Experimental Research on Recovery of Fluorite from a Polymetallic Mine Tailing in Inner Mongolia

-

摘要:

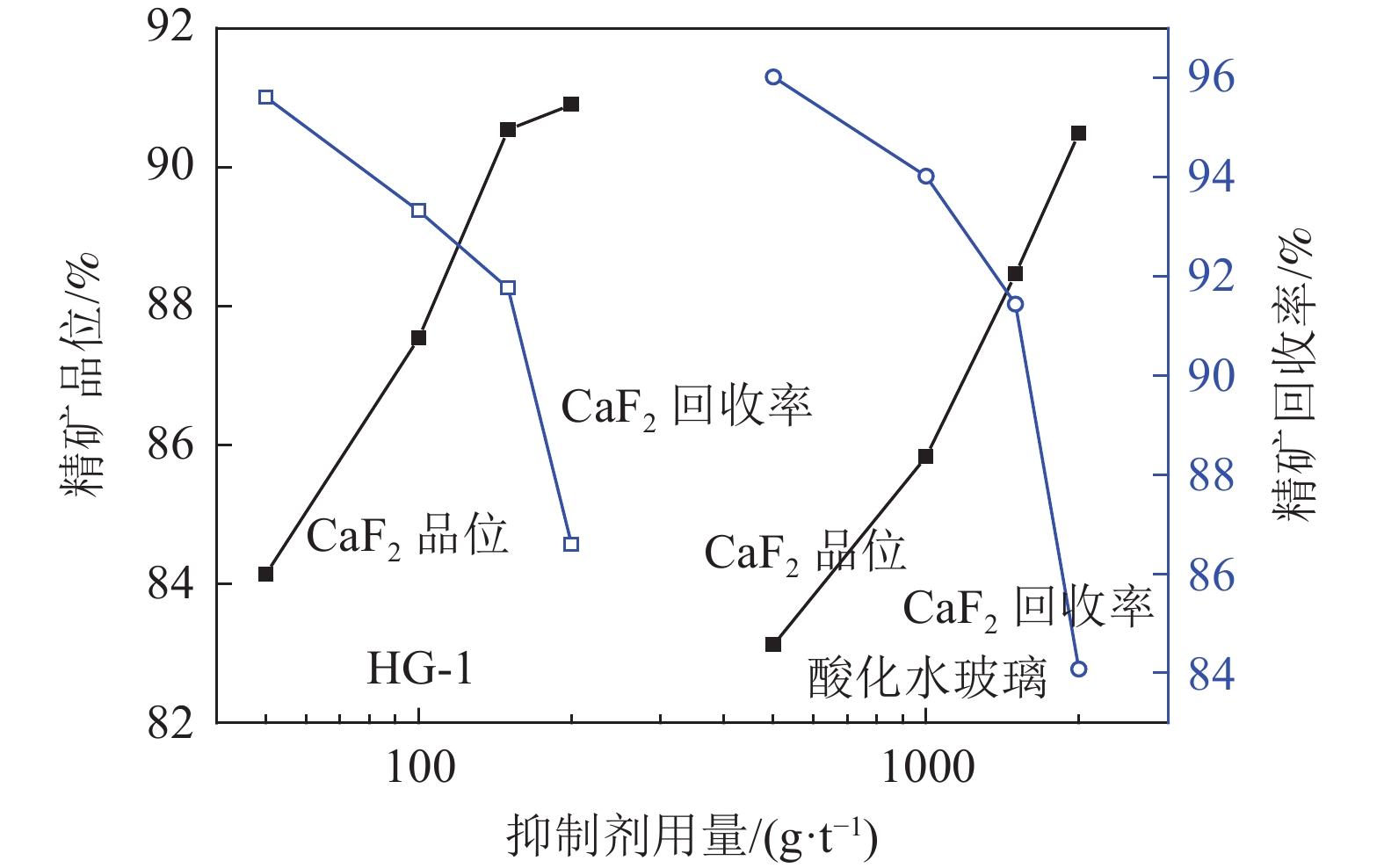

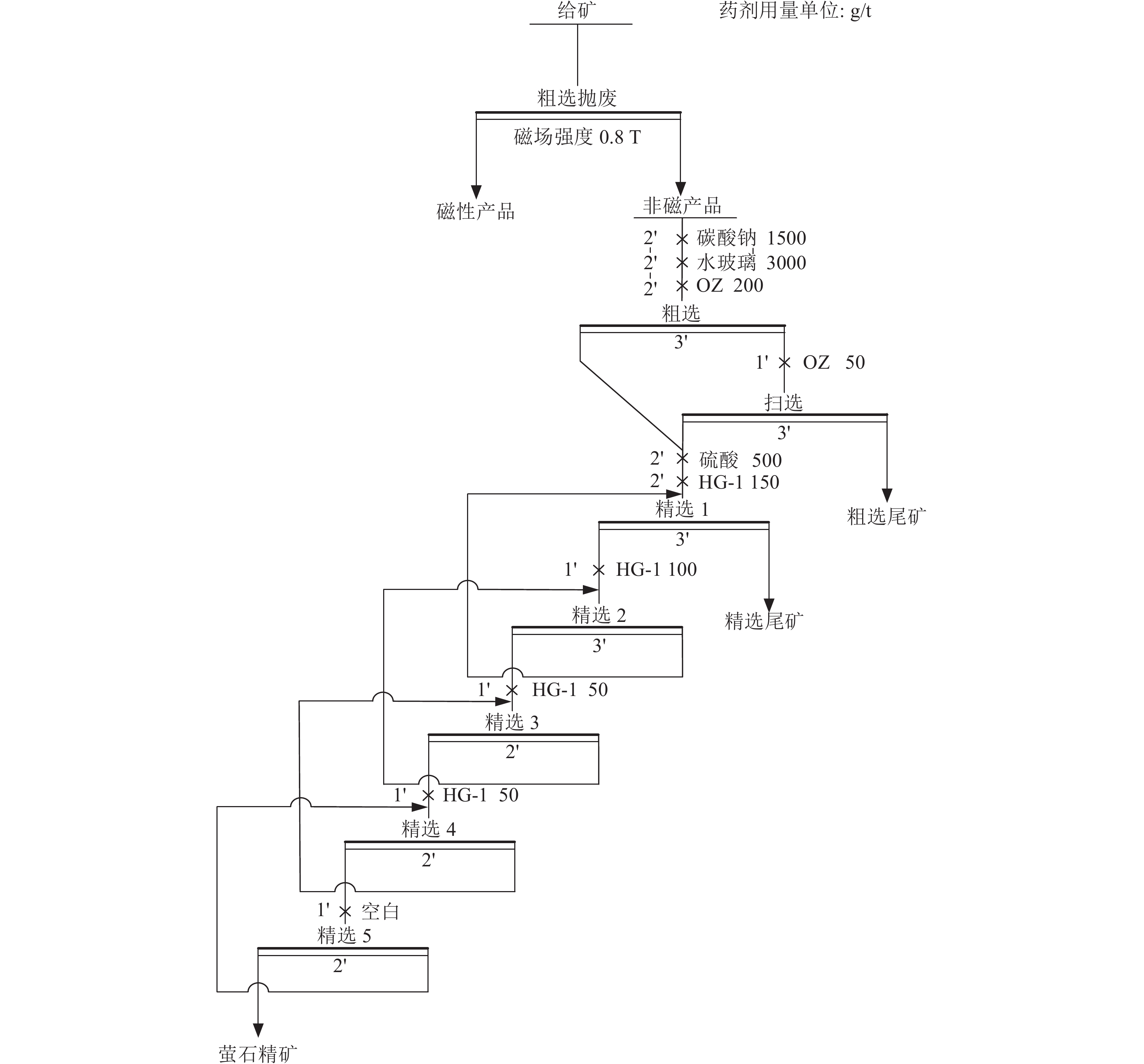

内蒙古某多金属矿浮选尾矿中含有萤石资源,由于受前期钨锡浮选药剂和矿石嵌布特性的影响,萤石浮选精矿品位最高为92%,回收率30%左右,尾矿中萤石资源未能有效回收。本研究通过预先磁选抛废提高萤石入选品位,采用有机抑制剂HG-1代替酸化水玻璃,在原料CaF2品位17.65%的条件下,获得CaF2品位97.26%,回收率63.15%的高品质萤石精矿,实现了该尾矿中萤石资源的综合回收。

Abstract:Flotation tailings of a polymetallic mine in Inner Mongolia contain fluorite resources. Due to the influence of the tungsten-tin flotation reagent and the ore embedded characteristics in the early stage, the fluorite flotation concentrate grade is up to 92%, and the recovery is about 30%. The fluorite resources in the tailings were not effectively recovered. In this study, the beneficiation feed grade of fluorite was improved by waste disposal with pre-magnetic separation, and organic depressor HG-1 was used instead of acidified water glass. Under the condition of original ore CaF2 grade of 17.65%, the fluorite concentrate with CaF2 grade of 97.26% and recovery of 63.15% was obtained, which realized the comprehensive recovery of fluorite resources in tailings.

-

-

表 1 矿样多元素分析结果/%

Table 1. Results of multi-element analysis of fluorite

CaF2 Cu Pb Zn As Sn Fe Al2O3 SiO2 WO3 CaO Bi MgO K2O 17.85 0.005 0.029 0.033 0.18 0.20 8.16 7.58 39.34 0.028 16.47 0.022 2.84 2.45 表 2 矿样磁性分析结果

Table 2. Results of magnetic analysis of fluorite

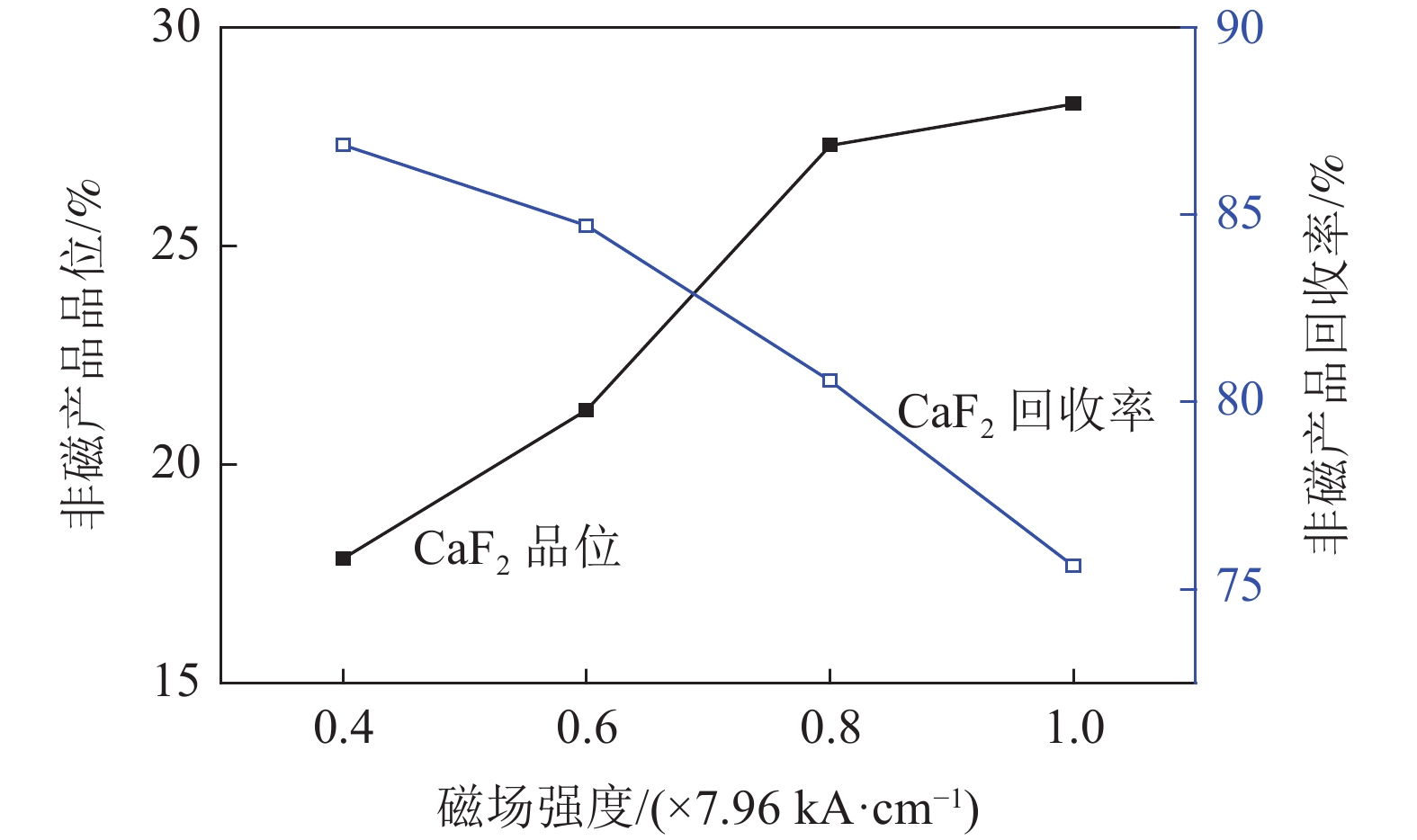

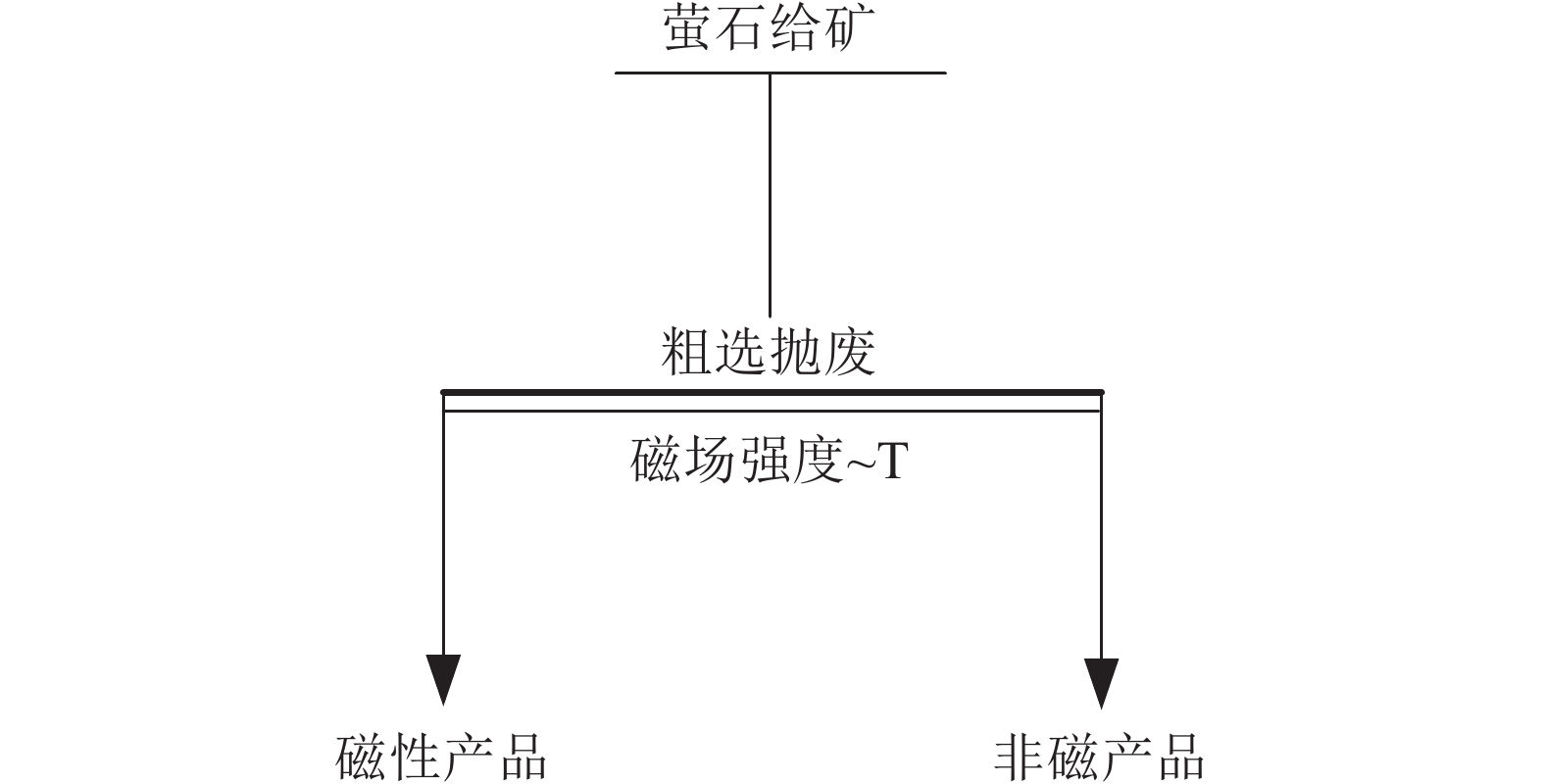

磁选产物 产率/% CaF2品位/% 分布率/% 累计品位/% 累计分布率/% 矿物种类 0~340 10.73 16.75 10.16 17.69 100.00 含磁铁矿萤石、钙铁榴石、角闪石、绿泥石 340~550 20.50 4.09 4.74 17.80 89.84 钙铁榴石、黑云母、绿帘石、角闪石 550~760 20.15 8.33 9.49 21.89 85.10 钙铝榴石、绿帘石、透辉石、符山石 760~970 9.93 8.12 4.56 27.52 75.61 符山石、钙铝榴石、白云母 970~1330 5.81 18.36 6.03 32.50 71.05 符山石、白云母 非磁产品 32.86 35.00 65.01 35.00 65.01 萤石、方解石、石英、长石 合计 100.00 17.69 100.00 - - - 表 3 全流程实验结果

Table 3. Results of whole test

产品名称 产率/% CaF2品位/% CaF2回收率/% 磁性产品 47.84 7.18 19.46 粗选尾矿 32.99 3.31 6.19 精选尾矿 7.71 25.64 11.20 萤石精矿 11.46 97.26 63.15 给矿 100.00 17.65 100.00 -

[1] 崔瑞, 王旭, 魏骞, 等. 湖北某重晶石-萤石型矿综合利用研究[J]. 矿产综合利用, 2019(2):70-74. doi: 10.3969/j.issn.1000-6532.2019.02.014

CUI R, WANG X, WEI Q, et al. Study on comprehensive utilization of a barite-fluorite ore in Hubei province[J]. Multipurpose Utilization of Mineral Resources, 2019(2):70-74. doi: 10.3969/j.issn.1000-6532.2019.02.014

[2] 曾小波, 印万忠. 共伴生型萤石矿浮选研究进展与展望[J]. 矿产综合利用, 2021(1):1-7. doi: 10.3969/j.issn.1000-6532.2021.01.001

ZENG X B, YIN W Z. Resesrch progress and prospect of flotation of assou ciated fluorite minerdls[J]. Multipurpose Utilization of Mineral Resources, 2021(1):1-7. doi: 10.3969/j.issn.1000-6532.2021.01.001

[3] 曹钊, 屈奇奇, 曹永丹, 等. 不同类型萤石矿浮选工艺技术现状与进展[J]. 金属矿山, 2017, 07(7):14-18. doi: 10.3969/j.issn.1001-1250.2017.07.002

CAO Z, QU Q Q, CAO Y D, et al. Status and development on flotation process technology f different types of fluorite ores[J]. Metal Mine, 2017, 07(7):14-18. doi: 10.3969/j.issn.1001-1250.2017.07.002

[4] 汤家焰, 王文才, 祝雯. 白云鄂博尾矿中萤石浮选工艺研究[J]. 化工矿物与加工, 2018, 47(9):22-26. doi: 10.16283/j.cnki.hgkwyjg.2018.09.007

TANG J Y, WANG W C, ZHU W. Study on flotation technology for fluorite in Baiyunebo tailings[J]. Industrial Minerals & Processing, 2018, 47(9):22-26. doi: 10.16283/j.cnki.hgkwyjg.2018.09.007

[5] 宁江峰, 李茂林, 崔瑞, 等. ZnSO4•7H2O与水玻璃组合抑制剂对萤石、方解石浮选分离的影响[J]. 矿产综合利用, 2020(6):186-192. doi: 10.3969/j.issn.1000-6532.2020.06.031

NING J F, LI M L, CUI R, et al. Effect of ZnSO4•7H2O and sodium silicate as combination inhibitors on flotation separation of fluorite and calcite[J]. Multipurpose Utilization of Mineral Resources, 2020(6):186-192. doi: 10.3969/j.issn.1000-6532.2020.06.031

[6] 马隆飞, 廖寅飞, 贺玉程, 等. 赣州某萤石尾矿浮选柱分选实验研究[J]. 矿产综合利用, 2019(2):89-93. doi: 10.3969/j.issn.1000-6532.2019.02.018

MA L F, LIAO Y F, HE Y C, et al. Experimental study on flotation column separation of a fluorite tailings in Ganzhou[J]. Multipurpose Utilization of Mineral Resources, 2019(2):89-93. doi: 10.3969/j.issn.1000-6532.2019.02.018

-

下载:

下载: