Study on the Process Mineralogy for the Flotation Tailings of a Gold Mine in Shandong Province

-

摘要:

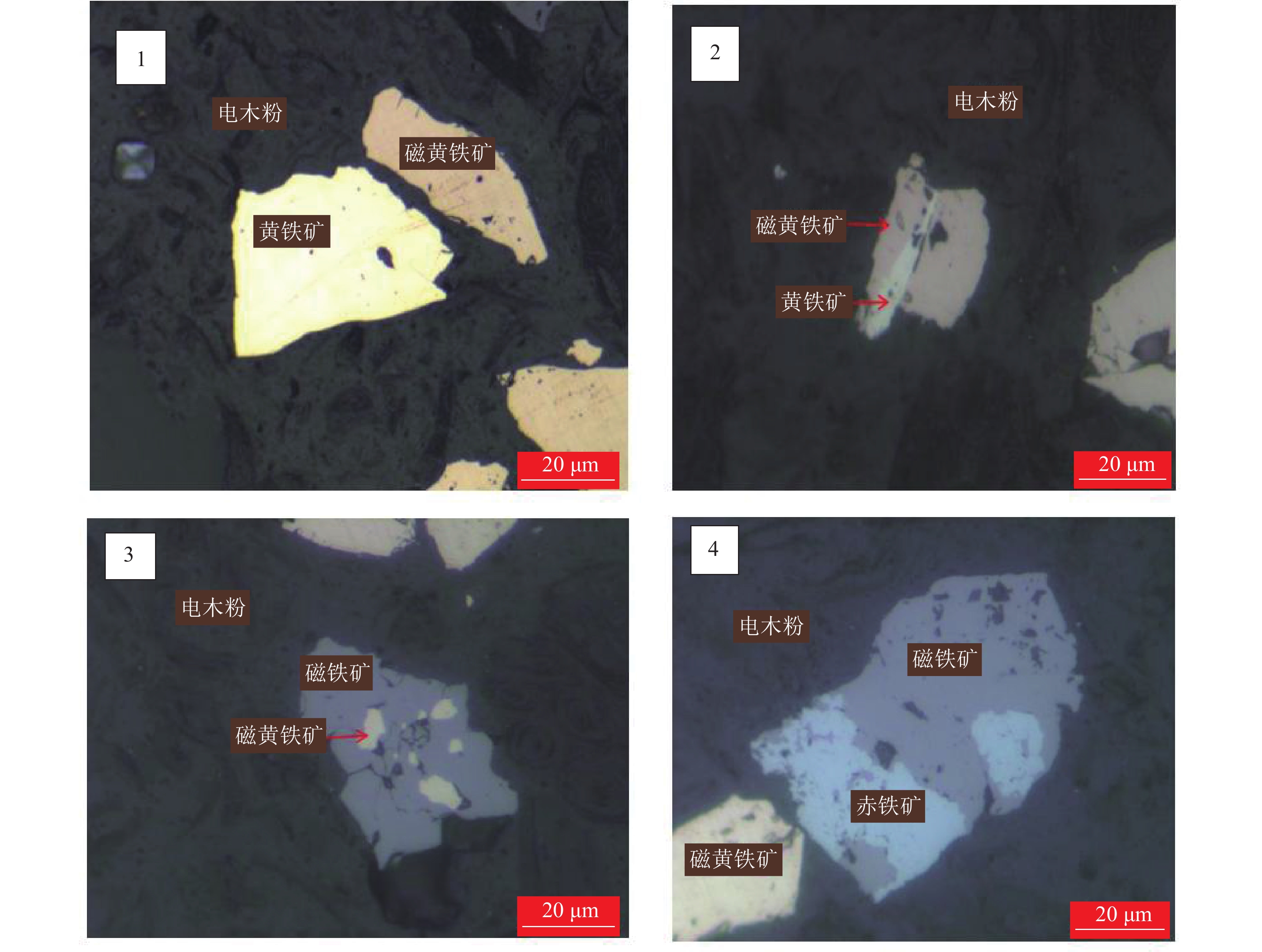

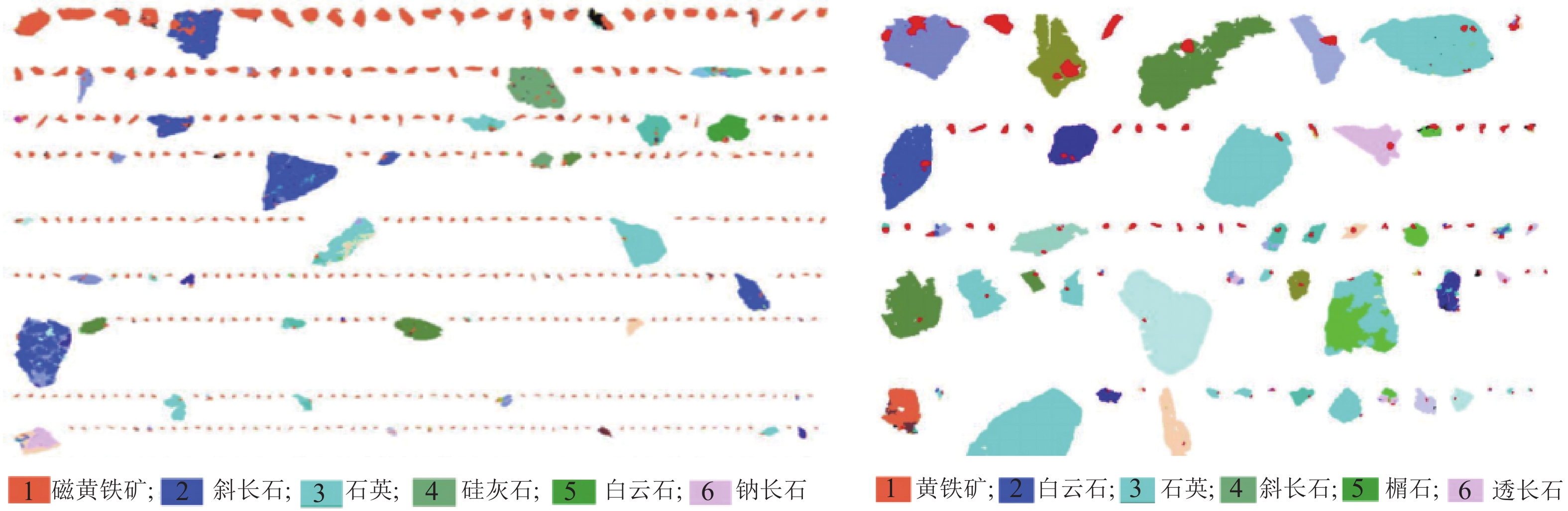

这是一篇工艺矿物学领域的论文。山东某金矿石含金2.0 g/t,含硫1.56%,属于典型低硫含金矿石。选厂采用浮选工艺回收金,金的回收率为90%,尾矿金品位0.17 g/t。为进一步降低尾矿中金的流失,提高浮选指标,采用MLA结合传统工艺矿物学手段查明金的流失原因。研究表明:主要的金属矿物为磁黄铁矿和黄铁矿,脉石矿物主要为长石和石英;脉石连生金及脉石包裹金占77.29%,粒度主要分布在-0.01 mm,这部分采用浮选工艺很难回收;金属硫化物连生金、金属硫化物包裹金及单体金占22.71%,流失不合理。基于尾矿工艺矿物学分析,下一步应该重点研究磨矿分级,降低有用矿物过磨程度,达到提高浮选指标的目的。

Abstract:This is anarticle in the field of process mineralogy. The grade of gold and sulfur in a gold mine from Shandong Province was 2.0 g/t and 1.56% respectively, which was a typical gold bearing ore with low sulfur. There covery of gold was made by flotation process in dressing mill, the gold recovery rate was 90%, the gold grade of tailings was 0.17 g/t. To reduce the loss of gold, and improve the flotation performance, MLA(Mineral Liberation Analyser)combined with frequently used process mineralogy method was used to ascertain the reasons for the loss of gold. The study show edpyrrhotite and pyritewere main metal licminerals, feldspar and quartz were a primary gangue miner. The gold locked to gangue and gold included with gangue accounted for 77.29%, of which the size distribution was below 0.01 mm, were difficult to recovered by flotation process. The gold locked or included by metal sulfides and monomer gold accounted for 22.71%, were unreasonable loss. Based on the analysis of process mineralogy of tailings:grinding and classification were the key to further work, which aimed to reduce degree of over grinding of useful minerals, achieve the improvement of beneficiation results.

-

Key words:

- Flotation /

- Gold tailings /

- Process mineralogy /

- MLA

-

-

表 1 尾矿多元素化学分析结果/%

Table 1. Analysis results of chemical multi-elements of tailings

Au* Ag* Cu Pb Zn Fe S As Ti C CaO MgO SiO2 Al2O3 Ti 0.17 1.04 0.01 0.04 0.01 3.59 0.29 0.00 0.65 1.61 8.05 2.36 31.53 5.34 0.65 *单位为g/t。 表 2 矿物组成及含量

Table 2. Mineral composition and content of tailings

矿物 磁黄铁矿 黄铁矿 黄铜矿 闪锌矿 赤铁矿、磁铁矿、褐铁矿 长石 含量/% 0.66 0.04 0.04 0.02 0.55 34.48 矿物 石英 方解石白云石 橄榄石角闪石 石榴石 辉石 云母 其他 合计 含量/% 22.79 13.53 10.63 8.53 3.36 3.01 2.36 100.00 表 3 磁黄铁矿及黄铁矿粒度分析

Table 3. Particle size analysis of pyrrhotite and pyrite

粒径/mm +0.074 -0.074+0.053 -0.053+0.037 -0.037+0.01 -0.01+0.005 -0.005 磁黄铁矿/% 4.11 3.15 16.23 58.07 16.01 2.43 黄铁矿/% — — — 47.94 40.53 11.53 表 4 磁黄铁矿及黄铁矿赋存状态

Table 4. Existence states of pyrrhotite and pyrite

赋存状态 单体 金属氧化物包裹及连生 脉石包裹及连生 含量/% 15.85 19.15 65.00 表 5 金矿物粒度测定结果

Table 5. Results of size measurement of gold minerals

粒径/mm +0.074 -0.074+0.053 -0.053+0.037 -0.037+0.01 -0.01 含量/% 8.75 3.94 3.68 16.49 67.14 表 6 金的流失状态

Table 6. Existence states of gold

赋存状态 单体 与硫化物连生 与脉石连生 硫化物包裹 脉石包裹 含量/% 7.32 4.21 60.82 11.18 16.47 -

[1] 王越, 王婧, 李潇雨, 等. 川西某金矿工艺矿物学研究及对选矿工艺的影响[J]. 矿产综合利用, 2021(4):206-210.WANG Y, WANG J, LI X Y, et al. Process mineralogy study of gold deposit in Western Sichuan area and its influence on mineral processing technology[J]. Multipurpose Utilization of Mineral Resources, 2021(4):206-210.

WANG Y, WANG J, LI X Y, et al. Process mineralogy study of gold deposit in Western Sichuan area and its influence on mineral processing technology[J]. Multipurpose Utilization of Mineral Resources, 2021(4):206-210.

[2] 邱显扬, 梁冬云, 洪秋阳, 等. 难处理金矿石的工艺矿物学及可选冶特性分析[J]. 贵金属, 2020, 41(2): 36-44.QIU X Y, LIANG D Y, HONG Q Y, et al. Process mineralogy and process improvement analysis of a refractory gold ore[J] Precious Metals. 2020, 41(2): 36-44.

QIU X Y, LIANG D Y, HONG Q Y, et al. Process mineralogy and process improvement analysis of a refractory gold ore[J] Precious Metals. 2020, 41(2): 36-44.

[3] 成岚, 李茂林, 黄光耀. 某铅锌尾矿浓密机溢流的工艺矿物学分析[J]. 中国有色金属学报, 2015(7):1953-1960.CHENG L, LI M L, HUANG G Y. Process mineralogy analysis of certain lead-zinc tailings thickener overflow[J]. The Chinese Journal of Nonferrous Metals, 2015(7):1953-1960.

CHENG L, LI M L, HUANG G Y. Process mineralogy analysis of certain lead-zinc tailings thickener overflow[J]. The Chinese Journal of Nonferrous Metals, 2015(7):1953-1960.

[4] 周利华, 陈晓芳, 苏妤芸. 山西某斑岩型金矿工艺矿物学特性[J]. 矿产综合利用, 2020(3):143-147ZHOU L H, CHEN X F, SU Y Y. Technological and mineralogical characteristics of a porphyry gold deposit in Shanxi province[J]. Multipurpose Utilization of Mineral Resources, 2020(3):143-147

ZHOU L H, CHEN X F, SU Y Y. Technological and mineralogical characteristics of a porphyry gold deposit in Shanxi province[J]. Multipurpose Utilization of Mineral Resources, 2020(3):143-147

[5] 赵瑜, 谢贤, 童雄. 基于工艺矿物学的某铅锌尾矿中资源综合回收可行性研究[J]. 矿产综合利用, 2021(4):154-158.ZHAO Y, XIE X, TONG X. Feasibility study on multipurpose recovery of resource in lead and zinc tailings based on process mineralogy[J]. Multipurpose Utilization of Mineral Resources, 2021(4):154-158.

ZHAO Y, XIE X, TONG X. Feasibility study on multipurpose recovery of resource in lead and zinc tailings based on process mineralogy[J]. Multipurpose Utilization of Mineral Resources, 2021(4):154-158.

[6] 高春庆, 张凛, 王海亮. 河北某铁矿工艺矿物学研究[J]. 金属矿山, 2021(3):136-141.GAO C Q, ZHANG L, WANG H L. Study on process mineralogy of an iron ore in Hebei province[J]. Metal Mine, 2021(3):136-141.

GAO C Q, ZHANG L, WANG H L. Study on process mineralogy of an iron ore in Hebei province[J]. Metal Mine, 2021(3):136-141.

[7] 陈福林, 杨晓军, 杨道广, 等. 甘肃某低品位钒钛磁铁矿工艺矿物学研究[J]. 矿产综合利用, 2020(6): 64-68, 42.CHEN F L, YANG X J, YANG D G, et al. Research on process mineralogy for a low-grade vanadium titano-magnetite in Gansu province[J]. Multipurpose Utilization of Mineral Resources2020(6): 64-68, 42.

CHEN F L, YANG X J, YANG D G, et al. Research on process mineralogy for a low-grade vanadium titano-magnetite in Gansu province[J]. Multipurpose Utilization of Mineral Resources2020(6): 64-68, 42.

[8] 孙志健, 吴熙群, 李成必, 等. 高含泥矿石浮选综述[J]. 有色金属(选矿部分), 2020(1):59-63.SUN Z J, WU X Q, LI C B, et al. A summary of high content slime ore flotation[J]. Nonferrous Metals(Mineral Processing Section), 2020(1):59-63.

SUN Z J, WU X Q, LI C B, et al. A summary of high content slime ore flotation[J]. Nonferrous Metals(Mineral Processing Section), 2020(1):59-63.

-

下载:

下载: