Effect of Pb2+, Zn2+ on Floatability of Chalcopyrite in Z-200 System and Its Mechanism

-

摘要:

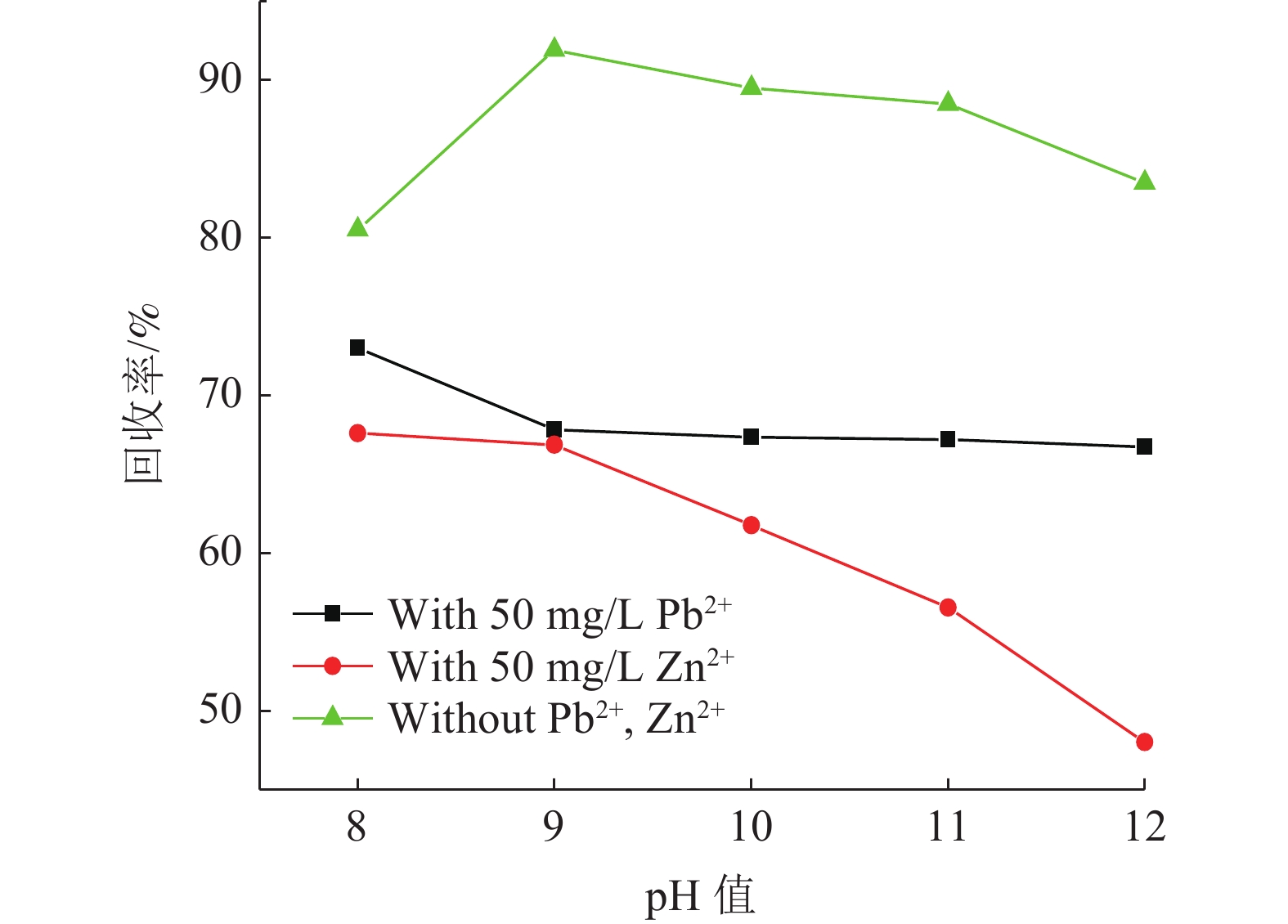

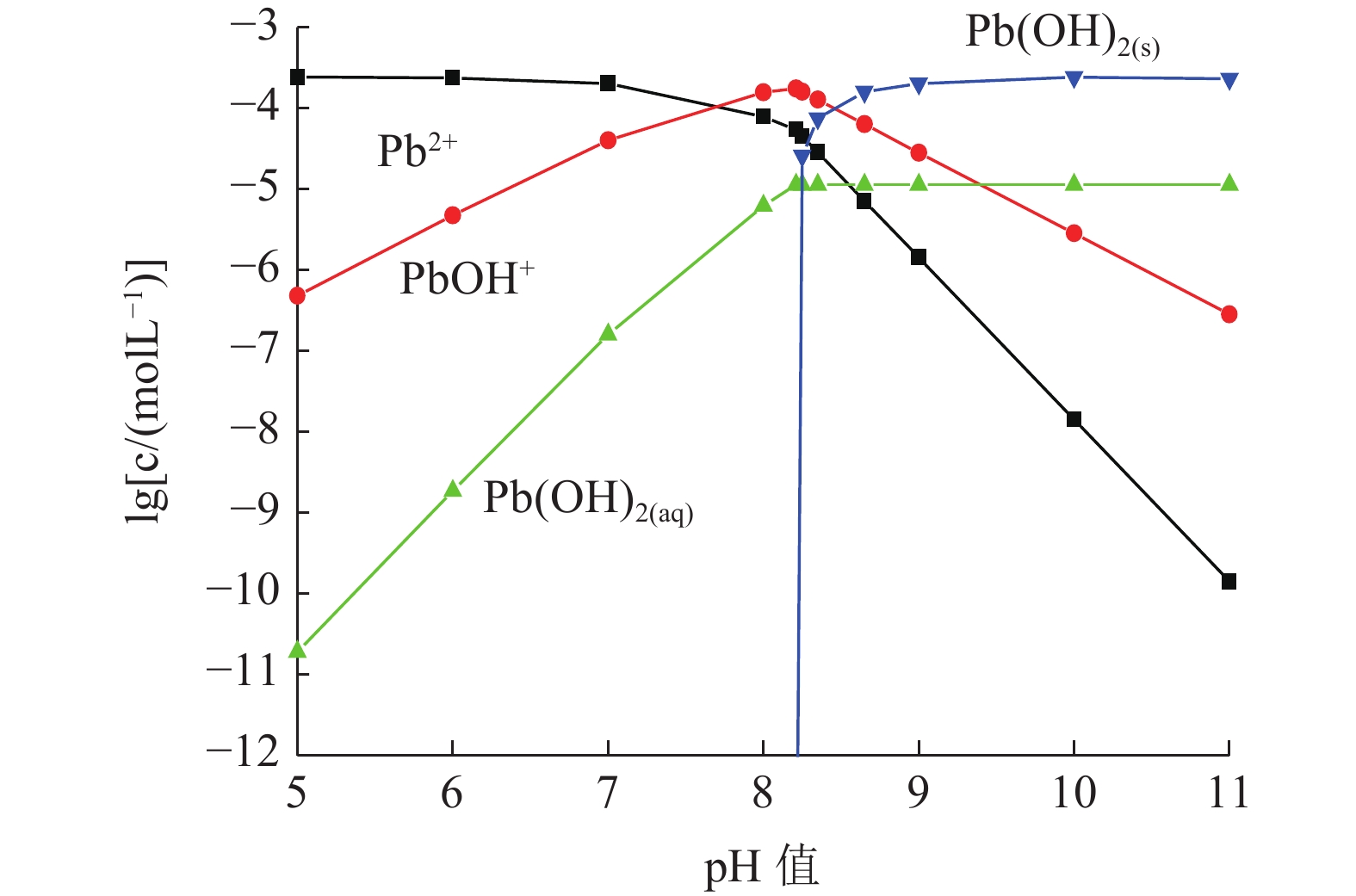

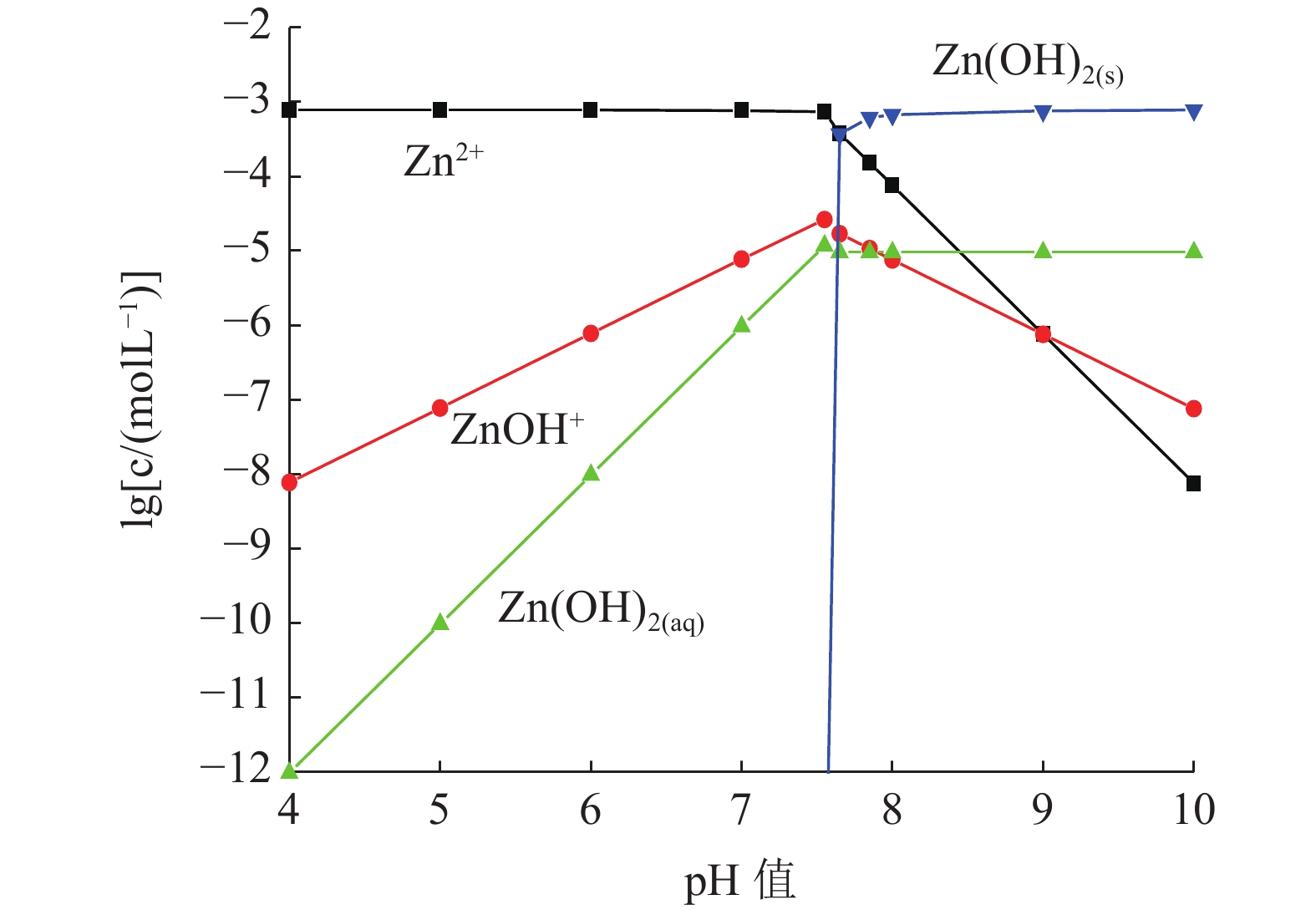

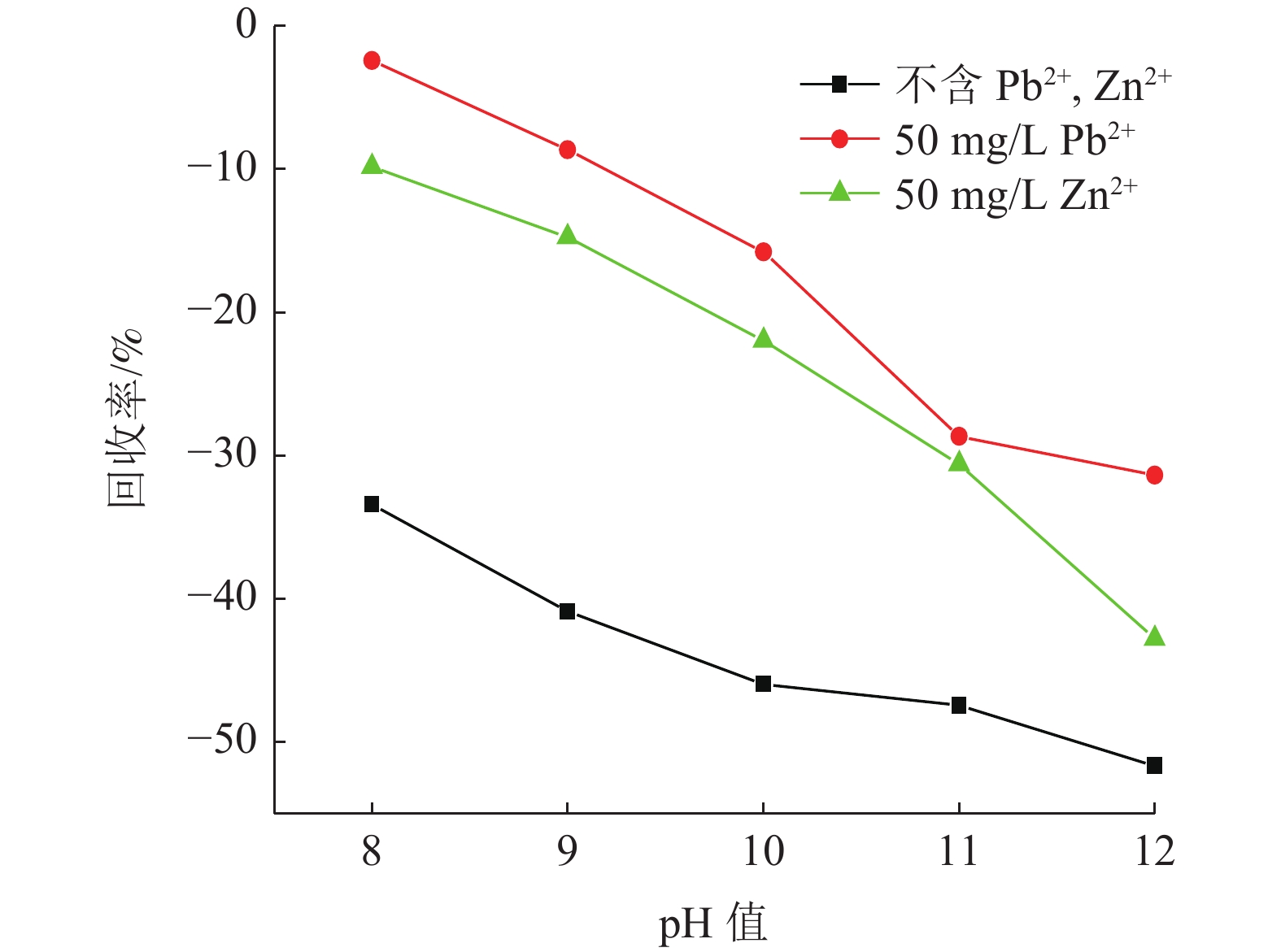

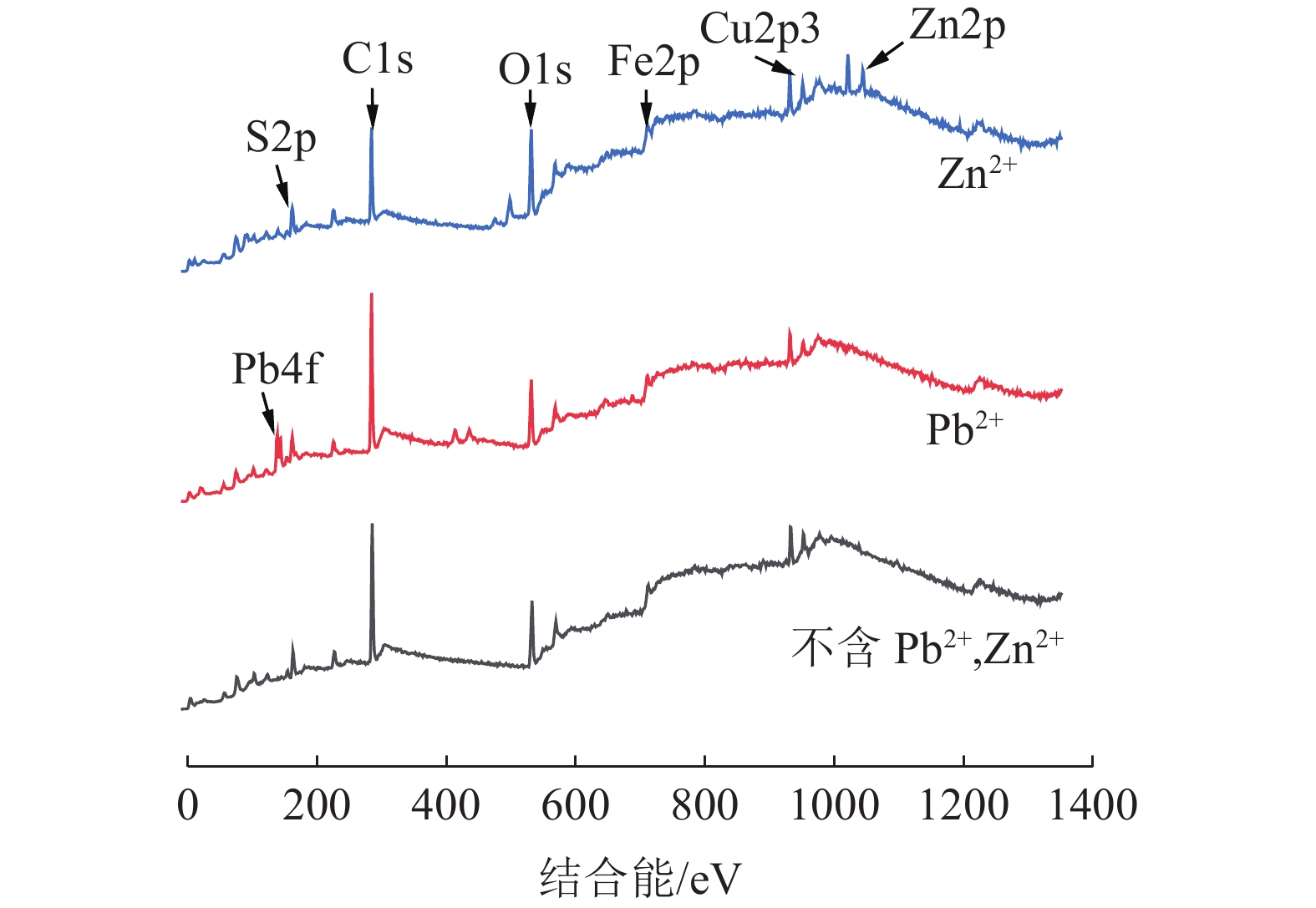

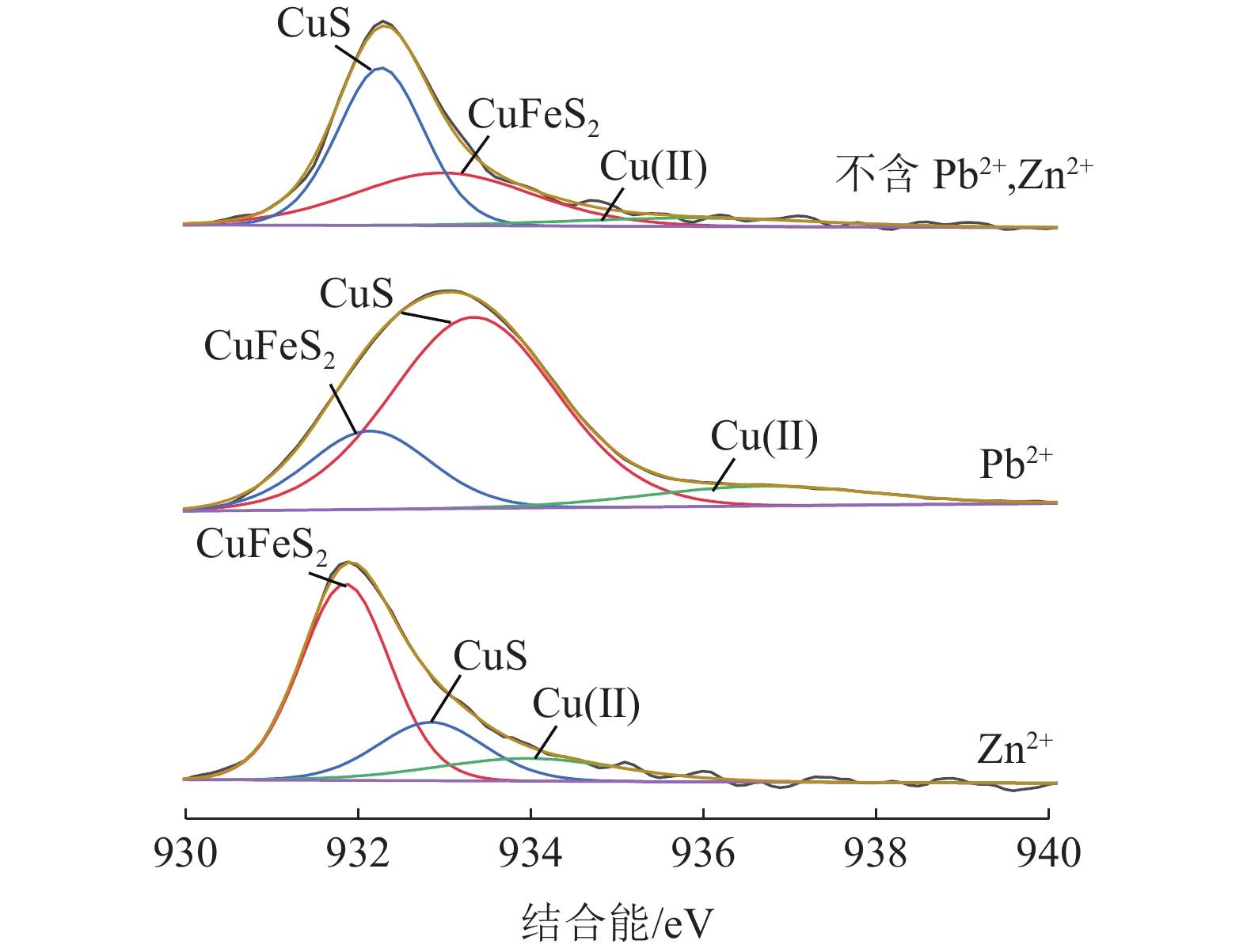

这是一篇矿物加工工程领域的论文。黄铜矿、方铅矿和闪锌矿通常会相互伴(共)生,为了探究Pb2+和Zn2+对黄铜矿浮选行为和表面性质的影响,本研究对黄铜矿进行了单矿物浮选实验,并利用溶液化学计算、Zeta电位和XPS检测等方法,对比研究了Pb2+和Zn2+对黄铜矿浮选行为和表面性质的影响。黄铜上的 Zn2+。矿石可浮性影响的差异。测试结果表明,Pb2+和Zn2+都会吸附在黄铜矿表面,改变黄铜矿表面的Zeta电位,抑制黄铜矿的可浮性,并且随着pH值的升高,抑制作用增强;结合浮选实验结果可知,浮选所处的矿浆pH值范围内,锌主要以Zn(OH)2沉淀的形式吸附在黄铜矿表面从而对黄铜矿的浮选产生抑制效果,所以Zn2+对黄铜矿浮选的抑制效果要比Pb2+显著;且XPS分析结果表明,Pb2+和Zn2+都能在黄铜矿表面形成沉淀物,并以化学吸附的形式出现在黄铜矿表面,从而抑制黄铜矿的可浮性。

Abstract:This is an article in the field of mineral processing engineering. Chalcopyrite, galena and sphalerite are usually associated with each other. In order to find out the influence of Pb2+ and Zn2+ on the flotation behavior and surface characteristics of chalcopyrite, the difference of the influence of Pb2+ and Zn2+ on the floatability of chalcopyrite was studied by single mineral flotation test, solution chemical calculation, Zeta potential and XPS detection. The results show that Pb2+ and Zn2+ are adsorbed on the surface of chalcopyrite, which changes the Zeta potential of chalcopyrite surface and inhibits the floatability of chalcopyrite, and the inhibition increases with the increase of pH value. According to the flotation test results, zinc is mainly adsorbed on the surface of chalcopyrite in the form of Zn(OH)2 precipitation in the range of pulp pH, which has an inhibitory effect on the flotation of chalcopyrite. Therefore, the inhibitory effect of Zn2+ on the flotation of chalcopyrite is more significant than that of Pb2+ and XPS results show that Pb2+ and Zn2+ can precipitate on the surface of chalcopyrite and exist on the surface of chalcopyrite in the form of chemical adsorption, thus inhibiting the floatability of chalcopyrite.

-

Key words:

- Mineral processing engineering /

- Chalcopyrite /

- Lead zinc ion /

- Floatability /

- Inhibition

-

-

表 1 黄铜矿表面原子相对百分含量及元素电子结合能

Table 1. Relative content and electron binding energy of atoms on chalcopyrite surface

序号 浓度/ (mg/L) 相对含量/% 电子结合能/eV Pb2+ Zn2+ Cu O S C Pb Zn Cu S Pb Zn 1 0 0 2.03 16.95 7.74 71.52 - - 932.49 162.35 - - 2 50 0 1.65 23.34 7.79 66.42 0.80 - 932.62 162.01 138.77 - 3 0 50 0.72 30.66 0.48 65.37 - 1.67 932.53 163.18 - 1022.09 表 2 Cu的价键形态及分峰拟合分布比例

Table 2. Distribution ratio of each sub-peak fitting form of Cu

序号 浓度/ (mg/L) 结合能/eV 相对含量/% Pb2+ Zn2+ CuFeS2 CuS Cu(Ⅱ) CuFeS2 CuS Cu(Ⅱ) 1 0 0 932.98 932.26 935.89 37.55 54.16 8.29 2 50 0 932.13 933.33 936.67 20.83 69.34 9.83 3 0 50 931.85 932.84 933.96 62.68 22.38 14.94 -

[1] 王威, 李以科, 封宁. 全球铜矿资源格局分析[J]. 资源与产业, 2013, 15(5):27-32.WANG W, LI Y K, FENG N. Global cooper resource pettern[J]. Resources and Industry, 2013, 15(5):27-32.

WANG W, LI Y K, FENG N . Global cooper resource pettern[J]. Resources and Industry,2013 ,15 (5 ):27 -32 .[2] 张汉彪, 薛伟. 刚果(金)某复杂难选氧化铜矿选矿试验研究[J]. 矿产综合利用, 2020(3):117-120.ZHANG H B, XUE W. Experimental study on beneficiation of a complex refractory copper oxide ore in Congo (DRC)[J]. Multipurpose Utilization of Mineral Resources, 2020(3):117-120.

ZHANG H B, XUE W . Experimental study on beneficiation of a complex refractory copper oxide ore in Congo (DRC)[J]. Multipurpose Utilization of Mineral Resources,2020 (3 ):117 -120 .[3] 黄真瑞, 钟宏, 王帅, 等. 黄铜矿浮选工艺及捕收剂研究进展[J]. 应用化工, 2013, 42(11): 2048-2051+2055.HUANG Z R, ZHONG H, WANG S , et al. Progress of flotation technology and collectors for chalcopyrite [J]. Applied Chemical Industry, 2013, 42 (11): 2048-2051 + 2055.

HUANG Z R, ZHONG H, WANG S , et al. Progress of flotation technology and collectors for chalcopyrite [J]. Applied Chemical Industry, 2013, 42 (11): 2048-2051 + 2055. [4] 肖炜, 田小松. 云南迪庆铜铅锌硫化矿浮选分离研究[J]. 矿产综合利用, 2020(1):65-70.XIAO W, TIAN X S. Study on flotation separation of copper-lead-zinc sulfide ore in Diqing Yunnan[J]. Multipurpose Utilization of Mineral Resources, 2020(1):65-70. doi: 10.3969/j.issn.1000-6532.2020.01.014

XIAO W, TIAN X S . Study on flotation separation of copper-lead-zinc sulfide ore in Diqing Yunnan[J]. Multipurpose Utilization of Mineral Resources,2020 (1 ):65 -70 .[5] 王亮, 李育彪, 李万青. 不同价态杂质离子对黄铜矿浮选的影响机理研究[J]. 金属矿山, 2018(12):84-88.WANG L, LI Y B, LI W Q. Influencing mechanism of ions with different valences on chalcopyrite flotation[J]. Metal Mineses, 2018(12):84-88. doi: 10.19614/j.cnki.jsks.201812015

WANG L, LI Y B, LI W Q . Influencing mechanism of ions with different valences on chalcopyrite flotation[J]. Metal Mineses,2018 (12 ):84 -88 .[6] 雷大士, 王宇斌, 郭月琴, 等. 陕西某含铋白钨矿选矿试验研究[J]. 中国钨业, 2017, 32(3):31-35.LEI D S, WANG Y B, GUO Y Q, et al. Beneficiation of a bismuth-containing scheelite in Shaanxi[J]. China Tungsten Industry, 2017, 32(3):31-35.

LEI D S, WANG Y B, GUO Y Q, et al . Beneficiation of a bismuth-containing scheelite in Shaanxi[J]. China Tungsten Industry,2017 ,32 (3 ):31 -35 .[7] 温 凯, 陈建华. 某含银复杂铜铅锌多金属硫化矿浮选试验[J]. 矿产综合利用, 2019(6):28-32.WEN K, CHEN J H. Experimental study on flotation of copper, lead and zinc polymetallic sulfide ore containing silver[J]. Multipurpose Utilization of Mineral Resources, 2019(6):28-32.

WEN K, CHEN J H . Experimental study on flotation of copper, lead and zinc polymetallic sulfide ore containing silver[J]. Multipurpose Utilization of Mineral Resources,2019 (6 ):28 -32 .[8] 鱼博, 王宇斌, 王妍, 等. 某铜铅锌多金属硫化矿工艺矿物学研究[J]. 中国钼业, 2021, 45(1):34-38.YU B, WANG Y B, WANG Y, et al. Research on process mineralogy of a copper-lead-zinc polymetallic sulphide ore[J]. China Molybdenum Industry, 2021, 45(1):34-38.

YU B, WANG Y B, WANG Y, et al . Research on process mineralogy of a copper-lead-zinc polymetallic sulphide ore[J]. China Molybdenum Industry,2021 ,45 (1 ):34 -38 .[9] 魏明安, 孙传尧. 矿浆中的难免离子对黄铜矿和黄铜矿浮选的影响[J]. 有色金属, 2008(2):92-95.WEI M A, SUN C Y. Influence of metal cations in pulp to chalcopyrite and galena floatability[J]. Nonferrous Metals(Mineral Processing Section), 2008(2):92-95.

WEI M A, SUN C Y . Influence of metal cations in pulp to chalcopyrite and galena floatability[J]. Nonferrous Metals(Mineral Processing Section),2008 (2 ):92 -95 .[10] 施帅, 何廷树, 李慧. Ca2+和Mg2+对辉钼矿可浮性的影响对比[J]. 过程工程学报, 2021, 21(2):153-159.SHI S, HE T S, LI H. Comparison of the effects of Ca2+and Mg2+ on the floatability of molybdenite[J]. Journal of Process Engineering, 2021, 21(2):153-159.

SHI S, HE T S, LI H . Comparison of the effects of Ca2+and Mg2+ on the floatability of molybdenite[J]. Journal of Process Engineering,2021 ,21 (2 ):153 -159 .[11] 刘微, 刘广义, 肖静晶, 等. N-异丁氧羰基硫脲浮选黄铜矿的机理[J]. 中国有色金属学报, 2017, 27(1):128-137.LIU W, LIU G Y, XIAO J J, et al. Mechanism of N-isobutoxycarbonyl thiourea (iBCTU) for chalcopyrite flotation[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1):128-137.

LIU W, LIU G Y, XIAO J J, et al . Mechanism of N-isobutoxycarbonyl thiourea (iBCTU) for chalcopyrite flotation[J]. The Chinese Journal of Nonferrous Metals,2017 ,27 (1 ):128 -137 .[12] 马鑫, 王帅, 钟宏. 苄基三硫代碳酸钠的合成及其对黄铜矿的浮选性能[J]. 中国有色金属学报, 2018, 28(5):1067-1075.MA X, WANG S, ZHONG H. Sodium benzyl trithiocarbonate synthesis and flotation performance to chalcopyrite[J]. Chinese Journal of Nonferrous metals, 2018, 28(5):1067-1075. doi: 10.19476/j.ysxb.1004.0609.2018.05.24

MA X, WANG S, ZHONG H . Sodium benzyl trithiocarbonate synthesis and flotation performance to chalcopyrite[J]. Chinese Journal of Nonferrous metals,2018 ,28 (5 ):1067 -1075 . -

下载:

下载: