Heavy Medium Separation of Spodumene Waste Rock in Sichuan

-

摘要:

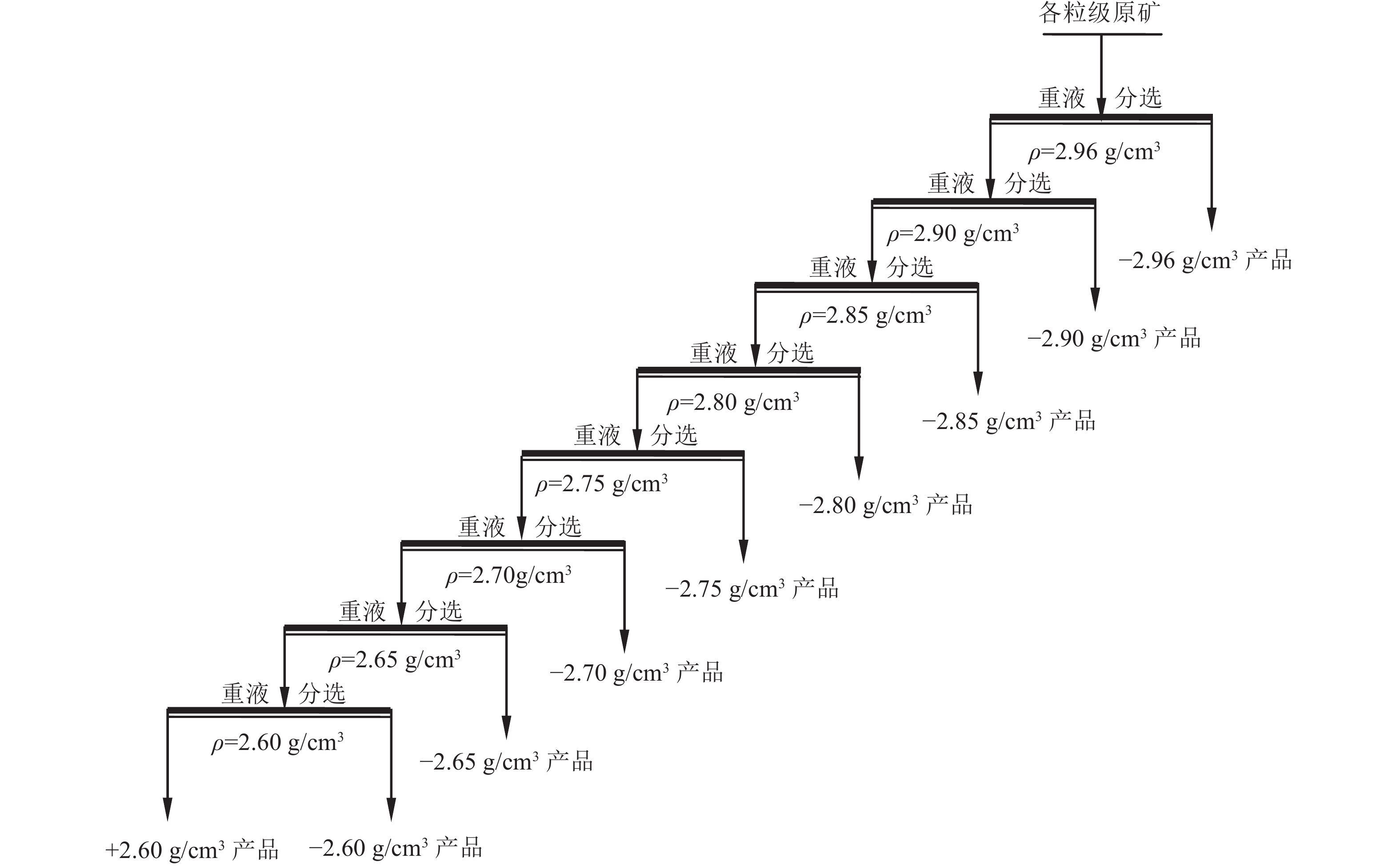

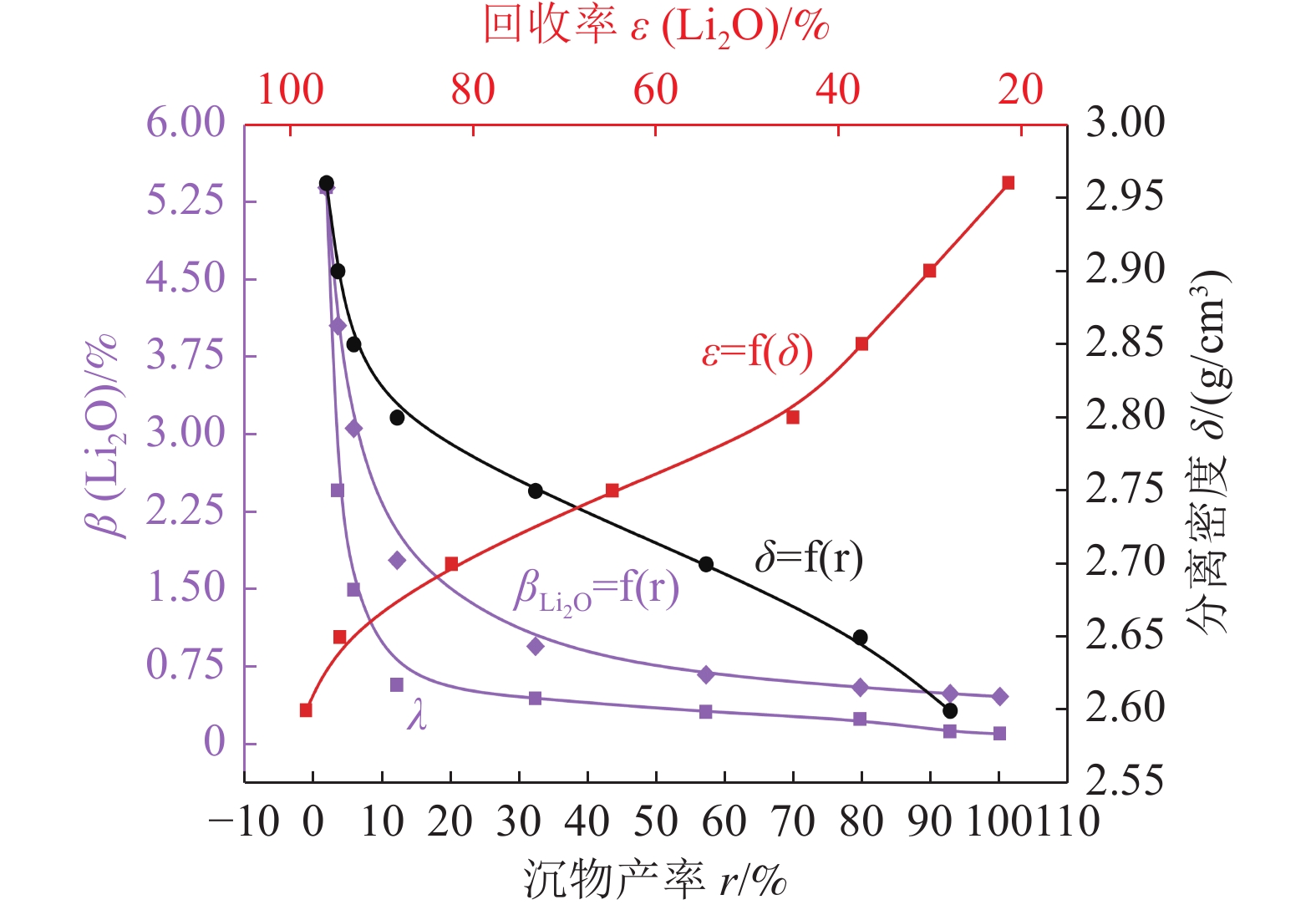

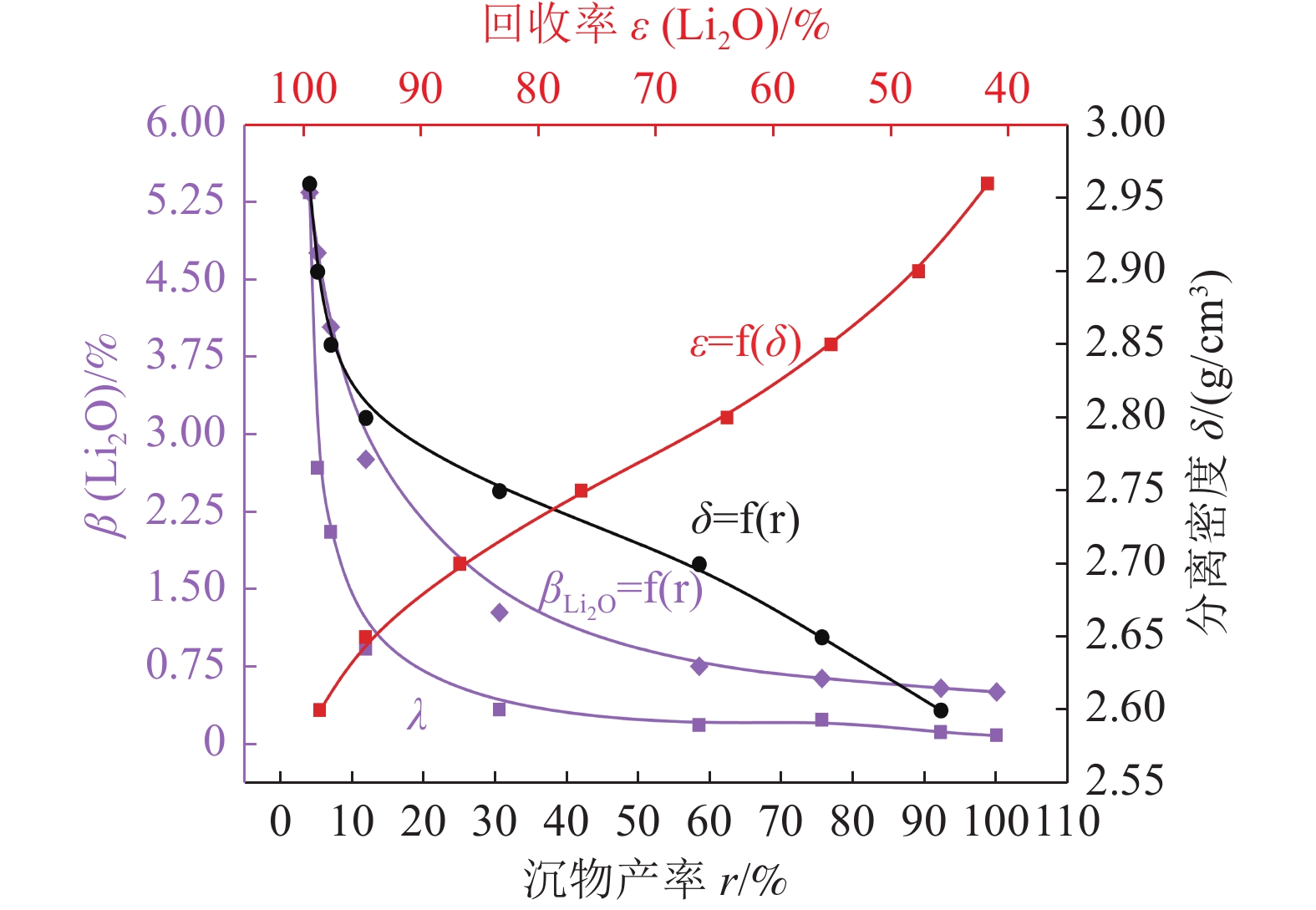

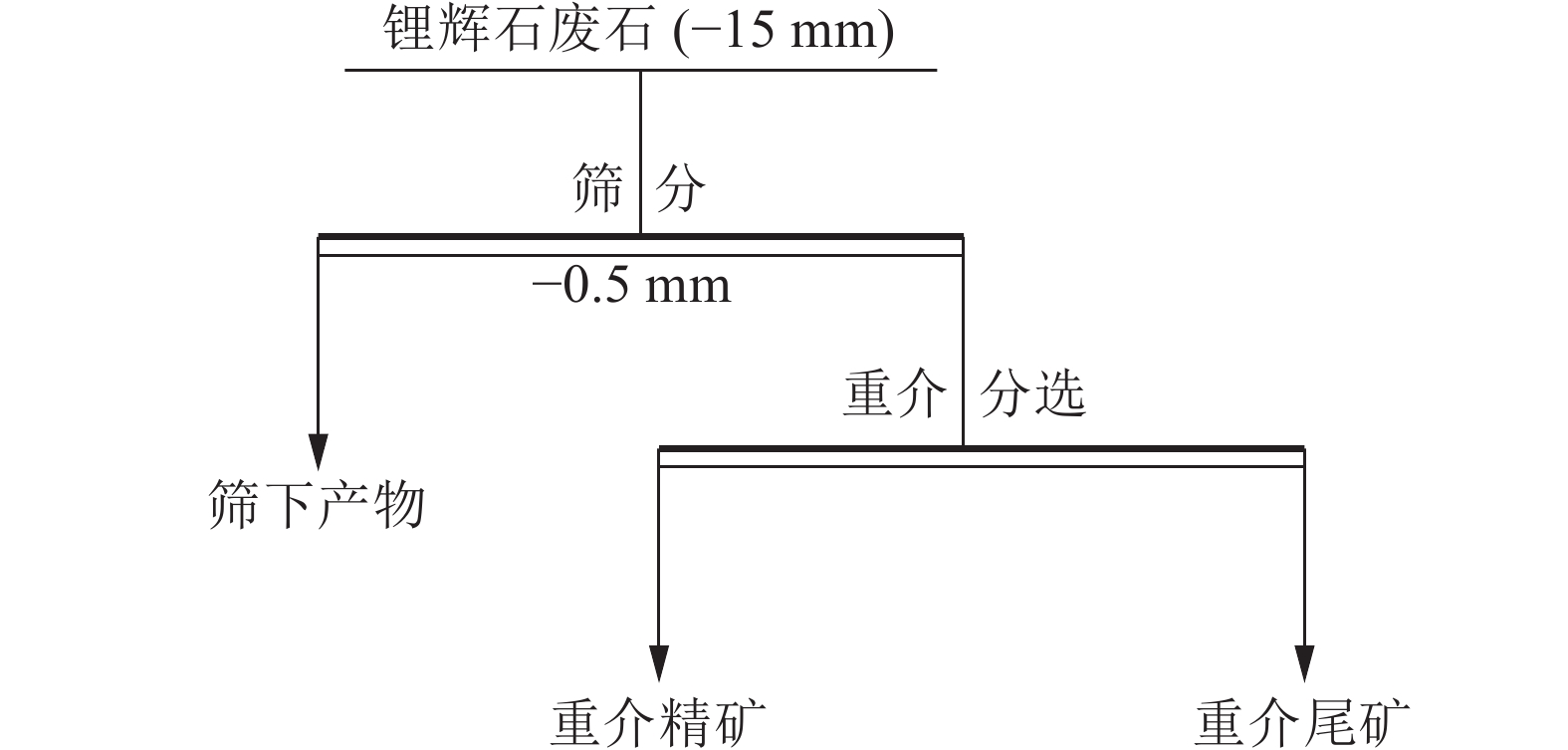

这是一篇矿物加工工程领域的文章。研究对象为四川某锂辉石废石,根据该锂辉石废石的矿物特性,对该锂辉石废石三种不同入料粒度(-15+0.5 mm、-10+0.5 mm、-5+0.5 mm)分别进行实验室重液分选实验,实验结果表明,该锂辉石废石采用重液分选效果较好,且以-10+0.5 mm作为后续重介实验的入料粒度范围,并选择2.70 g/cm3作为分选密度时,重液分选指标相对较好,但根据实际生产重介分选实验结果,最终在入选粒度为-15+0.5 mm,介质密度为2.0 g/cm3时,分选指标相对较好。

Abstract:This is an article in the field of mineral processing engineering. The study objects are a spodumene waste rock in Sichuan. According to the mineral characteristics of thisspodumene waste rock, heavy medium separation tests were carried out at three different feed particle sizes (-15+0.5 mm, -10+0.5 mm, -5+0.5 mm) of the spodumene waste rock in laboratory. The test results show that the application of heavy medium separation in beneficiation of spodumene waste rock is very effective, and when -10+0.5 mm is used as the feed particle size range of the subsequent waste rock in heavy medium separation, and 2.70 g/cm3 is selected as the separation density, the results of heavy medium separation effect is relatively good. However, according to the actual production of heavy medium separation test results, the separation index is relatively good when the selected particle size is -15+0.5 mm and the medium density is 2.0 g/cm3.

-

-

表 1 试样化学多项分析结果/%

Table 1. Results of chemical multi-analysis of samples

Li2O SiO2 Al2O3 BeO CaO Fe2O3 K2O MgO MnO Na2O P2O5 Rb2O TiO2 Nb2O5* Ta2O5* 0.46 71.78 14.51 0.001 84 2.58 3.59 2.91 1.49 0.057 3 2.83 0.044 5 0.037 7 0.168 30.00 8.59 *单位为g/t 表 2 原矿筛分分析结果(-15 mm)/%

Table 2. Results of particle size distribution of samples (-15 mm)

粒级/mm 产率/% Li2O品位/% Li2O分布率/% -15+8 31.31 0.53 34.07 -8+3 31.65 0.52 33.78 -3+0.5 14.34 0.57 16.77 -0.5 22.70 0.33 15.38 合计 100.00 0.49 100.00 表 3 原矿筛分分析结果(-10 mm)/%

Table 3. Results of particle size distribution of samples(-10 mm)

粒级/mm 产率/% Li2O品位/% Li2O分布率/% -10+5 39.70 0.46 38.33 -5+0.5 36.68 0.55 42.34 -0.5 23.62 0.39 19.33 合计 100.00 0.48 100.00 表 4 原矿筛分分析结果(-5 mm)/%

Table 4. Results of particle size distribution of samples(-5 mm)

粒级/mm 产率/% Li2O品位/% Li2O分布率/% -5+0.5 51.89 0.52 59.61 -0.5 48.11 0.38 40.39 合计 100.00 0.45 100.00 表 6 -10+0.5 mm锂辉石废石重液分选实验结果

Table 6. Results of heavy medium separation of samples(-10+0.5 mm)

密度/(g/cm3) 各单元组分 沉物累计 浮物累计 分选密度±0.1 (g/cm3) 产率/% Li2O

品位/%分布率/% 产率/% Li2O

品位/%分布率/% 产率/% Li2O

品位/%分布率/% 密度级/(g/cm3) 产率/% +2.96 3.58 5.20 36.30 3.58 5.20 36.30 100.00 0.53 100.00 2.96 7.58 -2.96+2.90 0.97 2.94 5.64 4.55 4.72 41.94 96.42 0.36 63.70 2.90 12.96 -2.90+2.85 3.03 1.40 7.87 7.58 3.39 49.81 95.45 0.33 58.06 2.85 17.80 -2.85+2.80 5.38 0.91 8.64 12.96 2.36 58.45 92.42 0.29 50.19 2.80 51.63 -2.80+2.75 8.42 0.46 7.28 21.38 1.61 65.73 87.04 0.26 41.55 2.75 69.00 -2.75+2.70 34.80 0.31 20.16 56.18 0.81 85.89 78.62 0.24 34.27 2.70 77.32 -2.70+2.65 20.40 0.24 8.90 76.58 0.65 94.79 43.82 0.18 14.11 2.65 78.62 -2.65+2.60 13.70 0.14 3.60 90.28 0.58 98.39 23.42 0.12 5.21 2.60 43.82 -2.60 9.72 0.09 1.61 100.00 0.53 100.00 9.72 0.09 1.61 合计 100.00 0.53 100.00 表 5 -15+0.5 mm锂辉石废石重液分选实验结果

Table 5. Results of heavy medium separation of samples(-15+0.5 mm)

密度/(g/cm3) 各单元组分 沉物累计 浮物累计 分选密度±0.1 g/cm3 产率/% Li2O

品位/%分布率/% 产率/% Li2O

品位/%分布率/% 产率/% Li2O

品位/%分布率/% 密度级/(g/cm3) 产率/% +2.96 1.99 5.39 21.49 1.99 5.39 21.49 100.00 0.47 100.00 2.96 5.97 -2.96+2.90 1.66 2.46 8.64 3.65 4.06 30.13 98.01 0.37 78.51 2.90 12.28 -2.90+2.85 2.32 1.50 7.42 5.97 3.06 37.55 96.35 0.33 69.87 2.85 30.44 -2.85+2.80 6.31 0.58 7.52 12.28 1.79 45.07 94.03 0.31 62.45 2.80 53.56 -2.80+2.75 20.15 0.45 19.70 32.43 0.96 64.77 87.72 0.29 54.93 2.75 73.70 -2.75+2.70 24.78 0.32 17.55 57.21 0.68 82.32 67.57 0.24 35.23 2.70 80.48 -2.70+2.65 22.46 0.25 12.19 79.67 0.56 94.51 42.79 0.19 17.68 2.65 67.57 -2.65+2.60 13.09 0.13 3.74 92.76 0.50 98.25 20.33 0.12 5.49 2.60 42.79 -2.60 7.24 0.11 1.75 100.00 0.47 100.00 7.24 0.11 1.75 合计 100.00 0.47 100.00 表 7 -5+0.5 mm锂辉石废石重液分选实验结果

Table 7. Results of heavy medium separation of samples(-5+0.5 mm)

密度/(g/cm3) 各单元组分 沉物累计 浮物累计 分选密度±0.1(g/cm3) 产率/% Li2O

品位/%分布率/% 产率/% Li2O

品位/%分布率/% 产率/% Li2O

品位/%分布率/% 密度级/(g/cm3) 产率/% +2.96 4.01 5.35 41.83 4.01 5.35 41.83 100.00 0.51 100.00 2.96 6.99 -2.96+2.90 1.13 2.68 5.88 5.14 4.77 47.71 95.99 0.31 58.17 2.90 11.88 -2.90+2.85 1.85 2.06 7.45 6.99 4.05 55.16 94.86 0.28 52.29 2.85 26.55 -2.85+2.80 4.89 0.93 8.86 11.88 2.77 64.02 93.01 0.25 44.84 2.80 53.28 -2.80+2.75 18.68 0.34 12.38 30.56 1.28 76.40 88.12 0.21 35.98 2.75 68.59 -2.75+2.70 27.86 0.19 10.32 58.42 0.76 86.72 69.44 0.17 23.60 2.70 80.33 -2.70+2.65 17.16 0.24 8.03 75.58 0.64 94.75 41.58 0.16 13.28 2.65 69.44 -2.65+2.60 16.63 0.12 3.89 92.21 0.55 98.64 24.42 0.11 5.25 2.60 41.58 -2.60 7.79 0.09 1.36 100.00 0.51 100.00 7.79 0.09 1.36 合计 100.00 0.51 100.00 表 8 锂辉石废石(-15+0.5 mm)重介旋流器分选实验结果

Table 8. Heavy medium cyclone separation test results of spodumene waste rock

产品名称 产率/% Li2O品位/% Li2O回收率/% 重介精矿 14.71 1.52 46.60 重介尾矿 66.03 0.28 38.54 筛下产物 19.26 0.37 14.86 重介总精矿 33.97 0.87 61.46 废石原矿 100.00 0.48 100.00 -

[1] 付小方, 张光明, 郝雪峰, 等. 中国锂资源亟待上升到国家战略层面统筹发展[J]. 中国战略新兴产业, 2018(8):30-32.FU X F, ZHANG G M, HAO X F, et al. China's lithium resources need to be raised to the national strategic level to coordinate development[J]. China Strategic Emerging Industry, 2018(8):30-32.

FU X F, ZHANG G M, HAO X F, et al. China's lithium resources need to be raised to the national strategic level to coordinate development[J]. China Strategic Emerging Industry, 2018(8):30-32.

[2] 董栋, 程宏伟, 郭保万, 等. 锂辉石选矿技术现状及展望[J]. 矿产保护与利用, 2018(4): 130-134.DONG D, CHENG H W, GUO B W, et al. Research situation and prospect on the mineral mrocessing technology of spodumene[J]. Conservation and Utilization of Mineral Resources 2018(4): 130-134.

DONG D, CHENG H W, GUO B W, et al. Research situation and prospect on the mineral mrocessing technology of spodumene[J]. Conservation and Utilization of Mineral Resources 2018(4): 130-134.

[3] 李成秀, 程仁举, 刘星. 我国锂辉石选矿技术研究现状及展望[J]. 矿产综合利用, 2021(5):1-8.LI C X, CHENG R J, LIU X. Research status and prospects of spodumene ore beneficiation technology in China[J]. Multipurpose Utilization of Mineral Resources, 2021(5):1-8.

LI C X, CHENG R J, LIU X. Research status and prospects of spodumene ore beneficiation technology in China[J]. Multipurpose Utilization of Mineral Resources, 2021(5):1-8.

[4] 陶家荣. 锂辉石矿重介质选矿工业试验与研究[J]. 有色金属(选矿部分), 2002(2):13-16.TAO J R. Industrial test and research on heavy medium beneficiation of spodumene ore[J]. Nonferrous Metals(mineral processing section), 2002(2):13-16.

TAO J R. Industrial test and research on heavy medium beneficiation of spodumene ore[J]. Nonferrous Metals(mineral processing section), 2002(2):13-16.

[5] 程仁举, 李成秀, 刘星, 等. 新疆某伟晶岩型锂辉石矿浮选实验研究[J]. 矿产综合利用, 2023(4):88-94.CHEN R J, LI C X, LIU X, et al. Flotation of a pegmatite type spodumene ore in Xinjiang[J]. Multipurpose Utilization of Mineral Resources, 2023(4):88-94.

CHEN R J, LI C X, LIU X, et al. Flotation of a pegmatite type spodumene ore in Xinjiang[J]. Multipurpose Utilization of Mineral Resources, 2023(4):88-94.

[6] 梅亚军, 李潇雨, 李成秀, 等. 四川可尔因选锂尾矿锂辉石再选实验研究[J]. 矿产综合利用, 2023(4):83-87.MEI Y J, LI X Y, LI C X, et al. Re-election of spodumene from lithium processing tailings in Keeryin, Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2023(4):83-87.

MEI Y J, LI X Y, LI C X, et al. Re-election of spodumene from lithium processing tailings in Keeryin, Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2023(4):83-87.

[7] 程仁举, 李成秀, 刘星, 等. 川西某伟晶岩型锂辉石矿浮选试验研究[J]. 矿产综合利用, 2020(6):148-152.CHENG R J, LI C X, LIU X, et al. Experimental research on the flotation of a pegmatite type spodumene ore in Western Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2020(6):148-152.

CHENG R J, LI C X, LIU X, et al. Experimental research on the flotation of a pegmatite type spodumene ore in Western Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2020(6):148-152.

[8] 梁雪峰, 黄杰, 吴国富等. 某地锂辉石矿重介质选矿扩大连续试验[J]. 现代矿业, 2017, 33(11):132-134.LIANG X F, HUANGJ, WUG F, et al. Expanded continuous test of heavy medium beneficiation of spodumene ore in a certain place[J]. Modern Mining, 2017, 33(11):132-134. doi: 10.3969/j.issn.1674-6082.2017.11.036

LIANG X F, HUANGJ, WUG F, et al. Expanded continuous test of heavy medium beneficiation of spodumene ore in a certain place[J]. Modern Mining, 2017, 33(11):132-134. doi: 10.3969/j.issn.1674-6082.2017.11.036

[9] 刘广学, 戴科伟, 常学勇, 等. 某低品位伟晶岩型锂辉石选矿试验[J]. 现代矿业, 2018, 34(11):99-102+109.LIU G X, DAI K W, CHANG X Y, et al. Beneficiation experiment on a low grade pegmatite type spodumene ore[J]. Modern Mining, 2018, 34(11):99-102+109. doi: 10.3969/j.issn.1674-6082.2018.11.023

LIU G X, DAI K W, CHANG X Y, et al. Beneficiation experiment on a low grade pegmatite type spodumene ore[J]. Modern Mining, 2018, 34(11):99-102+109. doi: 10.3969/j.issn.1674-6082.2018.11.023

[10] 刘广学, 彭团儿, 刘磊等. 重色浮联合选矿工艺回收某花岗岩型锂辉石中的锂[J]. 金属矿山, 2021(3):124-129.LIU G X, PENG T E, LIU L, et al. Recovery of lithium from a granite type spodumene by gravity-color-flotationcombination process[J]. Metal Mine, 2021(3):124-129.

LIU G X, PENG T E, LIU L, et al. Recovery of lithium from a granite type spodumene by gravity-color-flotationcombination process[J]. Metal Mine, 2021(3):124-129.

[11] 廖明和, 许温复, 王学平. 锂辉石重液分选试验[J]. 非金属矿, 2003(6):40-41.LIAO M H, XU W F, WANG X P. Heavy liquid separation test of spodumene[J]. Non-Metallic Mines, 2003(6):40-41.

LIAO M H, XU W F, WANG X P. Heavy liquid separation test of spodumene[J]. Non-Metallic Mines, 2003(6):40-41.

[12] 李文平, 赵磊, 包易等. 四川李家沟锂辉石矿重-浮联选工艺研究及工业试验[J]. 现代矿业, 2022, 38(11):137-140+262.LI W P, ZHAO L, BAO Y, et al. Study on gravity-flotation combined separation process and industrial test ofspodumene ore in Lijiagou, Sichuan.[J]. Modern Mining, 2022, 38(11):137-140+262.

LI W P, ZHAO L, BAO Y, et al. Study on gravity-flotation combined separation process and industrial test ofspodumene ore in Lijiagou, Sichuan.[J]. Modern Mining, 2022, 38(11):137-140+262.

-

下载:

下载: