Determination of Niobium, Tantalum, Lithium and Beryllium in Niobium Tantalum Ore by Alkali Fusion Inductively Coupled Plasma Mass Spectrometry

-

摘要:

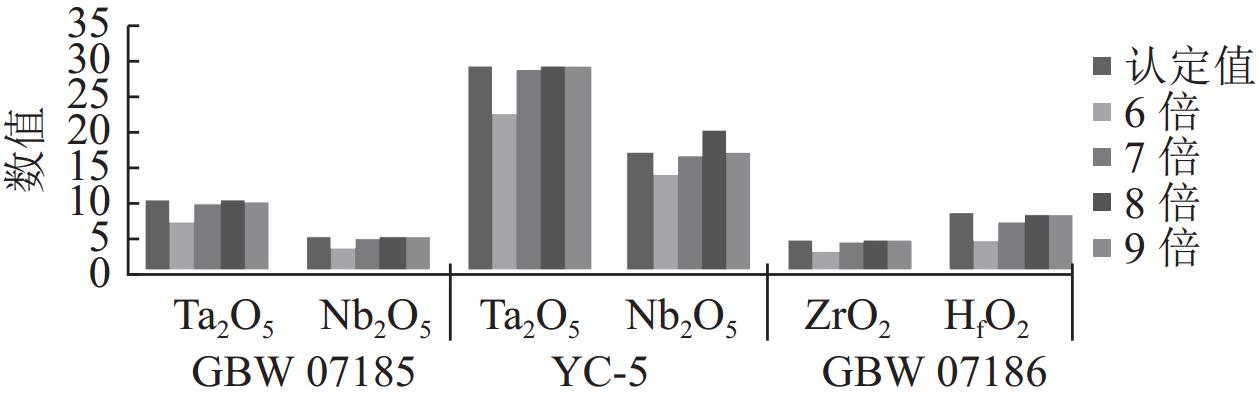

这是一篇矿物分析测试领域的论文。建立了碱熔-电感耦合等离子体质谱法同时测定铌钽矿中铌钽锂铍的快速测定方法。采用过氧化钠:氢氧化钠=1:1的混合熔剂分解样品,水提取使铌钽等元素完全形成沉淀,与液体分离,采用10%硫酸+10%过氧化氢溶液25 mL转化沉淀和溶液后用电感耦合等离子体质谱仪测定样品中铌、钽、锂、铍元素的含量。采用该方法测定国家一级标准物质GBW 07153、GBW 07155、GBW 07185,各元素的测定值与认定值基本一致,相对误差为0.50%~4.77%,相对标准偏差(n=6)为-0.009%~0.008%,适用于铌钽精矿、难分解或复杂样品中铌钽等元素的测定,并在生产实践中进行了应用。

Abstract:This is an article in the field of mineral analysis and testing. A rapid method for the simultaneous determination of Nb, Ta, Li and Be in Nb Ta ore by alkali fusion inductively coupled plasma mass spectrometry was established. The mixed alkali of sodium peroxide and sodium hydroxide=1:1 is used to decompose the sample. During extraction, niobium, tantalum and other elements are completely precipitated and separated from the liquid. The content of niobium, tantalum, lithium and beryllium in the sample is determined by inductively coupled plasma mass spectrometer after conversion and precipitation with 25 mL of 10% sulfuric acid+10% hydrogen peroxide solution. This method is used to determine the national first-class reference materials GBW 07153, GBW 07155 and GBW 07185. The measured values of each element are basically consistent with the certified values, with a relative error of 0.50%~4.77% and a relative standard deviation (n=6) of -0.009%~0.008%. It is applicable to the determination of niobium and tantalum in niobium tantalum concentrates, refractory or complex samples, and has been applied in production practice.

-

Key words:

- Mineral analysis and testing /

- Alkali fusion /

- Inductively coupled plasma mass spectrometry /

- Niobium /

- Tantalum /

- Lithium /

- Beryllium

-

-

表 1 等离子体质谱仪工作参数

Table 1. Working parameters of plasma mass spectrometer

工作条件 参数 工作条件 参数 入射功率/W 1350 每个质子通道数 3 反射功率/W 2.0 采样深度/mm 150 载气流速(Ar)/(L/min) 0.74 截取锥/mm 0.7 采样时间/s 65.00 采样锥/mm 1.1 样品提升率/(mL/min) 1.2 停留时间/ms 10 扫描方式 跳峰 扫描次数/次 50 分辨率(峰高)/u 0.75 雾化器流量/(L/min) 0.90 表 2 不同溶剂熔矿比较

Table 2. Comparison of molten ore with different solvents

分解方法 偏硼酸锂 过氧化钠 过氧化钠+氢氧化钠 氢氧化钠+硝酸钠 过氧化钠+氢氧化钠+硝酸钠 熔矿温度/℃ 1000 680 560 550 550 熔矿时间/min 10 10 10 10 10 提取方式 玻璃体不易提取 易提取 易提取 易提取 易提取 坩埚腐蚀 腐蚀重 腐蚀重 腐蚀轻 腐蚀轻 腐蚀轻 表 3 混合碱溶剂比例选择对比

Table 3. Comparison of mixed alkali flux ratio selection

GBW 07185 认定值 氢氧化钠 比例1∶2 比例1∶1 比例1∶0.5 过氧化钠 BeO/(μg/g) 溶液 11.6 12 12 11.5 12.1 沉淀 1 0.80 0.50 0.80 0.70 合计 12.5 12.60 12.80 12.50 12.30 12.80 Li2O/(μg/g) 溶液 107 104.8 109.2 107 105 沉淀 1 1.20 0.80 1 1 合计 106 108 106 110 108 106 Ta2O5/(μg/g) 溶液 4800 2500 10 18 20 沉淀 5410 7690 10195 10192 10180 合计 10200 10210 10190 10200 10210 10200 Nb2O5/(μg/g) 溶液 2460 1800 9 10 10 沉淀 2750 3400 51900 5195 5185 合计 5200 5210 5200 5210 5205 5195 表 4 所测各元素检出限及检测含量范围

Table 4. Detection limits and content ranges of each element

元素 检测限 检测含量范围 Li2O 0.025 μg/g 0.05 μg/g-30% BeO 0.018 μg/g 0.05 μg/g-30% Nb2O5 0.08 μg/g 0.10 μg/g-45% Ta2O5 0.05 μg/g 0.10 μg/g-40% 表 5 方法的准确度与精密度(n=6)

Table 5. Precision and accuracy of the method (n=6)

标样号 分析元素 平均值 标准值 精密度 正确度 RSD% ∆lgC GBW 07153

(锂矿石)BeO/(μg/g) 260 260 2.59 -0.001 Li2O% 2.27 2.29 2.62 0.003 Nb2O5/(μg/g) 61.7 61.1 4.77 -0.004 Ta2O5/(μg/g) 121 120 2.96 -0.004 GBW 07155

(铌钽矿石)BeO/(μg/g) 330.3 330 2.15 -0.001 Li2O% 0.78 0.779 0.91 -0.001 Nb2O5/(μg/g) 423.4 430 1.06 0.006 Ta2O5 697 700 0.85 0.002 GBW 07185

(稀有稀

土矿石)BeO% 12.25 12.5 1.84 0.008 Li2O 104 106 2.38 0.007 Nb2O5 5162 5200 1.03 0.003 Ta2O5 1.022 1.02 0.50 -0.009 表 6 与传统分析方法对比

Table 6. Comparison with traditional analysis methods

方法 前处理 测定方法 测定元素 Nb、Ta

测量范围分析时间 传统

方法酸溶-有机试剂苯萃取 比色法 Nb、Ta 0.1·10-6~1.0·10-2 10件/1人·16 h 碱熔-有机试剂展开 纸层析

重量法Nb、Ta 5.0·10-2~ 60.0·10-2 10件/1人·8 h 酸溶 原子吸收光谱法 Li2O 0.1·10-2~15.0·10-2 10件/1人·8 h 碱熔 磷酸盐重量法 BeO 1·10-2~50·10-2 10件/1人·16 h 碱熔 铍试剂比色法 BeO 10·10-6~1.0·10-2 10件/1人·8 h 本方法 碱熔-沉淀与溶液分开提取 ICP-MS 测定元素更多 0.05·10-6~30.0·10-2 10件/1人·8 h 表 7 不同含量段样品分析结果(n=6)

Table 7. Analysis results of samples with different contents ( n=6 )

矿种 分析元素/(μg/g) 相对偏差RSD% 尾矿样品 Nb2O5 42.0 41.2 42.3 42.5 42.6 42.5 -0.20 Ta2O5 30.8 29.6 31.0 29.8 31.3 30.8 1.26 Li2O 240 235 242 238 241 240 0.70 BeO 376 379 384 379 382 386 -0.92 原矿样品 Nb2O5 114 111 117 113 115 114 0.08 Ta2O5 122 118 124 120 127 122 -0.53 Li2O 67.6 66.0 68.3 66.3 67.7 67.6 0.52 BeO 92.3 91.5 93.1 91.3 93.0 92.3 -0.09 中矿样品 Nb2O5 80352 79709 81513 79869 80674 83028 -0.63 Ta2O5 60512 61028 63633 60148 62754 60268 -1.43 Li2O 5635 5590 5646 5601 5658 5612 0.20 BeO 3293 3267 3300 3273 3306 3280 0.20 精矿样品 Nb2O5 327100 330100 328400 329900 326600 326300 -0.29 Ta2O5 45400 45400 45800 45400 46000 46000 -0.58 Li2O 2210 2216 2211 2213 2214 2216 -0.15 BeO 1288 1286 1290 1283 1290 1289 0.03 -

[1] 李志伟, 赵晓亮, 李珍, 等. 敞口酸熔-电感耦合等离子体发射光谱法测定稀有多金属矿选矿样品中的铌钽和伴生元素[J]. 岩矿测试, 2017, 36(6):594-600.LI Z W, ZHAO X L, LI Z, et al. Determination of niobium, tantalum and associated elements in rare polymetallic ore dressing samples by open acid fusion-inductively coupled plasma atomic emission spectrometry[J]. Rock And Mineral Analysis, 2017, 36(6):594-600.

LI Z W, ZHAO X L, LI Z, et al. Determination of niobium, tantalum and associated elements in rare polymetallic ore dressing samples by open acid fusion-inductively coupled plasma atomic emission spectrometry[J]. Rock And Mineral Analysis, 2017, 36(6):594-600.

[2] 吴西顺, 王登红, 黄文斌, 等. 全球锂矿及伴生铍铌钽的采选冶技术发展趋势[J]. 矿产综合利用, 2020(1):1-9.WU X S, WANG D H, HUANG W B, et al. Global lithium ore and associated beryllium niobium tantalum mining technology development trend[J]. Multipurpose Utilization of Mineral Resources, 2020(1):1-9.

WU X S, WANG D H, HUANG W B, et al. Global lithium ore and associated beryllium niobium tantalum mining technology development trend[J]. Multipurpose Utilization of Mineral Resources, 2020(1):1-9.

[3] 姚玉玲, 赵朝辉, 刘淑君. 树脂交换分离—电感耦合等离子质谱法测定锡矿石的铌钽[J]. 矿产综合利用, 2021(5):146-151.YAO Y L, ZHAO C H, LIU S J. Resin exchange separation-inductively coupled plasma mass spectrometry determination of niobium and tantalum in tin ore[J]. Multipurpose Utilization of Mineral Resources, 2021(5):146-151.

YAO Y L, ZHAO C H, LIU S J. Resin exchange separation-inductively coupled plasma mass spectrometry determination of niobium and tantalum in tin ore[J]. Multipurpose Utilization of Mineral Resources, 2021(5):146-151.

[4] 郭晓瑞, 王甜甜, 张宏丽, 等. 电感耦合等离子体质谱法测定地球化学样品中铌钽钨锡[J]. 冶金分析, 2021, 41(3):44-50.GUO X R, WANG T T, ZHANG H L, et al. Determination of Nb, Ta, W, Sn in geochemical samples by inductively coupled plasma mass spectrometry[J]. Metallurgical Analysis, 2021, 41(3):44-50.

GUO X R, WANG T T, ZHANG H L, et al. Determination of Nb, Ta, W, Sn in geochemical samples by inductively coupled plasma mass spectrometry[J]. Metallurgical Analysis, 2021, 41(3):44-50.

[5] 高会艳. ICP-MS和 ICP-AES承担地球化学勘查样品及稀土矿石中铌钽方法体系的建立[J]. 岩矿测试, 2014, 33(3):312-320.GAO H Y. ICP-MS and ICP-AES undertake geochemical exploration samples and the establishment of niobium tantalum method system in rare earth ore[J]. Rock And Mineral Analysis, 2014, 33(3):312-320.

GAO H Y. ICP-MS and ICP-AES undertake geochemical exploration samples and the establishment of niobium tantalum method system in rare earth ore[J]. Rock And Mineral Analysis, 2014, 33(3):312-320.

[6] 郑平英. 等离子体原子发射光谱法测定矿石样品中铌钽的应用[J]. 科技资讯, 2014, 12(25):73, 76.ZHENG P Y. Application of ICP-AES in determination of niobium and tantalum in ore samples[J]. Technical Information, 2014, 12(25):73, 76.

ZHENG P Y. Application of ICP-AES in determination of niobium and tantalum in ore samples[J]. Technical Information, 2014, 12(25):73, 76.

[7] 李可及, 赵朝辉. 低稀释比熔融-X射线荧光光谱法分析铌钽矿石[J]. 理化检验(化学分册), 2018, 54(12):1410-1414.LI K J, ZHAO C H. Analysis of niobium-tantalum ore by low dilution melting-X-ray fluorescence spectrometry[J]. Physical Testing And Chemical Analysis, 2018, 54(12):1410-1414.

LI K J, ZHAO C H. Analysis of niobium-tantalum ore by low dilution melting-X-ray fluorescence spectrometry[J]. Physical Testing And Chemical Analysis, 2018, 54(12):1410-1414.

[8] 邵常丽. X射线荧光光谱法测定铌铁中铌钽铜钛铝磷[J]. 冶金分析, 2017, 37(6):50-54.SHAO C L. Determination of niobium, tantalum, copper, titanium, aluminum and phosphorus in ferroniobium by X-ray fluorescence spectrometry[J]. Metallurgical Analysis, 2017, 37(6):50-54.

SHAO C L. Determination of niobium, tantalum, copper, titanium, aluminum and phosphorus in ferroniobium by X-ray fluorescence spectrometry[J]. Metallurgical Analysis, 2017, 37(6):50-54.

[9] 许宁辉, 唐武, 于红艳. X荧光光谱法测定铌钨合金中钨、钼、锆元素[J]. 当代化工, 2020, 49(1):200-203.XU N H, TANG W, YU H Y. Determination of tungsten, molybdenum and zirconium in niobium tungsten alloy by X fluorescence spectrometry[J]. Contemporary Chemical Industry, 2020, 49(1):200-203.

XU N H, TANG W, YU H Y. Determination of tungsten, molybdenum and zirconium in niobium tungsten alloy by X fluorescence spectrometry[J]. Contemporary Chemical Industry, 2020, 49(1):200-203.

[10] 程文翠, 付永立, 马会春, 等. 纸上层析分离-ICP-AES测定稀有金属矿中的铌钽[J]. 分析实验室, 2018, 37(2):168-173.CHENG W C, FU Y L, MA H C, et al. Determination of niobium and tantalum in rare metal ores by paper chromatography separation-ICP-AES[J]. Analytical Laboratory, 2018, 37(2):168-173.

CHENG W C, FU Y L, MA H C, et al. Determination of niobium and tantalum in rare metal ores by paper chromatography separation-ICP-AES[J]. Analytical Laboratory, 2018, 37(2):168-173.

-

下载:

下载: