Effect of MO Collector on Coal Gasification Fine Slag Flotation

-

摘要:

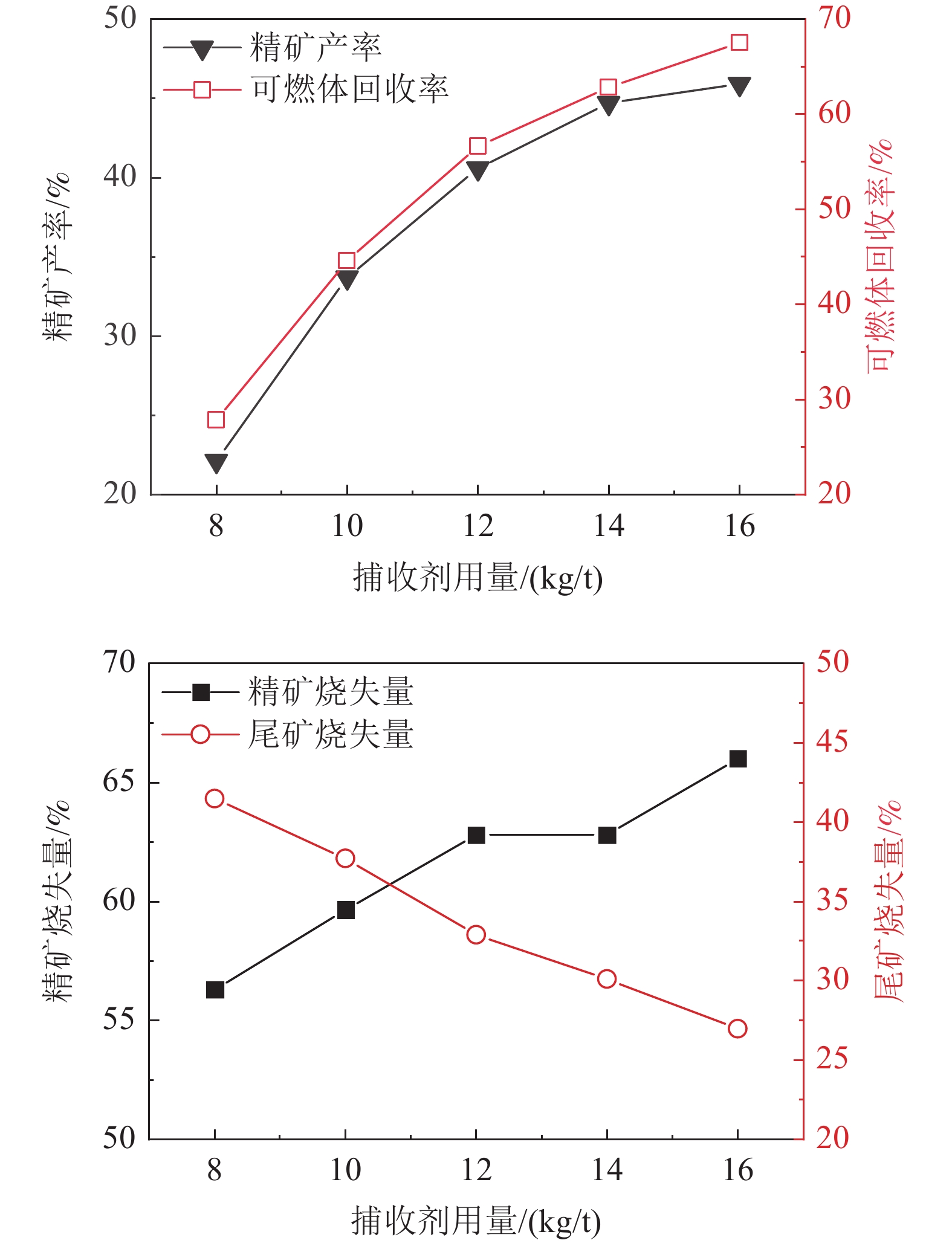

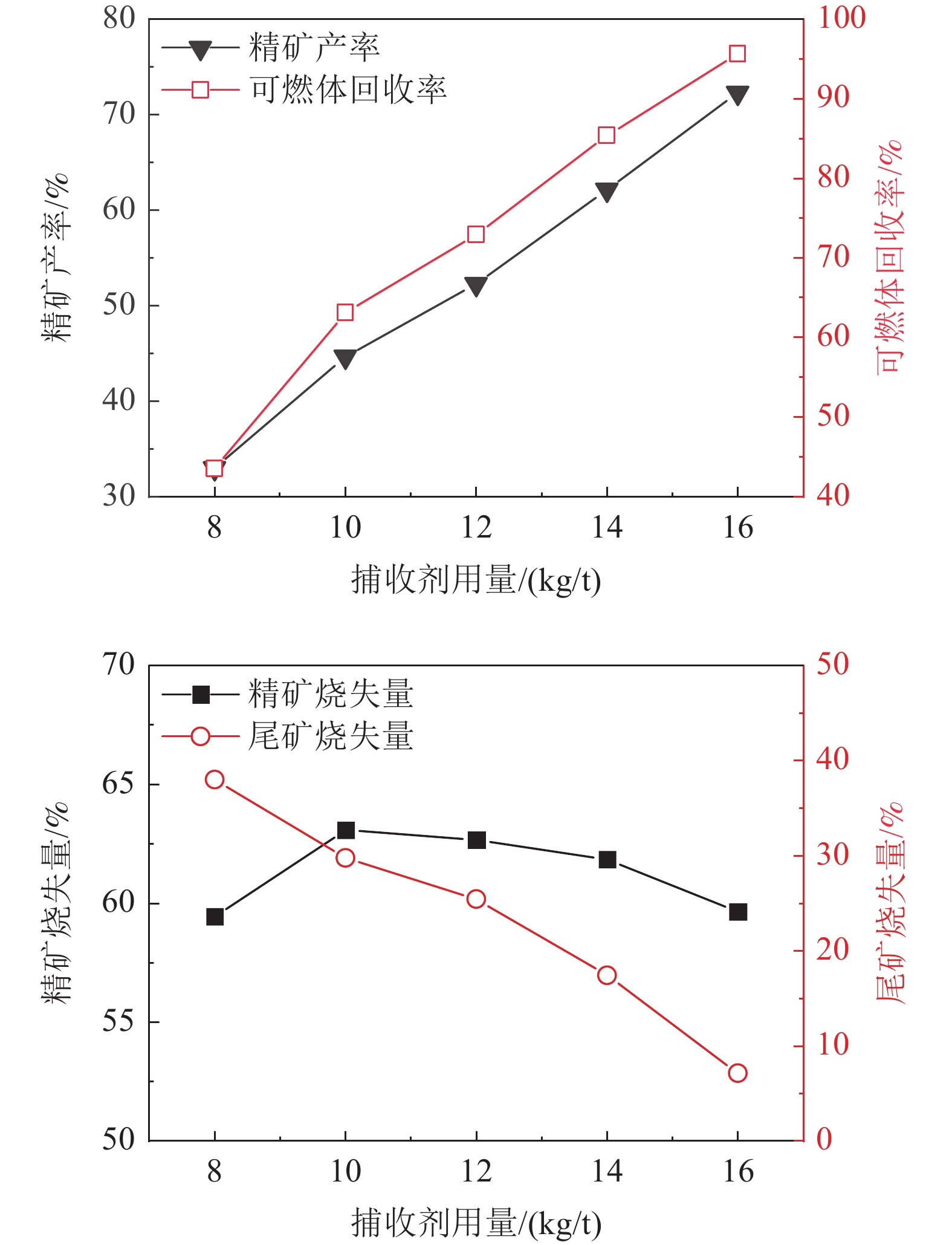

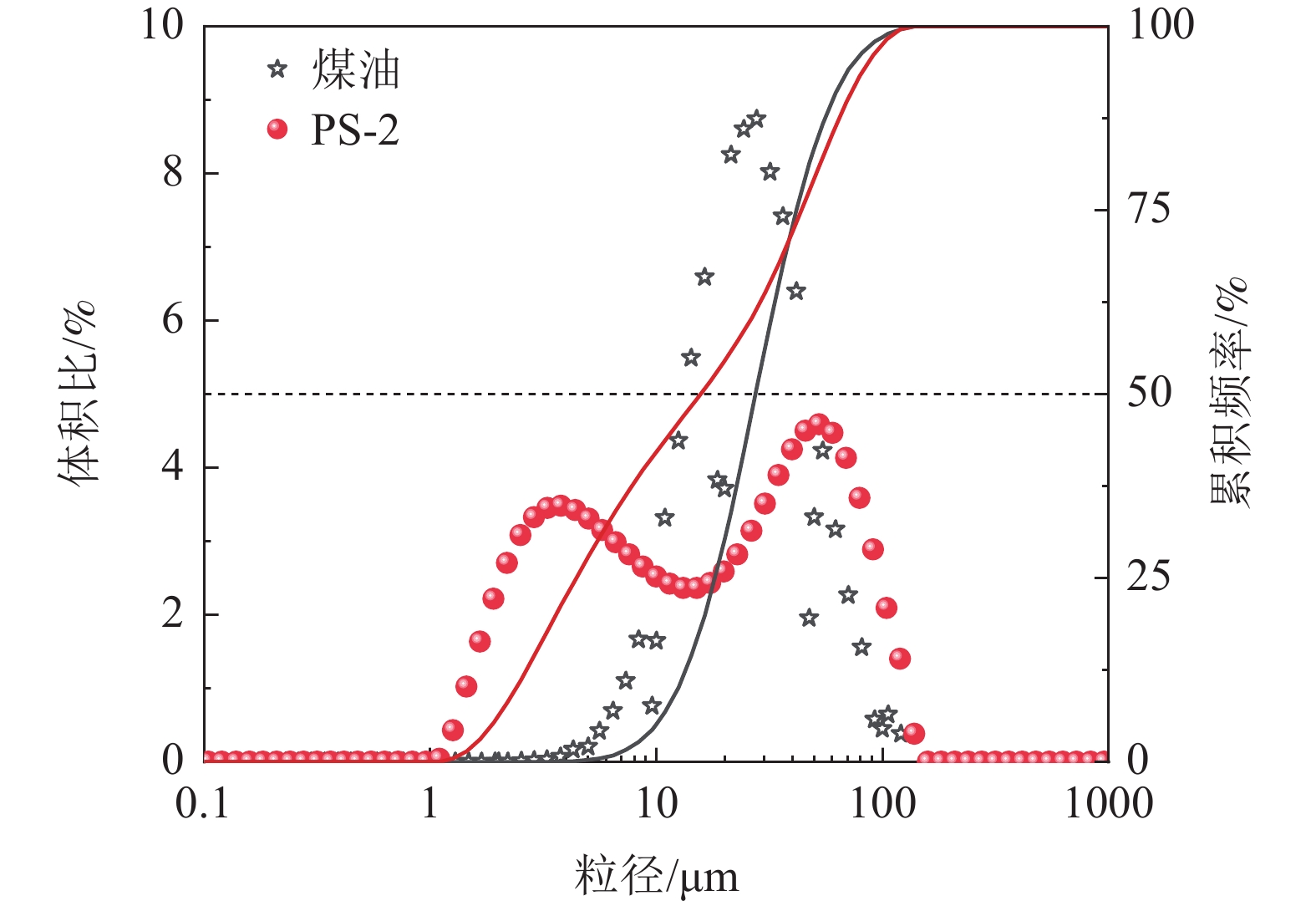

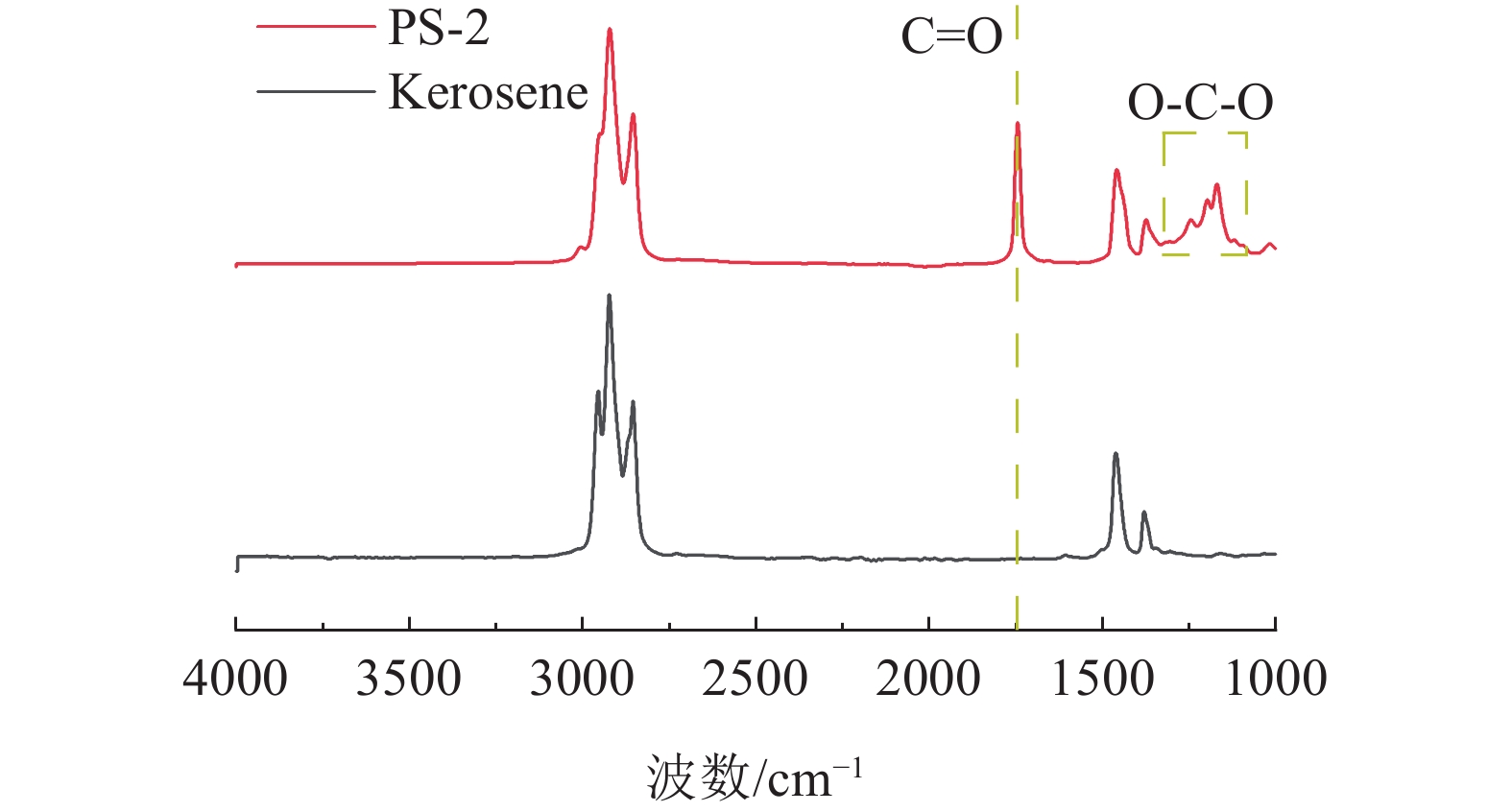

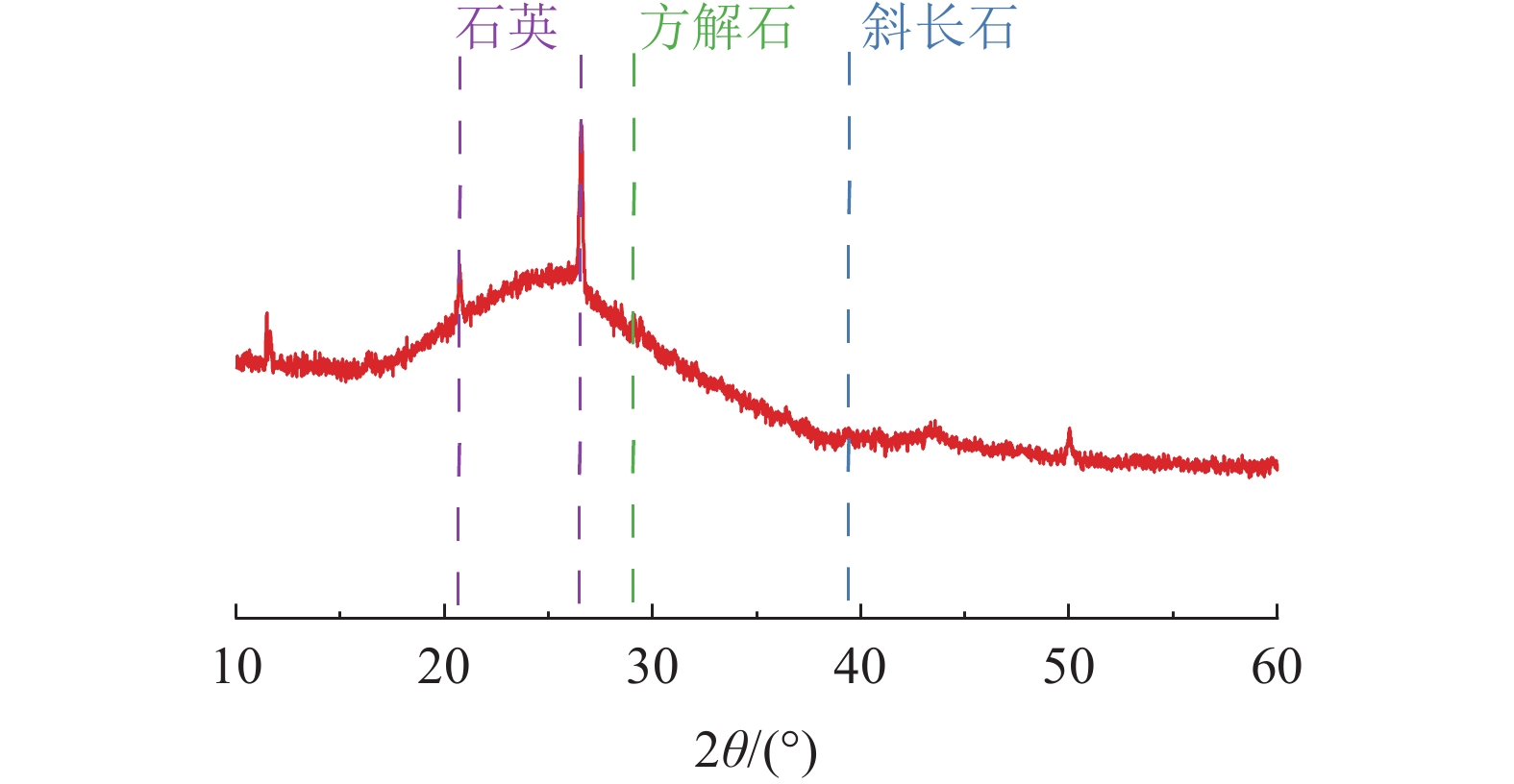

这是一篇矿物加工工程领域的文章。煤气化细渣的综合利用是现阶段的一大发展方向。煤气化细渣孔隙发达且含氧基团丰富,使得煤油等传统捕收剂难以回收其中的残炭。将油酸甲酯和煤油复配得到的药剂MO进行浮选实验,并通过激光粒度仪、红外光谱分析、接触角分析、XPS分峰拟合等手段进行机理探讨。结果表明,当MO药剂用量提高到16 kg/t时,尾矿烧失量降低到7.12%,可燃体回收率超过95.63%。MO药剂引入了极性基团酯基,其可以降低煤油表面的界面张力,增强捕收剂在水中的分散作用,从而增加残炭颗粒与捕收剂液滴的接触面积与碰撞概率,进而提高残炭颗粒的疏水性和可浮性。通过接触角分析不同药剂作用下残炭表面的疏水性,解释其与精矿产率的关系。通过XPS分析说明,MO与残炭表面的含氧官能团作用,能够在残炭的亲水位点形成有效的覆盖层,使得疏水部分朝外,降低了水化作用,增加了接触概率,增加该煤气化细渣的表面疏水性。MO药剂的使用为煤气化固体废弃物的综合利用提供了一种新途径。

Abstract:This is an article in the field of mineral processing engineering. Comprehensive utilization of coal gasification fine slag is a major development direction at present. Coal gasification fine slag has developed pores and rich oxygen groups, which makes it difficult for kerosene and other traditional collectors to recover the residual carbon. Flotation experiments were carried out on the compound MO of methyl oleate and kerosene, and the mechanism was discussed by means of laser particle size analyzer, FTIR, contact angle, and XPS. The results show that when the dosage of MO is increased to 16 kg/t, the loss on ignition of tailings is reduced to 7.12%, and the recovery of combustible is more than 95.63%. MO introduced polar group ester group, which can reduce the interfacial tension of kerosene surface, enhance the dispersing effect of collector in water, so as to increase the contact area and collision probability of carbon residue particles and collector droplet, and improve the hydrophobicity and floatability of carbon residue particles. The hydrophobicity of carbon residue was analyzed by contact angle and the relationship between the hydrophobicity and the rate of fine mineral was explained. XPS shows that the interaction between MO and oxygen-containing functional groups on the surface of the carbon residue can form an effective covering layer at the hydrophilic water level point of the carbon residue, which makes the hydrophobic part outward, reduces the hydration, increases the contact probability, and increases the surface hydrophobicity of the coal gasification fine slag. The use of MO agent provides a new way for comprehensive utilization of solid waste from coal gasification.

-

-

表 1 CGFS的粒度组成

Table 1. Particle size composition of CFFS

粒径/mm 产率/% 烧失量/% 筛上累计/% 累计产率 累计烧失量 -0.5+0.25 25.60 46.86 25.60 46.86 -0.25+0.125 17.78 35.57 43.37 42.23 -0.125+0.074 14.94 55.65 58.32 45.67 -0.074+0.045 9.05 60.06 67.37 47.60 -0.045 32.63 39.74 100.00 45.04 总计 100.00 45.04 表 2 CGFS的工业分析和元素分析

Table 2. Proximate and elementary analysis of CGFS

工业分析/% 元素分析/% Mad LOIad Vad FCad C H O N S 0.55 45.04 1.98 42.55 86.08 0.52 12.21 0.66 0.53 注:Mad为CGFS空气干燥基的水分;LOIad为CGFS空气干燥基的烧失量;Vad为CGFS空气干燥基的挥发分;FCad为CGFS空气干燥基的固定碳。 表 3 含氧基团的含量及形式

Table 3. Content analysis of functional groups

结合能/eV 官能团 含量/% UC 煤油处理后 MO处理后 284.8 C-C/C-H 68.69 74.82 76.34 286.1 C-O 14.80 14.45 12.45 287.5 C=O 4.56 5.22 5.29 289.0 COO- 11.95 5.51 5.92 -

[1] 程志红. “双碳目标”下表面改性与新型药剂在低阶煤浮选中的应用[J]. 矿产综合利用, 2022(2):15-21.CHENG Z H. Application of Surface modification and new reagents in low-rank coal flotation under "double carbon target"[J]. Multipurpose Utilization of Mineral Resources, 2022(2):15-21. doi: 10.3969/j.issn.1000-6532.2022.02.003

CHENG Z H. Application of Surface modification and new reagents in low-rank coal flotation under "double carbon target"[J]. Multipurpose Utilization of Mineral Resources, 2022(2):15-21. doi: 10.3969/j.issn.1000-6532.2022.02.003

[2] 王学斌, 于伟, 张韬, 等. 基于粒度分级的煤气化细渣特性分析及利用研究[J]. 洁净煤技术, 2021, 27(3):61-69.WANG X, YU W, ZHANG T, et al. Characteristic analysis and utilization of coal gasification fine slag based on particle size classification[J]. Clean Coal Technology, 2021, 27(3):61-69.

WANG X, YU W, ZHANG T, et al. Characteristic analysis and utilization of coal gasification fine slag based on particle size classification[J]. Clean Coal Technology, 2021, 27(3):61-69.

[3] Guo F, Zhao X, Guo Y, et al. Fractal analysis and pore structure of gasification fine slag and its flotation residual carbon[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2020, 585:124148. doi: 10.1016/j.colsurfa.2019.124148

[4] 肖永丰. 粉煤灰提取氧化铝方法研究[J]. 矿产综合利用, 2020(4):156-162.XIAO Y F. Study on the methods of leaching alumina from fly ash[J]. Multipurpose Utilization of Mineral Resources, 2020(4):156-162. doi: 10.3969/j.issn.1000-6532.2020.04.027

XIAO Y F. Study on the methods of leaching alumina from fly ash[J]. Multipurpose Utilization of Mineral Resources, 2020(4):156-162. doi: 10.3969/j.issn.1000-6532.2020.04.027

[5] Cao X, Kong L, Bai J, et al. Effect of water vapor on viscosity behavior of coal slags with high silicon-aluminum level under gasification condition[J]. Fuel, 2020, 260:116351. doi: 10.1016/j.fuel.2019.116351

[6] 张旭, 于昭仪, 何亚群, 等. 吡啶类离子液体在褐煤反浮选中的应用[J]. 矿产综合利用, 2022(2):116-120.ZHANG X, YU S Y, HE Y Q, et al. Application of pyridyl ionic liquids in the reverse flotation of shengli lignite[J]. Multipurpose Utilization of Mineral Resources, 2022(2):116-120. doi: 10.3969/j.issn.1000-6532.2022.02.021

ZHANG X, YU S Y, HE Y Q, et al. Application of pyridyl ionic liquids in the reverse flotation of shengli lignite[J]. Multipurpose Utilization of Mineral Resources, 2022(2):116-120. doi: 10.3969/j.issn.1000-6532.2022.02.021

[7] 卢天燊, 邓政斌, 刘志红, 等. 高灰难选煤泥分级浮选降灰实验研究[J]. 矿产综合利用, 2022(2):142-149.LU T J, DENG Z B, LIU Z H, et al. Experimental study on deashing of high ash and refractory coal slime by classification flotation[J]. Multipurpose Utilization of Mineral Resources, 2022(2):142-149. doi: 10.3969/j.issn.1000-6532.2022.02.026

LU T J, DENG Z B, LIU Z H, et al. Experimental study on deashing of high ash and refractory coal slime by classification flotation[J]. Multipurpose Utilization of Mineral Resources, 2022(2):142-149. doi: 10.3969/j.issn.1000-6532.2022.02.026

[8] 张帅, 李亚, 牛艳萍, 等. 某片麻岩鳞片石墨矿浮选实验研究[J]. 矿产综合利用, 2022(2):111-115.ZHANG S, LI Y, NIU Y P, et al. Flotation test of a gneiss scale graphite ore[J]. Multipurpose Utilization of Mineral Resources, 2022(2):111-115. doi: 10.3969/j.issn.1000-6532.2022.02.020

ZHANG S, LI Y, NIU Y P, et al. Flotation test of a gneiss scale graphite ore[J]. Multipurpose Utilization of Mineral Resources, 2022(2):111-115. doi: 10.3969/j.issn.1000-6532.2022.02.020

[9] 梁艳男, 王海楠, 周若谦, 等. 浮选微泡调控及其作用机制的研究进展[J]. 矿产综合利用, 2022(2):158-166.LIANG Y N, WANG H N, ZHOU R Q, et al. Investigation advances on regulation and mechanism of microbubbles in flotation[J]. Multipurpose Utilization of Mineral Resources, 2022(2):158-166. doi: 10.3969/j.issn.1000-6532.2022.02.029

LIANG Y N, WANG H N, ZHOU R Q, et al. Investigation advances on regulation and mechanism of microbubbles in flotation[J]. Multipurpose Utilization of Mineral Resources, 2022(2):158-166. doi: 10.3969/j.issn.1000-6532.2022.02.029

[10] 朱一民. 2020 年浮选药剂的进展[J]. 矿产综合利用, 2021(2):102-118.ZHU Y M. Development of flotation reagent in 2020[J]. Multipurpose Utilization of Mineral Resources, 2021(2):102-118. doi: 10.3969/j.issn.1000-6532.2021.02.019

ZHU Y M. Development of flotation reagent in 2020[J]. Multipurpose Utilization of Mineral Resources, 2021(2):102-118. doi: 10.3969/j.issn.1000-6532.2021.02.019

[11] 胡俊阳. 北方某煤气化炉渣的综合利用研究[D]. 绵阳: 西南科技大学, 2018.HU J Y. Study on the comprehensive utilization of a coal gasification slag in the north[J]. Mianyang: Southwest University of Science and Technology, 2018.

HU J Y. Study on the comprehensive utilization of a coal gasification slag in the north[J]. Mianyang: Southwest University of Science and Technology, 2018.

[12] Wang W, Liu D, Tu Y, et al. Enrichment of residual carbon in entrained-flow gasification coal fine slag by ultrasonic flotation[J]. Fuel, 2020, 278:118195. doi: 10.1016/j.fuel.2020.118195

[13] 王晓波, 符剑刚, 赵迪, 等. 煤气化细渣载体浮选提质研究[J]. 煤炭工程, 53(1): 155-159.WANG X B, FU J G, ZHAO D, et al. Study on flotation and quality improvement of gasified fine slag carrier[J]. Coal Engineering, 53(1): 155-159

WANG X B, FU J G, ZHAO D, et al. Study on flotation and quality improvement of gasified fine slag carrier[J]. Coal Engineering, 53(1): 155-159

[14] Fan G, Zhang M, Peng W, et al. Clean products from coal gasification waste by flotation using waste engine oil as collector: Synergetic cleaner disposal of wastes[J]. Journal of Cleaner Production, 2021, 286:124943. doi: 10.1016/j.jclepro.2020.124943

[15] Shi D, Zhang J, Hou X, et al. Adsorption mechanism of a new combined collector (PS-1) on unburned carbon in gasification slag[J]. Science of The Total Environment, 2022, 818:151856. doi: 10.1016/j.scitotenv.2021.151856

[16] Zhou W, Jiang L, Liu X, et al. Molecular insights into the effect of anionic-nonionic and cationic surfactant mixtures on interfacial properties of oil-water interface[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022: 128259.

[17] 包永红, 张义, 陈警卫, 等. 脉石矿物在细粒煤浮选过程的夹带回收特性研究[J]. 矿产综合利用, 2021(6):20-25.BAO Y H, ZHANG Y, CHEN J W, et al. Study on entrainment recovery characteristics of gangue minerals in flotation process of fine coal[J]. Multipurpose Utilization of Mineral Resources, 2021(6):20-25. doi: 10.3969/j.issn.1000-6532.2021.06.004

BAO Y H, ZHANG Y, CHEN J W, et al. Study on entrainment recovery characteristics of gangue minerals in flotation process of fine coal[J]. Multipurpose Utilization of Mineral Resources, 2021(6):20-25. doi: 10.3969/j.issn.1000-6532.2021.06.004

[18] Miao Z, Guo Z, Qiu G, et al. Synthesis of activated carbon from high-ash coal gasification fine slag and their application to CO2 capture[J]. Journal of CO2 Utilization, 2021, 50:101585. doi: 10.1016/j.jcou.2021.101585

-

下载:

下载: