Effect of Pretreatment Methods on the Yield of Humic Acid in Oxidized Coal

-

摘要:

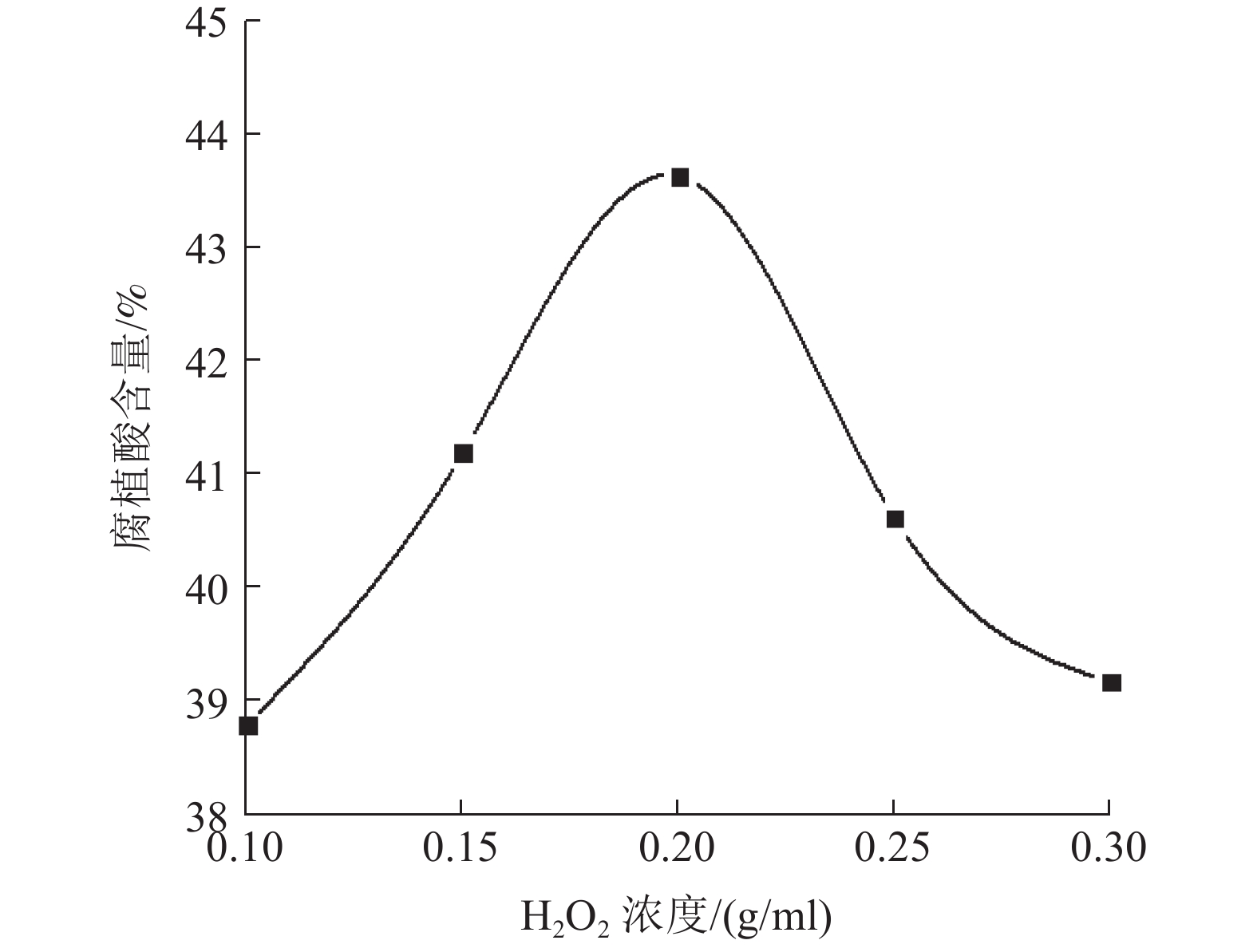

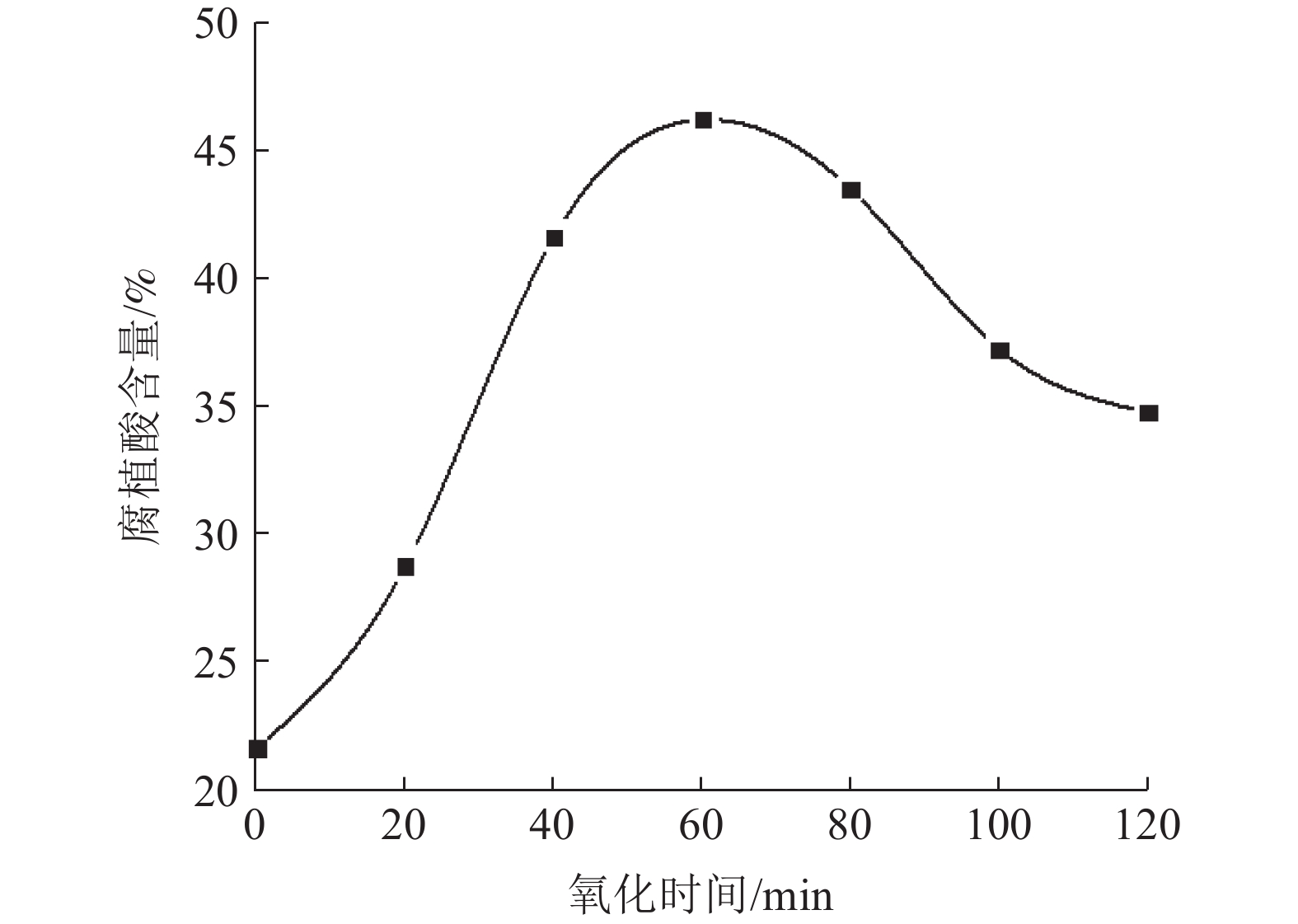

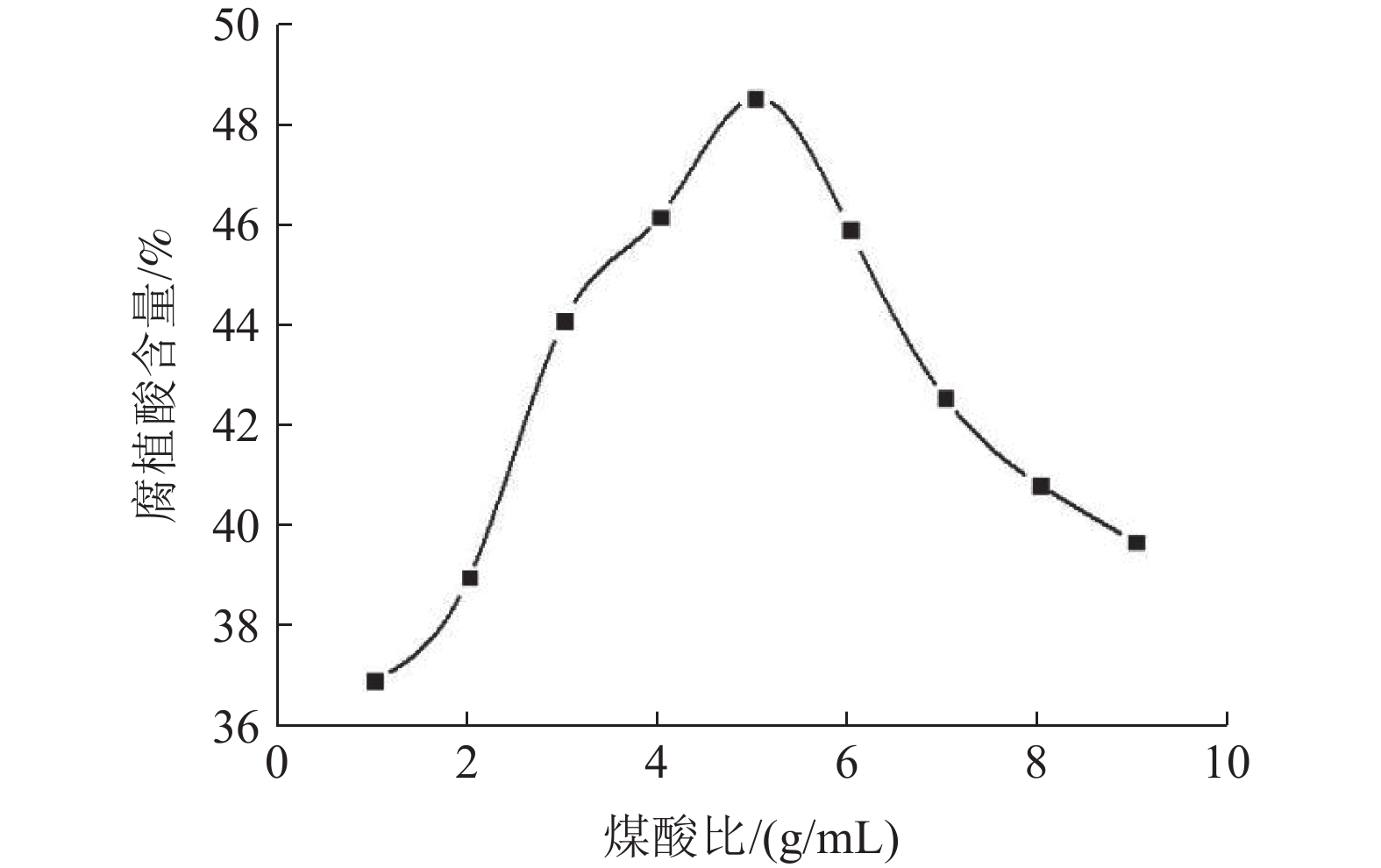

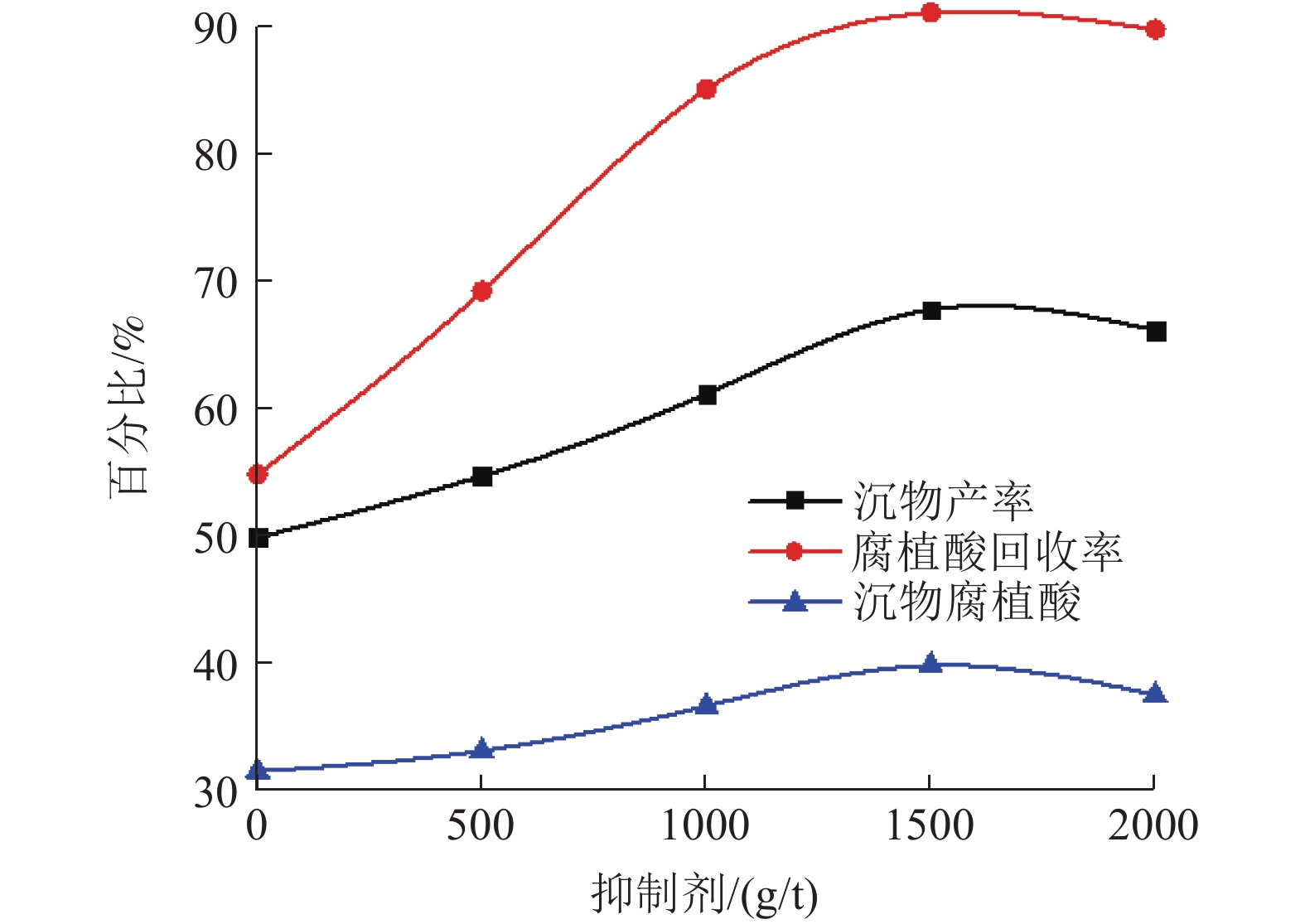

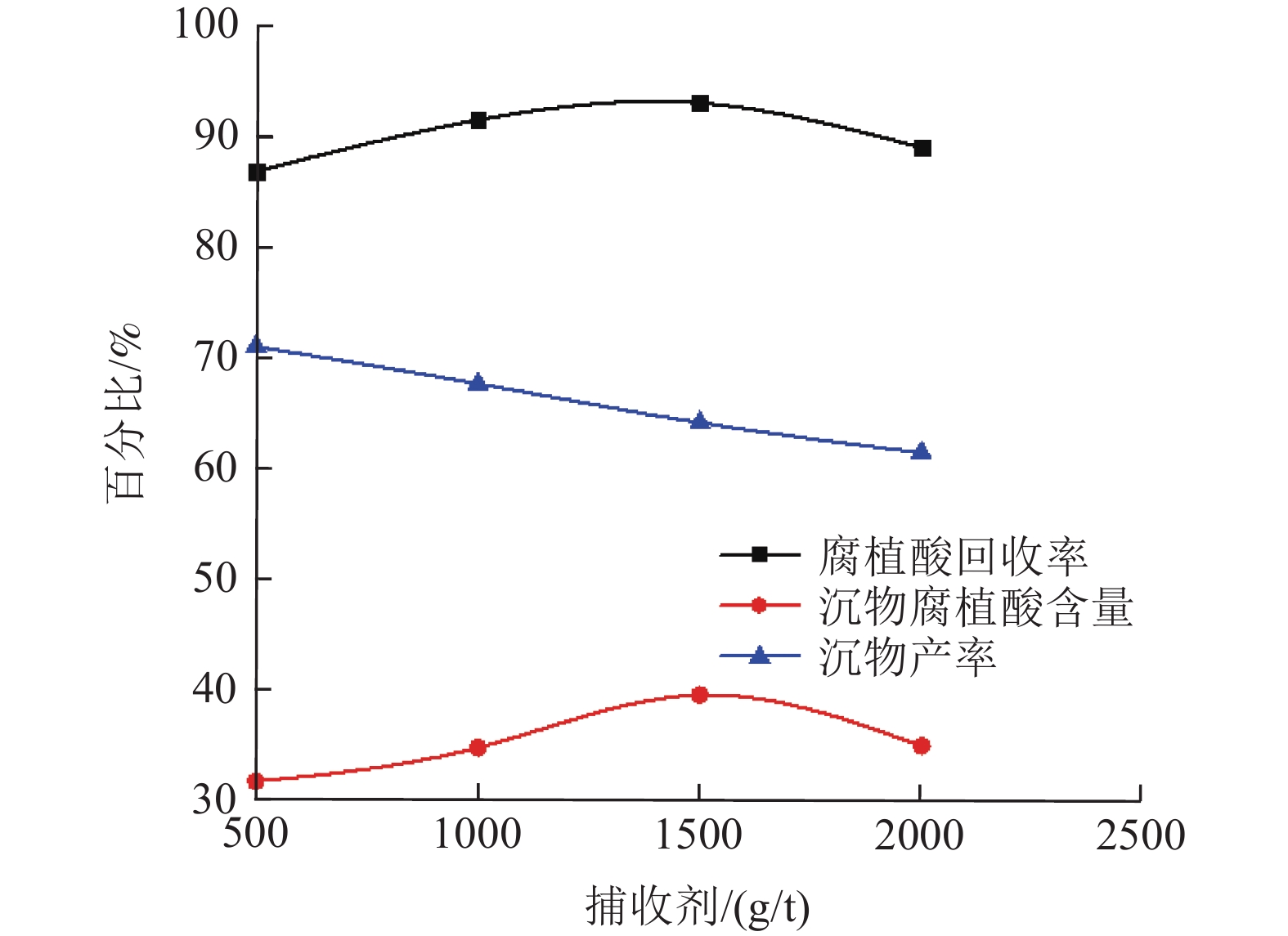

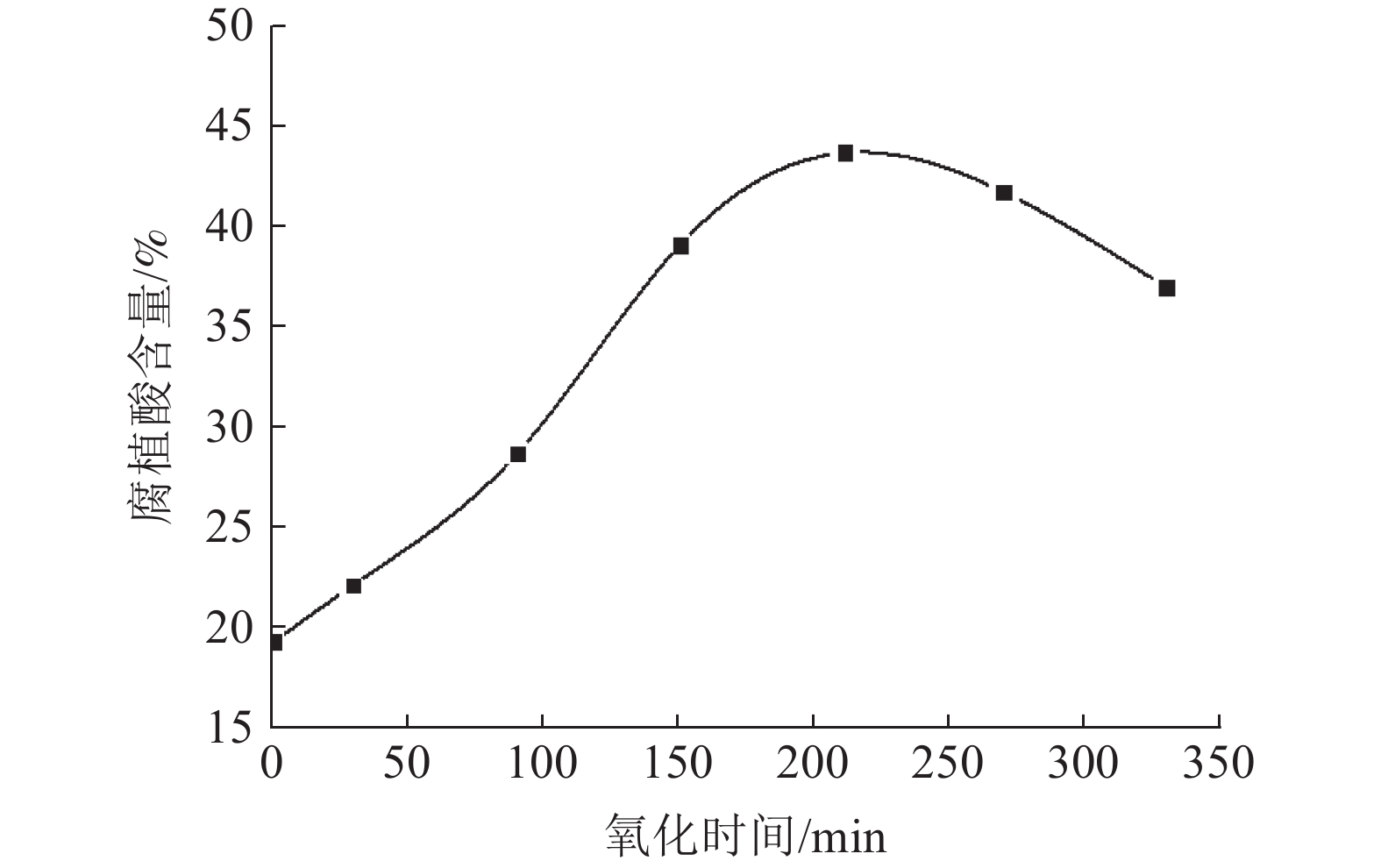

这是一篇矿物加工工程领域的论文。煤炭资源在开采和储存过程中会形成大量的氧化煤,造成煤炭资源的浪费和环境污染,从氧化煤中提取腐植酸可以达到氧化煤资源高值化利用的目的。为进一步提高氧化煤中腐植酸的含量和利用效率,本文采用H2O2氧化、浓H2SO4氧化以及反浮选三种手段对氧化煤样品进行预处理,考查了其对氧化煤中腐植酸含量的影响并运用傅立叶红外光谱( FTIR)分析了含氧官能团的变化情况。实验结果表明,氧化和反浮选均能提高腐植酸的利用效率,使用H2O2氧化后,煤样中腐植酸含量由21.58%提高到43.62%;通过浓H2SO4氧化后,腐植酸含量达到48.51%,腐植酸提取率达到81.08%。经反浮选处理提取腐植酸,可脱除部分矿物质,腐植酸富集在沉物中,腐植酸提取率也有提高,经氧化处理后提取的腐植酸含氧基团增加,亲水性增强。

Abstract:This is an essay in the field of mineral processing engineering. During the mining and storage process of coal resources, a large amount of oxidized coal is formed, resulting in waste of coal resources and environmental pollution. Extracting humic acid from oxidized coal can achieve the goal of high-value utilization of oxidized coal resources. In order to further improve the content and utilization efficiency of humic acid in oxidized coal, this article uses three methods: H2O2 oxidation, concentrated H2SO4 oxidation, and reverse flotation to pretreat oxidized coal samples. The influence of these methods on the content of humic acid in oxidized coal was investigated, and the changes in oxygen-containing functional groups were analyzed using Fourier transform infrared spectroscopy (FTIR). The experimental results show that both oxidation and reverse flotation can improve the utilization efficiency of humic acid. After using H2O2 oxidation, the humic acid content in coal samples increases from 21.58% to 43.62%; After oxidation with concentrated H2SO4, the content of humic acid reached 48.51%, and the extraction rate of humic acid reached 81.08%. Extracting humic acid through reverse flotation treatment can remove some minerals, and humic acid is enriched in sediment. The extraction rate of humic acid is also improved. After oxidation treatment, the extracted humic acid has an increase in oxygen-containing groups and enhanced hydrophilicity.

-

Key words:

- Mineral processing engineering /

- Oxidized coal /

- Humic acid /

- Extraction rate /

- Oxidation /

- Flotation

-

-

表 1 工业分析及腐植酸测定/%

Table 1. Industrial analysis and humic acid determination

Mad Aad Vad FCad 腐植酸 4.86 32.37 27.13 35.64 21.58 表 2 不同处理方法的结果对比/%

Table 2. Comparison of results of different methods

腐植酸 处理方法 未处理 H2O2氧化 H2SO4氧化 反浮选 提取率/% 61.78 63.20 81.08 66.94 含量/% 21.58 43.62 48.51 40.12 -

[1] 陈阳, 解维伟. 药剂C-1对氧化煤浮选的促进机理研究[J]. 煤炭工程, 2020, 52(9):153-156. CHEN Y, XIE W W. Study on the promotion mechanism of agent C-1 on oxidised coal flotation[J]. Coal Engineering, 2020, 52(9):153-156.

CHEN Y, XIE W W. Study on the promotion mechanism of agent C-1 on oxidised coal flotation[J]. Coal Engineering, 2020, 52(9): 153-156.

[2] 陈强. 高灰氧化煤的浮选试验研究[J]. 洁净煤技术, 2012, 18(2):10-12. CHEN Q. Flotation test study of high ash oxidised coal[J]. Clean Coal Technology, 2012, 18(2):10-12.

CHEN Q. Flotation test study of high ash oxidised coal[J]. Clean Coal Technology, 2012, 18(2): 10-12.

[3] 王市委, 陶秀祥, 陈松降, 等. 低阶煤-油泡浮选技术研究进展[J]. 矿产综合利用, 2020(4):48-58. WANG S W, TAO X X, CHEN S J, et al. Development of oily bubble flotation research for low-rank coal[J]. Multipurpose Utilization of Mineral Resources, 2020(4):48-58.

WANG S W, TAO X X, CHEN S J, et al. Development of oily bubble flotation research for low-rank coal[J]. Multipurpose Utilization of Mineral Resources, 2020(4): 48-58.

[4] 程万里, 邓政斌, 刘志红, 等. 煤泥浮选中矿物颗粒间相互作用力的研究进展[J]. 矿产综合利用, 2020(3):48-55. CHENG W L, DENG Z B, LIU Z H, et al. Research progress of interaction force between mineral particles in coal slurry flotation[J]. Multipurpose Utilization of Mineral Resources, 2020(3):48-55.

CHENG W L, DENG Z B, LIU Z H, et al. Research progress of interaction force between mineral particles in coal slurry flotation[J]. Multipurpose Utilization of Mineral Resources, 2020(3): 48-55.

[5] 桂夏辉, 邢耀文, 王婷霞. 煤泥浮选过程强化之二——低阶/氧化煤难浮机理探讨篇[J]. 选煤技术, 2017(2):79-83. GUI X H, XING Y W, WANG T X. Enhancement of coal slurry flotation process II - Exploration chapter on the mechanism of difficult flotation of low-order/oxidised coal[J]. Coal Beneficiation Technology, 2017(2):79-83.

GUI X H, XING Y W, WANG T X. Enhancement of coal slurry flotation process II - Exploration chapter on the mechanism of difficult flotation of low-order/oxidised coal[J]. Coal Beneficiation Technology, 2017(2): 79-83.

[6] 桂夏辉, 邢耀文, 连露露, 等. 煤泥浮选过程强化之三——低阶/氧化煤浮选界面强化篇[C]// 2018年全国选煤学术交流会.

GUI X H, XING Y W, LIAN L L, et al. Coal slurry flotation process enhancement III - low-order/oxidised coal flotation interface enhancement chapter[C]// 2018 National Coal Beneficiation Symposium.

[7] 王之春, 董宪姝. 腐植酸钠对煤泥浮选抑制规律的研究[J]. 中国煤炭, 2016, 42(2):83-87. WANG Z C, DONG X S. Research on the inhibition law of sodium humate on coal slurry flotation[J]. China Coal, 2016, 42(2):83-87.

WANG Z C, DONG X S. Research on the inhibition law of sodium humate on coal slurry flotation[J]. China Coal, 2016, 42(2): 83-87.

[8] 黄良仙, 韩星星, 马展, 等. 甘肃某地褐煤中腐植酸的提取工艺研究[J]. 陕西科技大学学报(自然科学版), 2019, 37(6):105-110. HUANG L X, HAN X X, MA Z, et al. Research on the extraction process of humic acid from lignite in Gansu[J]. Journal of Shaanxi University of Science and Technology (Natural Science Edition), 2019, 37(6):105-110.

HUANG L X, HAN X X, MA Z, et al. Research on the extraction process of humic acid from lignite in Gansu[J]. Journal of Shaanxi University of Science and Technology (Natural Science Edition), 2019, 37(6): 105-110.

[9] 安泉, 屈进州, 周安宁, 等. 低阶煤煤泥的淀粉抑制反浮选降灰实验研究[J]. 选煤技术, 2019(6):24-27+33. AN Q, QU J Z, ZHOU A N, et al. Experimental study on ash reduction by starch inhibited reverse flotation of low rank coal slurry[J]. Coal Selection Technology, 2019(6):24-27+33.

AN Q, QU J Z, ZHOU A N, et al. Experimental study on ash reduction by starch inhibited reverse flotation of low rank coal slurry[J]. Coal Selection Technology, 2019(6): 24-27+33.

[10] 阳虹, 李永生, 范云场, 等. 风化煤中腐植酸的提取及其光谱学研究[J]. 煤炭转化, 2013, 36(2):87-91. YANG H, LI Y S, FAN Y C, et al. Extraction of humic acid from weathered coal and its spectroscopic study[J]. Coal Conversion, 2013, 36(2):87-91.

YANG H, LI Y S, FAN Y C, et al. Extraction of humic acid from weathered coal and its spectroscopic study[J]. Coal Conversion, 2013, 36(2): 87-91.

-

下载:

下载: