Flotation Recovery Tests of Silver Minerals from a Cyanide Slag in Colombia

-

摘要:

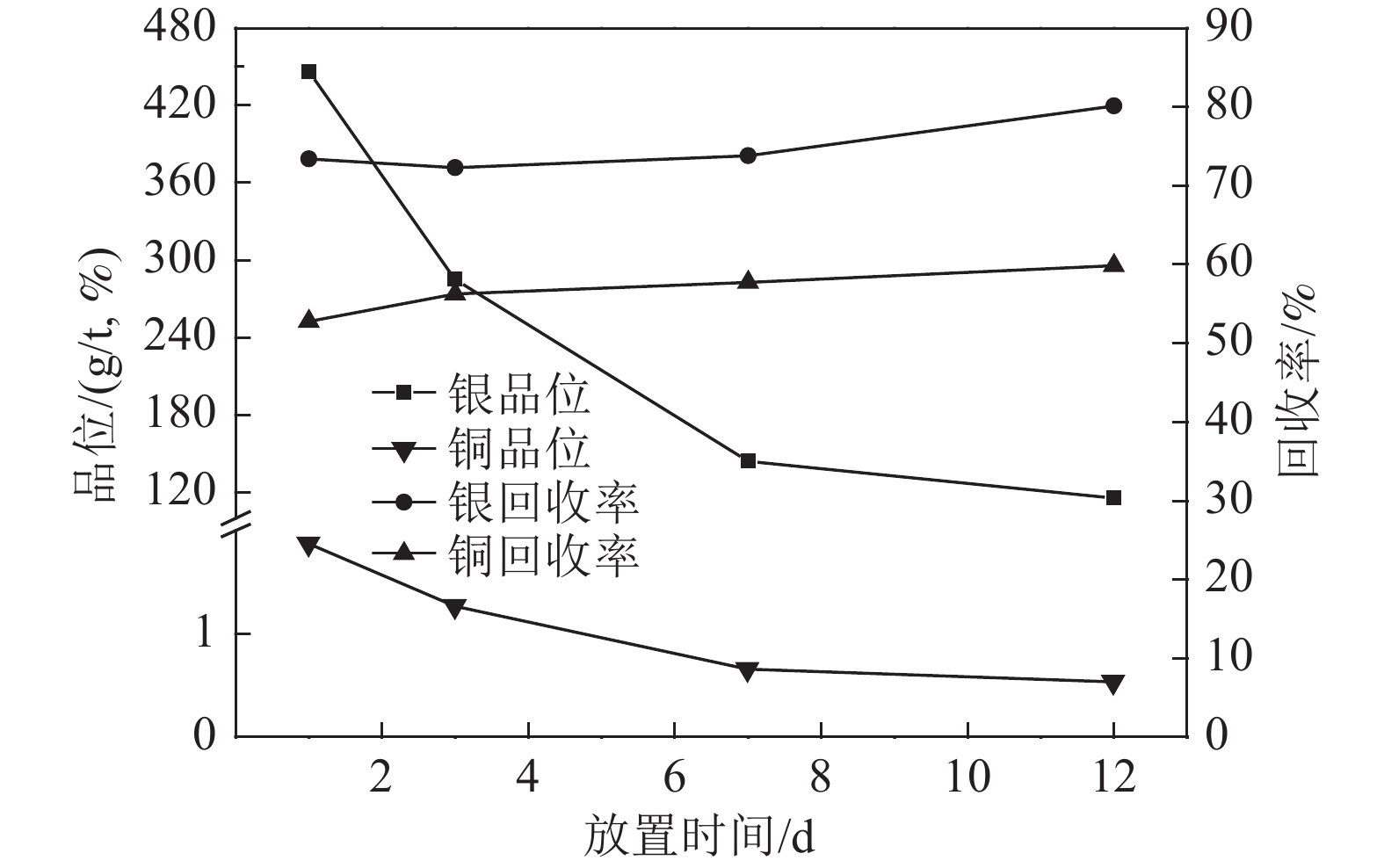

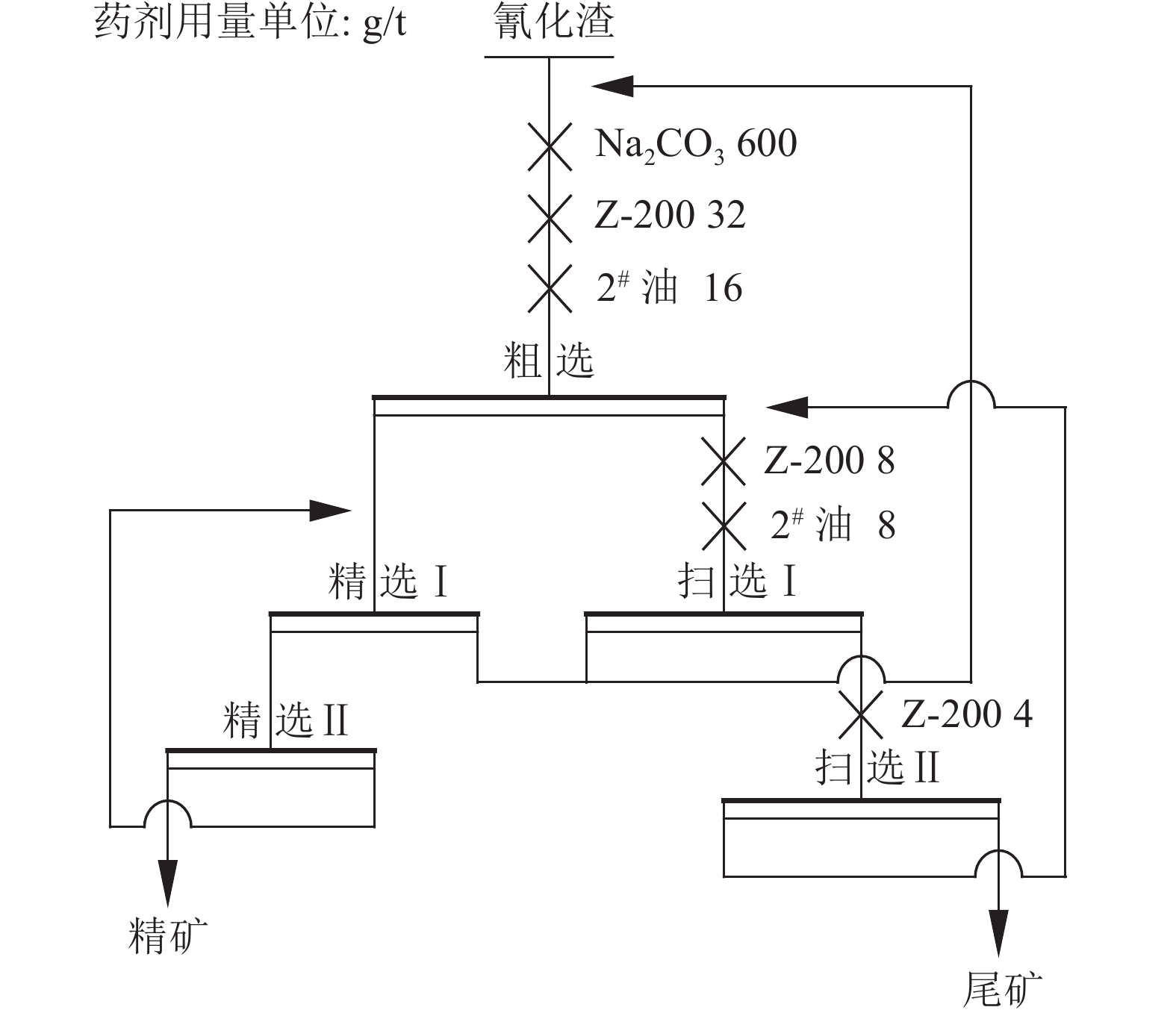

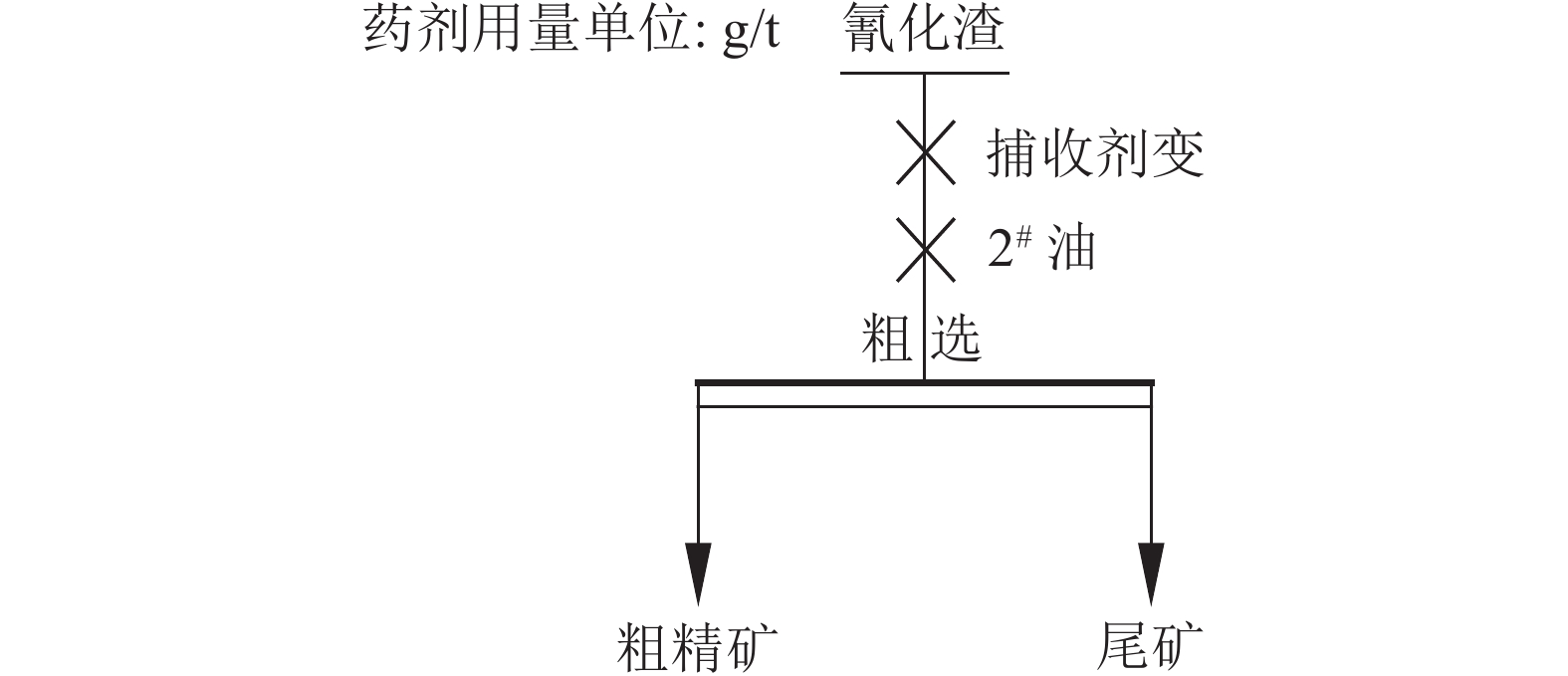

这是一篇矿物加工工程领域的论文。哥伦比亚某金矿采用SABC磨矿—重选—重选尾矿氰化浸出—氰化渣INCO法破氰工艺,磨矿细度-74 μm 80%,氰化浸出过程银浸出率约40%,氰化渣含银17.6 g/t,含铜0.099%。为进一步提高银回收率,实现资源高效利用,开展了氰化渣回收银矿物浮选实验研究。结果表明:①氰化渣中主要硫化矿物为黄铁矿,主要银矿物为含银锑黝铜矿、砷黝铜矿,主要铜矿物为黄铜矿。②银铜矿物共生关系密切,主要采用浮选回收铜矿物方法回收伴生银矿物;③采用一粗两扫两精闭路浮选工艺,可获得银精矿含银2 150.79 g/t,含铜9.63%,银回收率74.02%,铜回收率58.74%。④氰化渣破氰后进行浮选回收银矿物,极大提高了整体工艺银回收率并回收了部分铜矿物,提高了资源利用效率和经济效益。

Abstract:This is an article in the field of mineral processing engineering. The process of “SABC grinding – gravity separation – cyanidation leaching – INCO detoxification” were conducted on the gold ore in Colombia. The grinding fineness was 80% passing 74 μm. However, the leaching rate of silver is about 40% with silver and copper grades of 17.6 g/t and 0.099% in leaching tailings, respectively. Flotation tests were performed on the leaching tailings to recover the silver and copper to improve the total recovery, and improve the utilization efficiency of metal resources. It is revealed from the tests results that ①The sulfide minerals in the leaching tailings are mainly pyrite, the silver-bearing minerals are mainly antimony tetrahedrite and arsenite tetrahedrite. And the copper minerals are mainly chalcopyrite. ②The silver and copper were in a intimated correlation, which means that it can be used the copper flotation process to recover the associated silver minerals. ③ It is revealed that a flotation concentrate containing 2 150.79 g/t silver and 9.63% copper which corresponded to a recovery of 74.02% for silver and 58.74% for copper can be obtained by using the closed-circuit flotation process of one-stage roughing, two-stage cleaning and two-stage scavenging. ④ It is beneficial to use flotation process to recover silver and copper in leaching tailings of Colombia ores, which improves the total recovery of silver and the resource utilization efficiency.

-

-

表 1 氰化渣主要元素分析结果/%

Table 1. Analysis results of the main elements of the ores

Ag* Cu Fe S Zn Pb CaO MgO Al2O3 SiO2 17.60 0.099 4.26 5.72 0.10 0.06 4.52 3.96 16.18 57.27 *单位为g/t。 表 2 捕收剂种类实验结果

Table 2. Test results of flotation collectors

实验条件 产品 产率/% 品位/% 回收率/% Ag* Cu Ag Cu Z-200 粗精矿 1.90 620.8 2.68 67.57 49.46 尾矿 98.10 5.77 0.053 32.43 50.54 合计 100.00 17.45 0.10 100.00 100.00 丁基黄药 粗精矿 1.79 602.6 2.32 64.16 43.11 尾矿 98.21 6.14 0.056 35.84 56.89 合计 100.00 16.83 0.096 100.00 100.00 丁铵黑药 粗精矿 1.11 929.7 4.27 56.79 45.61 尾矿 98.89 7.94 0.057 43.21 54.39 合计 100.00 18.17 0.10 100.00 100.00 丁基黄药+

丁铵黑药粗精矿 2.00 576.6 2.46 65.56 48.23 尾矿 98.00 6.19 0.054 34.44 51.77 合计 100.00 17.62 0.10 100.00 100.00 *单位为g/t。 表 3 起泡剂实验结果

Table 3. Test results of flotation frother

实验条件 产品 产率/% 品位/% 回收率/% Ag* Cu Ag Cu 2#油 粗精矿 2.63 460.6 1.89 70.47 49.85 尾矿 97.37 5.22 0.051 29.53 50.15 合计 100.00 17.21 0.10 100.00 100.00 MP10931 粗精矿 3.00 376.8 1.54 67.05 49.85 尾矿 97.00 5.73 0.048 32.95 50.15 合计 100.00 16.87 0.093 100.00 100.00 MIBC 粗精矿 2.20 529.8 2.14 68.54 50.06 尾矿 97.80 5.46 0.048 31.46 49.94 合计 100.00 16.97 0.094 100.00 100.00 *单位为g/t。 表 4 调整剂实验结果

Table 4. Test results of flotation regulators

实验条件 产品 产率/% 品位/% 回收率/% Ag* Cu Ag Cu 空白 粗精矿 2.63 460.6 1.89 70.47 49.85 尾矿 97.37 5.22 0.051 29.53 50.15 合计 100.00 17.21 0.10 100.00 100.00 Na2CO3 粗精矿 2.82 446.3 1.86 73.43 52.79 尾矿 97.18 4.68 0.48 26.57 47.21 合计 100.00 17.12 0.099 100.00 100.00 CuSO4 粗精矿 8.96 141.9 0.60 74.10 55.21 尾矿 91.04 4.88 0.48 25.90 44.79 合计 100.00 17.15 0.098 100.00 100.00 *单位为g/t。 表 5 闭路实验结果

Table 5. Test results of closed-circuit flotation

产品 产率 品位/% 回收率/% Ag* Cu S Ag Cu S 精矿 0.61 2 150.79 9.63 12.46 74.02 58.74 1.07 尾矿 99.39 4.60 0.041 6.99 25.98 41.26 98.93 合计 100.00 17.60 0.099 7.03 100.00 100.00 100.00 *单位为g/t。 -

[1] 迈克 D. 亚当斯. 金矿处理技术-项目开发与运营[M]. Elsevier, 2016(1): 25-30.ADAMS M D. Gold ore processing-project development and operations[M]. Elsevier, 2016(1): 25-30.

ADAMS M D. Gold ore processing-project development and operations[M]. Elsevier, 2016(1): 25-30.

[2] 丘世澄, 邱显扬, 胡真, 等. 某金银矿石浮选—氰化联合流程选矿实验[J]. 金属矿山, 2019(11):98-103.QIU S C, QIU X Y, HU Z, et al. Tests of flotation and cyanidation united process for one gold and silver ore[J]. Metal Mine, 2019(11):98-103.

QIU S C, QIU X Y, HU Z, et al. Tests of flotation and cyanidation united process for one gold and silver ore[J]. Metal Mine, 2019(11):98-103.

[3] 刘静宇. 某金矿重选尾矿回收金、铜的工艺研究[J]. 矿产综合利用, 2020(1):112-115.LIU J Y. Recovery of gold and copper from tailings of gravity separation in a gold ore[J]. Multipurpose Utilization of Mineral Resources, 2020(1):112-115. doi: 10.3969/j.issn.1000-6532.2020.01.023

LIU J Y. Recovery of gold and copper from tailings of gravity separation in a gold ore[J]. Multipurpose Utilization of Mineral Resources, 2020(1):112-115. doi: 10.3969/j.issn.1000-6532.2020.01.023

[4] 祁磊, 席欣月, 蔡鑫, 等. 北衙硫化矿选厂尾矿中金银铁综合回收实验研究[J]. 矿产综合利用, 2021(4):182-187.QI L, XI X Y, CAI X, et al. Experimental research on comprehensive recovery of gold, silver and iron intailings of beiya sulfide ore concentrator[J]. Multipurpose Utilization of Mineral Resources, 2021(4):182-187. doi: 10.3969/j.issn.1000-6532.2021.04.029

QI L, XI X Y, CAI X, et al. Experimental research on comprehensive recovery of gold, silver and iron intailings of beiya sulfide ore concentrator[J]. Multipurpose Utilization of Mineral Resources, 2021(4):182-187. doi: 10.3969/j.issn.1000-6532.2021.04.029

[5] 刘建兵. 新疆某银矿选矿实验[J]. 矿产综合利用, 2016(2):22-25.LIU J B. Experimental research on mineral processing technology for a silver ore in Xinjiang[J]. Multipurpose Utilization of Mineral Resources, 2016(2):22-25. doi: 10.3969/j.issn.1000-6532.2016.02.004

LIU J B. Experimental research on mineral processing technology for a silver ore in Xinjiang[J]. Multipurpose Utilization of Mineral Resources, 2016(2):22-25. doi: 10.3969/j.issn.1000-6532.2016.02.004

[6] 杨俊龙, 郭艳华, 郭海宁, 等. 冶炼废弃渣综合回收金银新工艺实验研究[J]. 矿产综合利用, 2021(5):172-176.YANG J L, GUO Y H, GUO H N, et al. Experimental study on new comprehensive recovery technology of gold and silver from smelting waste residue[J]. Multipurpose Utilization of Mineral Resources, 2021(5):172-176. doi: 10.3969/j.issn.1000-6532.2021.05.028

YANG J L, GUO Y H, GUO H N, et al. Experimental study on new comprehensive recovery technology of gold and silver from smelting waste residue[J]. Multipurpose Utilization of Mineral Resources, 2021(5):172-176. doi: 10.3969/j.issn.1000-6532.2021.05.028

[7] 袁嘉声, 畅永锋, 郑春龙, 等. 氰化尾渣脱氰技术综述[J]. 中国有色金属学报, 2021(6):1568-1581.YAN J S, CHANG Y F, ZHENG C L, et al. Review on cyanide removal technology of cyanide tailings[J]. Chinese Journal of Nonferrous Metals, 2021(6):1568-1581. doi: 10.11817/j.ysxb.1004.0609.2021-37785

YAN J S, CHANG Y F, ZHENG C L, et al. Review on cyanide removal technology of cyanide tailings[J]. Chinese Journal of Nonferrous Metals, 2021(6):1568-1581. doi: 10.11817/j.ysxb.1004.0609.2021-37785

-

下载:

下载: