Recovering Fluorite from Kafang Copper-Tungsten Flotation Tailings, Yunnan Province

-

摘要:

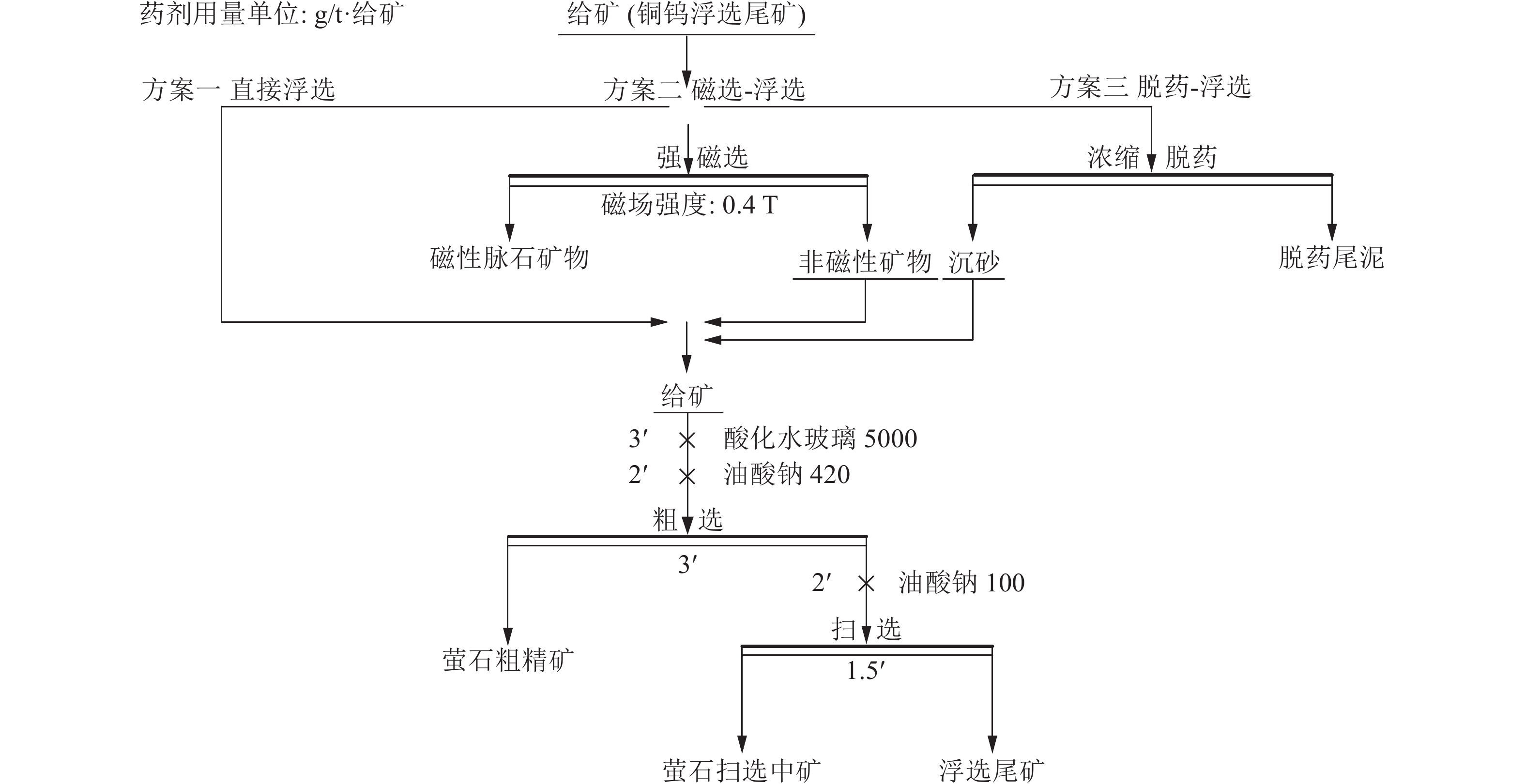

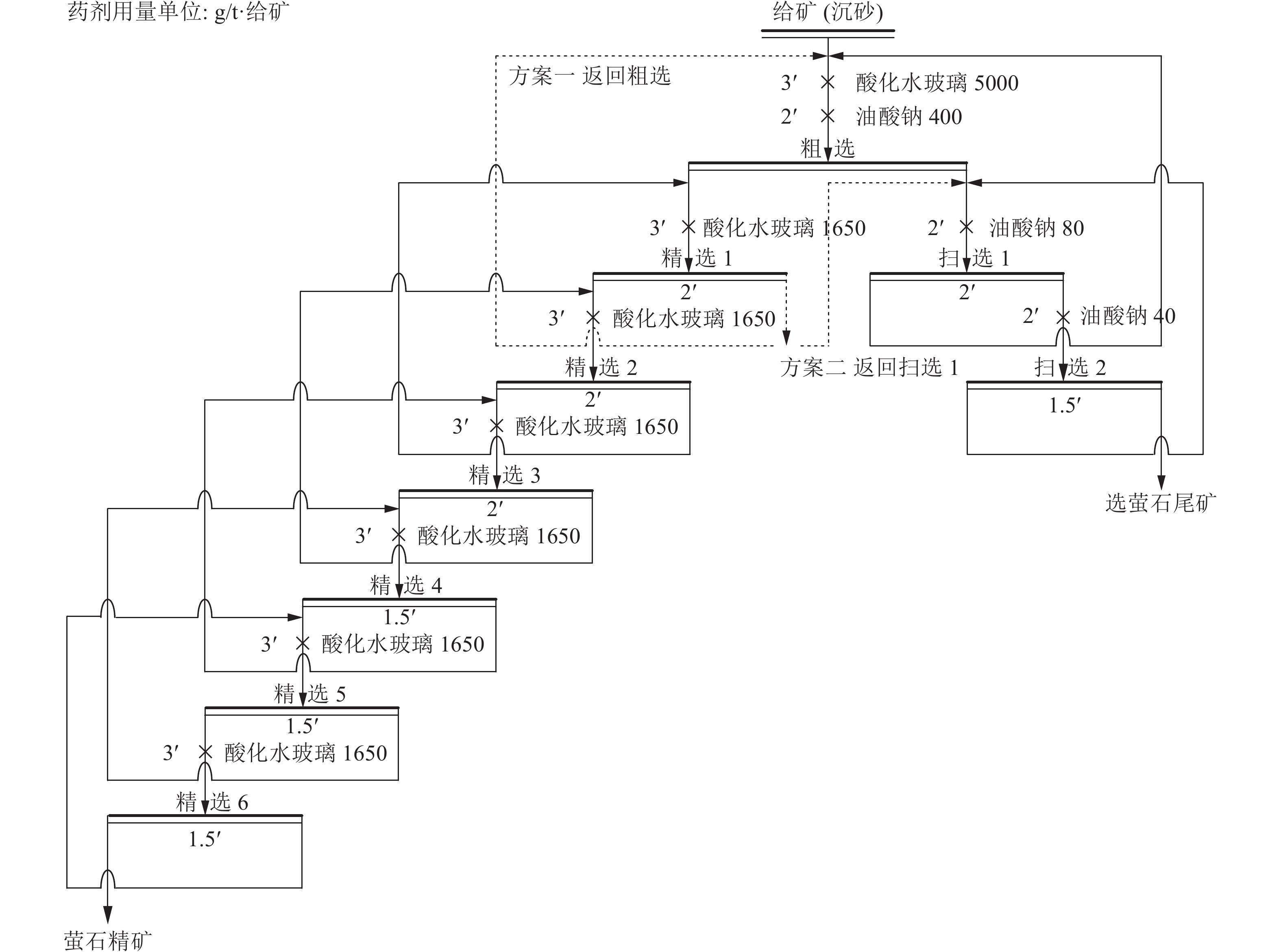

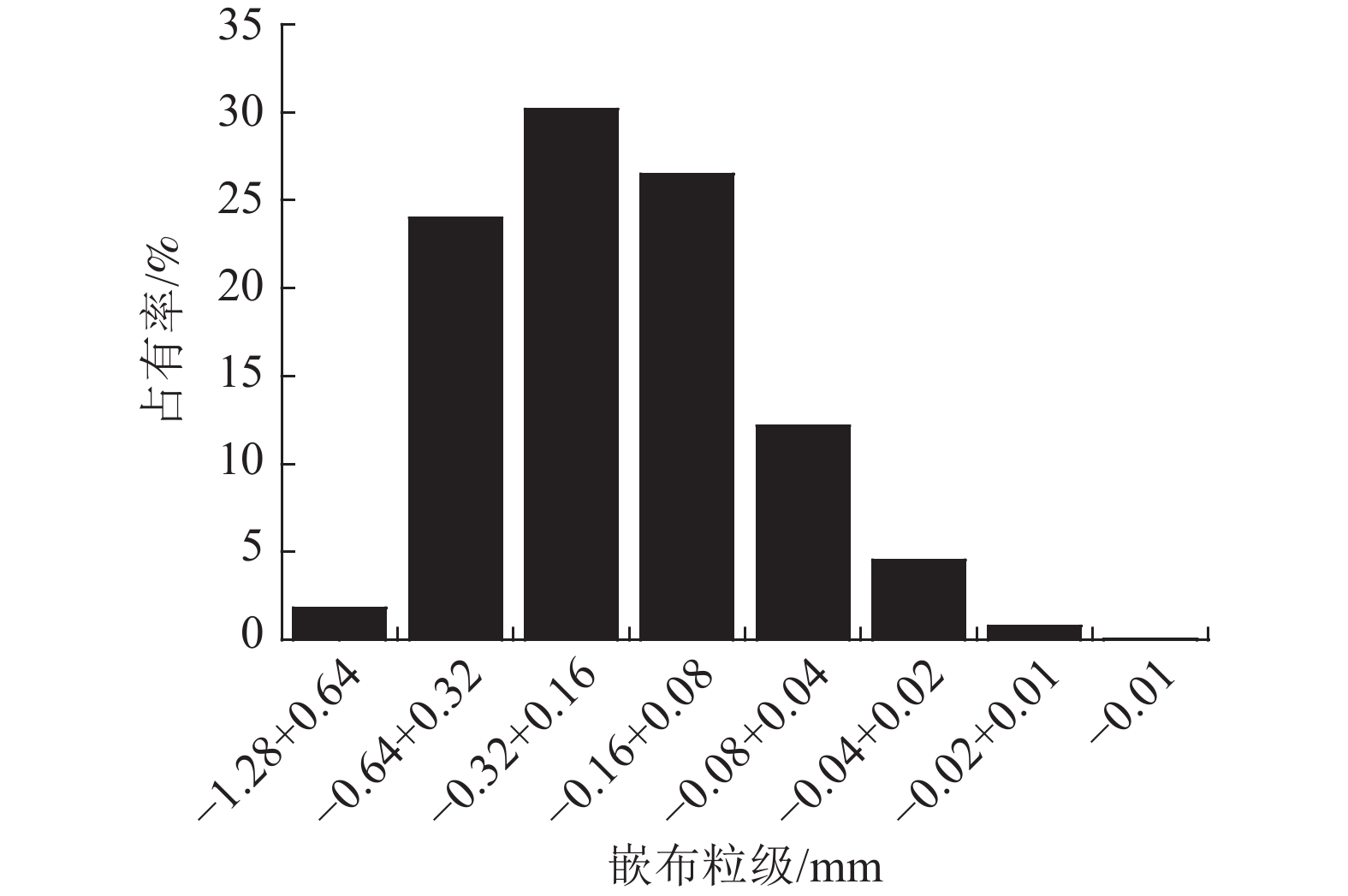

这是一篇矿物加工工程领域的论文。云锡集团卡房分公司新探获矿体除有价元素铜、钨以外,仍有价值不容小视的萤石资源。铜钨浮选尾矿中CaF2品位高达31.98%,萤石矿物整体属粗中粒嵌布,单体解离度在95%以上,脉石矿物以钙铁辉石、石英、长石为主。选矿小型实验首先采用强磁选预选脱除了钙铁辉石等磁性脉石矿物,减少了对萤石浮选的干扰,然后采用“一粗两扫六精”的浮选工艺,选择酸化水玻璃做调整剂,选择油酸钠做捕收剂,对中矿产率较大的精选1中矿返回至扫选1作业,最终获得了CaF2品位为96.27%、回收率为88.85%的萤石精矿产品,实现了卡房矿区萤石资源的高效综合利用。

Abstract:This is an essay in the field of mineral processing engineering. In addition to the valuable elements copper and tungsten, there are still valuable fluorite resources in the newly discovered ore bodies of Kafang Branch of Yunnan Tin Group. The grade of fluorite in copper and tungsten flotation tailings is as high as 31.98%, the fluorite is coarse medium grain embedded, and the liberation degree is more than 95%. Besides quartz and feldspar, the gangue minerals are mainly hedenbergite with weak magnetism. During beneficiation tests, magnetic separation has been first conducted to remove the hedenbergite into magnetic gangue minerals, which reduces the interference on fluorite flotation process. Then flotation tests have been conducted using “one roughing- two scavenging- six cleaning” process, during which acidified sodium silicate as collector, sodium oleate as collector and return the middlings to scavenging 1, and a fluorite concentrate assaying 96.27% CaF2 with operation recovery of 88.85% has been obtained, which realized the efficient and comprehensive utilization of fluorite resources in Kafang mining area.

-

-

表 1 铜钨浮选尾矿主要元素分析结果/%

Table 1. Analysis results of major elements of copper and tungsten flotation tailings

CaF2 SiO2 CaCO3 MgO Al2O3 Cu S WO3 31.98 26.51 10.67 1.57 5.79 0.05 0.13 0.03 表 2 铜钨浮选尾矿矿物组成测定结果

Table 2. Results of mineral composition of copper tungsten flotation tailings

矿物 含量% 矿物 含量% 矿物 含量% 萤石 32.350 绿泥石 1.793 钛铁矿 0.011 钙铁辉石 23.425 角闪石 0.381 方解石 6.834 石英 9.169 透闪石 0.055 菱铁矿 0.266 长石 14.513 钙铁榴石 0.365 方柱石 0.905 黑云母 6.390 钙铝榴石 0.302 绿泥石 1.793 表 3 铜钨浮选尾矿粒度组成分析结果

Table 3. Analysis results of particle size composition of copper tungsten flotation tailings

粒级/mm 产率/% CaF2品位/% CaF2占有率/% +0.074 18.63 23.00 13.40 -0.074+0.043 30.53 33.00 31.50 -0.043+0.020 30.55 34.00 32.48 -0.02+0.01 12.68 35.00 13.88 -0.01 7.61 36.73 8.74 给矿 100.00 31.98 100.00 表 4 预处理方案对比实验结果

Table 4. Comparative test results of pretreatment programmes

方案 产品名称 产率/% CaF2品位/% CaF2回收率/% 方案一

直接浮选萤石粗精矿 32.50 79.27 78.43 萤石扫选中矿 7.18 40.16 8.78 尾矿 60.32 6.96 12.79 给矿 100.00 32.84 100.00 方案二

磁选-浮选萤石粗精矿 32.01 88.20 86.01 萤石扫选中矿 2.05 38.22 2.39 浮选尾矿(A) 38.57 4.06 4.77 磁性脉石矿物(B) 27.37 8.19 6.83 总尾矿(A+B) 65.94 5.77 11.60 给矿 100.00 32.54 100.00 方案三

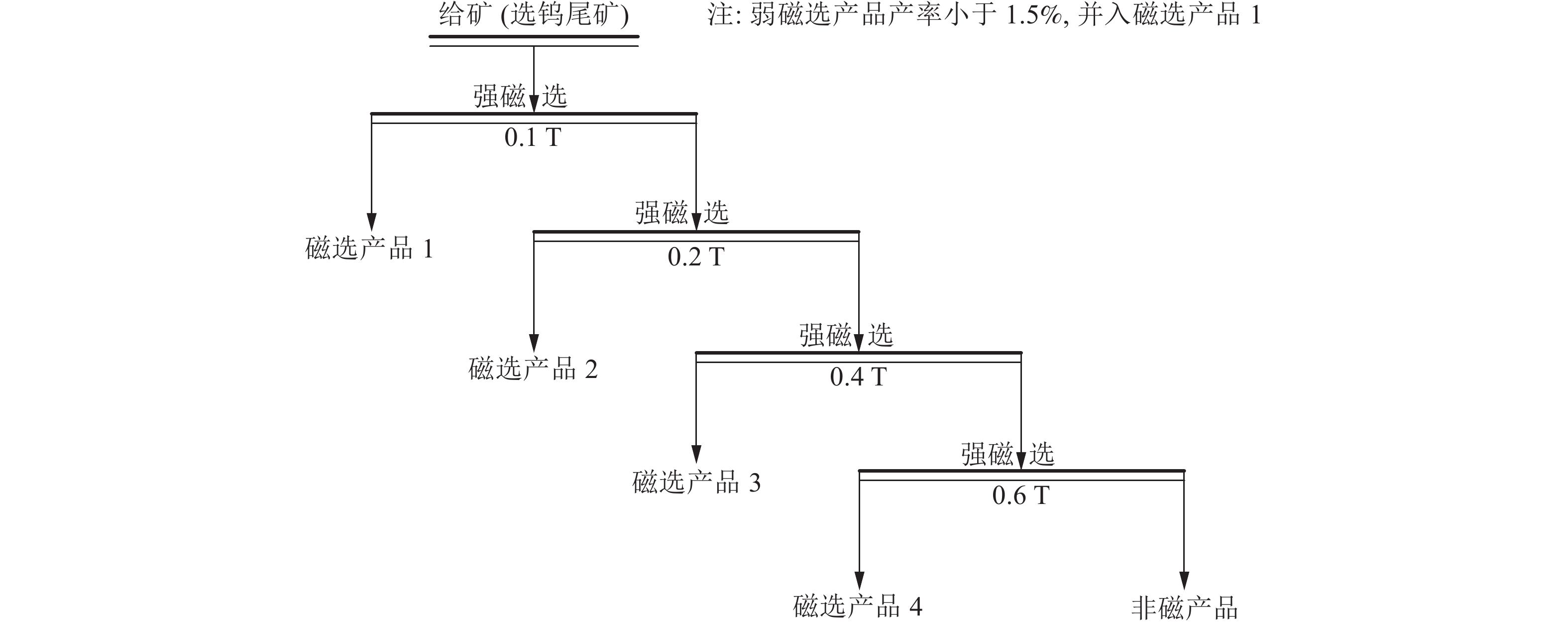

脱药-浮选萤石粗精矿 34.49 84.97 90.06 萤石扫选中矿 3.45 39.16 4.15 浮选尾矿(A) 57.33 2.01 3.54 脱药尾泥(B) 4.73 15.42 2.25 总尾矿(A+B) 62.06 3.03 5.79 给矿 100.00 32.54 100.00 表 5 磁场强度条件实验结果

Table 5. Test results of magnetic field strength conditions

产品名称 产率/% CaF2品位/% CaF2回收率/% 个别 累积 个别 平均 个别 累积 磁选产品1 8.87 7.62 2.07 磁选产品2 7.60 16.47 8.36 7.96 1.95 4.02 磁选产品3 11.40 27.87 8.51 8.19 2.97 6.99 磁选产品4 9.88 37.75 18.16 10.80 5.50 12.49 非磁产品 62.25 100.00 45.87 32.63 87.51 100.00 给矿 100.00 32.63 100.00 表 6 中矿返回方案对比实验结果

Table 6. Comparison test results of the medium ore return scheme

流程 产品名称 作业产率/% CaF2品位/% CaF2作业回收率/% 方案一

返回粗选萤石精矿 43.22 90.79 95.91 选萤石尾矿 56.78 2.95 4.09 给矿 100.00 40.91 100.00 方案二

返回扫选1萤石精矿 40.64 96.27 95.55 选萤石尾矿 59.36 3.07 4.45 给矿 100.00 40.94 100.00 表 7 全流程综合实验指标

Table 7. Comprehensive test indicators for the whole process

产品名称 产率/% CaF2品位/% CaF2回收率/% 萤石精矿 29.51 96.27 88.85 浮选尾矿 43.12 3.07 4.14 磁性脉石矿物 27.37 8.19 7.01 给矿 100.00 31.98 100.00 -

[1] 马隆飞, 廖寅飞, 贺玉程, 等. 赣州某萤石尾矿浮选柱分选实验研究[J]. 矿产综合利用, 2019(2):89-93. MA L F, LIAO Y F, HE Y C, et al. Experimental study on flotation column separation of a fluorite tailings in Ganzhou[J]. Multipurpose Utilization of Mineral Resources, 2019(2):89-93.

MA L F, LIAO Y F, HE Y C, et al. Experimental study on flotation column separation of a fluorite tailings in Ganzhou[J]. Multipurpose Utilization of Mineral Resources, 2019(2): 89-93.

[2] 吕良, 曹飞, 王守敬, 等. 豫西某石英型萤石矿浮选工艺研究[J]. 矿产综合利用, 2022(2):92-99. LV L, CAO F, WANG S J, et al. Study on flotation process of a quartz fluorite ore in Western Henan[J]. Multipurpose Utilization of Mineral Resources, 2022(2):92-99. doi: 10.3969/j.issn.1000-6532.2022.02.017

LV L, CAO F, WANG S J, et al. Study on flotation process of a quartz fluorite ore in Western Henan[J]. Multipurpose Utilization of Mineral Resources, 2022 (2): 92-99. doi: 10.3969/j.issn.1000-6532.2022.02.017

[3] 曾小波, 印万忠. 共伴生型萤石矿浮选研究进展与展望[J]. 矿产综合利用, 2021(1):1-7. ZENG X B, YIN W Z. Resesrch progress and prospect of flotation of assou ciated fluorite minerdls[J]. Multipurpose Utilization of Mineral Resources, 2021(1):1-7.

ZENG X B, YIN W Z. Resesrch progress and prospect of flotation of assou ciated fluorite minerdls[J]. Multipurpose Utilization of Mineral Resources, 2021(1): 1-7.

[4] 张红涛, 宋翔宇, 黄业豪, 等. 新型捕收剂YS-1浮选某萤石矿的实验研究[J]. 非金属矿, 2022(3):63-65+69. ZHANG H T, SONG X Y, HUANG Y H, et al. Experimental study on flotation of a fluorite ore with new collector YS-1[J]. Non-metallic ore, 2022(3):63-65+69. doi: 10.3969/j.issn.1000-8098.2022.03.016

ZHANG H T, SONG X Y, HUANG Y H, et al. Experimental study on flotation of a fluorite ore with new collector YS-1 [J]. Non-metallic ore, 2022(3): 63-65+69. doi: 10.3969/j.issn.1000-8098.2022.03.016

[5] 宋宪伟, 梅光军, 高志, 等. 河南硅酸盐型萤石浮选工艺研究[J]. 矿业研究与开发, 2022, 42(4):16-20. SONG X W, MEI G J, GAO Z, et al. Study on flotation process of silicate-type fluorite in Henan[J]. Mining Research and Development, 2022, 42(4):16-20.

SONG X W, MEI G J, GAO Z, et al. Study on flotation process of silicate-type fluorite in Henan [J]. Mining Research and Development, 2022, 42 (4): 16-20.

[6] 宁江峰,李茂林,崔瑞,等. ZnSO4•7H2O与水玻璃组合抑制剂对萤石、方解石浮选分离的影响[J]. 矿产综合利用, 2020(6):186-192. NING J F,LI M L,CUI R,et al. Effect of ZnSO4•7H2O and sodium silicate as combination inhibitors on flotation separation of fluorite and calcite[J]. Multipurpose Utilization of Mineral Resources, 2020(6):186-192.

Effect of ZnSO4•7H2O and sodium silicate as combination inhibitors on flotation separation of fluorite and calcite[J]. Multipurpose Utilization of Mineral Resources, 2020(6):186-192

[7] 曹志明, 严群, 钟志刚, 等. 萤石常温浮选药剂研究现状与展望[J]. 矿产综合利用, 2017(4):21-27. CAO Z M, YAN Q, ZHONG Z G, et al. Research status and prospect of fluorite flotation agent at ambient temperature[J]. Multipurpose Utilization of Mineral Resources, 2017(4):21-27. doi: 10.3969/j.issn.1000-6532.2017.04.005

CAO Z M, YAN Q, ZHONG Z G, et al. Research status and prospect of fluorite flotation agent at ambient temperature [J]. Multipurpose Utilization of Mineral Resources, 2017 (4): 21-27. doi: 10.3969/j.issn.1000-6532.2017.04.005

[8] 胡开文, 周清波, 曾志飞, 等. 某萤石选矿厂浮选流程改造实践[J]. 现代矿业, 2018(10):137-138+153. HU K W, ZHOU Q B, ZENG Z F, et al. Flotation process reform practice of a fluorite concentrator[J]. Modern Mining, 2018(10):137-138+153.

HU K W, ZHOU Q B, ZENG Z F, et al. Flotation process reform practice of a fluorite concentrator [J]. Modern Mining, 2018 (10): 137-138+153.

[9] 钱有军, 高莉. 某钨多金属矿尾矿伴生萤石综合回收选矿实验[J]. 现代矿业, 2018(9):20-22. QIAN Y J, GAO L. Comprehensive recovery and beneficiation test of fluorite associated with tailings of a tungsten-polymetallic ore[J]. Modern Mining, 2018(9):20-22.

QIAN Y J, GAO L. Comprehensive recovery and beneficiation test of fluorite associated with tailings of a tungsten-polymetallic ore [J]. Modern Mining, 2018 (9): 20-22.

[10] 赵一鸣, 张轶男, 林文蔚. 我国夕卡岩矿床中的辉石和似辉石特征及其与金属矿化的关系[J]. 矿床地质, 1997(4):31-32+36-38+40-42. ZHAO Y M, ZHANG Y N, LIN W W. Pyroxene and pyroxene-like characteristics of skarn deposits in China and their relationship with metal mineralization[J]. Geology of Deposits, 1997(4):31-32+36-38+40-42.

ZHAO Y M, ZHANG Y N, LIN W W. Pyroxene and pyroxene-like characteristics of skarn deposits in China and their relationship with metal mineralization [J]. Geology of Deposits, 1997 (4): 31-32+36-38+40-42.

[11] 许道刚, 龙冰, 王小生, 等. 高泥尾砂浮选萤石实验研究[J]. 矿产综合利用, 2022(2):150-153. XU D G, LONG B, WANG X S, et al. Experimental research on reprocessing fluorite from high mud tailings[J]. Multipurpose Utilization of Mineral Resources, 2022(2):150-153.

XU D G, LONG B, WANG X S, et al. Experimental research on reprocessing fluorite from high mud tailings[J]. Multipurpose Utilization of Mineral Resources, 2022 (2): 150-153.

[12] 文伟, 陈福林, 余新文, 等. 某含硫萤石重晶石共伴生氟碳铈稀土矿硫脱除必要性及回收实验[J]. 矿产综合利用, 2019(6):45-48. WEN W, CHEN F L, YU X W, et al. Experimental study on the necessity and recovery of sulfur removal from a fluorocarbon-cerium rare earth ore associated with fluorite barite[J]. Multipurpose Utilization of Mineral Resources, 2019(6):45-48. doi: 10.3969/j.issn.1000-6532.2019.06.010

WEN W, CHEN F L, YU X W, et al. Experimental study on the necessity and recovery of sulfur removal from a fluorocarbon-cerium rare earth ore associated with fluorite barite[J]. Multipurpose Utilization of Mineral Resources, 2019 (6): 45-48. doi: 10.3969/j.issn.1000-6532.2019.06.010

[13] 曾礼强, 蒋巍, 陈文胜, 等. 钨矿浮选残余药剂对伴生萤石浮选的影响研究及实践[J]. 中国钨业, 2021(6):32-40. ZENG L Q, JIANG W, CHEN W S, et al. Study and practice on influence of residual agent in tungsten ore flotation on flotation of associated fluorite[J]. Tungsten Industry of China, 2021(6):32-40. doi: 10.3969/j.issn.1009-0622.2021.06.004

ZENG L Q, JIANG W, CHEN W S, et al. Study and practice on influence of residual agent in tungsten ore flotation on flotation of associated fluorite [J]. Tungsten Industry of China, 2021 (06): 32-40. doi: 10.3969/j.issn.1009-0622.2021.06.004

[14] 刘忠义, 马子龙, 刘杰, 等. 含云母方解石型萤石矿的浮选柱分选实验研究[J]. 矿产综合利用, 2019(2):60-64. LIU Z Y, MA Z L, LIU J, et al. Experimental research on flotation column separation of micaceous calcite-type fluorite[J]. Multipurpose Utilization of Mineral Resources, 2019(2):60-64.

LIU Z Y, MA Z L, LIU J, et al. Experimental research on flotation column separation of micaceous calcite-type fluorite[J]. Multipurpose Utilization of Mineral Resources, 2019(2): 60-64.

[15] 崔瑞, 王旭, 魏骞, 等. 湖北某重晶石-萤石型矿综合利用研究[J]. 矿产综合利用, 2019(2):70-74. CUI R, WANG X, WEI Q, et al. Study on comprehensive utilization of a barite-fluorite ore in Hubei Province[J]. Multipurpose Utilization of Mineral Resources, 2019(2):70-74.

CUI R, WANG X, WEI Q, et al. Study on comprehensive utilization of a barite-fluorite ore in Hubei Province[J]. Multipurpose Utilization of Mineral Resources, 2019(2): 70-74.

-

下载:

下载: