 10.3969/j.issn.1008-9500.2019.09.016

[27] 郭建荣, 荆旭冬, 周蓉. 烟化炉液态渣连续吹炼应用实践[J]. 铜业工程, 2017(3):68-70. doi: 10.3969/j.issn.1009-3842.2017.03.018

GUO J R, JING X D, ZHOU R. The application and practice on continuous smelting of liquid slag in fuming furnace[J]. Copper Engineering, 2017(3):68-70. doi: 10.3969/j.issn.1009-3842.2017.03.018

[28] 杨淑霞. 韩国温山锌冶炼厂利用奥斯麦特技术处理锌渣情况介绍[J]. 有色冶金设计与研究, 2001(1):18-24. doi: 10.3969/j.issn.1004-4345.2001.01.005

YANG S X. Introduction of Onsan zinc smelter in South Korea using Osmelt technology to treat zinc slag[J]. Nonferrous Metals Engineering & Research, 2001(1):18-24. doi: 10.3969/j.issn.1004-4345.2001.01.005

[29] 董铁红. 利用旋涡炉工艺处理锌冶炼残渣[J]. 节能, 2009, 28(6):37-38. doi: 10.3969/j.issn.1004-7948.2009.06.013

DONG T H. Treating zinc smelted residue by vortex furnace technics[J]. Energy Conservation, 2009, 28(6):37-38. doi: 10.3969/j.issn.1004-7948.2009.06.013

[30] 高丽霞, 戴子林, 张魁芳, 等. 从湿法锌冶炼废渣中提取银和铅[J]. 有色金属(冶炼部分), 2018(5):29-32.

GAO L X, DAI Z L, ZHANG K F, et al. Extraction of sliver and lead from slag of zinc hydrometallurgy[J]. Nonferrous Metals(Extractive Metallurgy), 2018(5):29-32.

[31] 郭翠香, 赵由才. 从含铅锌烟尘中综合回收铅和锌[J]. 化工环保, 2008(1):77-80. doi: 10.3969/j.issn.1006-1878.2008.01.019

GUO C X, ZHAO Y C. Recovery of Pb and Zn from smoke dust[J]. Environmental Protection of Chemical Industry, 2008(1):77-80. doi: 10.3969/j.issn.1006-1878.2008.01.019

[32] 石振武, 杨守洁, 薛群虎. 从铅锌废渣中氨浸锌试验研究[J]. 湿法冶金, 2019, 38(4):271-275. doi: 10.13355/j.cnki.sfyj.2019.04.004

SHI Z W, YANG S J, XUE Q H. Recovery of zinc from lead-zinc slag using ammonia[J]. Hydrometallurgy of China, 2019, 38(4):271-275. doi: 10.13355/j.cnki.sfyj.2019.04.004

[33] 郭朝晖, 程义, 邱冠周, 等. Pb/Zn冶炼废渣中有价金属生物浸出条件优化[J]. 中国有色金属学报, 2008(5):923-928. doi: 10.3321/j.issn:1004-0609.2008.05.029

GUO Z H, CHENG Y, QIU G Z, et al. Optimization on bioleaching of metal values from Pb/Zn smelting slag[J]. The Chinese Journal of Nonferrous Metals, 2008(5):923-928. doi: 10.3321/j.issn:1004-0609.2008.05.029

[34] Jiang G, Peng B, Liang Y, et al. Recovery of valuable metals from zinc leaching residue by sulfate roasting and water leaching[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(5):1180-1187. doi: 10.1016/S1003-6326(17)60138-9

[35] 肖军辉, 王进明, 傅开彬, 等. 选冶联合工艺回收云南某铅锌尾渣中Pb和Zn[J]. 金属矿山, 2017(6):192-196. doi: 10.3969/j.issn.1001-1250.2017.06.038

XIAO J H, WANG J M, FU K B, et al. Recovery of Pb and Zn from Pb-Zn tailings in Yunnan by beneficiation metallurgy combined process[J]. Metal Mine, 2017(6):192-196. doi: 10.3969/j.issn.1001-1250.2017.06.038

[36] Liu W, Han J W, Qin W Q, et al. Reduction roasting of high iron bearing zinc calcine for recovery of zinc and iron[J]. Cnandian Metallurgical Quarterly, 2014, 53(2):176-182. doi: 10.1179/1879139513Y.0000000113

[37] Banza A N, Gock E. Mechanochemical processing of chrysocolla with sodium sulphide[J]. Minerals Engineering, 2003, 16(12):1349-1354. doi: 10.1016/j.mineng.2003.08.010

[38] 闵小波, 陈杰, 梁彦杰, 等. 含锌废渣水热硫化浮选回收的工艺研究[J]. 有色金属科学与工程, 2013, 4(6):1-7. doi: 10.13264/j.cnki.ysjskx.2013.06.011

MIN X B, CHEN J, LIANG Y J, et al. Recovery of zinc from sludge by a combination of hydrothermal sulfidation and flotation[J]. Nonferrous Metals Science and Engineering, 2013, 4(6):1-7. doi: 10.13264/j.cnki.ysjskx.2013.06.011

[39] 曾懋华, 奚长生, 彭翠红, 等. 浮选含铅废渣富集铅的研究[J]. 有色金属(选矿部分), 2004(1):12-15.

ZENG M H, XI C S, PENG C H, et al. Study on flotation lead from waste residue of lead[J]. Nonferrous Metals (Mineral Processing Section), 2004(1):12-15.

[40] Li Y, Wang J, Chang W, et al. Sulfidation roasting of low grade lead-zinc oxide ore with elemental sulfur[J]. Minerals Engineering, 2010, 23(7):563-566. doi: 10.1016/j.mineng.2010.01.004

[41] Zheng Y X, Liu W, Qin W Q, et al. Improvement for sulphidation roasting and its application to treat lead smelter slag and zinc recovery[J]. Canadian Metallurgical Quarterly, 2015, 54(1):92-100. doi: 10.1179/1879139514Y.0000000155

[42] Han J, Liu W, Wang D, et al. Selective sulfidation of lead smelter slag with pyrite and flotation behavior of synthetic ZnS[J]. Metallurgical and Materials Transactions. B, Process Metallurgy and Materials Processing Science, 2016, 47(4):2400-2410. doi: 10.1007/s11663-016-0693-y

-

下载:

下载: