Optimization of Recovery of Valuable Metals from Lead Smelting Water Quenching Slags by Response Surface Methodology

-

摘要:

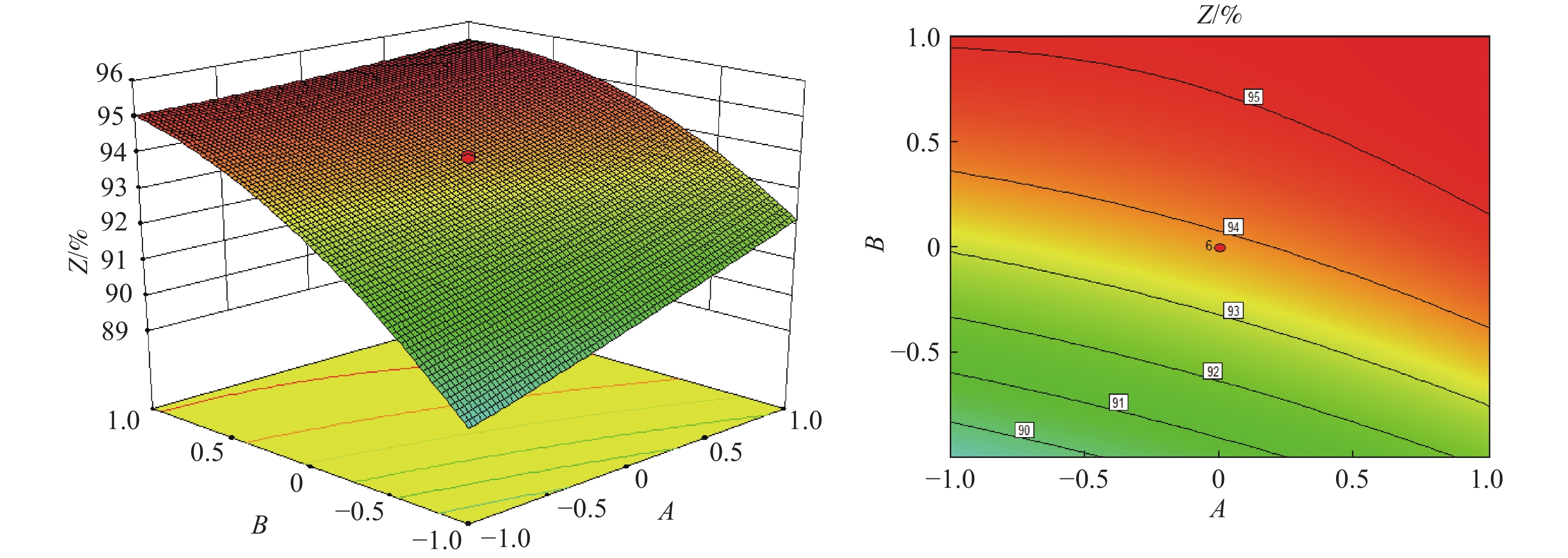

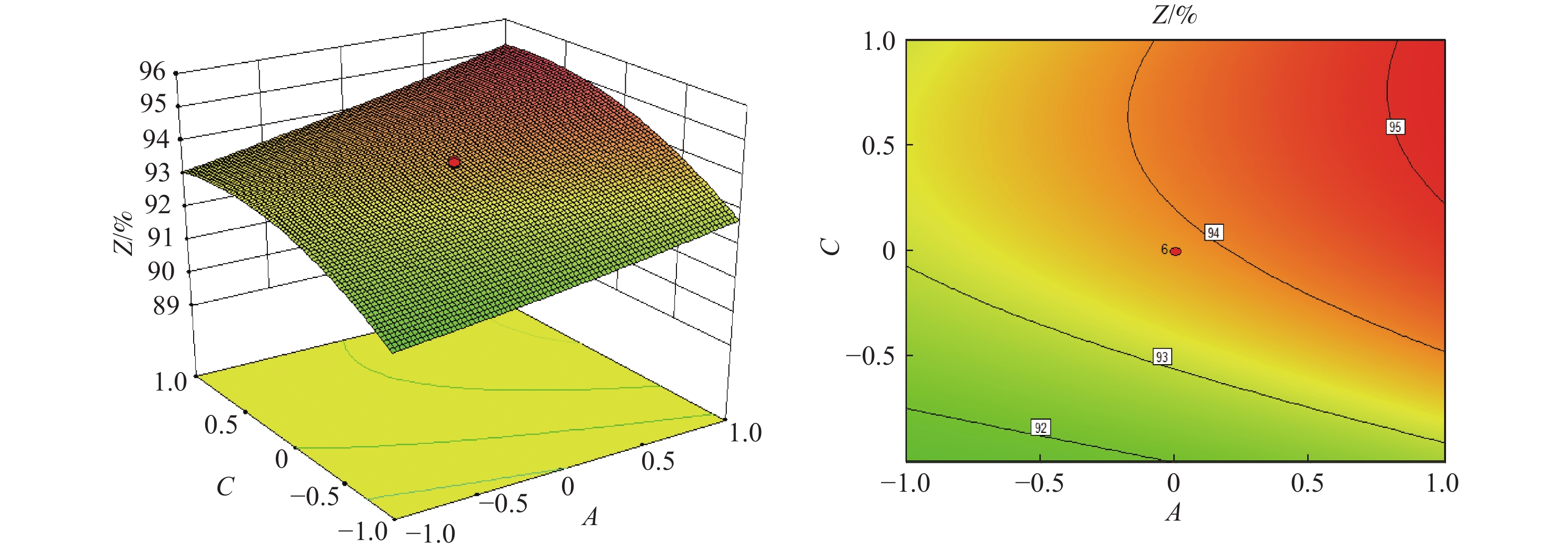

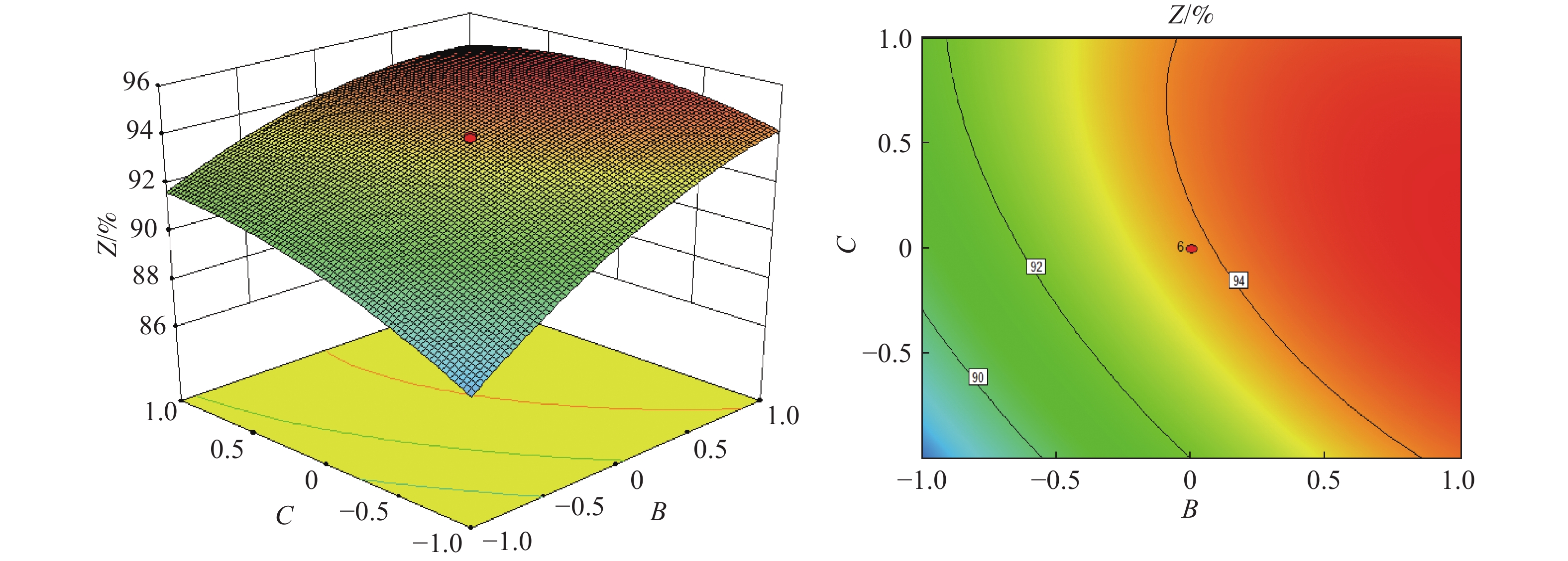

在酸性条件下氧压浸出水淬渣,通过响应曲面法的模型优化设计和分析,研究了浸出过程中氧压温度、硫酸浓度、液固比对选择性浸出率的影响,得到较佳优化浸出的工艺条件,并获得了二阶多项式模型。在氧压温度171.4 ℃、硫酸浓度48.62 g/L、液固比6.42 的较佳优化条件下,选择性浸出率模型预测值分别为95.59%,实验真实值平均浸出率为95.61%。

Abstract:Water quenching slags were leached by oxygen pressure at the acidic conditions. The effects of ratio of oxygen pressure temperature, sulfuric acid concentration, liquid-solid ratio on the selective leaching were investigated using response surface methodology for optimal and analysis. Optimal process parameters on Mn leaching from water quenching slags and two order polynomial equation of model were obtained. At the optimal conditions as follows, the oxygen pressure temperature of 171.4 ℃, sulfuric acid concentration of 48.62 g/L, liquid-solid ratio of 6.42. The results show that the theoretical leaching ratio of model predicts can reach 95.59%, while the experimental average values are 95.61%.

-

-

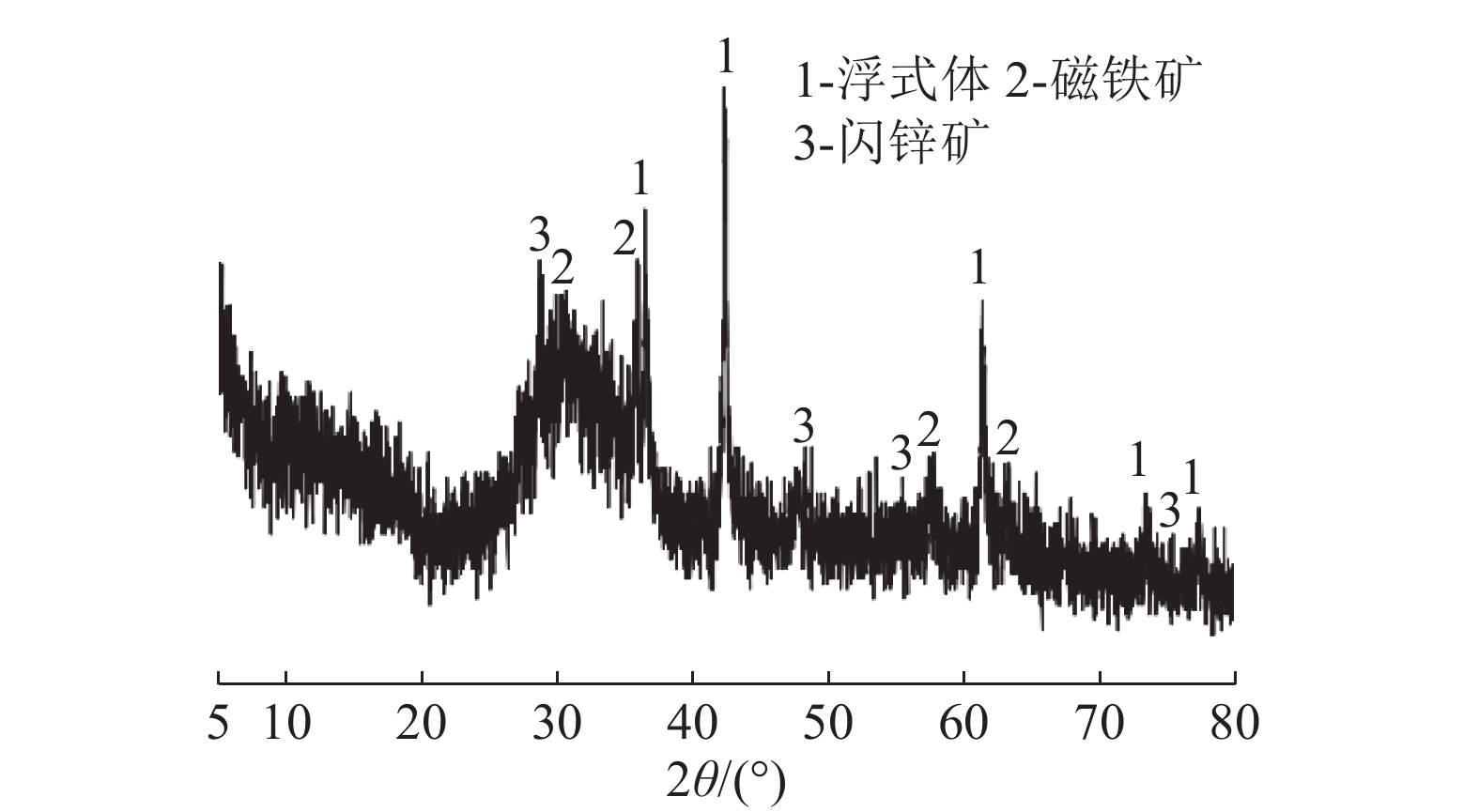

表 1 水淬渣的主要化学成分/%

Table 1. Main composition of water quenching slags

Cu Pb Zn Fe SiO2 MgO CaO As 1.41 0.03 6.21 24.93 20.28 1.74 17.30 0.01 表 2 水淬渣中Cu物相分析结果

Table 2. Phase analysis results of Cu in lead smelting water quenching slags

名称 硫化铜 氧化铜 金属铜 其他铜 共计 含量/% 0.89 0.17 0.21 0.14 1.41 占有率/% 63.12 12.07 14.89 9.92 100.00 表 3 水淬渣中Fe物相分析结果

Table 3. Phase analysis results of Fe in lead smelting water quenching slags

名称 硅酸铁 磁性氧化铁 金属铁 氧化铁 硫化铁 共计 含量/% 14.17 7.64 0.21 2.77 0.14 24.93 占有率/% 56.84 30.65 0.84 11.11 0.56 100.00 表 4 中心组合设计响应曲面实验的因素水平及编码值对照

Table 4. Level and coded symbols of variable for central composite design test

种类 因子 编码变量水平 t步进值 a=-1.68 -1 0 1 a=+1.68 氧压温度/℃ A 153.18 160 170 180 186.82 10 硫酸浓度/(g/L) B 23.18 30 40 50 56.62 10 液固比/(L/S) C 4.32 5 6 7 7.68 1 表 5 中心组合设计及结果

Table 5. Arrangement and results of central composite design

序号 影响因子 浸出率 /% 选择性浸

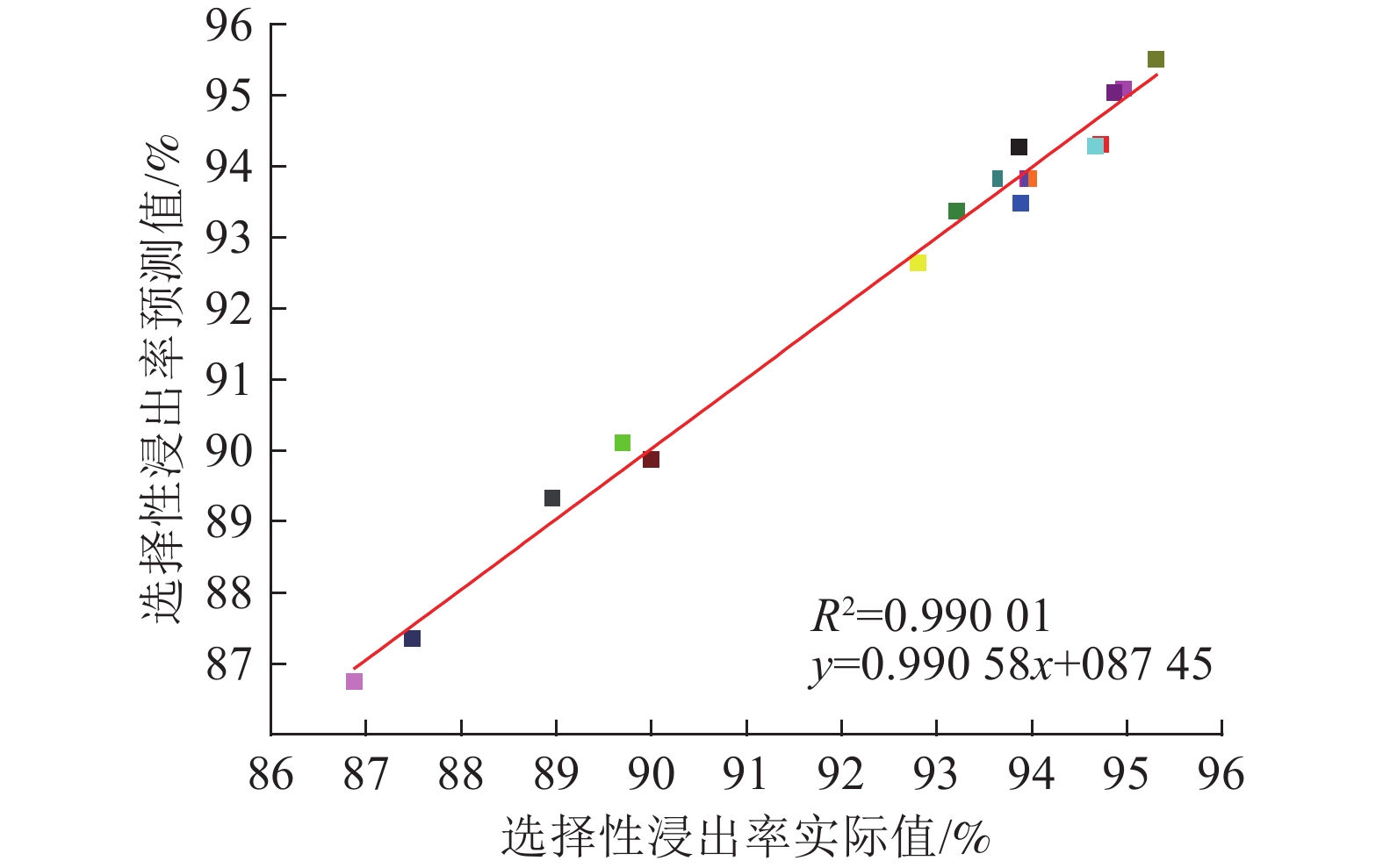

出率Z/%A/℃ B/(g/L) C/(L/S) Cu Fe 1 186.82 40.00 6.00 96.20 0.89 95.31 2 170.00 40.00 7.68 94.46 1.25 93.21 3 160.00 50.00 7.00 96.23 1.56 94.67 4 170.00 40.00 4.32 91.06 1.06 90.00 5 180.00 50.00 7.00 96.62 1.65 94.97 6 180.00 50.00 5.00 95.92 1.19 94.73 7 180.00 30.00 7.00 94.39 0.50 93.89 8 170.00 40.00 6.00 96.36 1.56 94.80 9 160.00 30.00 7.00 90.95 1.25 89.70 10 170.00 40.00 6.00 94.80 1.01 93.79 11 160.00 30.00 5.00 88.04 1.16 86.88 12 170.00 40.00 6.00 94.71 1.04 93.67 13 170.00 40.00 6.00 94.98 1.10 93.88 14 170.00 40.00 6.00 95.07 1.10 93.97 15 180.00 30.00 5.00 91.64 2.68 88.96 16 170.00 40.00 6.00 94.85 1.00 93.85 17 170.00 56.82 6.00 96.81 1.94 94.87 18 160.00 50.00 5.00 96.15 2.28 93.87 19 170.00 23.18 6.00 87.88 0.39 87.49 20 153.18 40.00 6.00 93.65 0.84 92.81 表 6 选择性浸出率模型可信度分析

Table 6. Credibility analysis of selective leaching ratio

标准差 平均值 C.V./% Press R2 R2Adj R2Pred 信噪比 0.35 92.72 0.37 10.27 0.990 5 0.981 9 0.919 1 35.663 表 7 选择性浸出率的方差分析结果

Table 7. Analysis of variance(ANOVA) for selective leaching ratio

方差分析 平方和 自由度 均方值 F值 Pb>F 模型 125.48 9 13.94 115.42 0.000 3 A 9.91 1 9.91 82.05 <0.000 1 B 71.38 1 71.38 590.87 <0.000 1 C 14.74 1 14.74 122.03 <0.000 1 AB 3.26 1 3.26 27.02 0.000 4 AC 0.3 1 0.3 2.49 0.145 9 BC 5.63 1 5.63 46.59 <0.000 1 A2 0.11 1 0.11 0.90 0.365 0 B2 12.50 1 12.50 103.48 <0.000 1 C2 8.79 1 8.79 72.78 <0.000 1 残差 1.21 10 0.12 -

[1] 王振东, 雷霆, 施哲, 等. 烟化法处理鼓风炉炼铅炉渣试验研究[J]. 云南冶金, 2007, 36(1):45-47.WANG Z D, LEI T, SHI Z, et al. Experimentation on treatment of slag from lead smelting furnace by fuming process[J]. Yunnan Metallurgy, 2007, 36(1):45-47. doi: 10.3969/j.issn.1006-0308.2007.01.011

WANG Z D, LEI T, SHI Z, et al. Experimentation on treatment of slag from lead smelting furnace by fuming process[J]. Yunnan Metallurgy, 2007, 36(1):45-47. doi: 10.3969/j.issn.1006-0308.2007.01.011

[2] 梁彦杰. 铅锌冶炼渣硫化处理新方法研究[D]. 长沙: 中南大学, 2012.LIANG Y J. Study on novel sulfidation technologies in managing Zn &Pb smelting waste[D]. Changsha: Central South University, 2012.

LIANG Y J. Study on novel sulfidation technologies in managing Zn &Pb smelting waste[D]. Changsha: Central South University, 2012.

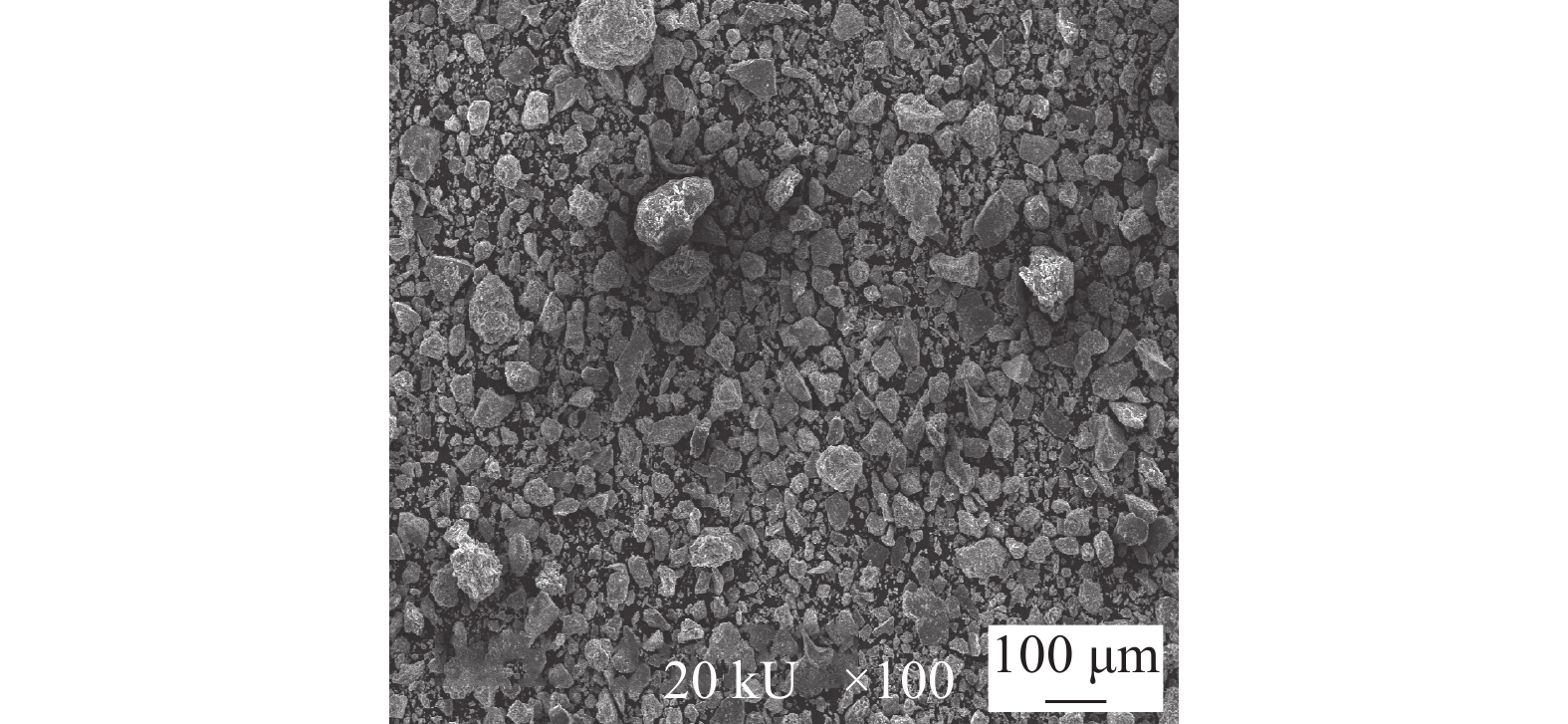

[3] 孙红燕, 孔馨, 张瑾勋, 等. 铅冶炼水淬渣球磨工艺研究[J]. 湿法冶金, 2019, 38(167):80-83.SUN H Y, KONG X, ZHANG J X, et al. Ball-milling of water quenching slag from lead smelting[J]. Hydrometallurgy of China, 2019, 38(167):80-83.

SUN H Y, KONG X, ZHANG J X, et al. Ball-milling of water quenching slag from lead smelting[J]. Hydrometallurgy of China, 2019, 38(167):80-83.

[4] 朱国邦. 从粗铅冶炼鼓风炉水淬渣中回收锌的试验研究[J]. 云南冶金, 2017, 46(5): 4.ZHU G B. The experimental study on zinc recovery from the water-quenched slag of crude lead smelting furnace[J]. Yunnan Metallurgy, 2017, 46(5): 39-42.

ZHU G B. The experimental study on zinc recovery from the water-quenched slag of crude lead smelting furnace[J]. Yunnan Metallurgy, 2017, 46(5): 39-42.

[5] Shu Y, Ma C, Zhu L, et al. Leaching of lead slag component by sodium chloride and diluted nitric acid and synthesis of ultrafine lead oxide powders[J]. Journal of Power Sources, 2015, 281(may 1): 219-226.

[6] Kim E, Horckmans L, Spooren J, et al. Selective leaching of Pb, Cu, Ni and Zn from secondary lead smelting residues[J]. Hydrometallurgy, 2017, 169:372-381. doi: 10.1016/j.hydromet.2017.02.027

[7] Ozge Gok, Corby G Anderson. Dissolution of low-grade chalcopyrite concentrate in acidified nitrite electrolyte[J]. Hydrometallurgy, 2013, 134-135.

[8] Azizi D, Shafaei S Z, Noaparast M, et al. Modeling and optimization of low-grade Mn bearing ore leaching using response surface methodology and central composite rotatable design[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9):2295-2305. doi: 10.1016/S1003-6326(11)61463-5

[9] 信晓飞, 张晋霞, 冯洪均. 响应曲面法优化含锌尘泥选择性浸出工艺[J]. 矿产综合利用, 2021(2):146-151.XIN X F, ZHANG J X, FENG H J. Optimization of selective leaching technology from zinc-bearing dust using response surface methodology[J]. Multipurpose Utilization of Mineral Resources, 2021(2):146-151. doi: 10.3969/j.issn.1000-6532.2021.02.025

XIN X F, ZHANG J X, FENG H J. Optimization of selective leaching technology from zinc-bearing dust using response surface methodology[J]. Multipurpose Utilization of Mineral Resources, 2021(2):146-151. doi: 10.3969/j.issn.1000-6532.2021.02.025

[10] 马爱元, 郑雪梅, 李松, 等. 响应曲面优化NH3-(NH4)3AC-H2O体系浸出冶金废渣提锌工艺研究[J]. 矿产综合利用, 2021(1):186-192.MA A Y, ZHENG X M, LI S, et al. Study on zinc extraction process of NH3-(NH4)3AC-H2O system by response surface optimization[J]. Multipurpose Utilization of Mineral Resources, 2021(1):186-192. doi: 10.3969/j.issn.1000-6532.2021.01.031

MA A Y, ZHENG X M, LI S, et al. Study on zinc extraction process of NH3-(NH4)3AC-H2O system by response surface optimization[J]. Multipurpose Utilization of Mineral Resources, 2021(1):186-192. doi: 10.3969/j.issn.1000-6532.2021.01.031

-

下载:

下载: