Process and Mechanism of Sulfate Roasting-Water Extraction of Lithium from Lithium Mica Ore

-

摘要:

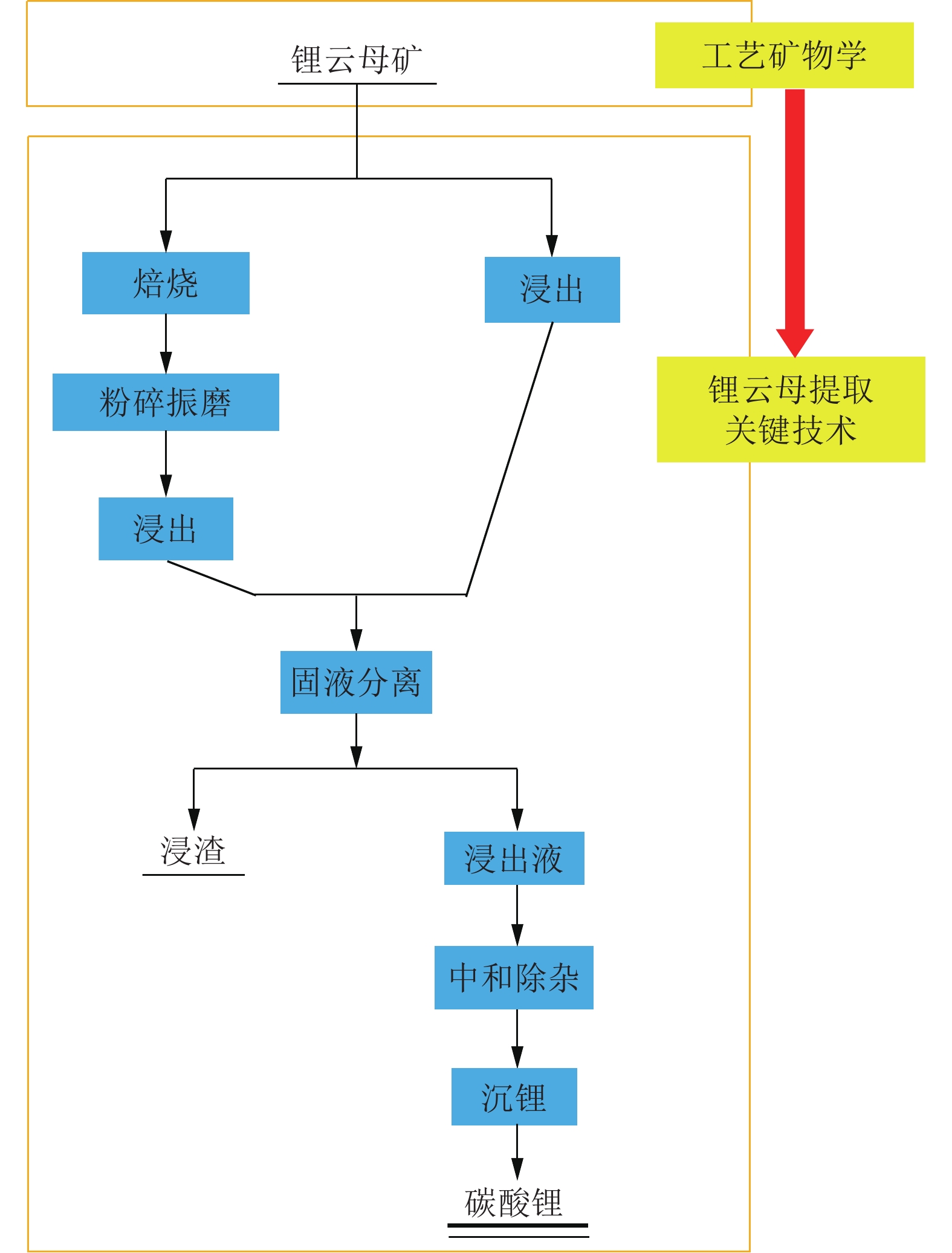

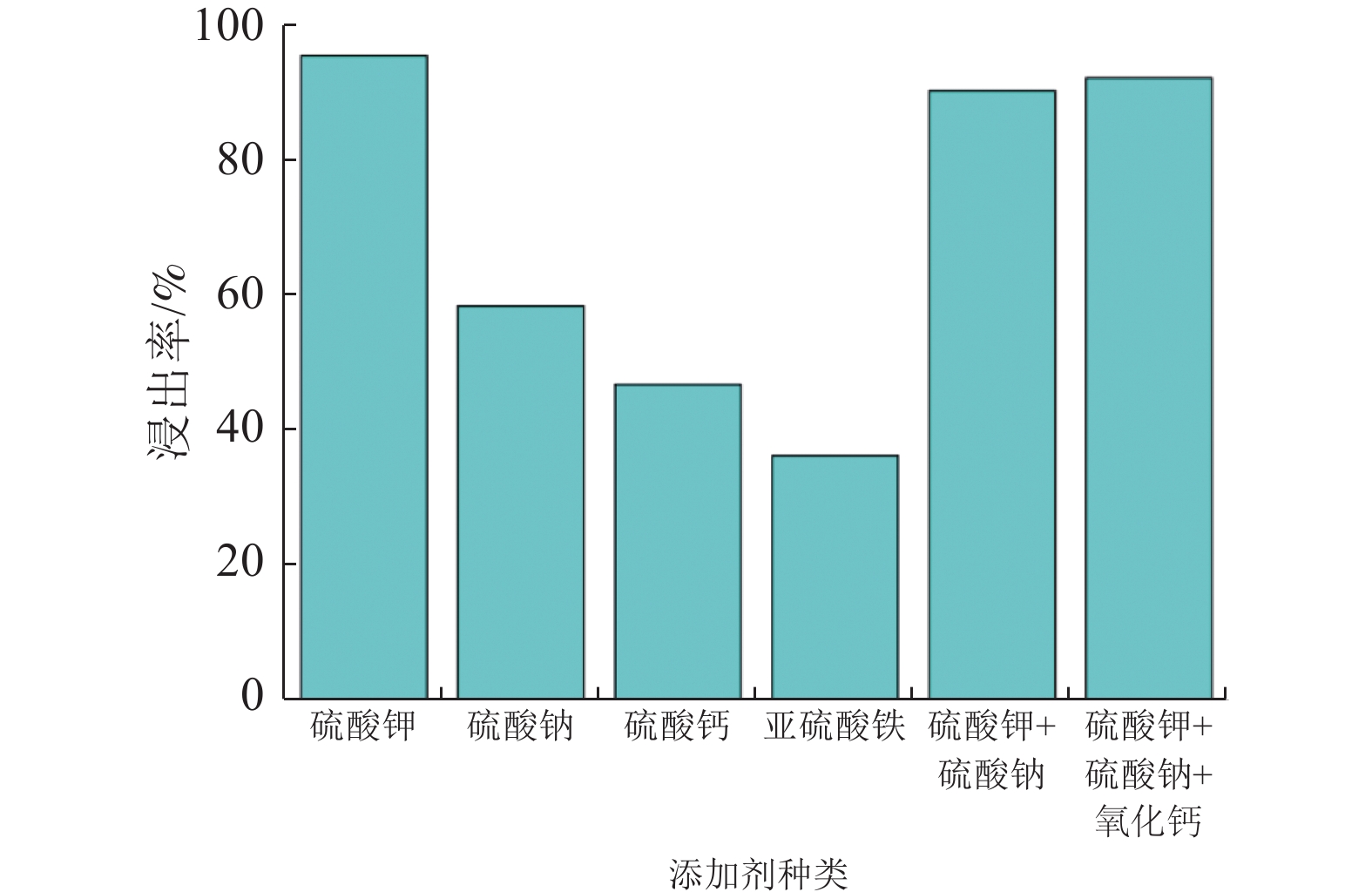

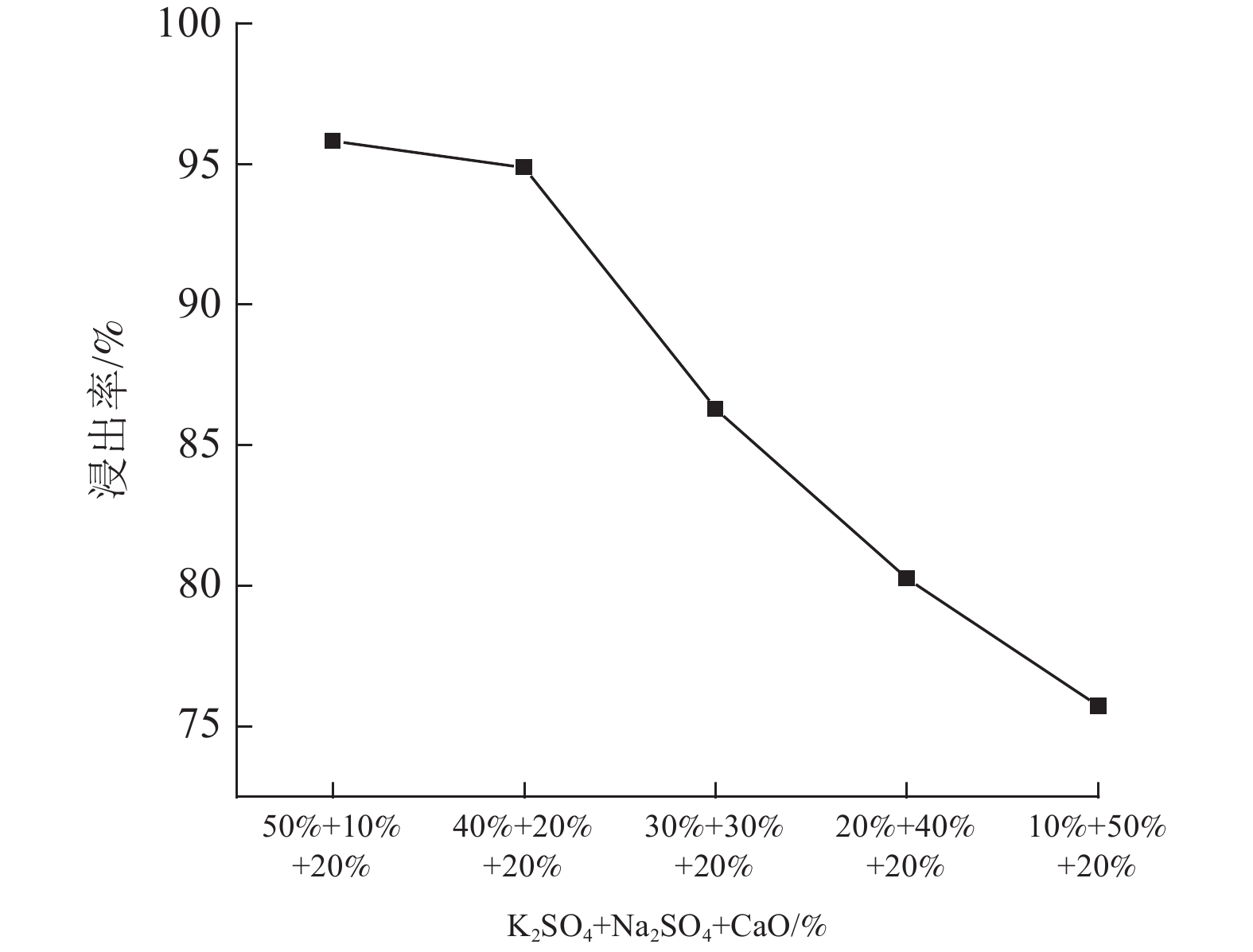

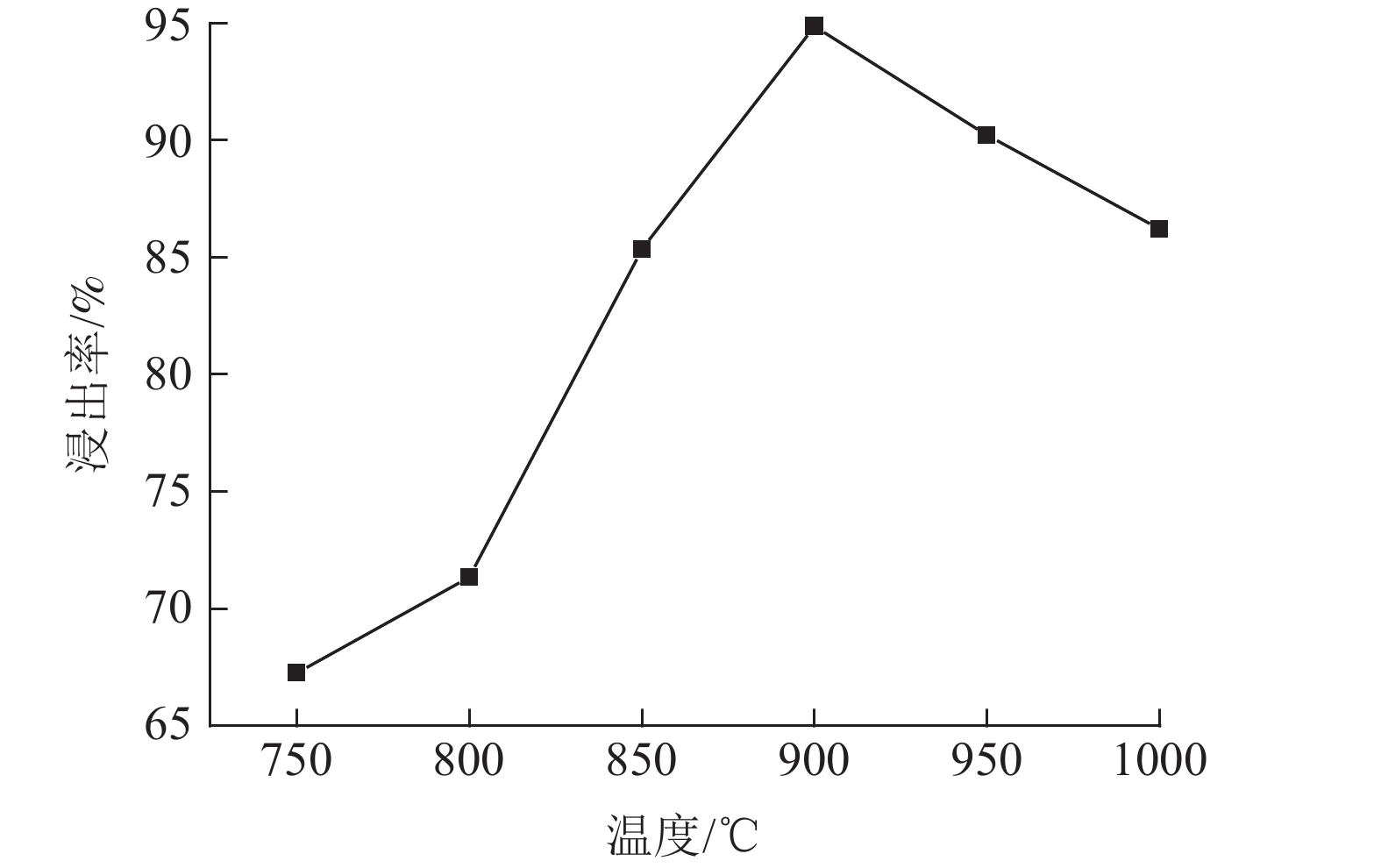

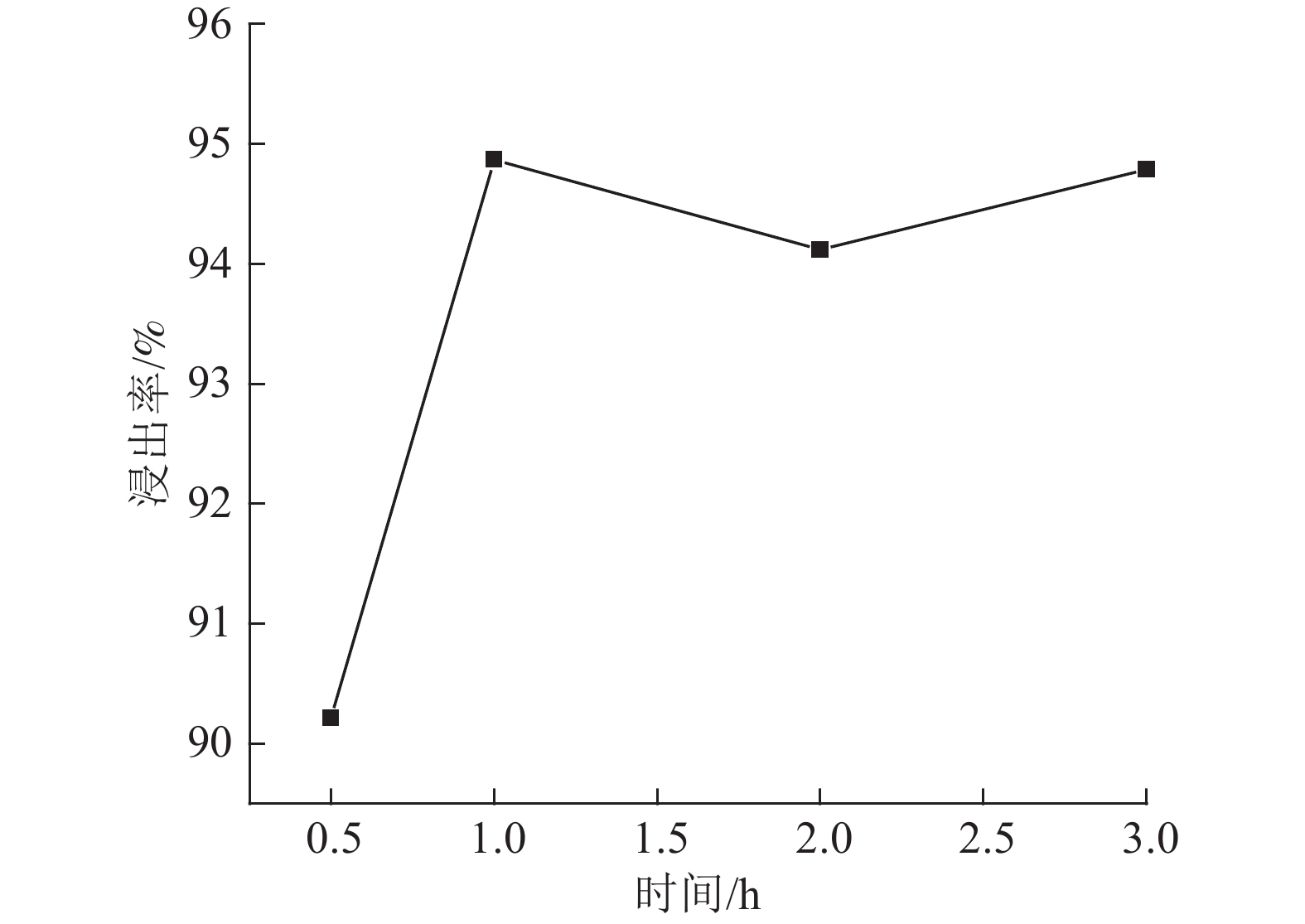

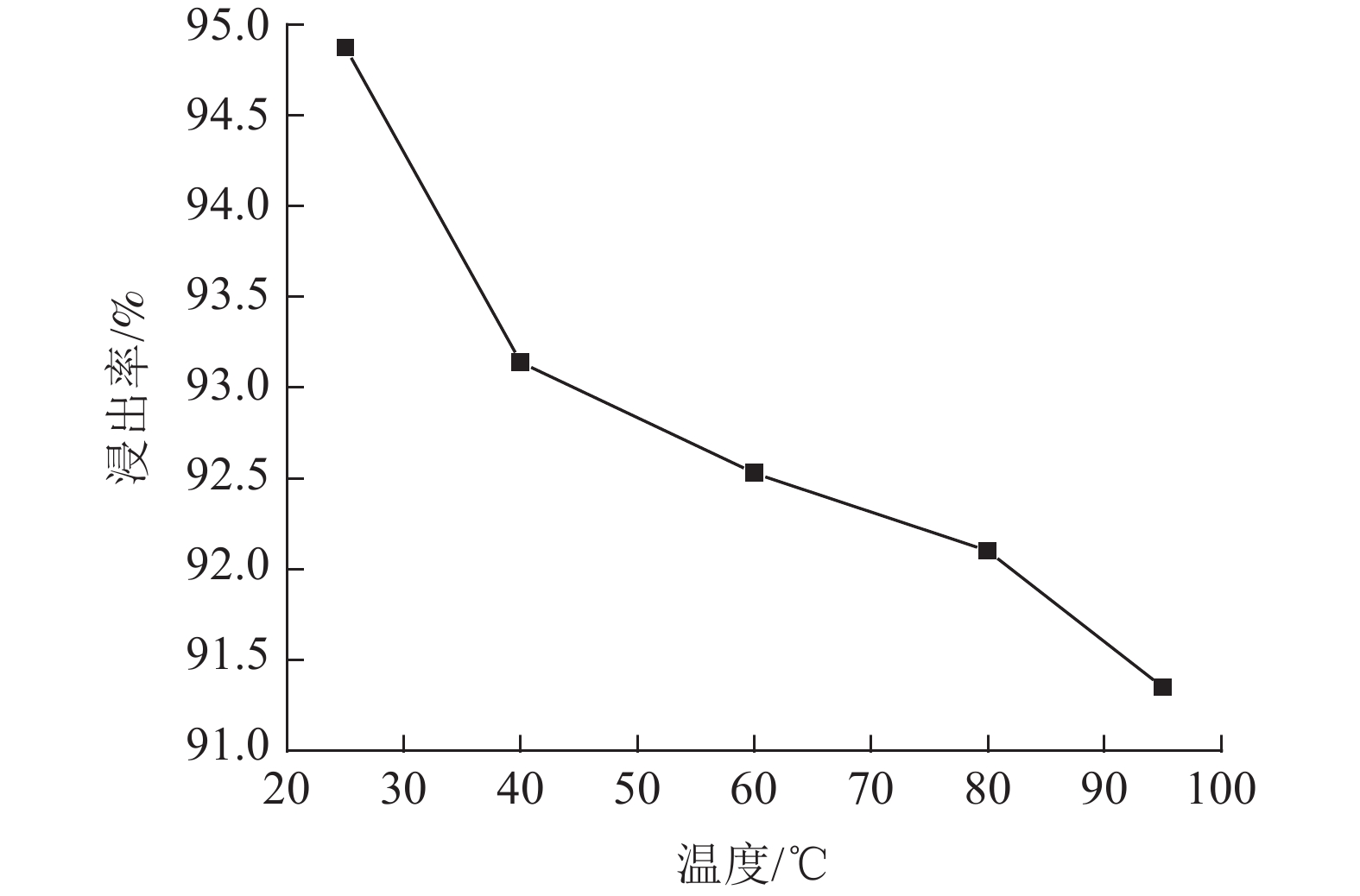

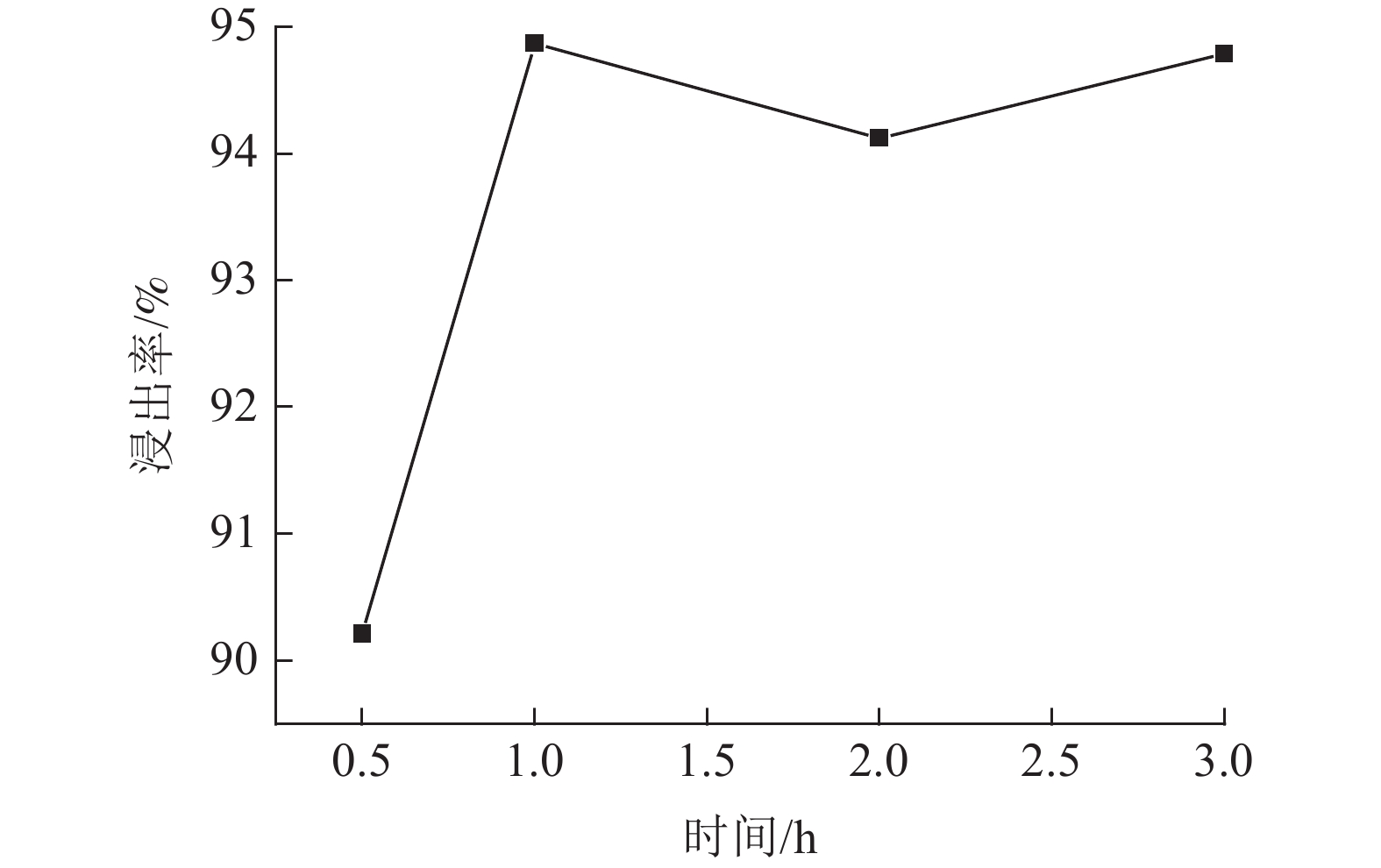

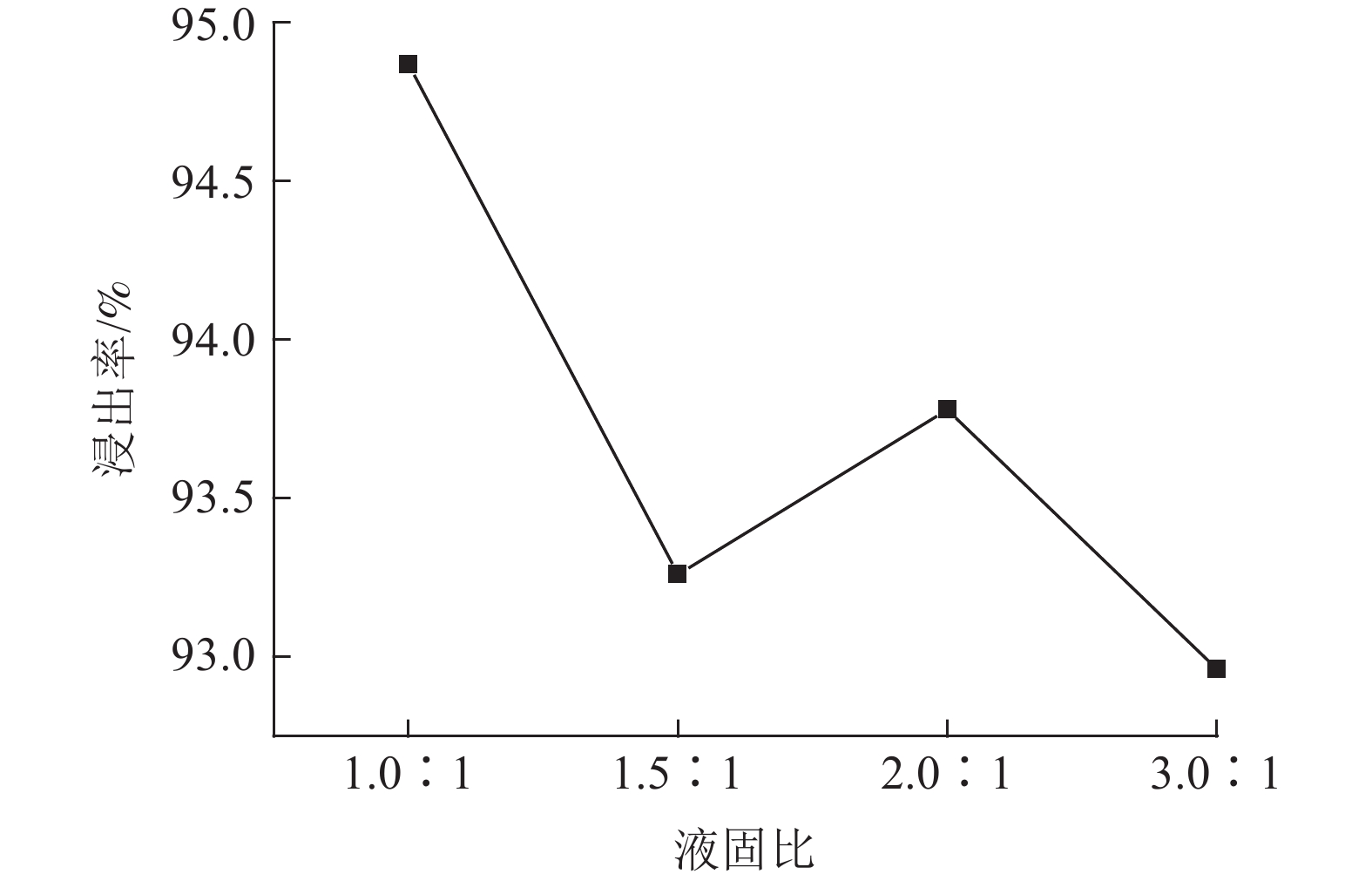

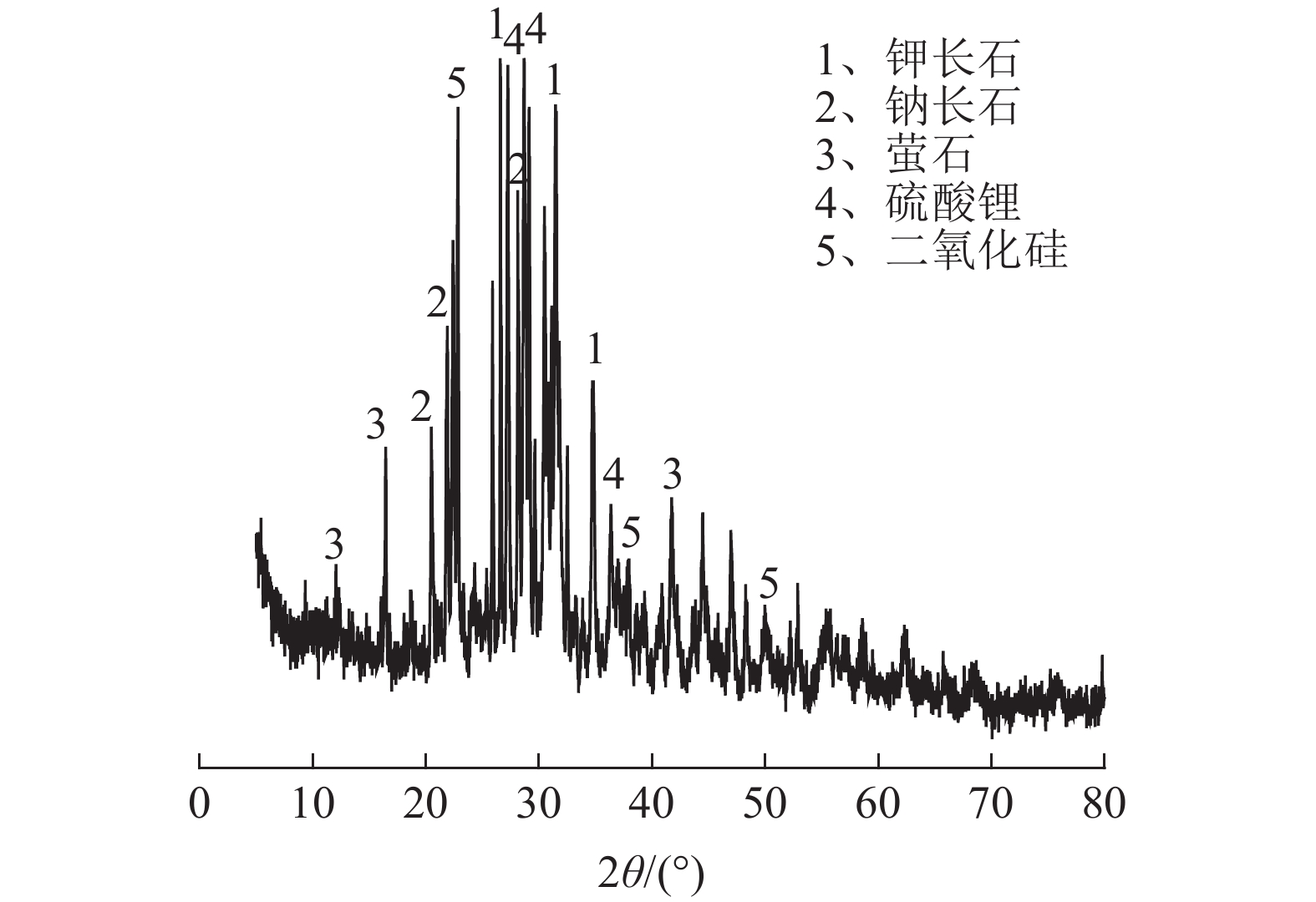

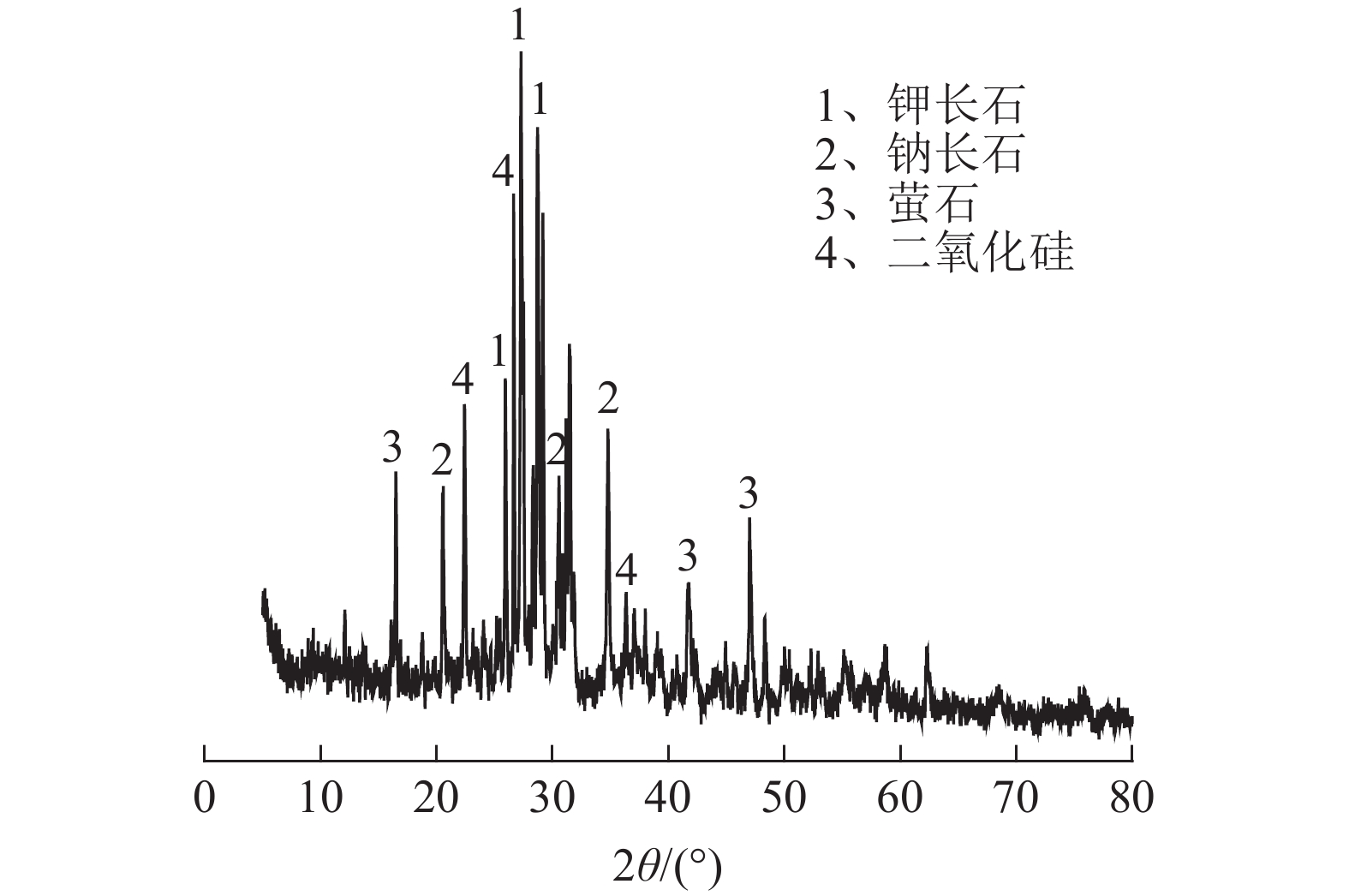

这是一篇冶金工程领域的文章。以江西某地锂云母矿为原料,通过对焙烧-浸出、拌酸熟化、直接酸浸出、碱压煮法等工艺进行探索实验,最终采用加硫酸盐焙烧-水浸法从锂云母矿中提锂。同时研究了焙烧温度、焙烧时间、添加剂种类、添加剂用量、浸出液固比、浸出温度等条件对锂浸出率影响,结果显示,焙烧温度对锂浸出率影响较大,在适当的焙烧温度范围内,锂的浸出效果较好。向锂云母矿中加入40%硫酸钾、20%硫酸钠、20%氧化钙,在900 ℃下焙烧1 h,焙砂按液固比1∶1在常温下浸出1 h,锂浸出率可达94.87%。这说明采用硫酸盐作添加剂来焙烧提锂效果较好,通过研究焙烧机理可知,加入硫酸盐经高温焙烧后,矿物结构被重构,矿中钠钾离子与锂云母中的锂离子置换,使其从难溶性铝硅酸盐矿物中分离,生成可溶性的硫酸锂,从而经水浸后进入溶液中。

Abstract:This is an essay in the field of metallurgical engineering. Taking a lithium mica ore in Jiangxi as raw material, the roasting-leaching, mixed acid ripening, direct acid leaching and alkali pressure cooking process were explored. Finally, the sulfate roasting-water leaching method was used to extract lithium from lithium mica ore. At the same time, the effects of roasting temperature, roasting time, additive type, additive amount, liquid-solid ratio and leaching temperature on lithium leaching rate were studied. The results show that roasting temperature has a great influence on lithium leaching rate, and the leaching effect of lithium is better in the appropriate roasting temperature range. 40% potassium sulfate, 20% sodium sulfate and 20% calcium oxide were added to the lithium mica ore, calcinated at 900 ℃ for 1 h, and the calcine was leached at room temperature for 1 h according to the liquid-solid ratio of 1∶1. The lithium leaching rate reached 94.87%. This shows that the effect of using sulfate as an additive to roast and extract lithium is better. Through the study of the roasting mechanism, it can be seen that the mineral structure is reconstructed after the addition of sulfate after high temperature roasting. The sodium and potassium ions in the ore are replaced with lithium ions in the lithium mica, so that they are separated from the insoluble aluminum silicate minerals to generate soluble lithium sulfate, which is then immersed in water and then into the solution.

-

Key words:

- Metallurgical engineering /

- Lithium mica /

- Sulfate /

- Calcination /

- Leach /

- Mechanism

-

-

表 1 锂云母矿的主要成分/%

Table 1. Main components of lithium mica

Rb2O Cs2O Li2O K2O Na2O Al2O3 TFe CaO MgO SiO2 P2O5 F 1.04 0.21 2.69 8.45 1.21 22.40 0.64 0.10 0.021 50.05 0.67 5.02 表 2 锂云母矿石矿物组成及含量

Table 2. Mineral composition and content of lithium mica ore

矿物名称 矿物含量/% 矿物中Li含量/% 配分率/% 锂云母 48.00 3.03 98.60 白云母 25.50 0.08 1.39 铯榴石 0.04 1.07 0.01 石英 5.71 / / 斜长石 10.45 / / 钾长石 8.60 / / 磷灰石 0.06 / / 黑云母 0.07 / / 高岭石 1.40 / / 绿泥石 0.03 / / 磁铁矿 0.03 / / 黄铁矿 0.01 / / 黄铜矿 0.01 / / 南平石 0.03 / / 三水铝石 0.01 / / 托帕石 0.08 / / 合计 100.00 100.00 表 3 焙烧-浸出实验结果

Table 3. Results of roasting-leaching experiments

工艺 产品 质量/g Li2O含量/(g/t) Li2O浸出率/% 碳酸盐焙烧-水浸 焙砂 144.4 17 470 浸渣 139.35 17 390 3.94 硫酸盐焙烧-水浸 焙砂 173.29 18 152 浸渣 108.74 1 226 96.10 氯化焙烧-水浸 焙砂 161.48 13 024 浸渣 111.61 6 885 63.46 原矿 100.00 26 900 表 4 直接酸浸法实验结果

Table 4. Test results of direct acid leaching method

工艺 产品 质量/g Li2O含量/(g/t) Li2O浸出率/% 盐酸直接酸浸 浸渣 93.25 26 300 8.83 原矿 100.00 26 900 硫酸酸浸 81.66 12 452 62.20 硫酸酸浸+NaF 86.47 14 371 53.80 硫酸酸浸+CaF2 84.19 13 500 57.75 表 5 拌酸熟化-水浸结果

Table 5. Results of mixed acid ripening - water leaching

酸用量 产品 质量/g Li2O含量/(g/t) Li2O浸出率/% 原矿 100.00 26 900 2.0:1 浸渣 68.01 5 683 85.63 1.5:1 浸渣 73.63 5 994 83.59 1.2:1 浸渣 78.25 6 383 81.43 1.0:1 浸渣 83.10 6 655 79.44 0.8:1 浸渣 88.17 6 902 77.38 表 6 压煮法提锂结果

Table 6. Results of lithium extraction by pressure boiling method

添加剂 产品 质量/g Li2O含量/

(g/t)Li2O

浸出率/%原矿 100.00 26 900 焙砂 96.62 27 509 90%Ca(OH)2+2%Na2CO3 浸渣 121.58 10 354 52.64 10%CaO+20%NaCl 浸渣 111.65 19 746 17.05 50%CaO+10%NaOH 浸渣 108.73 18 973 22.39 表 7 综合条件验证实验结果

Table 7. Results were verified by comprehensive conditions

实验 产品 质量/g 锂含量/ (g/t) 锂浸出率/% 1 焙烧渣 1 732.9 17 752 94.85 浸渣 1 087.4 1 456 2 焙烧渣 1 708.6 17 965 94.83 浸渣 1 063.4 1 491 3 焙烧渣 1 756.2 17 198 94.93 浸渣 1104.3 1 391 综合浸出率 94.87 -

[1] 吴西顺, 王登红, 黄文斌, 等. 全球锂矿及伴生铍铌钽的采选冶技术发展趋势[J]. 矿产综合利用, 2019(1):1-6. WU X S, WANG D H, HUANG W B, et al. Global technical development trends of litihium minerals and associated beryllium-niobium-tantalum exploitation[J]. Multipurpose Utilization of Mineral Resources, 2019(1):1-6.

WU X S, WANG D H, HUANG W B, et al. Global technical development trends of litihium minerals and associated beryllium-niobium-tantalum exploitation[J]. Multipurpose Utilization of Mineral Resources, 2019(1): 1-6.

[2] 李成秀, 程仁举, 刘星. 我国锂辉石选矿技术研究现状及展望[J]. 矿产综合利用, 2021(5):1-8. LI C X, CHENG R J, LIU X. Research status and prospects of spodumene ore beneficiation technology in China[J]. Multipurpose Utilization of Mineral Resources, 2021(5):1-8.

LI C X, CHENG R J, LIU X. Research status and prospects of spodumene ore beneficiation technology in China[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 1-8.

[3] Wei Xiang, Shengke Liang, Zhiyong Zhou, et al . Extraction of lithium from salt lake brine containing borate anion and high concentration of magnesium[J]. Hydrometallurgy, 2016, 166.

[4] Xiang Zhong Kong, Hua Ye, Yu Qin. Factors of extracting lithium from lepidolite by sulfate roasting and dilute sulphuric acid leaching[J]. Applied Mechanics and Materials, 2014, 3013(522-524).

[5] 雷祖伟, 钟宏. 含铷、铯锂云母矿的复合盐焙烧-浸出性能及机理[J]. 矿产综合利用, 2019(3):152-158. LEI Z W, ZHONG H. Composite salt roasting-leaching performance and mechanism of lepidolite containing rubidium and cesium[J]. Multipurpose Utilization of Mineral Resources, 2019(3):152-158.

LEI Z W, ZHONG H. Composite salt roasting-leaching performance and mechanism of lepidolite containing rubidium and cesium[J]. Multipurpose Utilization of Mineral Resources, 2019(3): 152-158.

[6] 徐正震, 梁精龙, 李慧, 等. 含锂资源中锂的提取研究现状及展望[J]. 矿产综合利用, 2021(5):32-37. XU Z Z, LIANG J L, LI H, et al. Research status and prospects of lithium extraction from lithium containing resources[J]. Multipurpose Utilization of Mineral Resources, 2021(5):32-37.

XU Z Z, LIANG J L, LI H, et al. Research status and prospects of lithium extraction from lithium containing resources[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 32-37.

[7] 周贺鹏, 耿亮, 郭亮, 等. 江西宜春低品位锂云母矿综合回收工艺研究[J]. 非金属矿, 2020, 43(4):59-61+98. ZHOU H P, GENG L, GUO L, et al. Experimental study on comprehensive recovery of low-grade lepidolite in Yichun, Jiangxi Province[J]. Non-Metallic Mines, 2020, 43(4):59-61+98.

ZHOU H P, GENG L, GUO L, et al. Experimental study on comprehensive recovery of low-grade lepidolite in Yichun, Jiangxi Province[J]. Non-Metallic Mines, 2020, 43(4): 59-61+98.

[8] 孙友润. 提高锂云母-石灰石烧结法Li2O回收率的途径[J]. 稀有金属与硬质合金, 2000, 143(4):23-27. SUN Y R. Approach to improve the recovery of Li2O by Li mica-limestone sintering process[J]. Rare Metals and Cemented Carbides, 2000, 143(4):23-27.

SUN Y R. Approach to improve the recovery of Li2O by Li mica-limestone sintering process[J]. Rare Metals and Cemented Carbides, 2000, 143(4): 23-27.

[9] 柳林, 刘磊, 张亮, 等. 氯化焙烧—水浸从锂云母精矿中提锂实验[J]. 有色金属(冶炼部分), 2021(2):72-76. LIU L, LIU L, ZHANG L, et al. Research on recovery of lithium from lepidolite concentrate by chlorination roasting and water leaching[J]. Nonferrous Metals (Extractive Metallurgy), 2021(2):72-76.

LIU L, LIU L, ZHANG L, et al . Research on recovery of lithium from lepidolite concentrate by chlorination roasting and water leaching[J]. Nonferrous Metals (Extractive Metallurgy), 2021(2): 72-76.

[10] 张秀峰, 伊跃军, 谭秀民, 等. 硫酸熟化锂云母提取锂铷铯的机理及动力学特征[J]. 中南大学学报(自然科学版), 2021, 52(9): 3093−3102.

ZHANG X F, YI Y J, TAN X M, et al. Mechanism and kinetics characteristics of sulfuric acid baking process for extracting lithium, rubidium and cesium from lepidolite[J]. Journal of Central South University(Science and Technology)2021, 52(9): 3093−3102.

[11] 陈亚, 廖婷, 陈白珍, 等. 纯碱压煮法从锂辉石中提取锂的研究[J]. 有色金属(冶炼部分), 2011(9):21-23+32. CHEN Y, LIAO T, CHEN B Z, et al. Extraction of lithium from spodumene by sodium carbonate autoclave process[J]. Nonferrous Metals(Extractive Metallurgy), 2011(9):21-23+32.

CHEN Y, LIAO T, CHEN B Z, et al . Extraction of lithium from spodumene by sodium carbonate autoclave process[J]. Nonferrous Metals(Extractive Metallurgy), 2011(9): 21-23+32.

[12] 韩晓, 方迪. 电感耦合等离子体原子发射光谱(ICP-AES)法测定岩矿中锂的含量[J]. 中国无机分析化学, 2021, 11(2):36-39. HAN X, FANG D. Determination of lithium in rock and ore by inductively coupled plasma atomic emission spectrometry (ICP-AES )[J]. Chinese Jorunal of Inorganic Analytical Chemistry, 2021, 11(2):36-39.

HAN X, FANG D. Determination of lithium in rock and ore by inductively coupled plasma atomic emission spectrometry (ICP-AES )[J]. Chinese Jorunal of Inorganic Analytical Chemistry , 2021, 11(2): 36-39.

-

下载:

下载: