Molecular Dynamics Simulation Study on Adsorption Behavior of Three Anionic Collectors on Wulfenite Surface

-

摘要:

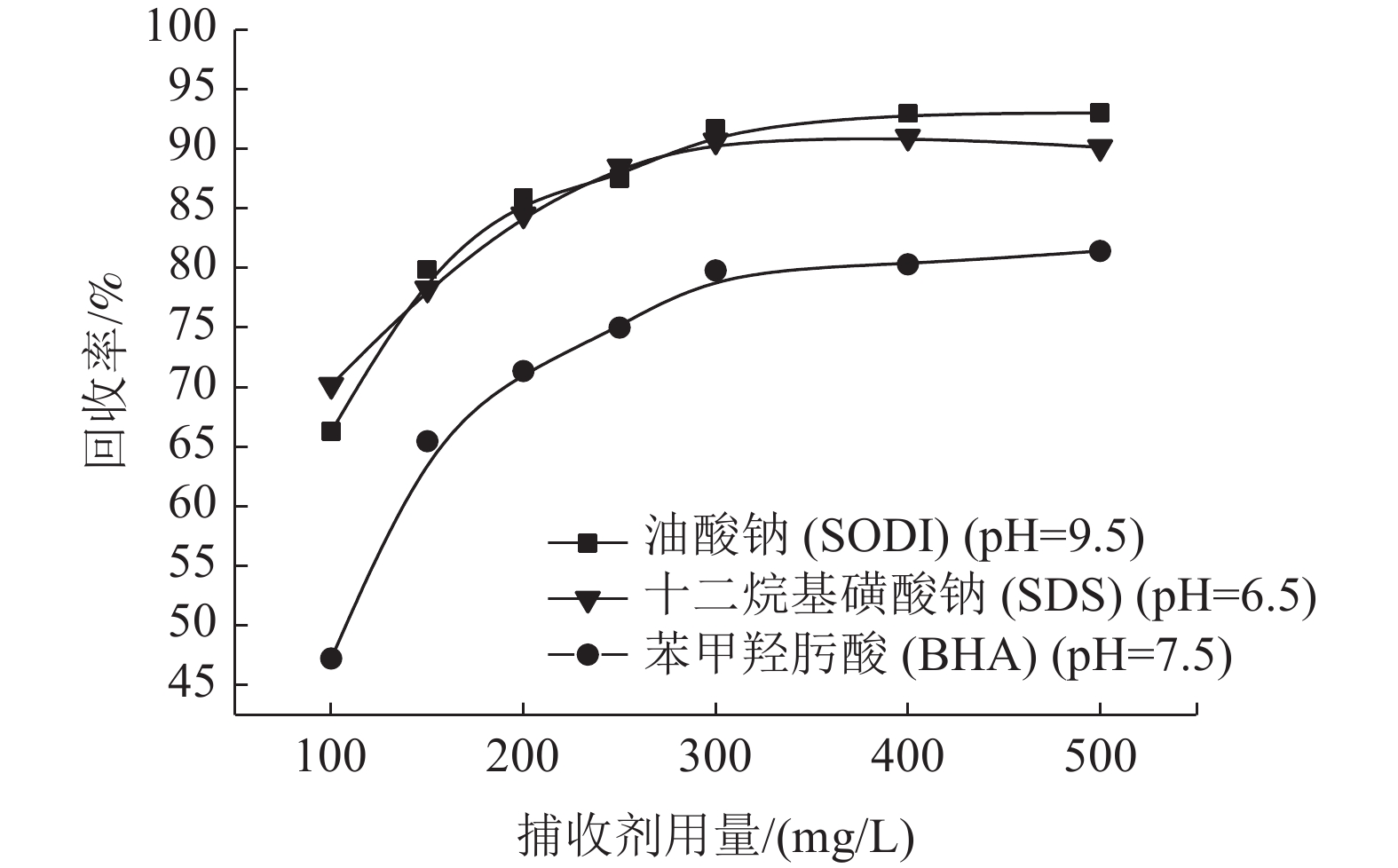

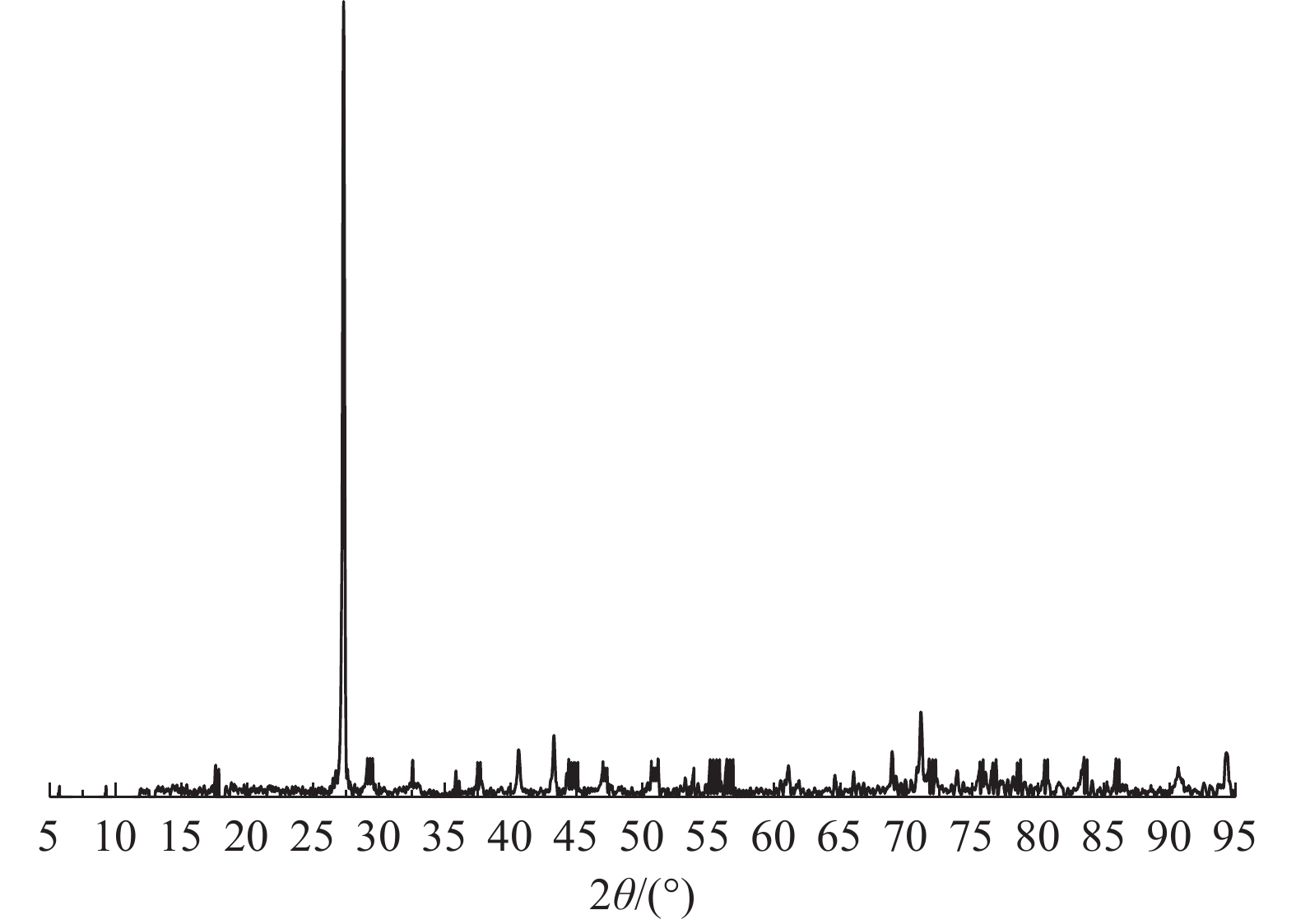

这是一篇矿物加工工程领域的论文。以油酸钠、十二烷基磺酸钠、苯甲羟肟酸三种阴离子捕收剂在彩钼铅矿{112}表面的吸附为研究对象,首先考查了矿浆pH值和捕收剂种类对彩钼铅矿吸附行为的影响,然后采用Materials Studio中Dmol3模块和Forcite模块,对三种捕收剂的吸附行为进行了前线轨道理论分析和分子动力学模拟研究。结果表明,在各捕收剂适宜的pH值范围内,油酸钠和十二烷基磺酸钠对彩钼铅矿的捕收性能更强;计算模拟研究结果表明,三种捕收剂对彩钼铅矿{112}面均表现出较强的吸附作用,彩钼铅矿晶体表面的钼原子由于原Mo-O键的断裂,表现出了更强的吸附活性,与捕收剂极性基中的单键氧原子共同组成了吸附作用的活性质点,对比吸附作用有效质量和相互作用能,三种捕收剂对彩钼铅矿的吸附能力大小依次为:油酸钠>十二烷基磺酸钠>苯甲羟肟酸,与浮选行为研究结果一致。

Abstract:This is an article in the field of mineral processing engineering. The adsorption kinetics of sodium oleate (SODI), sodium dodecyl sulfonate (SDS) and benzohydroxamic acid (BHA) on the surface of wulfenite were taken as the research subject.Firstly, flotation tests of pure wulfenite were conducted to study the effects of pH value and collectortype on wulfenite flotation behavior, then, the frontier orbital theory analysis and molecular dynamics simulation on adsorption behavior of these three collectors was studied by using Dmol3 module and Forcite module in Materials Studio respectively. The flotation tests resultsindicate that SODI and SDS show better collecting property than BHAin their respectiveappropriate pH range. Computational simulation study results also shows that thesethreecollectors all have strong adsorption on wulfenite {112} surface, and the molybdenumatomsonthe surface show stronger adsorption activity than other atoms due to the breakage of theoriginal Mo-O bonds, and together with the single bond oxygen atoms in polar group of collectors, arethe active particles of the adsorption process. According to the effective mass and the adsorptioninteraction energy, the adsorption ability of these there collectors could be listed as follows:SODI>SDS>BHA, which are consistent with the flotation tests.

-

-

表 1 三种捕收剂与彩钼铅矿的前线轨道能量及作用有效质量

Table 1. Frontier orbital energy and effective mass of three collectors and wulfenite

矿物/药剂 前线轨道值 与彩钼铅矿作用有效质量

|ΔE|/eVEHOMO/eV ELUMO/eV 彩钼铅矿 -6.023 -3.737 / 油酸钠离子(SODI) -3.099 -2.963 0.638 十二烷基磺酸钠离子(SDS) -5.489 -2.882 1.752 苯甲羟肟酸离子(BHA) -5.957 -1.044 2.220 -

[1] 张汉鑫, 李慧, 梁精龙, 等. 稀有金属钼资源回收现状及进展[J]. 矿产综合利用, 2020(1):47-49.ZHANG H X, LI H, LIANG J L, et al. Current status and progress of rare metal molybdenum resource recovery[J]. Multipurpose Utilization of Mineral Resources, 2020(1):47-49.

ZHANG H X, LI H, LIANG J L, et al . Current status and progress of rare metal molybdenum resource recovery[J]. Multipurpose Utilization of Mineral Resources,2020 (1 ):47 -49 .[2] 傅开彬, 彭铁峰, 汤鹏成, 等. 贵州某含铅锌彩钼铅矿碱浸提钼工艺研究[J]. 武汉理工大学学报, 2017(7):57-60.FU K B, PENG T F, TANG P C, et al. Research on the alkaline leaching process of molybdenum from a lead-zinc-bearing wulfenite in Guizhou[J]. Journal of Wuhan University of Technology, 2017(7):57-60.

FU K B, PENG T F, TANG P C, et al . Research on the alkaline leaching process of molybdenum from a lead-zinc-bearing wulfenite in Guizhou[J]. Journal of Wuhan University of Technology,2017 (7 ):57 -60 .[3] 胡真, 宋宝旭, 邹坚坚, 等. 某稀土矿床中伴生彩钼铅矿的综合回收试验研究[J]. 有色金属(选矿部分), 2013(S1):124-128.HU Z, SONG B X, ZOU J J, et al. Experimental research on comprehensive recovery of associated wulfenite in a rare earth deposit[J]. Nonferrous Metals (Mineral Processing Section), 2013(S1):124-128.

HU Z, SONG B X, ZOU J J, et al . Experimental research on comprehensive recovery of associated wulfenite in a rare earth deposit[J]. Nonferrous Metals (Mineral Processing Section),2013 (S1 ):124 -128 .[4] 曹耀华, 刘红召, 高照国, 等. 从彩钼铅粗精矿碱性浸出液中提取钼的新工艺[J]. 湿法冶金, 2012, 31(2):118-121.CAO Y H, LIU H Z, GAO Z G, et al. A new process for extracting molybdenum from the alkaline leaching solution of wulfeniteconcentrate[J]. Hydrometallurgy, 2012, 31(2):118-121.

CAO Y H, LIU H Z, GAO Z G, et al . A new process for extracting molybdenum from the alkaline leaching solution of wulfeniteconcentrate[J]. Hydrometallurgy,2012 ,31 (2 ):118 -121 .[5] 李秀娟. 稀土矿床中彩钼铅矿的选冶新技术及捕收特性研究[D]. 昆明: 昆明理工大学, 2014.LI X J. Research on the new technology of beneficiation and smelting of wulfenite in rare earth deposits and its collection characteristics[D]. Kunming: Kunming University of Science and Technology, 2014.

LI X J. Research on the new technology of beneficiation and smelting of wulfenite in rare earth deposits and its collection characteristics[D]. Kunming: Kunming University of Science and Technology, 2014. [6] 何桂春, 华亚南, 蒋巍, 等. 分子动力学模拟及其在选矿中的应用[J]. 有色金属科学与工程, 2015, 6(5):91-96.HE G C, HUA Y N, JIANG W, et al. Molecular dynamics simulation and its application in mineral processing[J]. Non-Ferrous Metal Science and Engineering, 2015, 6(5):91-96.

HE G C, HUA Y N, JIANG W, et al . Molecular dynamics simulation and its application in mineral processing[J]. Non-Ferrous Metal Science and Engineering,2015 ,6 (5 ):91 -96 .[7] Baoxu Song, Dongping Tao, Peilun Li, et al. Cleavage nature and surface appearances of wulfenite by first-principles calculations and experimental measurement[J]. Results in Physics, 2019, 16(2020).

[8] 刘明宝, 郭万中, 田思雨, 等. 油酸钠与苯甲羟肟酸钠协同体系中金红石的浮选机理[J]. 过程工程学报, 2020, 20(11):1296-1303.LIU M B, GUO W Z, TIAN S Y, et al. The flotation mechanism of rutile in the synergistic system of sodium oleate and sodium benzhydroxamate[J]. The Chinese Journal of Process Engineering, 2020, 20(11):1296-1303.

LIU M B, GUO W Z, TIAN S Y, et al . The flotation mechanism of rutile in the synergistic system of sodium oleate and sodium benzhydroxamate[J]. The Chinese Journal of Process Engineering,2020 ,20 (11 ):1296 -1303 .[9] 蒋海勇, 齐越超, 张辉, 等. 十二烷基磺酸钠浮选重晶石的作用机理[J]. 材料研究与应用, 2020, 14(2):138-143.JIANG H Y, QI Y C, ZHANG H, et al. The mechanism of sodium dodecyl sulfonate flotation of barite[J]. Materials Research and Application, 2020, 14(2):138-143.

JIANG H Y, QI Y C, ZHANG H, et al . The mechanism of sodium dodecyl sulfonate flotation of barite[J]. Materials Research and Application,2020 ,14 (2 ):138 -143 . -

下载:

下载: