Process Mineralogy of Molybdenum Ore with High Oxidation Rate in Sandaozhuang Mining Area

-

摘要:

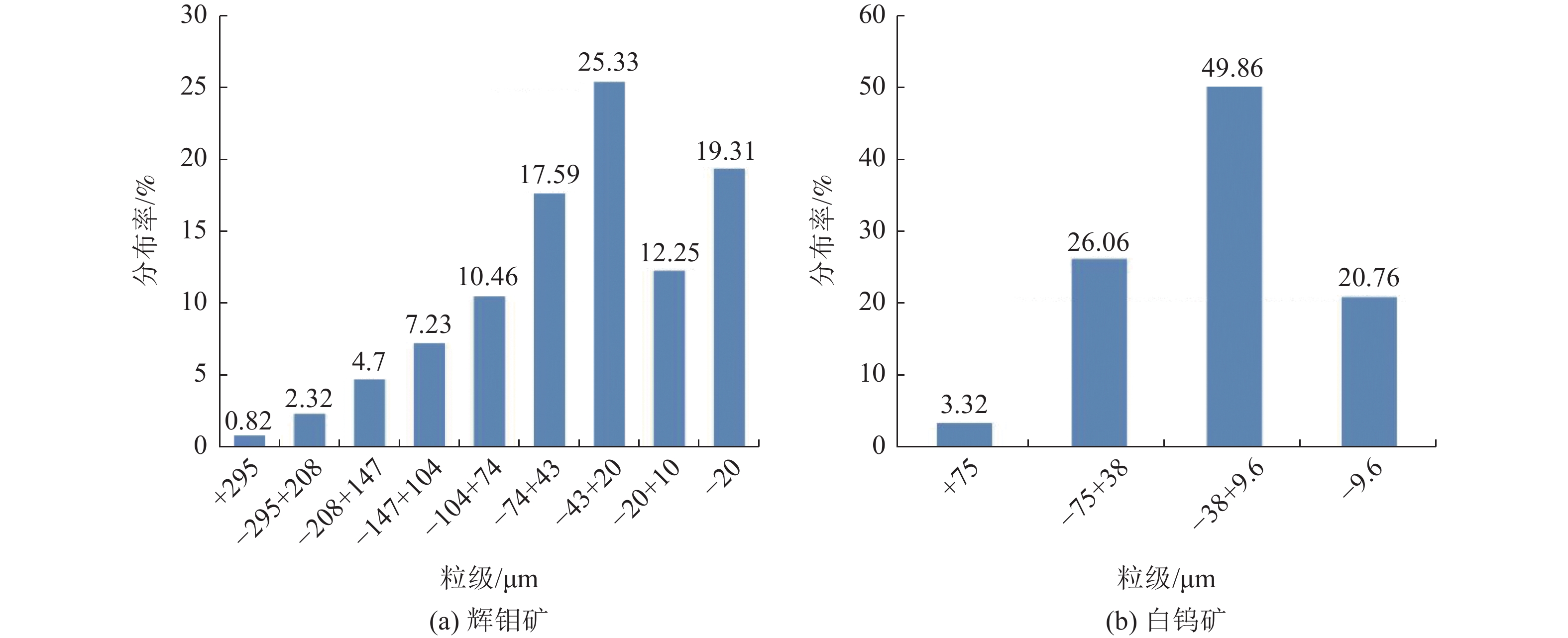

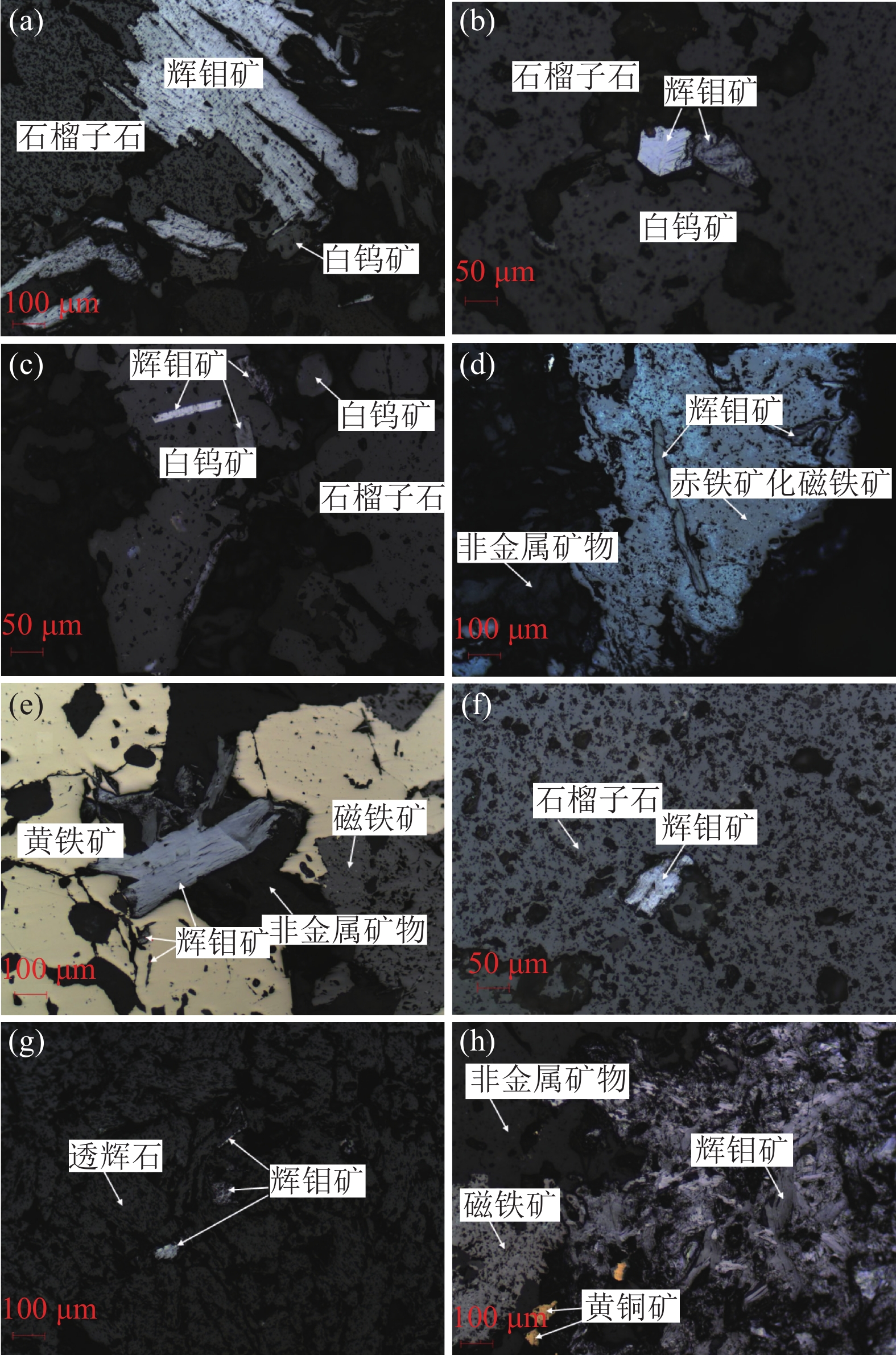

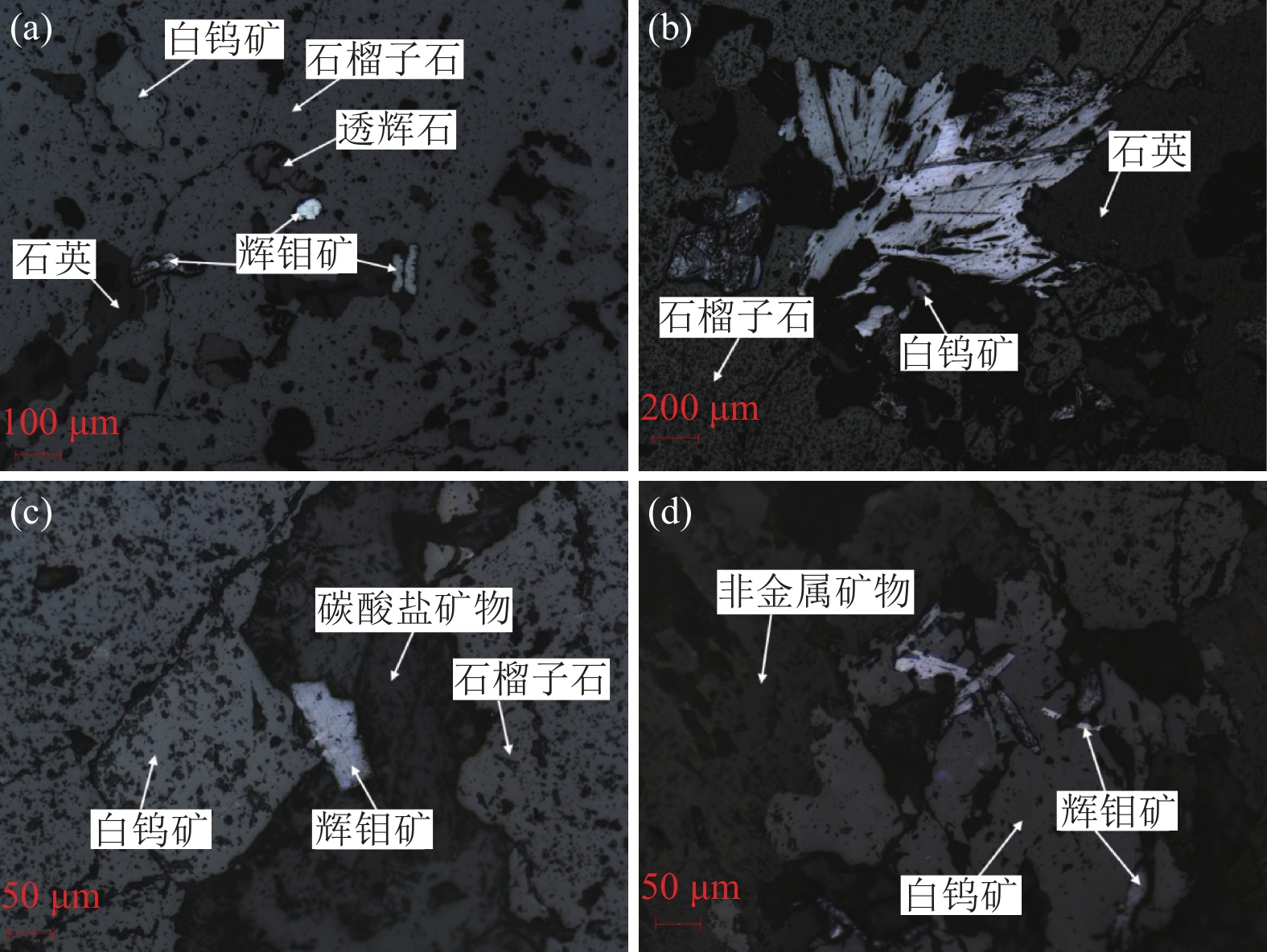

这是一篇工艺矿物学领域的论文。本文利用化学多元素分析、化学物相分析、光学显微镜及矿物参数自动分析系统(MLA)等综合手段,对三道庄矿区高氧化率钼矿石的矿石化学成分、矿物组成、钼和钨的赋存状态以及目的矿物的嵌布特征等影响钼回收的矿物学因素进行了系统的工艺矿物学研究。结果表明,矿石中Mo含量为 0.06%,WO3含量0.10%;矿石中主要金属矿物为黄铁矿、磁铁矿、辉钼矿、白钨矿和黄铜矿,非金属矿物主要为石榴子石、石英、透辉石以及蚀变形成的角闪石,并含有少量的碳酸盐矿物、斜长石、磷灰石、萤石以及蚀变形成的绿帘石;原矿钼物相分析表明,原矿中硫化钼占比为72.13%,氧化钼占比为27.87%,氧化钼的载体矿物主要为白钨矿,该部分钼将随钨的回收而回收,所以会影响钼精矿的回收率;矿石中铜的含量虽然较低(为0.016%),但有部分黄铜矿可浮性较好,会使钼精矿中铜含量超标,所以铜抑制剂的选择和流程结构的确定也是该矿石选矿回收关注的焦点。

Abstract:This is an essay in the field of process mineralogy. By means of chemical multi-element analysis, chemical phase analysis, optical microscope and automatic mineral parameter analysis system (MLA), the systematic research on process mineralogy of the molybdenum ore with high oxidation rate in Sandaozhuang mining area has been done in this study, which mainly include mineralogical factors affecting molybdenum recovery, such as ore chemical composition, mineral composition, occurrence state of molybdenum and tungsten and embedding characteristics of target minerals. The results show that the content of Mo in the ore is 0.06%, and the content of WO3 in the ore is 0.10%. The main metal minerals in the ore are pyrite, magnetite, molybdenite, scheelite and chalcopyrite. Nonmetallic minerals are mainly garnet, quartz, diopside and amphibole formed by alteration, and contain a small number of carbonate minerals, plagioclase, apatite, fluorite and epidote formed by alteration. The phase analysis of molybdenum in the raw ore shows that the proportion of molybdenum sulfide in the raw ore is 72.13%, and the proportion of molybdenum oxide is 27.87%. The carrier mineral of molybdenum oxide is mainly scheelite. This part of molybdenum will be recovered with the recovery of tungsten, so it will affect the recovery rate of molybdenum concentrate. Although the Cu content in the ore is low (0.016%), some chalcopyrite has good floatability, which will make the copper content in molybdenum concentrate exceed the standard. Therefore, the selection of copper inhibitors and the determination of process structure are also the focus of the beneficiation and recovery of the ore.

-

-

表 1 原矿多元素分析结果 /%

Table 1. Element analysis results of raw ore

Mo WO3 Cu Pb Zn S TFe Mn P TiO2 SiO2 TC 0.06 0.10 0.016 0.0023 0.0086 1.53 13.20 1.47 0.14 0.28 40.36 0.77 Al2O3 CaO MgO Ni As* Au* Ag* K2O Na2O LOI Co Bi 3.67 21.60 1.81 0.0045 0.0001 0.09 1.00 0.24 0.22 3.53 0.0034 0.0003 *单位为:g/t。 表 2 原矿钼物相分析结果

Table 2. Iron chemical phase analysis results of the ore

名 称 硫化钼中钼 氧化钼中钼 总计 含量/% 0.044 0.017 0.061 分布率/% 72.13 27.87 100.00 表 3 原矿钨物相分析结果

Table 3. Iron chemical phase analysis results of the ore

名 称 白钨矿中WO3 钨华中WO3 黑钨矿中WO3 总计 含量/% 0.112 0.01 0.0016 0.1236 占有率/% 90.62 8.09 1.29 100.00 表 4 矿石中主要矿物组成及含量/%

Table 4. Main minerals composition and contents of the ore

辉钼矿 白钨矿 石榴子石 石英 透辉石 磁铁矿 斜长石 角闪石 黄铁矿 碳酸盐矿物 0.11 0.16 59.11 11.16 7.10 1.34 2.38 6.26 2.85 4.96 磷灰石 绿泥石 萤石 钾长石 褐铁矿 黑云母 白云母 榍石 黄铜矿 辉铜矿 0.47 1.50 0.73 0.97 0.37 0.15 0.14 0.19 0.04 微量 表 5 辉钼矿能谱分析结果/%

Table 5. Energy spectrum analysis results of molybdenite

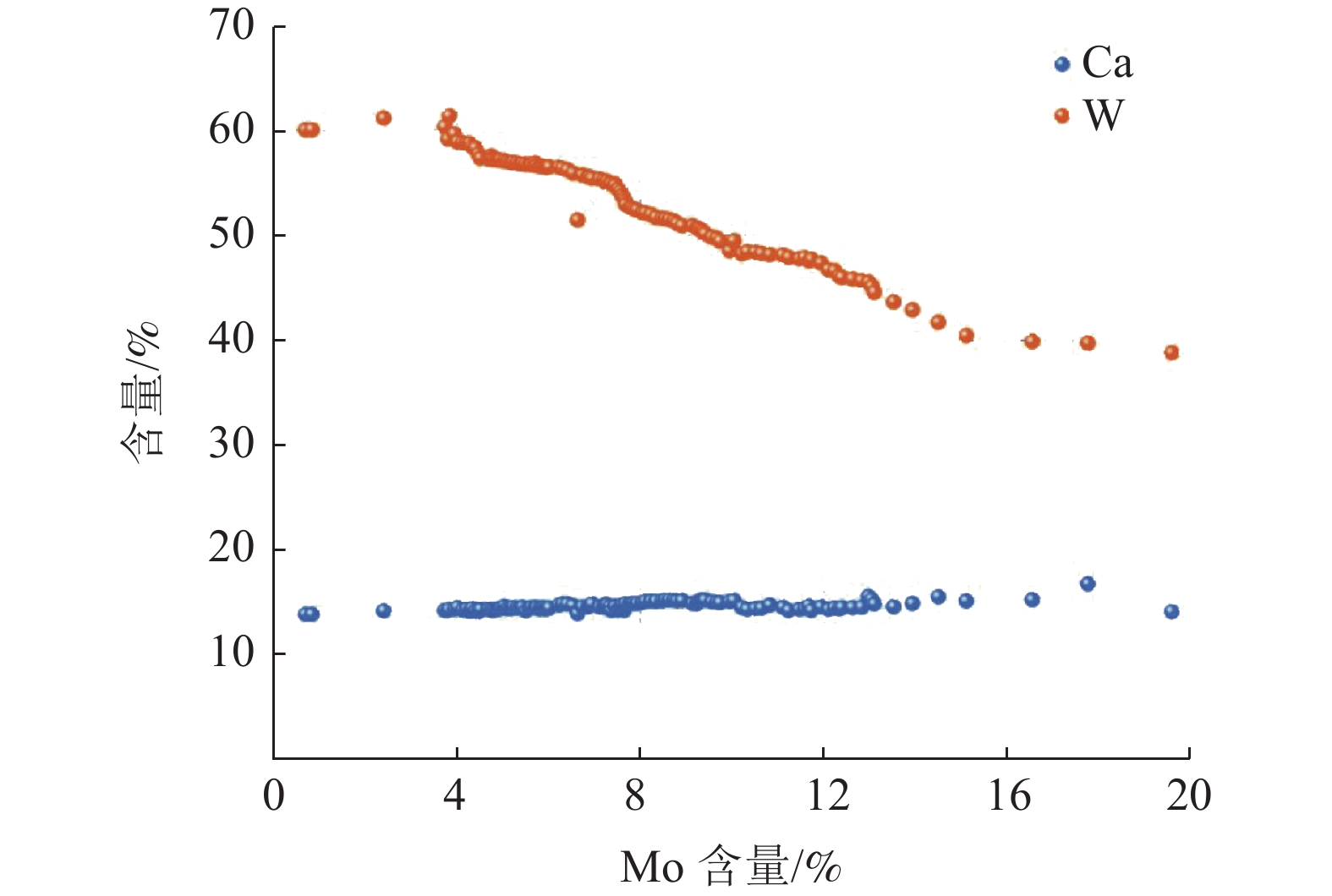

序号 Mo S O 1 59.14 39.35 1.50 2 59.83 38.72 1.45 3 59.63 38.64 1.73 4 59.22 39.24 1.54 5 59.31 39.74 0.95 6 60.17 38.81 1.02 平均 59.55 39.08 1.37 表 6 白钨矿能谱分析结果/%

Table 6. Energy spectrum analysis results of scheelite

序号 O Mo Ca W 1 25.76 17.78 16.76 39.71 2 23.00 6.75 14.56 55.69 3 26.52 13.06 15.28 45.13 4 26.13 11.60 14.44 47.83 5 26.47 9.96 15.09 48.49 6 28.26 14.51 15.55 41.68 7 24.55 7.69 14.87 52.89 8 25.31 10.05 15.19 49.45 9 27.99 6.64 13.94 51.43 10 25.91 12.99 15.59 45.51 …… …… …… …… …… 120 27.48 9.01 13.12 50.39 平均 25.80 8.97 14.50 50.82 因数据过多,只列举部分数据 表 7 辉钼矿和白钨矿与其他矿物连生关系/%

Table 7. Intergrowth relationship between molybdenite and scheelite and other minerals

矿物名称 石英 斜长石 石榴子石 碳酸盐矿物 钾长石 萤石 绿泥石 辉钼矿 1.28 0.05 2.66 0.79 0.15 0.16 1.04 白钨矿 1.64 0.43 7.21 0.92 0.03 0.43 0.32 矿物名称 透辉石 角闪石 磷灰石 榍石 黑云母 帘石 磁铁矿 辉钼矿 0.01 4.31 0.01 0.00 0.03 0.30 0.64 白钨矿 1.70 4.09 0.27 0.08 0.00 0.23 0.06 矿物名称 褐铁矿 黄铁矿 辉钼矿 白钨矿 钼钙矿 其他 自由边长 辉钼矿 0.38 1.53 0.00 0.51 0.00 0.08 86.05 白钨矿 0.27 0.04 0.34 0.00 0.18 0.44 81.33 -

[1] 张亮, 杨卉芃, 冯安生, 等. 全球钼矿资源现状及市场分析[J]. 矿产综合利用, 2019(3):11-16. ZHANG L, YANG H P, FENG A S, et al. Study on general situation and analysis of supply and demand of global molybdenum resource[J]. Multipurpose Utilization of Mineral Resources, 2019(3):11-16.

ZHANG L, YANG H P, FENG A S, et al. Study on general situation and analysis of supply and demand of global molybdenum resource[J]. Multipurpose Utilization of Mineral Resources, 2019(3): 11-16.

[2] 陈丽娟, 李治杭, 姚辉, 等. 辉钼矿浮选药剂研究进展[J]. 现代矿业, 2022, 38(2):19-23+27. CHEN L J, LI Z H, YAO H, et al. Research progress of molybdenite flotation reagents[J]. Modern Mining, 2022, 38(2):19-23+27.

CHEN L J, LI Z H, YAO H, et al. Research progress of molybdenite flotation reagents[J]. Modern Mining, 2022, 38(2): 19-23+27.

[3] 刘翠华. 钼矿石的物相分析及其氧化率[J]. 山西冶金, 2018, 41(2):8-10+14. LIU C H. Phase analysis and oxidation ratio for molybdenum ores[J]. Shanxi Metallurgy, 2018, 41(2):8-10+14.

LIU C H. Phase analysis and oxidation ratio for molybdenum ores[J]. Shanxi Metallurgy, 2018, 41(2): 8-10+14.

[4] 刘明实, 万选志, 刘子龙, 等. 某高氧化率铜矿石的选矿实验研究[J]. 矿产综合利用, 2019(6):24-27. LIU M S, WAN X Z, LIU Z L, et al. Experimental study on beneficiation of the high mud and high oxidation rate copper ore[J]. Multipurpose Utilization of Mineral Resources, 2019(6):24-27.

LIU M S, WAN X Z, LIU Z L, et al. Experimental study on beneficiation of the high mud and high oxidation rate copper ore[J]. Multipurpose Utilization of Mineral Resources, 2019(6): 24-27.

[5] 李国尧. 某高氧化率铜矿石浮选实验[J]. 现代矿业, 2017, 33(12):102-104. LI G Y. Flotation test on high oxidation copper ore[J]. Modern Mining, 2017, 33(12):102-104. doi: 10.3969/j.issn.1674-6082.2017.12.026

LI G Y. Flotation test on high oxidation copper ore[J]. Modern Mining, 2017, 33(12): 102-104. doi: 10.3969/j.issn.1674-6082.2017.12.026

[6] 王伊杰, 文书明, 刘丹, 等. 云南某高氧化率混合铜矿石选矿实验[J]. 现代矿业, 2013, 29(5):20-22. WANG Y J, WEN S M, LIU D, et al. Experimental research on beneficiation of a Yunnan mixed copper ore with a high oxidation rate[J]. Modern Mining, 2013, 29(5):20-22.

WANG Y J, WEN S M, LIU D, et al. Experimental research on beneficiation of a Yunnan mixed copper ore with a high oxidation rate[J]. Modern Mining, 2013, 29(5): 20-22.

[7] 张成强, 李洪潮, 张颖新, 等. 我国复杂难选钼矿资源选矿技术进展[J]. 中国矿业, 2009, 18(10):64-66+86. ZHANG C Q, LI H C, ZHANG Y X, et al. Progress in China's beneficiation technology for complex refractory molybdenum ore[J]. Modern Mining, 2009, 18(10):64-66+86.

ZHANG C Q, LI H C, ZHANG Y X, et al. Progress in China's beneficiation technology for complex refractory molybdenum ore[J]. Modern Mining, 2009, 18(10): 64-66+86.

[8] 张文, 田承涛, 翁孝卿, 等. 矿物解离分析系统在磷石膏工艺矿物学研究中的应用[J]. 矿产综合利用, 2022(1):205-210. ZHANG W, TIAN C T, WENG X Q, et al. Research on the process mineralogy of phosphogypsum using mineral liberation analysis system[J]. Multipurpose Utilization of Mineral Resources, 2022(1):205-210.

ZHANG W, TIAN C T, WENG X Q, et al. Research on the process mineralogy of phosphogypsum using mineral liberation analysis system[J]. Multipurpose Utilization of Mineral Resources, 2022(1): 205-210.

[9] 秦玉芳, 马莹, 李娜, 等. 白云鄂博尾矿稀土的工艺矿物学研究[J]. 矿冶, 2021, 30(6):120-126. QIN Y F, MA Y, LI N, et al. Study on the process mineralogy of rare earth in Bayan Obo tailings[J]. Mining and Metallurgy, 2021, 30(6):120-126.

QIN Y F, MA Y, LI N, et al. Study on the process mineralogy of rare earth in Bayan Obo tailings[J]. Mining and Metallurgy, 2021, 30(6): 120-126.

[10] 赵玉卿, 应永朋, 熊艳, 等. BPMA在某低品位铌钽矿工艺矿物学研究中的应用[J]. 矿产综合利用, 2021(5):129-134. ZHAO Y Q, YING Y P, XIONG Y, et al. Application of BPMA in process mineralogy of a low-grade Nb-Ta ore[J]. Multipurpose Utilization of Mineral Resources, 2021(5):129-134.

ZHAO Y Q, YING Y P, XIONG Y, et al. Application of BPMA in process mineralogy of a low-grade Nb-Ta ore[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 129-134.

[11] 傅开彬, 徐信, 侯普尧, 等. 朝鲜某隐晶质石墨工艺矿物学及可浮性研究[J]. 金属矿山, 2021(3):148-152. FU K B, XU X, HOU P Y, et al. Study on process mineralogy and floatability of a cryptocrystalline graphite in North Korea[J]. Metal Mine, 2021(3):148-152. doi: 10.19614/j.cnki.jsks.202103021

FU K B, XU X, HOU P Y, et al. Study on process mineralogy and floatability of a cryptocrystalline graphite in North Korea[J]. Metal Mine, 2021(3): 148-152. doi: 10.19614/j.cnki.jsks.202103021

[12] 刘月东, 刘凤泽, 王新富, 等. 滇西北羊拉铜矿床 3175 m中段铜矿石和构造岩地球化学特征及地质意义[J]. 有色金属(矿山部分), 2022, 74(1):56-67. LIU Y D, LIU F Z, WANG X F, et al. Geochemical characteristics of copper ore and tectonite in the underground tunnel 3175 m section from Yangla copper deposit in northwest Yunnan and their geological implications[J]. Nonferrous Metals(Mining Section), 2022, 74(1):56-67.

LIU Y D, LIU F Z, WANG X F, et al. Geochemical characteristics of copper ore and tectonite in the underground tunnel 3175 m section from Yangla copper deposit in northwest Yunnan and their geological implications[J]. Nonferrous Metals(Mining Section) , 2022, 74(1): 56-67.

-

下载:

下载: