Effect of Special Components in Blast Furnace Slag of Baotou Iron and Steel Company on Self-pulverization Behavior of Steel Slags

-

摘要:

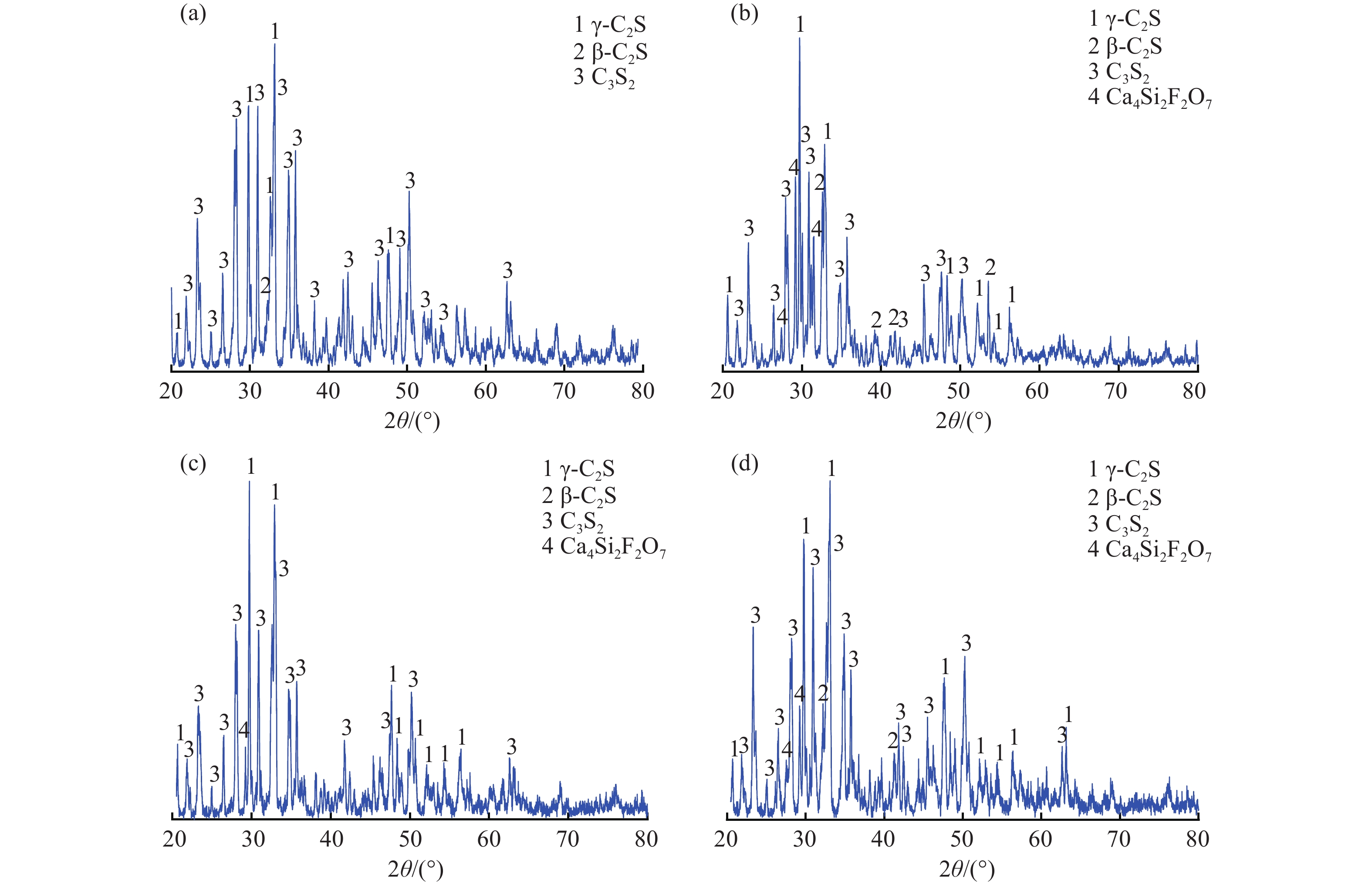

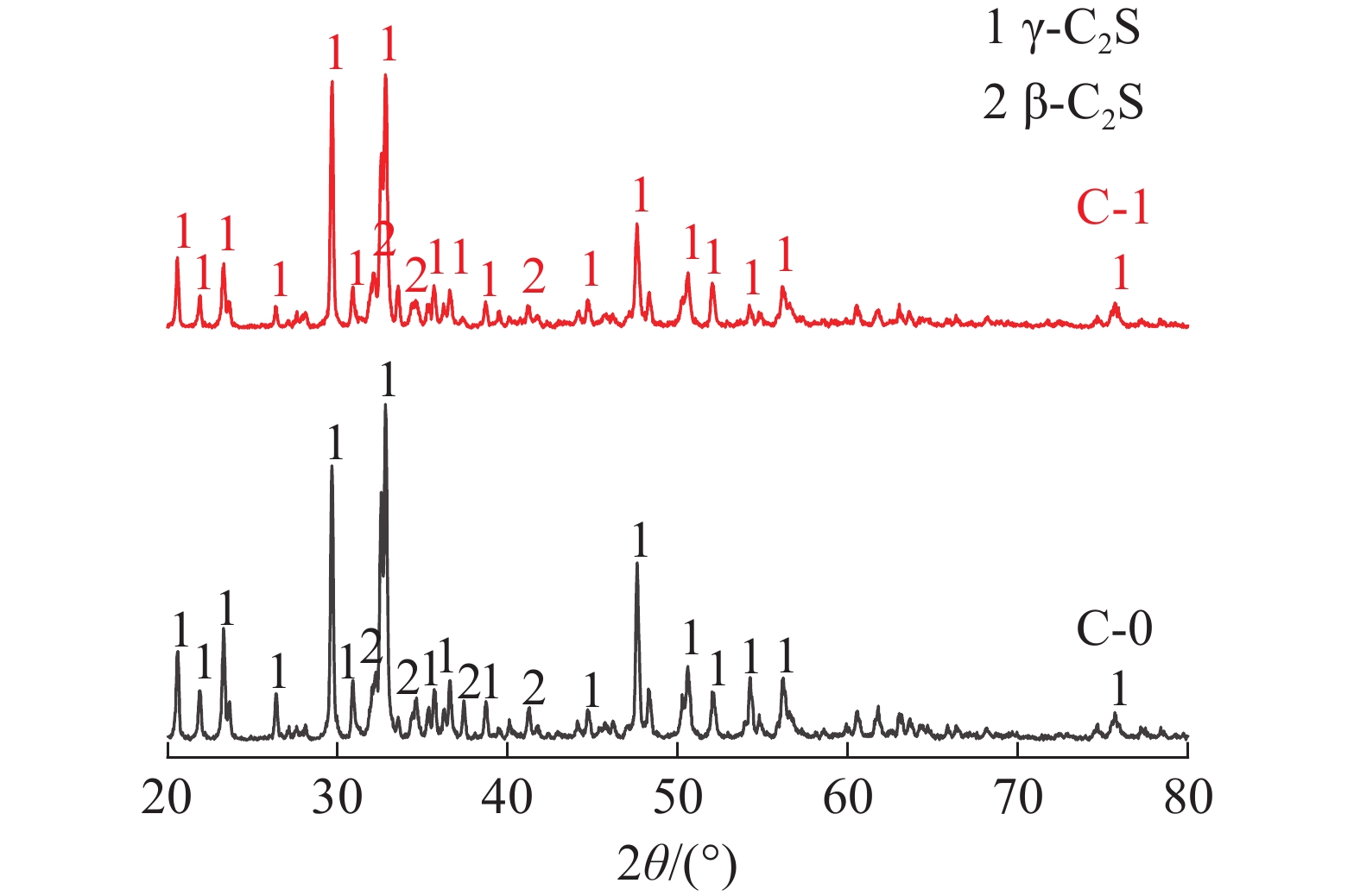

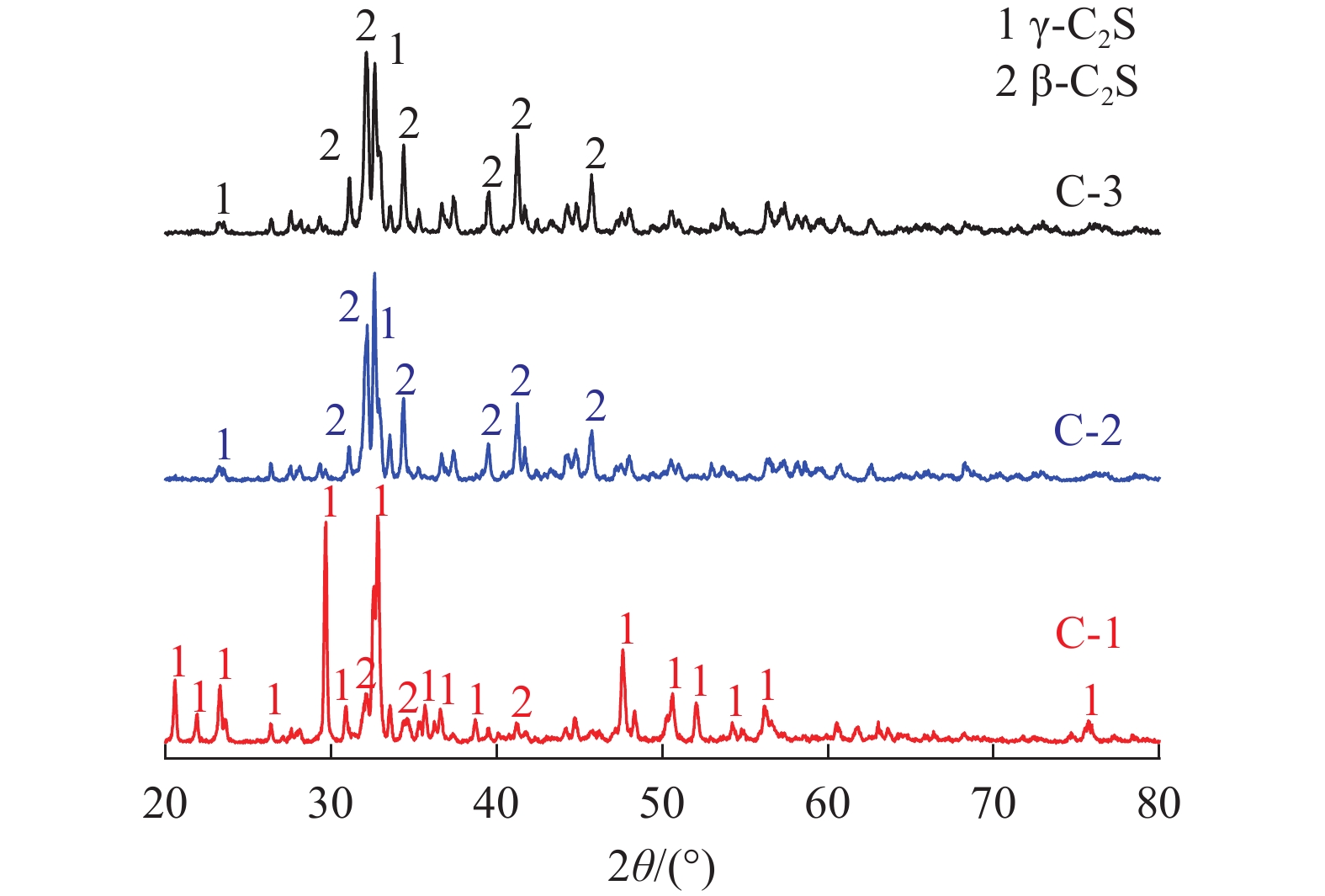

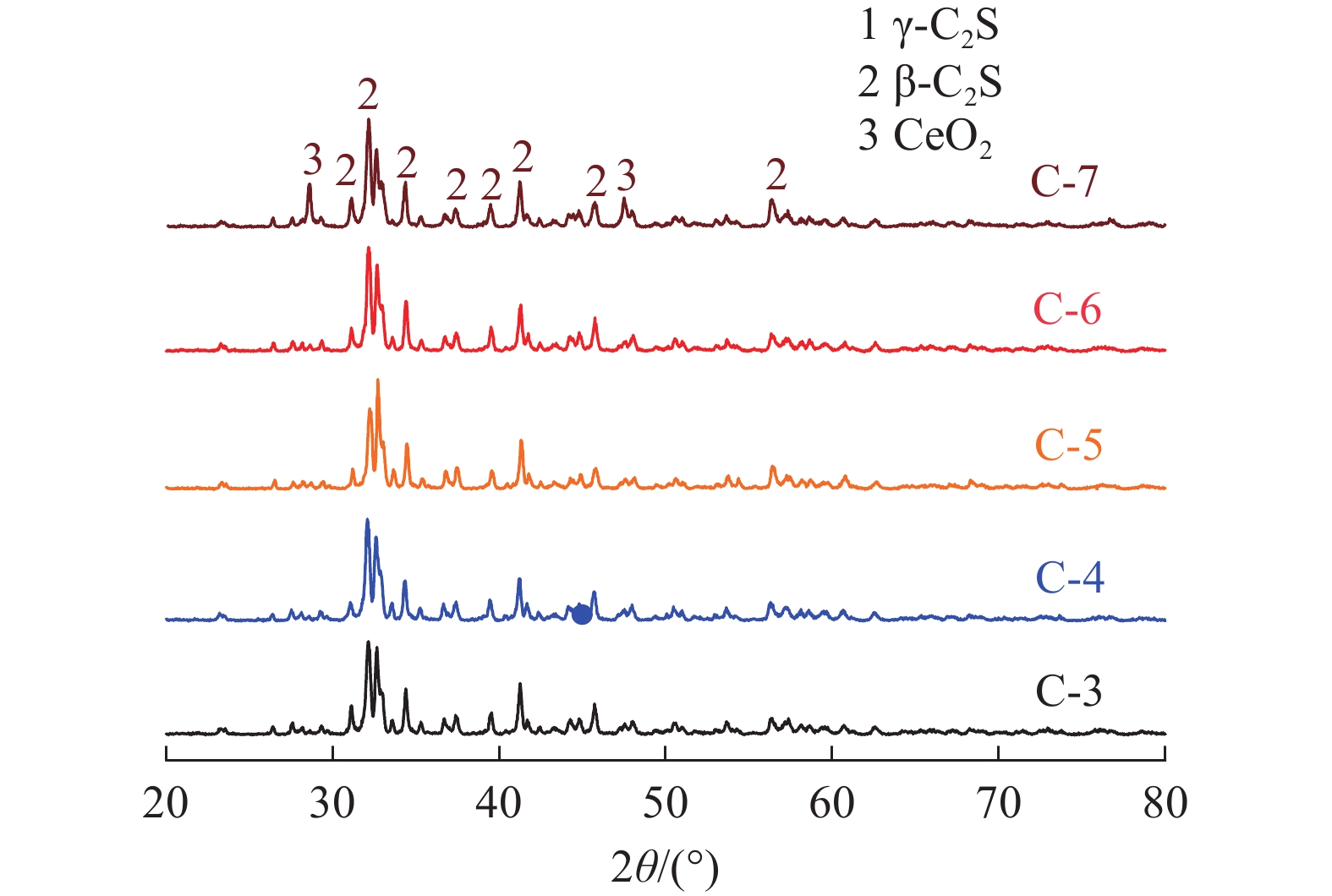

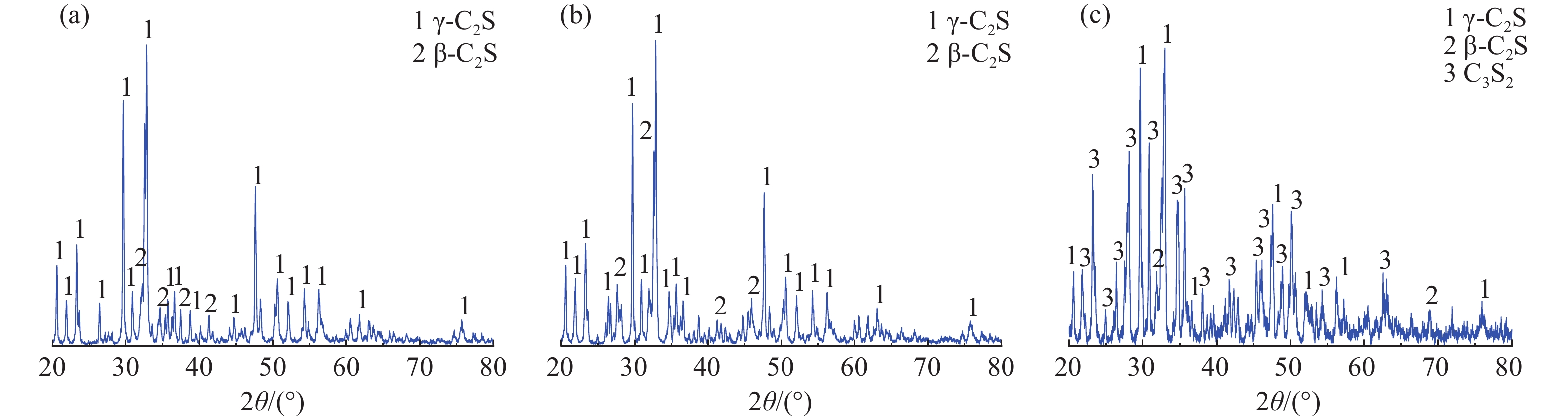

这是一篇冶金工程领域的文章。我国钢渣累计堆存量大,给资源和环境造成巨大压力。本文提出“应用熔融高炉渣与钢渣混合以实现钢渣自粉化”的新思路,就包钢高炉渣中特殊成分(CaF2和CeO2)对钢渣自粉化的影响机理进行系统研究。以分析纯CaO、SiO2、CaF2、CeO2为原料,按n(CaO)∶n(SiO2)=2∶1的配料制备了纯C2S试样,接着分别掺入不同质量分数的CaF2和CeO2,将试样在1 450 ℃恒温焙烧1 h后随炉冷却,探究CaF2和CeO2对C2S自粉化行为的影响规律。结果表明,将CaF2掺入C2S中,当CaF2含量低于2.5%时,对C2S的自粉化几乎没有影响,但在CaF2含量超过2.5%时,试样出现了不同程度的结块现象,影响了C2S的自粉化,考虑到过量的CaF2会对环境产生影响,因此CaF2的掺入量应控制在2.5%以下;将CeO2掺入C2S中,当CeO2含量为0.25%时,C2S仍能完全自粉化,但CeO2含量超过0.5%时,C2S不再出现自粉化现象,因此CeO2含量必须低于0.25%,C2S自粉化效果较好。

Abstract:This is an article in the field of metallurgical engineering, which proposed a new idea of mixing molten blast furnace slag with steel slag to achieve self-pulverization of steel slag, and systematically studied the influence mechanism of special components of CaF2 and CeO2 in blast furnace slag of Baotou Iron and Steel Company on the self-pulverization of steel slags. Using analytically pure CaO, SiO2, CaF2 and CeO2 as starting materials, pure C2S specimens were prepared with n ( CaO ) : n ( SiO2 ) = 2 : 1, then different mass fractions of CaF2 and CeO2 were added, respectively. The effect of CaF2 and CeO2 on the self-pulverization behavior of C2S was investigated by calcining the specimen at 1 450 °C for 1 h and cooling with the furnace. The results showed when CaF2 was incorporated into C2S and the content of CaF2 was less than 2.5%, it had little effect on the self-pulverization of C2S. However, when the content of CaF2 was more than 2.5%, the specimen had different degrees of agglomeration, which affected the self-pulverization of C2S. Considering that excessive CaF2 would affect the environment, the content of CaF2 should be controlled below 2.5%. When CeO2 incorporated into C2S and the content was 0.25%, C2S could still be completely self-pulverized, but when the CeO2 content was more than 0.5%, C2S no longer self-pulverized.Therefore, the CeO2 content must be less than 0.25 %, and the self-pulverization effect of C2S was relatively good.

-

-

表 1 试样中CaF2加入量/%

Table 1. CaF2 addition in the specimen

外掺原料 F-0 F-1 F-2 F-3 F-4 F-5 F-6 F-7 CaF2 - 0.5 1.0 1.5 2.5 3.5 4.5 5.0 表 2 试样中CeO2加入量/%

Table 2. CeO2 addition in the specimen

外掺原料 C-0 C-1 C-2 C-3 C-4 C-5 C-6 C-7 CeO2 - 0.25 0.50 0.75 1.00 1.25 1.50 5.00 其中,F-0、C-0样为空白样。 表 3 基于Factsage7.1计算得到的生成物含量/g

Table 3. Product content calculated based on Factsage7.1

反应物 生成物 Ca3Si2O7 CaF2 Ca3Si2O7 Ca4Si2F2O7 99.5 0.5 97.653 2.347 99.0 1.0 95.306 4.694 98.5 1.5 92.959 7.041 97.5 2.5 88.265 11.735 96.5 3.5 83.571 16.429 95.5 4.5 78.877 21.123 95.0 5.0 76.530 23.470 -

[1] 高洋. 高钛高炉渣综合利用现状及展望[J]. 矿产综合利用, 2019(1):6-10.GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1):6-10. doi: 10.3969/j.issn.1000-6532.2019.01.002

GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1):6-10. doi: 10.3969/j.issn.1000-6532.2019.01.002

[2] 邓志豪, 王珏, 周云. 转炉渣系矿物相研究[J]. 安徽工业大学学报(自然科学版), 2011, 28(3):201-204.DENG Z H, WANG J, ZHOU Y. Study on mineral phase of converter slag system[J]. Journal of Anhui University of Technology (Natural Science Edition), 2011, 28(3):201-204.

DENG Z H, WANG J, ZHOU Y. Study on mineral phase of converter slag system[J]. Journal of Anhui University of Technology (Natural Science Edition), 2011, 28(3):201-204.

[3] 闫英师, 李玉凤, 赵礼兵. 改性钢渣吸附重金属离子的研究现状[J]. 矿产综合利用, 2021(1):8-13.YAN Y S, LI Y F, ZHAO L B. Research status of heavy metal ions adsorption by modified steel slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):8-13. doi: 10.3969/j.issn.1000-6532.2021.01.002

YAN Y S, LI Y F, ZHAO L B. Research status of heavy metal ions adsorption by modified steel slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):8-13. doi: 10.3969/j.issn.1000-6532.2021.01.002

[4] 刘洋, 张春霞. 钢铁渣的综合利用现状及发展趋势[J]. 矿产综合利用, 2019(2):21-25.LIU Y, ZHANG C X. Comprehensive utilization situation and development trend of iron and steel slag in China and abroad[J]. Multipurpose Utilization of Mineral Resources, 2019(2):21-25. doi: 10.3969/j.issn.1000-6532.2019.02.004

LIU Y, ZHANG C X. Comprehensive utilization situation and development trend of iron and steel slag in China and abroad[J]. Multipurpose Utilization of Mineral Resources, 2019(2):21-25. doi: 10.3969/j.issn.1000-6532.2019.02.004

[5] Gencel Osman, Karadag Omer, Oren Osman Hulusi, et al. Steel slag and its applications in cement and concrete technology: A review[J]. Construction and Building Materials, 2021, 283.

[6] 张作良, 陈韧. 转炉钢渣物相组成及其显微形貌[J]. 材料与冶金学报, 2019, 18(1):37-40.ZHANG Z L, CHEN R. Physical phase composition of converter steel slag and its micro-morphology[J]. Journal of Materials and Metallurgy, 2019, 18(1):37-40.

ZHANG Z L, CHEN R. Physical phase composition of converter steel slag and its micro-morphology[J]. Journal of Materials and Metallurgy, 2019, 18(1):37-40.

[7] 林超. 石煤改质转炉钢渣自粉化及提钒的基础研究[D]. 马鞍山: 安徽工业大学, 2018.LIN C. Basic research on self-powdering and vanadium extraction from stone-coal modified converter steel slag [D]. Maanshan: Anhui University of Technology, 2018.

LIN C. Basic research on self-powdering and vanadium extraction from stone-coal modified converter steel slag [D]. Maanshan: Anhui University of Technology, 2018.

[8] 林超, 高卫, 钟娜娜, 等. SiO2改质对转炉钢渣中C2S相优势析出及钢渣自粉化的影响[J]. 冶金工程, 2018, 5(2):77-84.LIN C, GAO W, ZHONG N N, et al. Effect of SiO2 modification on the dominant precipitation of C2S phase in converter steel slag and self-powdering of steel slag[J]. Metallurgical Engineering, 2018, 5(2):77-84. doi: 10.12677/MEng.2018.52011

LIN C, GAO W, ZHONG N N, et al. Effect of SiO2 modification on the dominant precipitation of C2S phase in converter steel slag and self-powdering of steel slag[J]. Metallurgical Engineering, 2018, 5(2):77-84. doi: 10.12677/MEng.2018.52011

[9] 冯修吉, 龙世宗. 微量离子对 $ \mathrm{\beta } $-C2S稳定性的影响及其机理研究[J]. 硅酸盐学报, 1985(4):424-432.FENG X J, LONG S Z. Effect of trace ions on the stability of -C2S and its mechanism[J]. Journal of Silicate, 1985(4):424-432.

FENG X J, LONG S Z. Effect of trace ions on the stability of -C2S and its mechanism[J]. Journal of Silicate, 1985(4):424-432.

[10] 邹千, 马妍, 王玺堂, 等. Ba2+离子掺杂对C2S结构稳定性的影响[J]. 耐火材料, 2016, 50(4):265-268.ZOU Q, MA Y, WANG X T, et al. Effect of Ba2+ ion doping on the structural stability of C2S[J]. Refractory Materials, 2016, 50(4):265-268. doi: 10.3969/j.issn.1001-1935.2016.04.007

ZOU Q, MA Y, WANG X T, et al. Effect of Ba2+ ion doping on the structural stability of C2S[J]. Refractory Materials, 2016, 50(4):265-268. doi: 10.3969/j.issn.1001-1935.2016.04.007

[11] 王莉. 冶金工业固体废物钢渣的综合利用探讨[J]. 冶金管理, 2020(5):197-199.WANG L. Discussion on comprehensive utilization of steel slag as solid waste in metallurgical industry[J]. Metallurgical Management, 2020(5):197-199.

WANG L. Discussion on comprehensive utilization of steel slag as solid waste in metallurgical industry[J]. Metallurgical Management, 2020(5):197-199.

[12] 钟侚, 蹇守卫, 柯凯. V5+及Cr3+掺杂对C2S多晶型的影响机制[J]. 济南大学学报(自然科学版), 2011, 25(4):349-353.ZHONG X, JIAN S W, KE K. Mechanisms of the effects of V5+ and Cr3+ doping on the polycrystalline shape of C2S[J]. Journal of Jinan University (Natural Science Edition), 2011, 25(4):349-353.

ZHONG X, JIAN S W, KE K. Mechanisms of the effects of V5+ and Cr3+ doping on the polycrystalline shape of C2S[J]. Journal of Jinan University (Natural Science Edition), 2011, 25(4):349-353.

[13] 许莹, 王巧玲, 胡晨光, 等. 氟化钙对重构钢渣胶凝活性和体积安定性的影响[J]. 钢铁钒钛, 2018, 39(5):86-92.XU Y, WANG Q L, HU C G, et al. Effect of calcium fluoride on the gelling activity and volume stability of reconstituted steel slag[J]. Iron and Steel Vanadium and Titanium, 2018, 39(5):86-92.

XU Y, WANG Q L, HU C G, et al. Effect of calcium fluoride on the gelling activity and volume stability of reconstituted steel slag[J]. Iron and Steel Vanadium and Titanium, 2018, 39(5):86-92.

[14] 王达志, 包燕平, 王敏. CaF2和Na2O对钢渣含磷相析出过程的影响[A]. 中国金属学会. 第十二届中国钢铁年会论文集--2. 炼钢与连铸[C]. 中国金属学会: 中国金属学会, 2019: 7.WANG D Z, BAO Y P, WANG M. Effects of CaF2 and Na2O on the precipitation process of phosphorus-containing phases from steel slag[A]. Chinese Society for Metals. Proceedings of the 12th Annual Conference on Steel in China - 2. Steelmaking and Continuous Casting[C]. Chinese Society for Metals: Chinese Society for Metals, 2019: 7.

WANG D Z, BAO Y P, WANG M. Effects of CaF2 and Na2O on the precipitation process of phosphorus-containing phases from steel slag[A]. Chinese Society for Metals. Proceedings of the 12th Annual Conference on Steel in China - 2. Steelmaking and Continuous Casting[C]. Chinese Society for Metals: Chinese Society for Metals, 2019: 7.

-

下载:

下载: