Flotation of an Arsenic Bearing High Sulfur Gold Mine in Gansu Province

-

摘要:

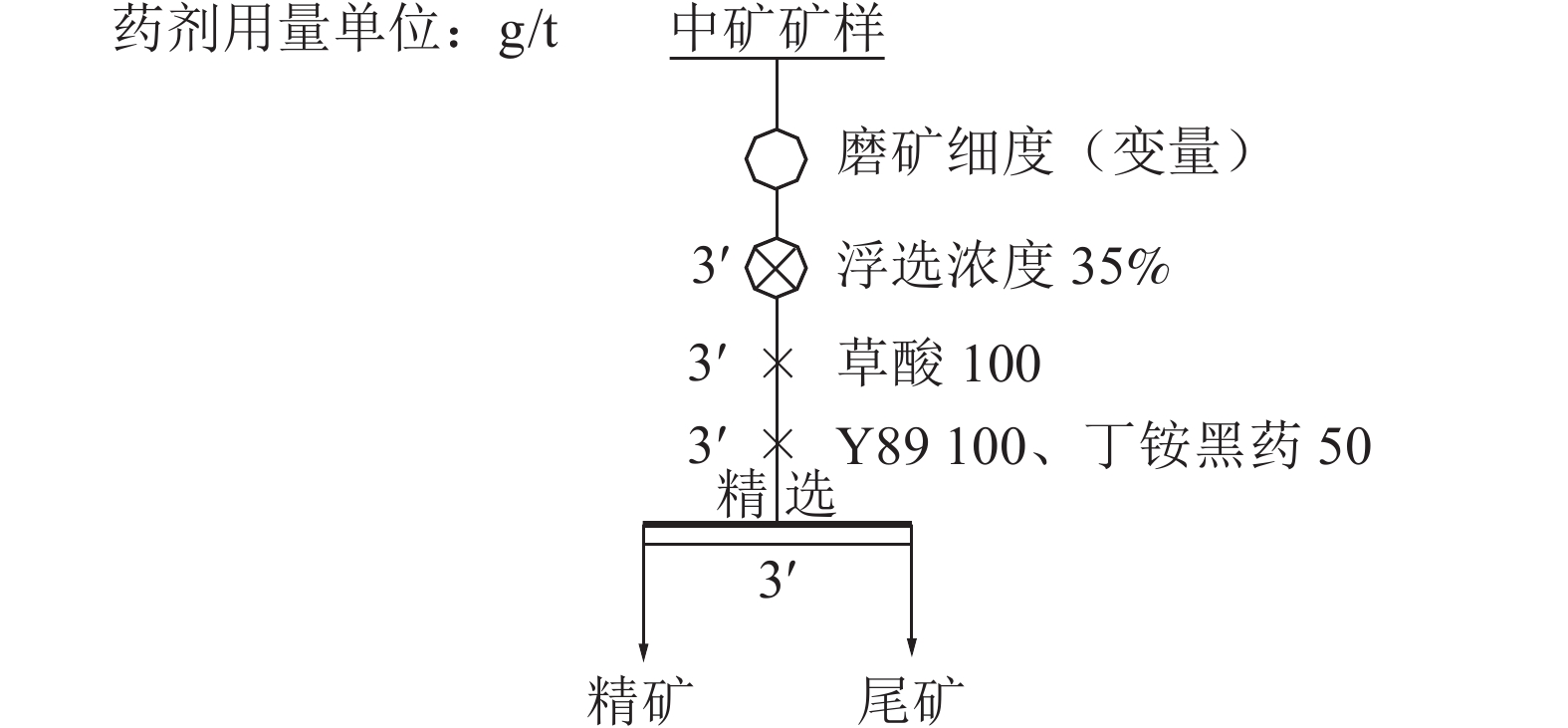

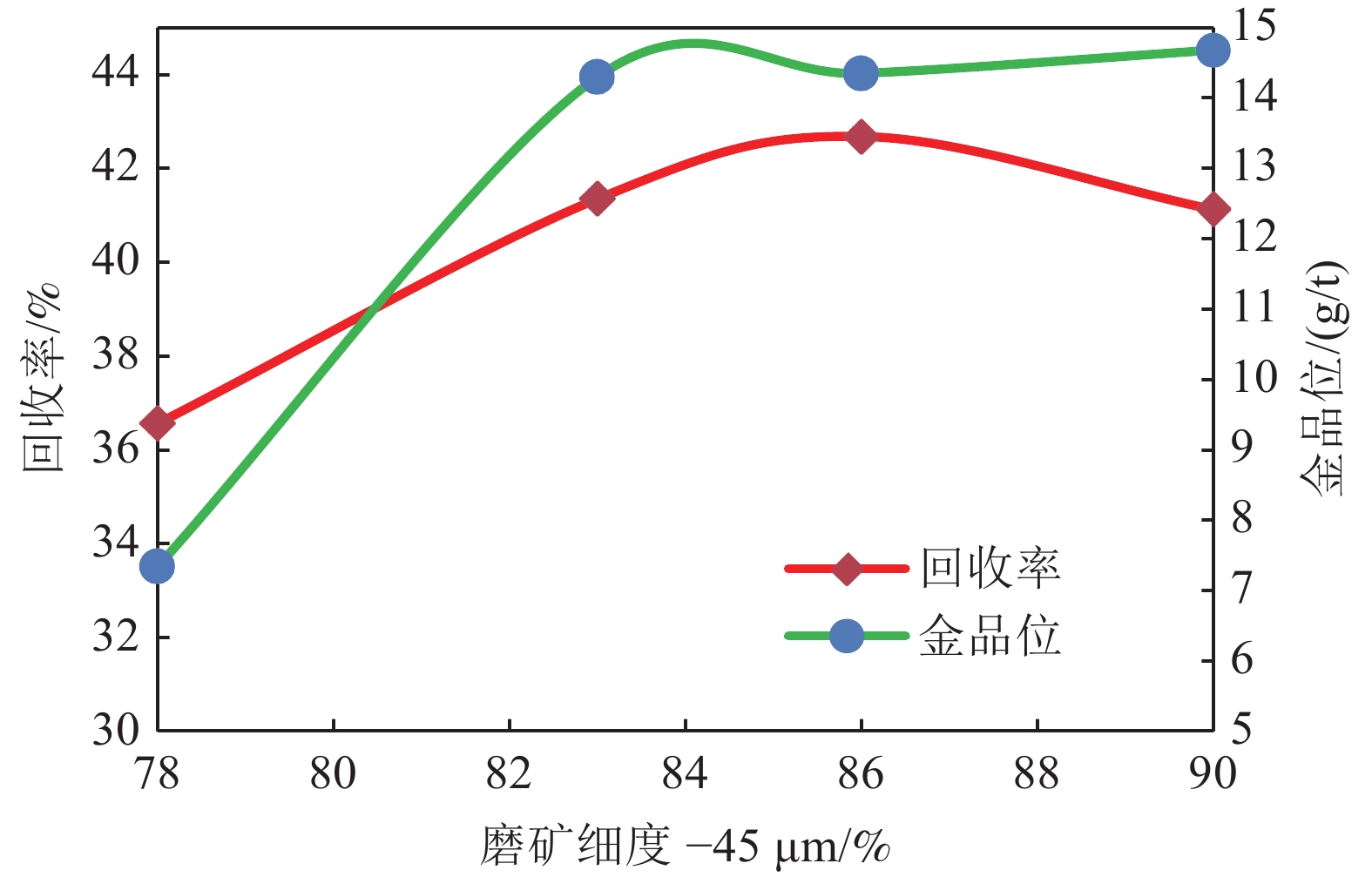

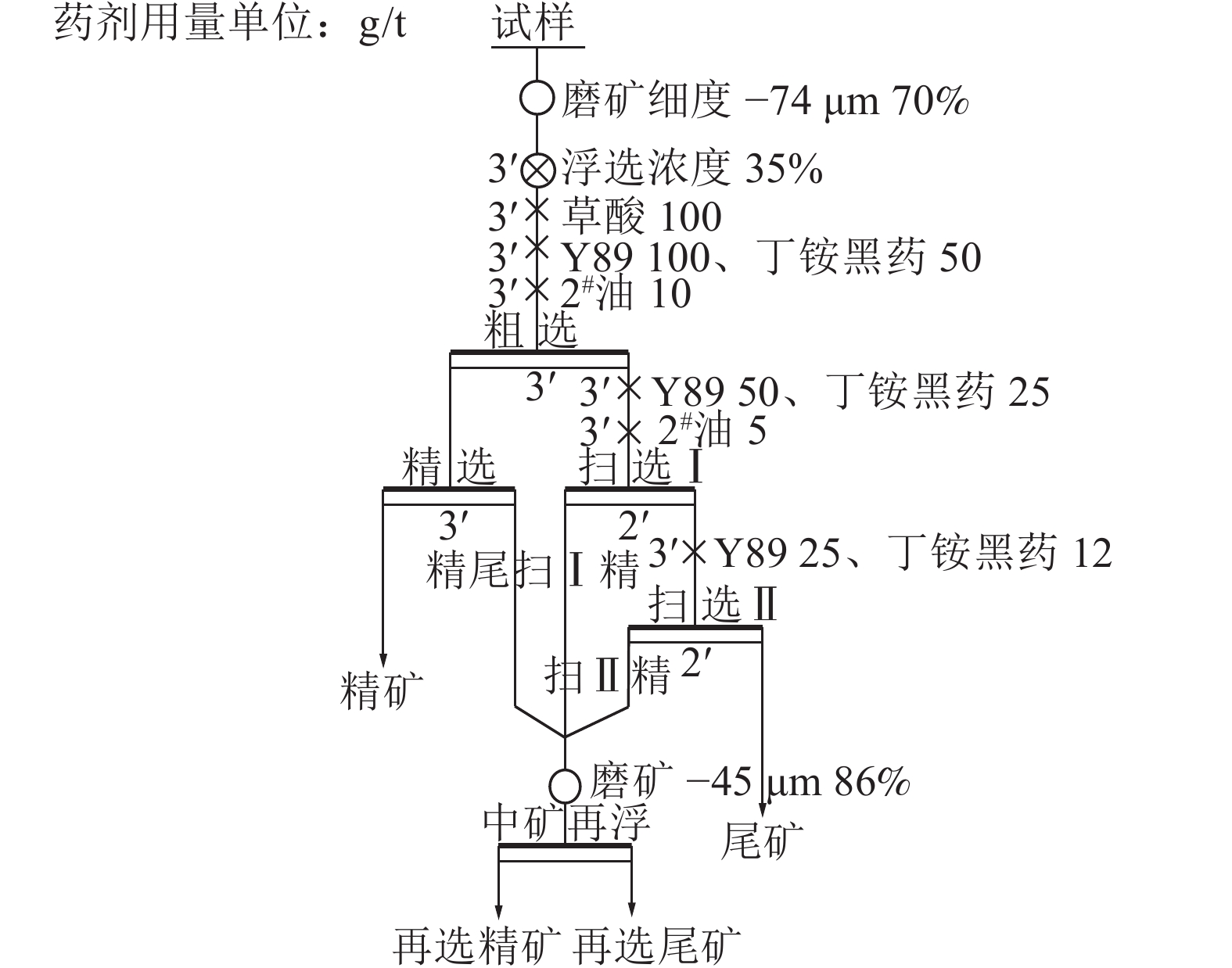

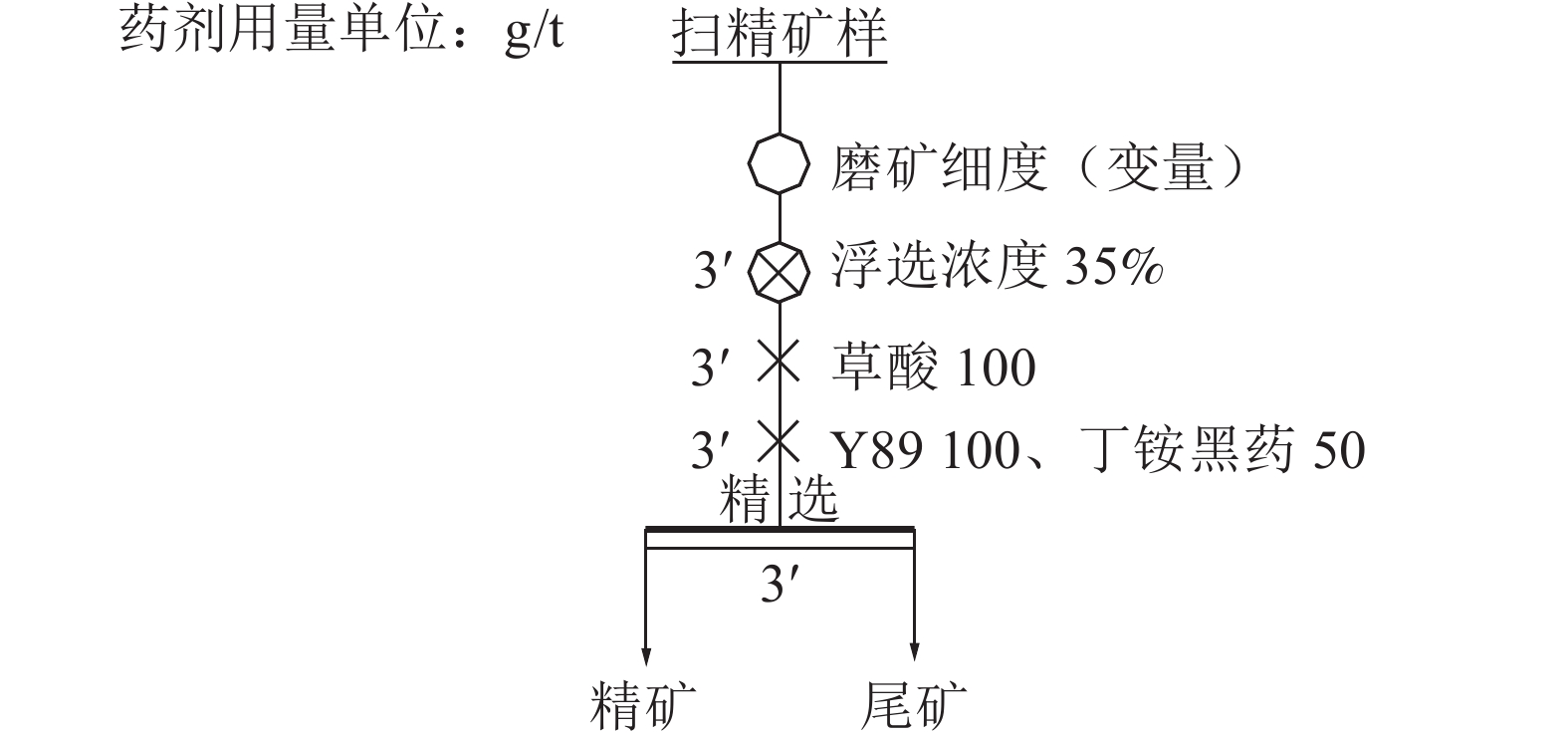

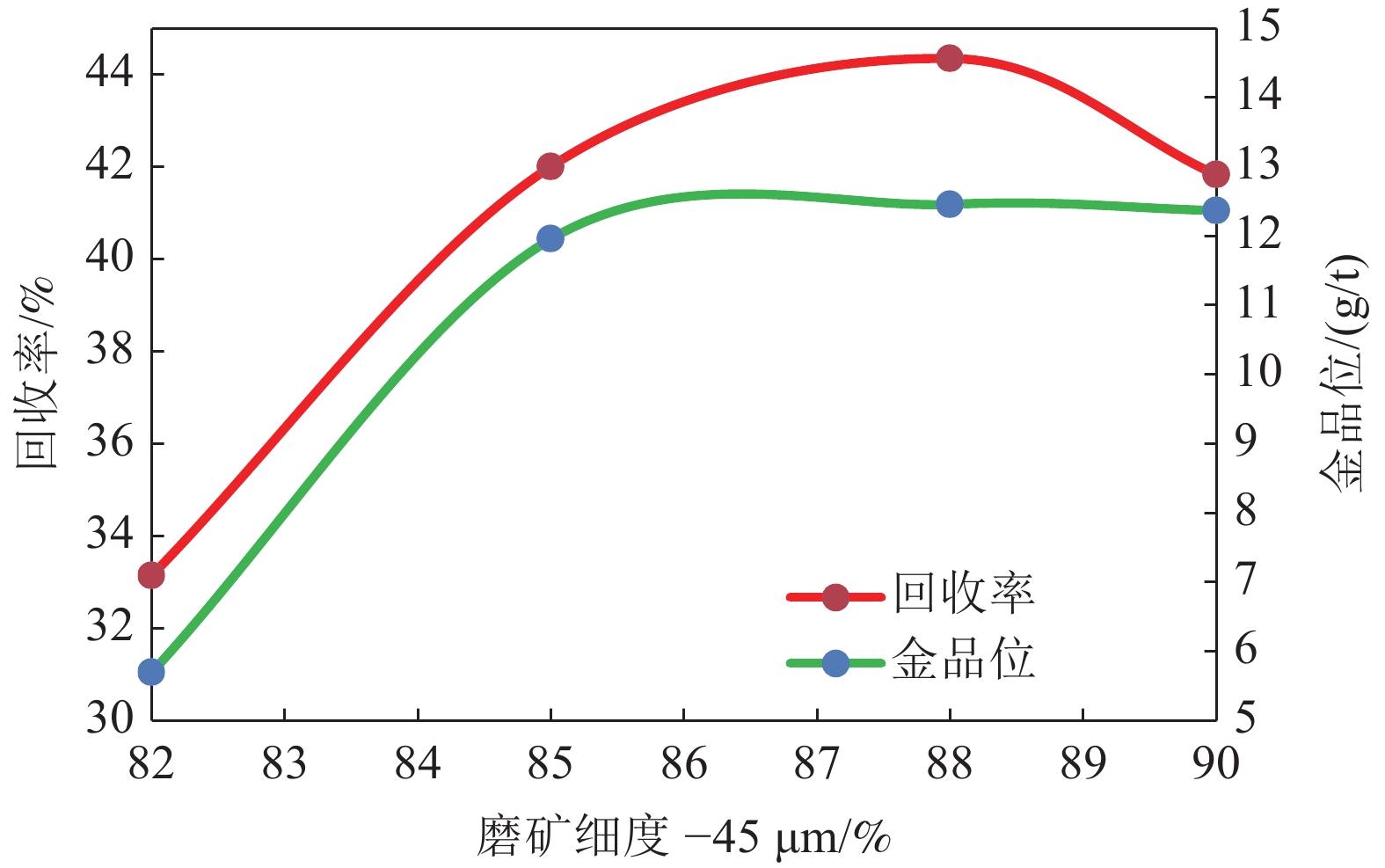

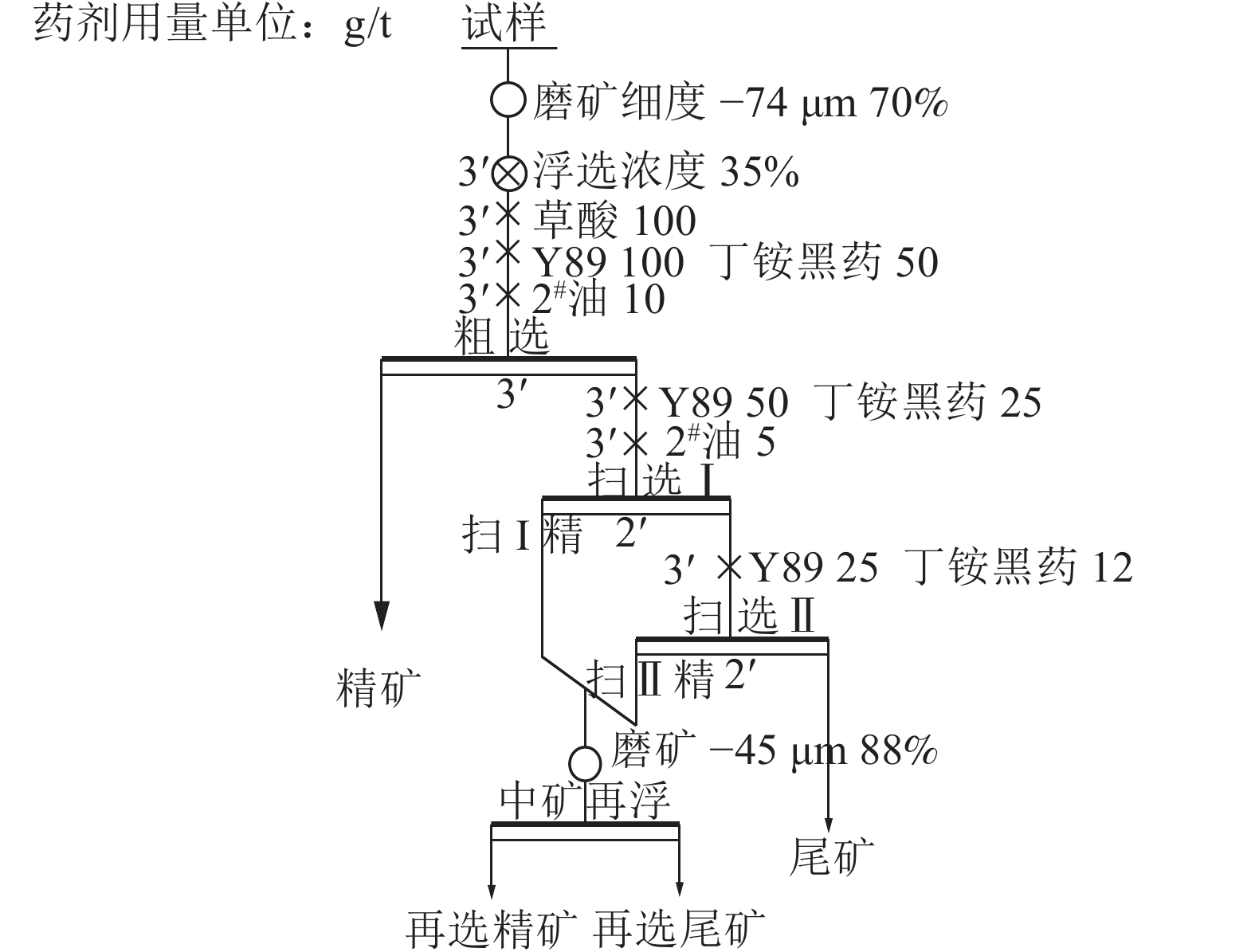

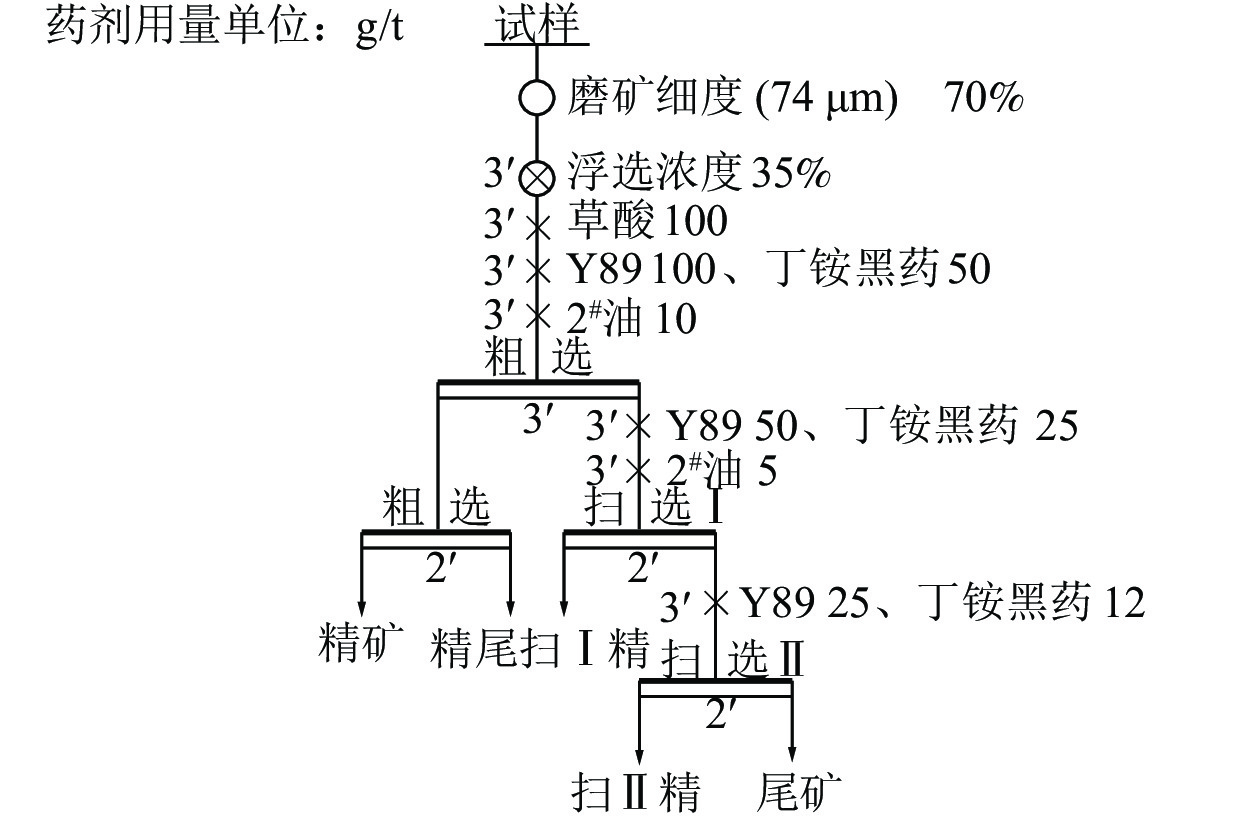

这是一篇矿物加工工程领域的论文。某含砷高硫金矿中金矿物与黄铁矿、毒砂共生关系密切,在实际生产过程中精矿金回收率不理想。为提高精矿金回收率,同时兼顾精矿金品位,针对该矿物特点,通过系统条件实验、浮选时间实验和精选实验得到了浮选工艺参数和流程,继而开展开路实验和闭路实验,获得了较好的浮选指标。为进一步提升浮选指标,对浮选中矿进行再磨再浮实验,并对中矿再磨浮选尾矿进行氰化浸出实验,最终得到金选冶总回收率91.94%的满意指标。

Abstract:This is an article in the field of mineral processing engineering. The gold mineral in an arsenic bearing high sulfur gold mine has a close symbiotic relationship with pyrite and arsenopyrite, and the recovery rate of concentrate gold is not ideal in the actual production process. In order to improve the recovery rate of concentrate gold and take into account the grade of concentrate gold, according to the characteristics of this mineral, the flotation process parameters and process are obtained through system condition test, flotation time test and beneficiation test, and then the open circuit test and closed circuit test are carried out to obtain better flotation indexes. In order to further improve the flotation index, the regrinding and flotation test of flotation middling is carried out, and the cyanide leaching test of middling regrinding flotation tailings is carried out. Finally, the satisfactory index of 91.94% of the total recovery of gold dressing and metallurgy is obtained.

-

Key words:

- Mineral processing engineering /

- Mineralogical technology /

- Arsenic /

- High sulfur /

- Middling regrinding

-

-

表 1 化学有效元素分析结果/%

Table 1. Chemical active element analysis results

Au* Ag* Cu Pb Zn Fe S As SiO2 Al2O3 MgO CaO Na2O K2O 6.64 2.62 0.013 0.027 0.015 14.47 3.69 1.65 18.99 1.12 0.80 23.45 0.03 0.36 *单位为 g/t 表 2 样品中金矿物解离特征

Table 2. Dissociation characteristics of gold minerals in samples

解离度

X单体

X=100%75%≤X<100% 50%≤X<75% 25%≤X<50% 0<X<25% 包裹

X=0合计 含量/% 4.60 10.07 57.97 2.54 0.89 23.93 100.00 表 3 样品中主要金矿物嵌布程度统计

Table 3. Statistics of embedding degree of main gold minerals in the samples

矿物 单体/% 共生体/% 合计/% 黄铁矿 黄铁矿和毒砂 毒砂 毒砂和菱铁矿 菱铁矿 含量/% 4.60 74.32 7.76 4.49 6.82 2.01 100.00 表 4 主要矿物粒度分布情况

Table 4. Particle size distribution of main minerals

粒级/μm 黄铁矿 毒砂 含量/% 正累积/% 含量/% 正累积/% +104 4.79 4.79 4.03 4.03 -104+74 10.73 15.52 8.11 12.14 -74+38 42.04 57.56 36.37 48.51 -38+20 24.60 82.16 30.30 78.81 -20+15 5.98 88.14 7.42 86.23 -15+10 5.03 93.17 5.25 91.48 -10+5 5.01 98.18 6.19 97.67 -5 1.82 100 2.33 100 平均粒径 47.46 43.57 表 5 主要矿物嵌布特征

Table 5. Distribution characteristics of main minerals

矿物名称 单体/% 共生体/% 合计/% 金属硫化物 其他脉石矿物 黄铁矿 14.08 6.85 79.07 100.00 毒砂 19.47 3.18 77.35 100.00 表 6 开路实验结果

Table 6. Test results of open circuit

样品名称 产率/% 金品位/(g/t) 金回收率/% 精矿 11.31 42.79 72.99 精尾 9.38 11.66 16.50 扫Ⅰ精 2.33 8.40 2.95 扫Ⅱ精 1.59 4.12 0.99 尾矿 75.39 0.58 6.57 合计 100.00 6.63 100.00 表 7 闭路实验结果

Table 7. Results of closed circuit test

产物名称 作业产率/% 金品位/(g/t) 金回收率/% 精矿 14.63 37.18 82.17 尾矿 85.37 1.38 17.83 合计 100.00 6.62 100.00 表 8 精尾和扫精混合再磨浮选实验结果

Table 8. Flotation test results of cleaner tailings and scavenger concentrate mixed Regrinding

样品名称 产率/% 金品位/(g/t) 金回收率/% 精矿 15.27 35.48 81.71 中矿浮精 2.75 14.84 6.15 合计(综合精矿) 18.02 32.34 87.86 中矿浮尾 7.85 4.45 5.30 尾矿 74.13 0.61 6.84 合计(综合尾矿) 81.98 0.98 12.14 总计 100.00 6.63 100.00 表 9 再选精矿浮选实验结果

Table 9. Flotation test results of Scavenger concentrate regrinding

样品名称 产率/% 金品位/(g/t) 金回收率/% 粗精 18.39 32.03 88.57 再选精矿 1.36 12.01 2.45 合计(综合精矿) 19.75 30.60 91.02 再选尾矿 6.51 2.75 1.92 尾矿 73.76 0.58 6.43 合计(综合尾矿) 80.27 0.76 8.98 总计 100.00 6.65 100.00 -

[1] 王刚强, 叶正国, 孙业友. 安徽某高硫含砷硫金矿硫砷分离试验[J]. 现代矿业, 2019, 35(12):127-129+153.WANG G Q, YE Z G, SUN Y Y. Sulfur-arsenic separation test of a high-sulfur arsenic-bearing sulfur-gold mine in Anhui[J]. Modern Mining, 2019, 35(12):127-129+153. doi: 10.3969/j.issn.1674-6082.2019.12.036

WANG G Q, YE Z G, SUN Y Y. Sulfur-arsenic separation test of a high-sulfur arsenic-bearing sulfur-gold mine in Anhui[J]. Modern Mining, 2019, 35(12):127-129+153. doi: 10.3969/j.issn.1674-6082.2019.12.036

[2] 皇甫明柱, 盛 娜, 邓久帅. 安徽某高硫金矿选矿实验[J]. 现代矿业, 2016(9):82-85.HUANGFU M Z, SHENG N, DENG J S. Beneficiation test of a high sulfur gold deposit in Anhui[J]. Modern Mining, 2016(9):82-85. doi: 10.3969/j.issn.1674-6082.2016.09.023

HUANGFU M Z, SHENG N, DENG J S. Beneficiation test of a high sulfur gold deposit in Anhui[J]. Modern Mining, 2016(9):82-85. doi: 10.3969/j.issn.1674-6082.2016.09.023

[3] 张晓民, 李恒, 李越, 等. 碳质物对高含碳金矿浮选影响的试验研究[J]. 有色金属工程, 2020, 10(2):74-81.ZHANG X M, LI H, LI Y, et al. Experimental study on the effect of carbonaceous material on the flotation of highly carbonaceous gold ores[J]. Nonferrous Metal Engineering, 2020, 10(2):74-81. doi: 10.3969/j.issn.2095-1744.2020.02.012

ZHANG X M, LI H, LI Y, et al. Experimental study on the effect of carbonaceous material on the flotation of highly carbonaceous gold ores[J]. Nonferrous Metal Engineering, 2020, 10(2):74-81. doi: 10.3969/j.issn.2095-1744.2020.02.012

[4] 明平田, 李飞. 某微细粒蚀变岩型金矿高效浮选新工艺研究[J]. 矿产综合利用, 2019(4):73-78.MING P T, LI F. Study on a new high efficiency flotation process for a microgranular altered rock gold mine[J]. Multipurpose Utilization of Mineral Resources, 2019(4):73-78. doi: 10.3969/j.issn.1000-6532.2019.04.015

MING P T, LI F. Study on a new high efficiency flotation process for a microgranular altered rock gold mine[J]. Multipurpose Utilization of Mineral Resources, 2019(4):73-78. doi: 10.3969/j.issn.1000-6532.2019.04.015

[5] 杨松林, 程东江, 王仁朋. 山东招远银金多金属矿床金矿物特征研究[J]. 矿产综合利用, 2021(6):195-197.YANG S L, CHENG D J, WANG R P. Characteristics of gold minerals in Zhaoyuan silver gold polymetallic deposit, Shandong Province[J]. Multipurpose Utilization of Mineral Resources, 2021(6):195-197.

YANG S L, CHENG D J, WANG R P. Characteristics of gold minerals in Zhaoyuan silver gold polymetallic deposit, Shandong Province[J]. Multipurpose Utilization of Mineral Resources, 2021(6):195-197.

[6] 赵 杰, 赵志强, 罗思岗, 等. 某含砷金矿浮选提金降砷实验研究[J]. 矿冶工程, 2021(4):63-65.ZHAO J, ZHAO Z Q, LUO S G, et al. Experimental study on flotation gold extraction and arsenic reduction of an arsenic bearing gold mine[J]. Mining and Metallurgy Engineering, 2021(4):63-65.

ZHAO J, ZHAO Z Q, LUO S G, et al. Experimental study on flotation gold extraction and arsenic reduction of an arsenic bearing gold mine[J]. Mining and Metallurgy Engineering, 2021(4):63-65.

[7] 黄长峰, 曹玉川. 湖南某金矿浮选工艺研究[J]. 矿冶工程, 2020(10):65-67.HUANG C F, CAO Y C. Study on flotation process of a gold mine in Hunan[J]. Mining and Metallurgy Engineering, 2020(10):65-67. doi: 10.3969/j.issn.0253-6099.2020.05.016

HUANG C F, CAO Y C. Study on flotation process of a gold mine in Hunan[J]. Mining and Metallurgy Engineering, 2020(10):65-67. doi: 10.3969/j.issn.0253-6099.2020.05.016

-

下载:

下载: