Practice and Application of Regrinding and Re-election of Swept Concentrate from a Low-grade Difficult Gold Ore in Qinghai Province

-

摘要:

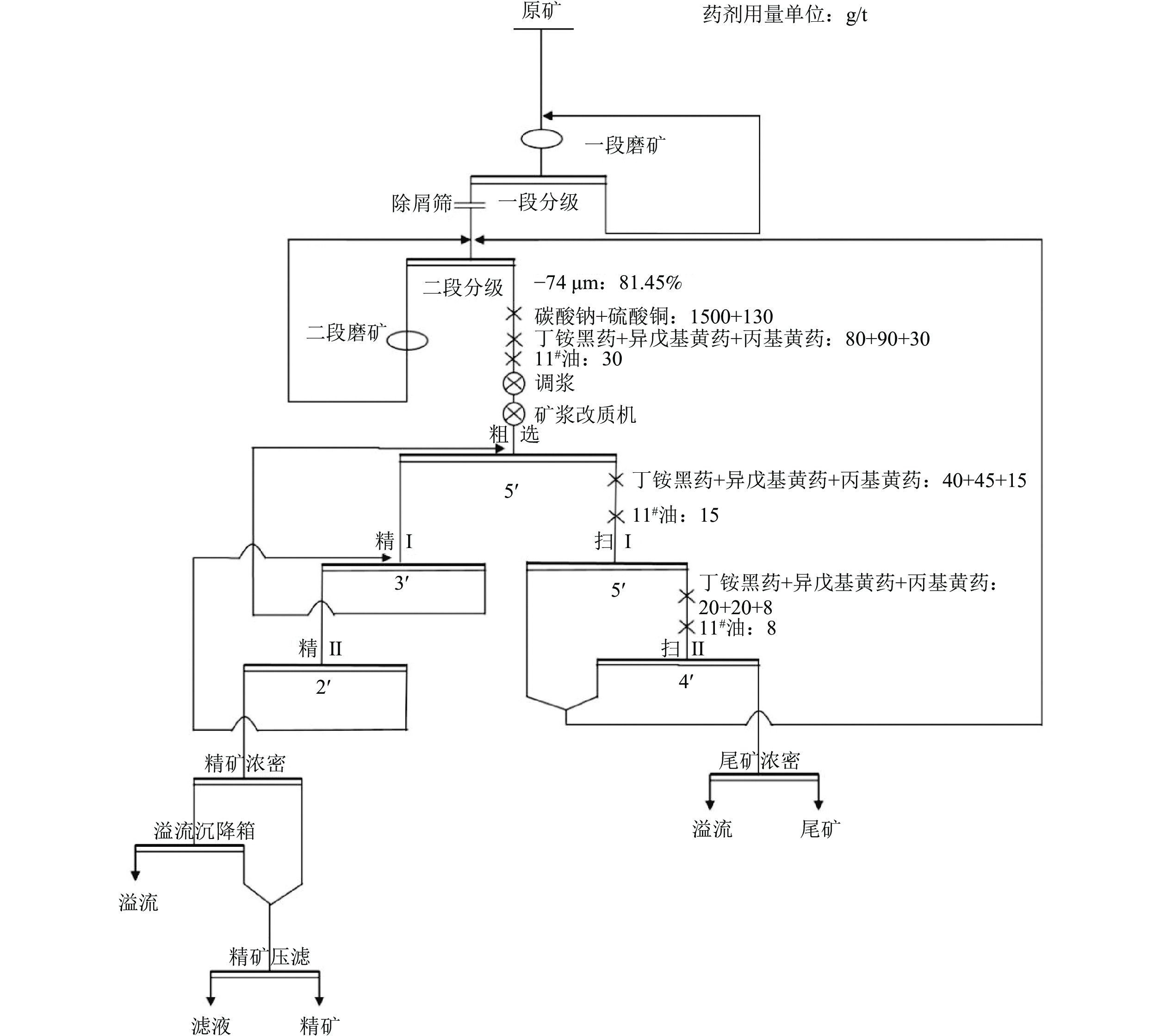

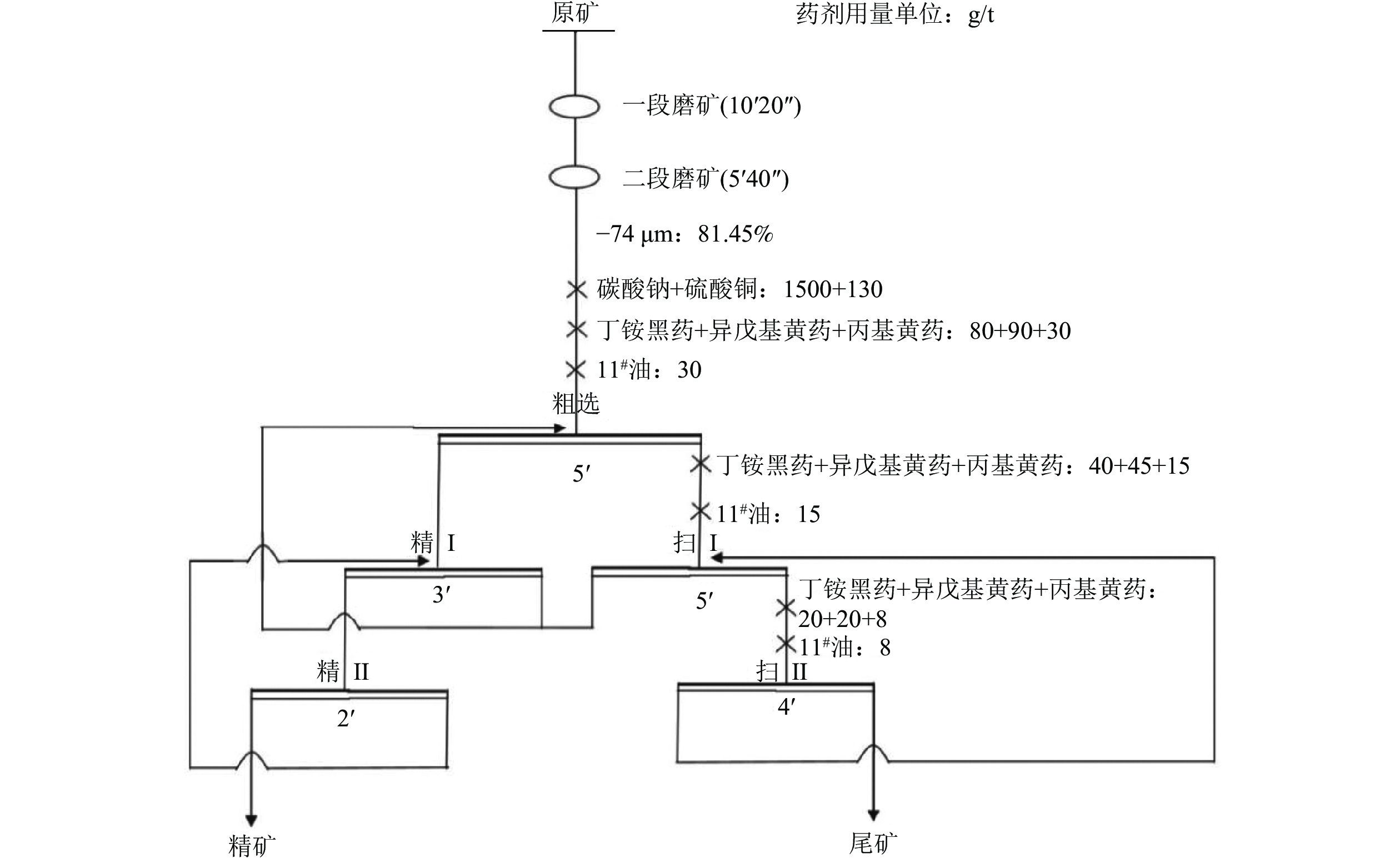

这是一篇矿物加工工程领域的论文。青海某低品位高砷高碳难选金矿原矿品位约为2.38 g/t,工业生产金回收率77%左右,通过开展工艺流程考查和矿物学分析,该矿山选厂扫选精矿金品位约3~6 g/t,主要载金矿物毒砂和黄铁矿单体解离度较低,分别为76.23%和78.74%,其单独浮选,金回收率约30%~50%。为了进一步提高该难选金矿选矿回收率,该矿山在实验室模拟选厂工艺流程开展扫选总精矿再磨再选实验研究,制定扫选精矿集中返回二段分级泵池的工艺流程方案,并完成该选厂工艺技改设计和实践等工作,技改后生产应用结果表明,扫选精矿集中返回再磨,其主要载金矿物毒砂和黄铁矿单体解离度分别提高至78.03%和80.63%,相比较顺序返回,扫选精矿再磨再选工艺在不影响精矿品位的前提下,选厂金的回收率由77.14%提高至81.13%,有效提高了该难选金矿浮选回收率。

Abstract:This is an article in the field of mining processing engineering. The gold grade of a low-grade, high-arsenic, high-carbon refractory gold ore in Qinghai is about 2.38 g/t, and the industrial recovery rate of gold is about 77%. Through process flow investigation and mineralogical analysis, the gold grade of the mine's concentrator scavenging concentrate is about 3~6 g/t. The main gold-bearing minerals, arsenopyrite and pyrite, have low dissociation degrees of 76.23% and 78.74%, respectively. When floated separately, the gold recovery rate is about 30%~50%. In order to further improve the recovery rate of gold in this refractory gold mine, the mine conducted laboratory simulation of the process flow of the concentrator to carry out the experimental study of regrinding and re-separation of the scavenging concentrate, formulated the process flow scheme of returning the scavenging concentrate to the second stage grading pump pool in a centralized manner, and completed the process technology improvement design and process technology improvement practice of the concentrator. The production application results after the technological transformation showed that the single dissociation degree of the main gold-bearing minerals, arsenopyrite and pyrite, increased to 78.03% and 80.63% respectively when the scavenging concentrate was returned in a centralized manner, compared to the sequential return. The regrinding and re-separation process of the scavenging concentrate did not affect the grade of the concentrate under the premise of centralized return. The recovery rate of gold in the concentrator was increased from 77.14% to 81.13%, effectively improving the gold recovery index of this refractory gold mine.

-

-

表 1 原矿化学多元素分析结果/%

Table 1. Analysis results of mineral chemical multi-elements

Au* Ag* As MgO Pb Cu TFe Al2O3 SiO2 K2O CaO S TC Zn 2.41 <2.00 0.60 1.48 0.01 <0.01 3.79 13.2 72.00 3.41 2.08 2.05 1.23 0.01 *单位为g/t。 表 2 扫选精矿毒砂单体解离度测定结果

Table 2. Determination results of monomer dissociation of arsenopyrite from scavenging concentrate

粒级

/μm产率/% 单体颗粒数/n 不同比例连生体颗粒数 单体解离度

/%1/8 2/8 3/8 4/8 5/8 6/8 7/8 合计(n1) +106 12.17 25 112 15 9 8 5 1 1 29.88 45.56 -106+90 9.98 46 211 22 20 18 17 7 2 66.00 41.07 -90+74 4.44 115 117 50 19 25 20 23 17 91.38 55.72 -74+45 18.72 220 160 30 29 24 15 20 25 96.63 69.48 -45+38 4.21 326 30 29 23 12 8 5 4 37.88 89.59 -38 50.48 515 50 47 26 8 4 0 0 34.25 93.76 合计 100.00 总解离度/% 76.23 表 3 扫选精矿黄铁矿单体解离度测定结果

Table 3. Determination results of monomer dissociation of pyrite from scavenging concentrate

粒级

/μm产率/% 单体颗粒数/n 不同比例连生体颗粒数 单体解离度

/%1/8 2/8 3/8 4/8 5/8 6/8 7/8 合计(n1) +106 12.17 77 91 108 40 20 15 10 9 88.13 46.63 -106+90 9.98 252 85 110 70 75 58 40 18 183.88 57.81 -90+74 4.44 310 28 40 20 30 38 35 82 157.75 66.27 -74+45 18.72 430 90 50 65 62 77 42 17 173.63 71.24 -45+38 4.21 500 8 10 15 17 25 9 5 44.38 91.85 -38 50.48 630 35 38 25 15 8 7 4 44.50 93.40 合计 100.00 总解离度/% 78.74 表 4 选厂原矿、精矿、尾矿粒级筛析结果

Table 4. Screening results of the original ore, concentrate and tailings of the concentrator

粒级

/μm产率/% 品位 回收率/% Au/(g/t) S/% As/% 原矿 精矿 尾矿 原矿 精矿 尾矿 原矿 精矿 尾矿 原矿 精矿 尾矿 Au S As +106 5.96 3.14 11.04 1.00 4.75 0.65 0.32 3.96 0.01 0.16 0.85 0.1 40.55 97.12 42.50 -106+90 9.55 7.02 10.61 1.12 6.75 0.55 1.08 7.73 0.01 0.22 1.28 0.07 55.41 99.20 72.13 -90+74 3.37 5.51 3.02 1.14 7.65 0.54 2.18 13.1 0.01 0.4 1.66 0.07 56.63 99.62 86.13 -74+45 17.84 23.59 14.05 1.69 12.5 0.56 2.9 23.87 0.22 0.54 3.86 0.1 70.00 93.27 83.65 -45+38 5.07 7.92 4.3 3.15 13.2 0.58 3.66 27.46 0.21 0.93 6.73 0.1 85.34 94.99 90.59 -38 58.21 52.81 56.98 2.98 37.2 0.59 2.03 24.98 0.43 0.71 7.87 0.21 81.49 80.20 72.35 累计 100.00 100.00 100.00 2.40 24.68 0.59 2.08 22.39 0.29 0.60 5.81 0.16 77.42 87.30 75.67 表 5 选厂扫选精矿实验室浮选实验结果

Table 5. Flotation test results of laboratory scavenging concentrate in the concentrator

班次 金品位/(g/t) 粗选金精

矿产率%回收

率/%金富

集比给矿

(扫Ⅱ精)尾矿 精矿 一班 6.16 5.06 10.70 19.46 33.82 1.74 二班 3.17 2.83 7.30 16.04 36.94 2.30 三班 5. 23 3.60 9.15 29.34 51.35 1.75 表 6 原矿和原矿+扫选精矿实验室实验结果对比

Table 6. Comparison of roughing test results between raw ore and raw ore + scavenging concentrate

实验方案 金品位/(g/t) 精矿产

率%金回收

率%金富

集比原矿 尾矿 精矿 现场流程 2.35 0.75 16.7 10.03 71.29 7.11 扫选精矿

集中返回2.79 0.69 16.3 10.44 78.60 5.84 表 7 闭路实验结果对比

Table 7. Comparison of simulation closed-loop test results

流程 金品位(g/t) 精矿产率% 金回收率% 金富集比 原矿 尾矿 精矿 中矿顺序返回 2.38 0.47 25.70 7.57 81.75 10.80 中矿返回二段

分级泵池2.36 0.40 25.49 7.81 84.37 10.80 说明:考虑到实验的可操作性和稳定性,暂不考虑分级的影响,原矿磨10 min20 s后,将实验的扫一、扫二精矿加入磨机与原矿再磨5 min20 s,进行浮选实验。 表 8 扫选精矿集中返回至二段分级泵池技改前后选矿指标对比

Table 8. Comparison of beneficiation indexes before and after technical transformation of centralized return of scavenging concentrate to two-stage classification pump sump

工艺名称 时间 品位/(g/t) 精矿产

率/%回收

率/%金富

集比原矿 精矿 尾矿 原工艺 2021-03-05 2.23 23.58 0.55 7.29 77.14 10.57 技改工艺 2021-06-12 2.25 23.69 0.46 7.71 81.13 10.53 表 9 技改后原矿、精矿、尾矿粒级筛析结果

Table 9. Screening results of raw ore, concentrate and tailings particle size after technical transformation

粒级

/μm产率/% 品位 回收率/% Au/(g/t) S/% As/% 原矿 精矿 尾矿 原矿 精矿 尾矿 原矿 精矿 尾矿 原矿 精矿 尾矿 Au S As +106 5.11 3.44 5.66 1.21 2.33 0.55 0.99 5.43 0.06 0.21 0.63 0.06 71.40 94.99 78.95 -106+90 9.57 11.22 10.80 1.29 5.24 0.54 1.03 6.82 0.03 0.22 1.09 0.04 64.82 97.52 84.94 -90+74 3.88 7.30 5.22 1.48 7.95 0.59 1.18 7.90 0.14 0.28 1.46 0.07 64.96 89.73 78.78 -74+45 16.15 21.41 15.88 2.41 14.60 0.53 2.31 14.85 0.03 0.57 3.72 0.04 80.95 98.90 93.99 -45+38 5.82 7.56 6.36 3.34 24.50 0.60 3.18 18.59 0.12 0.92 6.15 0.07 84.10 96.85 93.46 -38 59.46 49.07 56.08 2.65 37.40 0.44 1.91 18.81 0.07 0.60 7.20 0.07 84.39 96.69 89.20 累计 100.00 100.00 100.00 2.40 24.58 0.49 1.89 15.34 0.07 0.55 5.04 0.06 81.22 96.94 89.82 说明:相关数据计算方法同表4。 表 10 技改后扫选精矿毒砂单体解离度测定结果

Table 10. Determination results of monomer dissociation of arsenopyrite from scavenging concentrate after technical transformation

粒级

/μm产率/% 单体颗粒数/n 不同比例连生体颗粒数 单体解离度

/%1/8 2/8 3/8 4/8 5/8 6/8 7/8 合计(n1) +106 10.13 30 55 33 20 12 8 2 1 36.00 45.45 106+90 8.63 60 155 52 22 13 29 15 6 81.75 42.33 -90+74 5.28 133 120 62 34 23 33 23 26 115.38 53.55 -74+45 16.72 295 180 45 39 25 39 30 20 125.25 70.20 -45+38 6.31 375 30 26 16 18 10 6 5 40.38 90.28 -38 52.93 559 41 37 35 12 7 1 0 38.63 93.54 合计 100.00 总解离度/% 78.03 表 11 技改后扫选精矿黄铁矿单体解离度测定结果

Table 11. Determination results of monomer dissociation of pyrite from scavenging concentrate after technical transformation

粒级

/μm产率/% 单体颗粒数/n 不同比例连生体颗粒数 单体解离度

/%1/8 2/8 3/8 4/8 5/8 6/8 7/8 合计(n1) +106 10.13 73 93 84 46 22 10 8 6 78.38 48.22 106+90 8.63 238 87 111 88 33 55 37 20 167.75 58.66 -90+74 5.28 330 52 40 42 39 44 52 65 175.13 65.33 -74+45 16.72 450 115 70 44 55 69 45 36 184.25 70.95 -45+38 6.31 511 12 8 9 15 20 10 9 42.25 92.36 -38 52.93 646 35 45 33 9 11 4 2 44.13 93.61 合计 100.00 总解离度/% 80.63 -

[1] 康维刚, 陈京玉. 老挝某金矿石重选-环保药剂浸金研究[J]. 贵金属, 2022, 43(1):61-66.KANG W G, CHEN J Y. Study on gravity separation and environmental friendly agent leaching of a gold ore in Laos[J]. Precious Metals, 2022, 43(1):61-66. doi: 10.3969/j.issn.1004-0676.2022.01.011

KANG W G, CHEN J Y. Study on gravity separation and environmental friendly agent leaching of a gold ore in Laos[J]. Precious Metals, 2022, 43(1):61-66. doi: 10.3969/j.issn.1004-0676.2022.01.011

[2] 石宝宝, 杨晓峰, 翟存楼, 等. 山东某低品位金矿工艺矿物学[J]. 矿产综合利用, 2022(6):184-188.SHI B B, YANG X F, ZHAI C L, et al. Detailed study on technological mineralogy of a low grade gold ore in Shandong[J]. Multipurpose Utilization of Mineral Resources, 2022(6):184-188. doi: 10.3969/j.issn.1000-6532.2022.06.031

SHI B B, YANG X F, ZHAI C L, et al. Detailed study on technological mineralogy of a low grade gold ore in Shandong[J]. Multipurpose Utilization of Mineral Resources, 2022(6):184-188. doi: 10.3969/j.issn.1000-6532.2022.06.031

[3] 孙晓妍, 周永星, 宋宝旭, 等. 山东某含金硫铁矿强化浮选回收实验研究[J]. 贵金属, 2022, 43(3):50-55.SUN X Y, ZHOU Y X, SONG B X, et al. Experimental study on enhanced flotation recovery of an gold-bearing on Shandong Province[J]. Precious Metals, 2022, 43(3):50-55. doi: 10.3969/j.issn.1004-0676.2022.03.009

SUN X Y, ZHOU Y X, SONG B X, et al. Experimental study on enhanced flotation recovery of an gold-bearing on Shandong Province[J]. Precious Metals, 2022, 43(3):50-55. doi: 10.3969/j.issn.1004-0676.2022.03.009

[4] 冯大伟, 王玲. 选冶联合处理低品位含金尾矿的实验研究[J]. 黄金科学技术, 2021, 29(2):315-323.FENG D W, WANG L. Experimental research on treatment of low-grade gold-bearing tailings by combined process of concentration and smelting[J]. Gold Science and Technology, 2021, 29(2):315-323.

FENG D W, WANG L. Experimental research on treatment of low-grade gold-bearing tailings by combined process of concentration and smelting[J]. Gold Science and Technology, 2021, 29(2):315-323.

[5] 李林积, 王丹, 邱鹏玉. 西秦岭格尔托金矿金的赋存状态及可选性实验研究[J]. 矿产综合利用, 2019(4):83-86.LI L J, WANG D, QIU P Y. Experimental study on occurrence and optionality of gold in Gelto gold deposit, western Qinling[J]. Multipurpose Utilization of Mineral Resources, 2019(4):83-86. doi: 10.3969/j.issn.1000-6532.2019.04.017

LI L J, WANG D, QIU P Y. Experimental study on occurrence and optionality of gold in Gelto gold deposit, western Qinling[J]. Multipurpose Utilization of Mineral Resources, 2019(4):83-86. doi: 10.3969/j.issn.1000-6532.2019.04.017

[6] 何敏亭, 杨洪英, 牛桂强, 等. 焦家金矿低品位超细洗矿矿泥工艺矿物学研究[J]. 有色金属(选矿部分), 2022(2):16-23.HE M T, YANG H Y, NIU G Q, et al. Mineralogical study on low grade ultrafine sline washing process in Jiaojia Gold Mine[J]. Nonferrous Metals(Mineral Processing Section), 2022(2):16-23.

HE M T, YANG H Y, NIU G Q, et al. Mineralogical study on low grade ultrafine sline washing process in Jiaojia Gold Mine[J]. Nonferrous Metals(Mineral Processing Section), 2022(2):16-23.

[7] 张立征, 王彩霞, 赵福财. 甘肃某微细粒浸染型难处理金矿选矿实验研究[J]. 矿冶工程, 2011, 31(4):45-47.ZHANG L Z, WANG C X, ZHAO F C. Mineral processing experiments on fine-disseminated refractory god ore from Gansu[J]. Mining and Metallurgical Engineering, 2011, 31(4):45-47. doi: 10.3969/j.issn.0253-6099.2011.04.012

ZHANG L Z, WANG C X, ZHAO F C. Mineral processing experiments on fine-disseminated refractory god ore from Gansu[J]. Mining and Metallurgical Engineering, 2011, 31(4):45-47. doi: 10.3969/j.issn.0253-6099.2011.04.012

[8] 刘国晨. 某石英脉型金矿石选矿工艺开发实验研究[J]. 矿产综合利用, 2019(5):75-79.LIU G C. Experimental study on mineral processing development of a quartz vein type gold ore[J]. Multipurpose Utilization of Mineral Resources, 2019(5):75-79. doi: 10.3969/j.issn.1000-6532.2019.05.016

LIU G C. Experimental study on mineral processing development of a quartz vein type gold ore[J]. Multipurpose Utilization of Mineral Resources, 2019(5):75-79. doi: 10.3969/j.issn.1000-6532.2019.05.016

[9] 王普蓉, 徐国印, 苏刚. 昌宁含铁低品位高泥锡石矿重-磁选工艺研究 [J]. 矿产综合利用, 2022 (1): 136-141.WANG P R, XU G Y, SU G , et al. Study on gravity and magnetic separation process of an iron-containing low-grade and high slime tin ore in Changning[J]. Multipurpose Utilization of Mineral Resources, 2022 (1): 136-141.

WANG P R, XU G Y, SU G , et al. Study on gravity and magnetic separation process of an iron-containing low-grade and high slime tin ore in Changning[J]. Multipurpose Utilization of Mineral Resources, 2022 (1): 136-141.

[10] 蔡明明, 张文平, 徐超, 等. 某难选金矿物工艺矿物学研究[J]. 矿产综合利用, 2022(5):193-198.CAI M M, ZHANG W P, XU C, et al. Study on process mineralogy of a refractory gold ore[J]. Multipurpose Utilization of Mineral Resources, 2022(5):193-198.

CAI M M, ZHANG W P, XU C, et al. Study on process mineralogy of a refractory gold ore[J]. Multipurpose Utilization of Mineral Resources, 2022(5):193-198.

[11] 杨佐怀, 董越, 郭俊杰, 等, 新疆某金矿选冶联合工艺研究[J]. 矿产综合利用, 2022 (3): 121-125.YANG Z H, DONG Y, GUO J J, et al. Beneficiation and metallurgical process study for a gold mine in Xinjiang[J]. Multipurpose Utilization of Mineral Resources, 2022 (3): 121-125.

YANG Z H, DONG Y, GUO J J, et al. Beneficiation and metallurgical process study for a gold mine in Xinjiang[J]. Multipurpose Utilization of Mineral Resources, 2022 (3): 121-125.

[12] 石贵明, 周意超, 刘琴, 等. 广东大尖山某铅锌多金属矿石选矿实验[J]. 金属矿山. 2018(4): 88-92.SHI G M, ZHOU Y C, LIU Q, et al. Beneficiation test of a lead-zinc polymetallic ore from Dajianshan, Guangdong Province[J]. Metal Mine. 2018(4): 88-92.

SHI G M, ZHOU Y C, LIU Q, et al. Beneficiation test of a lead-zinc polymetallic ore from Dajianshan, Guangdong Province[J]. Metal Mine. 2018(4): 88-92.

[13] 苏志远. 某中等硫化物含砷碳微细粒浸染型难选矿石选矿生产实践[J]. 黄金, 2014, 35(12):49-53.SU Z Y. The beneficiation practice of a refractory ore containing medium sulphide and arsenic-carbon fine-grained disseminated ore[J]. Gold, 2014, 35(12):49-53. doi: 10.11792/hj20141213

SU Z Y. The beneficiation practice of a refractory ore containing medium sulphide and arsenic-carbon fine-grained disseminated ore[J]. Gold, 2014, 35(12):49-53. doi: 10.11792/hj20141213

[14] 钟国建, 肖骁, 龙渊, 等. 硫精矿立磨再磨再选回收铜实验研究[J]. 矿冶工程, 2016, 36(1):52-55.ZHONG G J, XIAO X, LONG Y, et al. Reclaiming copper minerals from sulfur concentrate after reground with vertical mill[J]. Mining and Metallurgical Engineering, 2016, 36(1):52-55. doi: 10.3969/j.issn.0253-6099.2016.01.013

ZHONG G J, XIAO X, LONG Y, et al. Reclaiming copper minerals from sulfur concentrate after reground with vertical mill[J]. Mining and Metallurgical Engineering, 2016, 36(1):52-55. doi: 10.3969/j.issn.0253-6099.2016.01.013

[15] 骆忠, 蒋太国, 李娜. 中矿集中再磨工艺对铜浮选指标的影响[J]. 矿冶工程, 2019, 28(1): 25-29.LUO Z, JIANG T G, LI N. Effect of centralized regrinding process of middings on copper flotation index[J]. Mining and Metallurgy, 2016, 36(1): 25-29.

LUO Z, JIANG T G, LI N. Effect of centralized regrinding process of middings on copper flotation index[J]. Mining and Metallurgy, 2016, 36(1): 25-29.

[16] 袁喜振, 苏敏, 邓林欣, 等. 谦比希铜矿的选矿指标优化实验[J]. 矿产综合利用, 2021, 6: 185-189.YUAN X Z, SU M, DENG L X, et al. Optimization test of beneficiation index of Chambishi copper mine[J]. Multipurpose Utilization of Mineral Resources, 2021, 6: 185-189.

YUAN X Z, SU M, DENG L X, et al. Optimization test of beneficiation index of Chambishi copper mine[J]. Multipurpose Utilization of Mineral Resources, 2021, 6: 185-189.

[17] 马世收. 七宝山金矿扫选精矿的分级再磨改造[J]. 金属矿山. 2003(4): 61-62.MA S S. Classification and regrinding reform of scavenging concentrate in Qibaoshan gold mine[J]. Metal Mine. 2003(4): 61-62. Print.

MA S S. Classification and regrinding reform of scavenging concentrate in Qibaoshan gold mine[J]. Metal Mine. 2003(4): 61-62. Print.

[18] 叶国华, 童雄, 张杰, 等. 某难选铜矿浮选新工艺实验研究[J]. 有色金属(选矿部分), 2006(6):16-23.YE G H, TONG X, ZHANG J, et al. Experimental study on a new flotation process for refractory copper ore[J]. Nonferrous Metals(Mineral Processing Section), 2006(6):16-23.

YE G H, TONG X, ZHANG J, et al. Experimental study on a new flotation process for refractory copper ore[J]. Nonferrous Metals(Mineral Processing Section), 2006(6):16-23.

[19] 王守敬. 华阳川铀多金属矿工艺矿物学研究. 金属矿山[J]. 2019(4): 122-126.WANG S J. Study on process mineralogy of Huayangchuan uranium polymetallic ore[J]. Metal Mine. 2019(4): 122-126.

WANG S J. Study on process mineralogy of Huayangchuan uranium polymetallic ore[J]. Metal Mine. 2019(4): 122-126.

-

下载:

下载: